Surface preparation method of flexibility-controllable liquid drop self-driven multistage gradient structure

A gradient structure, self-driven technology, applied in the field of material surface modification, can solve the problems of expensive production equipment and complicated preparation process, and achieve the effect of improved hydrophobicity and simple and economical preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

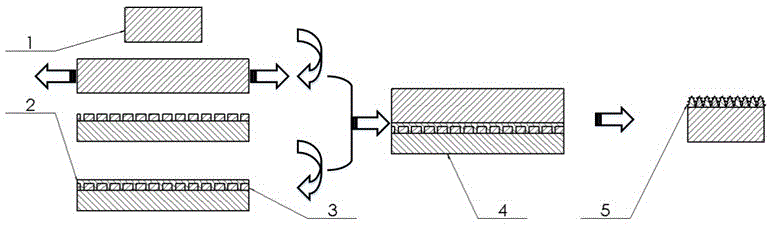

[0021] Refer to attached picture. Embodiment 1 The present embodiment comprises the following steps:

[0022] Step (1) Preparation of coating solution: 5g of polydimethylsiloxane (PDMS) coating solution prepolymer and 0.5g of crosslinking agent were mixed and stirred evenly, and then placed in a vacuum drying oven for 20 minutes with a vacuum pump to remove bubbles in the solution to prepare a polydimethylsiloxane coating solution;

[0023] Step (2) Prepare the masking plate: take a silicon template 3 with a length of 50 mm, a width of 25 mm, and a thickness of 1 mm, and use a three-dimensional drawing software to draw a gradient structure layout diagram. The gradient structure layout diagram is 10 μm in diameter and 40 μm in depth. The unit holes are distributed in a gradient on the template. The gradient distribution method is based on the long side of the template. The unit hole spacing in the first 1mm distance is 10μm, and the unit hole spacing in the second 1mm distance...

Embodiment 2

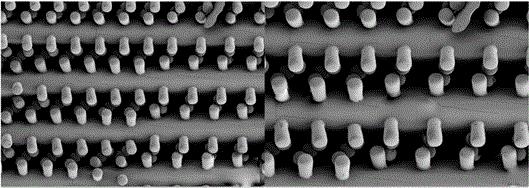

[0027] Example 2 The difference from Example 1 is that the multi-level structure of Example 2 includes a primary buckling base and secondary cylindrical protrusions, and the secondary columnar protrusions are distributed radially and uniformly on the surface of the buckling structure, and the cylindrical The body is 40 μm high and 10 μm wide, arranged in a gradient on the template. The column-to-column distance is 10 μm in the distance of 1 mm along the long side of the template, and the distance between the column and the column is increased to 20 μm in the next 1 mm distance, and so on, such as figure 2shown. This multi-level composite structure can change the interface of different phases, change the interfacial energy, increase the hydrophobicity of the material surface, and due to the existence of the gradient structure, there is a difference in hydrophobicity between different regions of the material surface. Since the flexible base VHB tape 4 is used, the density arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com