Preparation device for aquatic feed

A preparation device, a technology for aquatic feed, applied in feed, mixer with rotating stirring device, application, etc., can solve the problems of poor mixing effect, inconvenient cleaning, lack of crushing and mixing, etc., and achieve the effect of improving mixing , easy to clean and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

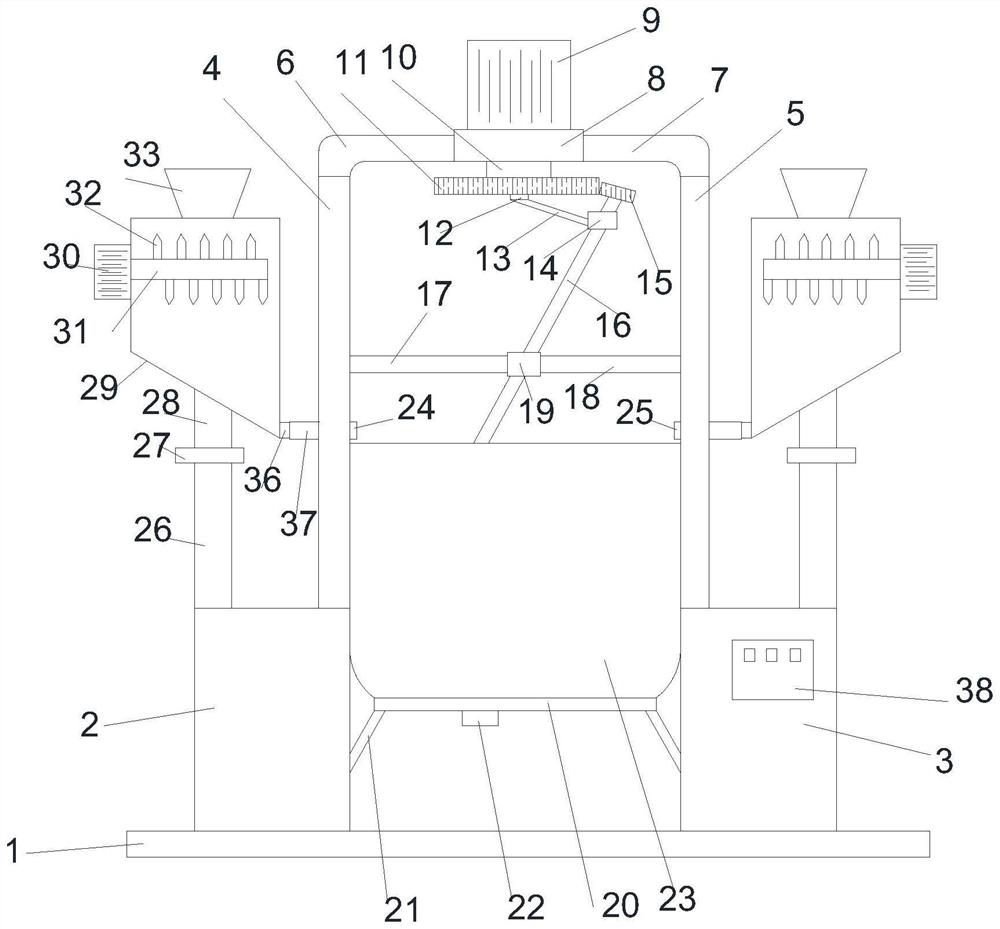

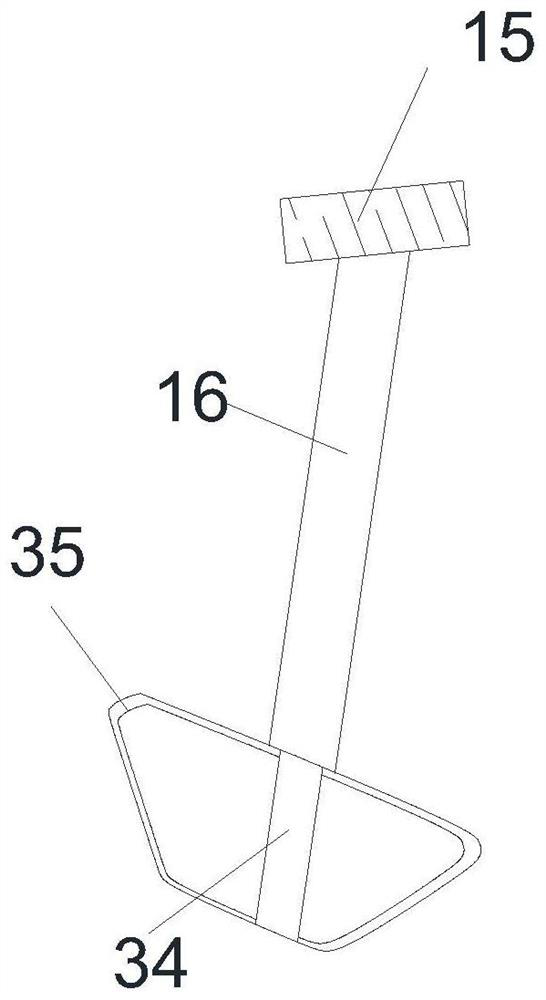

[0022] Example: a preparation device for aquatic feed, such as figure 1 , figure 2 As shown, it includes a bottom plate 1, a barrel body 23, a stirrer, a mounting plate 8, and a base 1 2 and a base 2 3 that are relatively arranged on the top of the bottom plate 1. The tops of the base 1 2 and the base 2 3 are respectively provided with a column 1 4, a column Two 5, the top of column one 4 and column two 5 are respectively provided with mandrel one 6, mandrel two 7, mandrel one 6, mandrel two 7 are far away from one end of upright post 4, post two 5 and the side of mounting plate 8 The top of the mounting plate 8 is provided with a vertically placed motor 9, the output end of the motor one 9 is provided with an output shaft 10, the output shaft 10 penetrates the mounting plate 8 and is provided with a rotating disk 11 at the end, and the bottom of the rotating disk 11 is provided with an output shaft 10. There is a fixed column 12, the fixed column 12 is provided with a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com