Special equipment for two-medium quenching heat treatment and cooling and technology of equipment

A technology of heat treatment cooling and dual medium quenching, applied in heat treatment equipment, quenching agent, quenching device, etc., can solve the problems of low success rate, large error, difficult operation, etc., achieve a high degree of automation, avoid deformation and cracking, labor low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The ball mill is a crushing and grinding equipment used in the production of thermal power plants, cement, mining, chemical, metallurgical and other enterprises. The liner is used to protect the cylinder from direct impact and friction of the grinding body and materials. Form the liner to adjust the movement state of the grinding body to enhance the crushing effect of the grinding body on the material, which helps to improve the grinding efficiency of the ball mill, increase the output, and reduce the metal consumption.

[0054] The liner is one of the most important working parts in the normal operation of the ball mill, and it is also a vulnerable part.

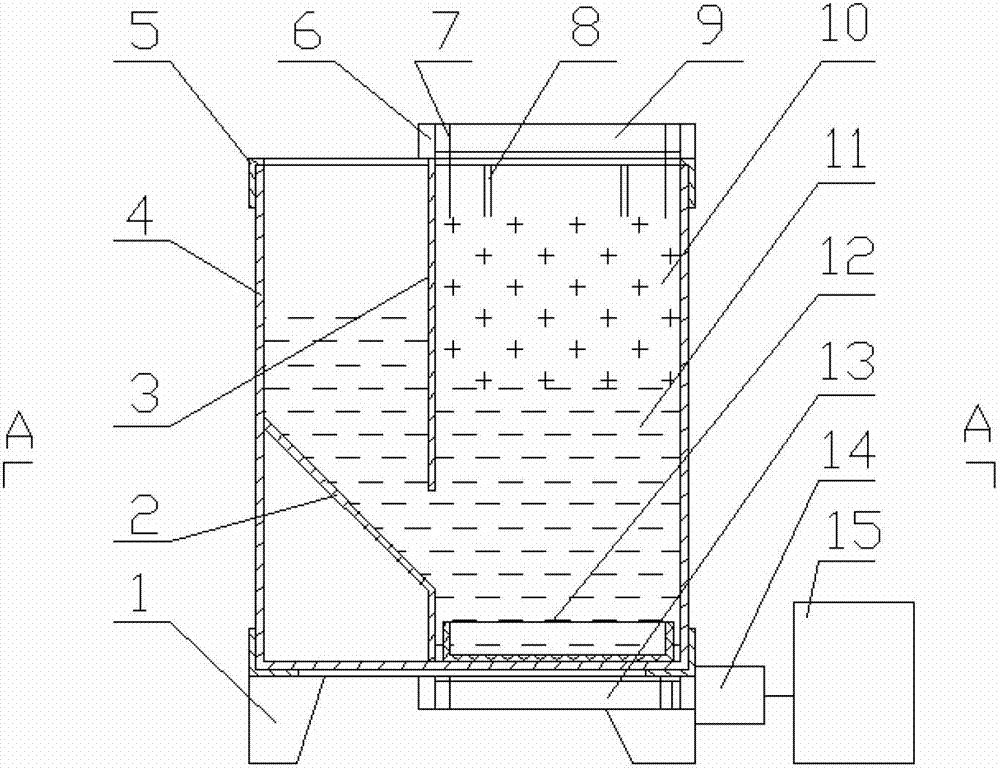

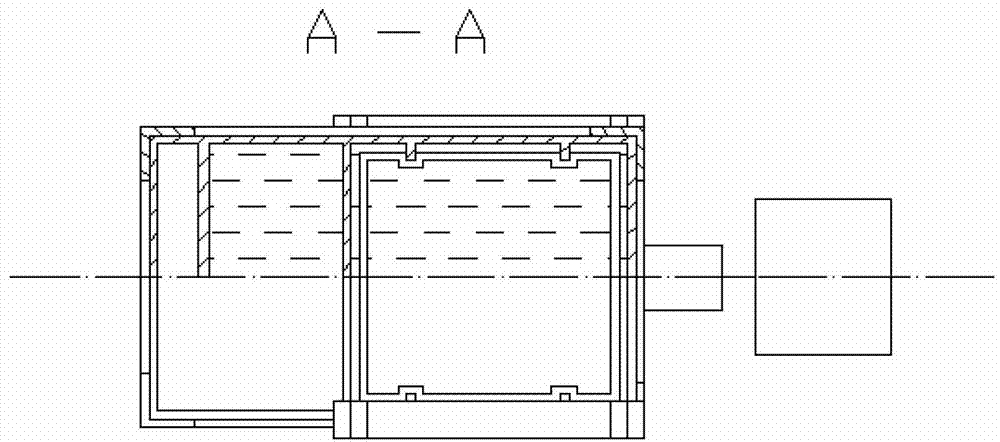

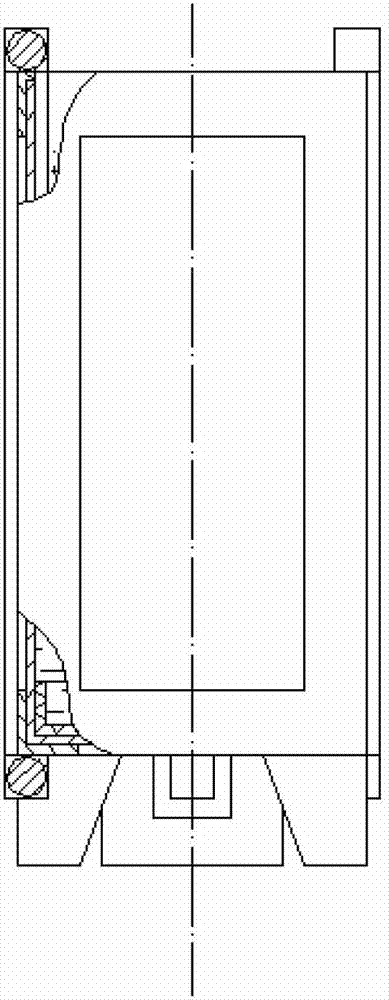

[0055] A medium-alloy steel liner plate made of ZG40Cr5MoRE, with a thickness of 20mm, after heating and heat preservation to form austenite, put it into the water tank of the special equipment for dual-medium quenching heat treatment and cooling provided by the present invention, and press the start button on the con...

Embodiment 2

[0058] A stamping die made of T8 steel, the thickness of the thickest part is 30 mm, after heating and heat preservation to form austenite, put it into the water tank of the special equipment for dual-medium quenching heat treatment and cooling provided by the present invention, and press the control cabinet 15 at the same time Press the start button on the button, and the single-chip microcomputer automatically delays for 2 seconds to ensure that the stamping die enters the net basket 12 automatically due to the slide plate 2 under the action of gravity; The time is 6 seconds, using the up, down, up, down, up movement method; the residence time in the oil is 100 seconds, using the up and down repeated movement method; then move the oil up, stay in the air, and wait for it to be removed Walk. During the cooling process, the stamping die in the supercooled austenite state automatically enters the oil from the water at a slightly higher temperature than Ms, realizing the water q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com