Dryer for drying a material web

A dryer and web weaving technology, which is applied in the direction of dryers, drying, heating to dry solid materials, etc., can solve the problem of reducing energy demand of drying devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

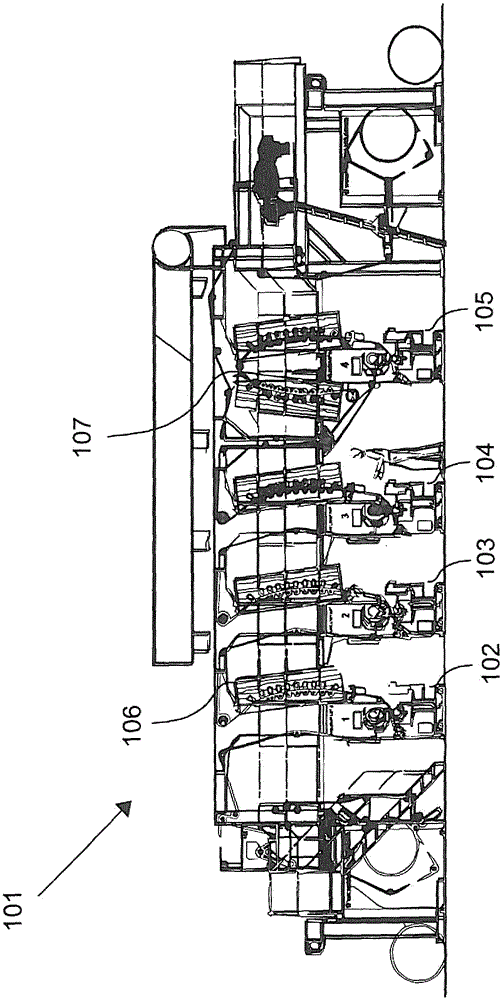

[0022] figure 1 A gravure printing machine according to the prior art is shown. The gravure printing machine 101 includes four printing units 102 , 103 , 104 and 105 . Correspondingly provided in the first three printing units is an intermediate dryer 106, in which the web material does not move around the entire printing unit, but in which the web material is passed through the drying process. After the dry section, it is directly guided from top to bottom to the next printing unit. In the last printing unit 105, by contrast, an end dryer 107 is provided in the form of a drying hood in which the material web surrounds the entire printing unit before it is passed on to the winding 105 moves.

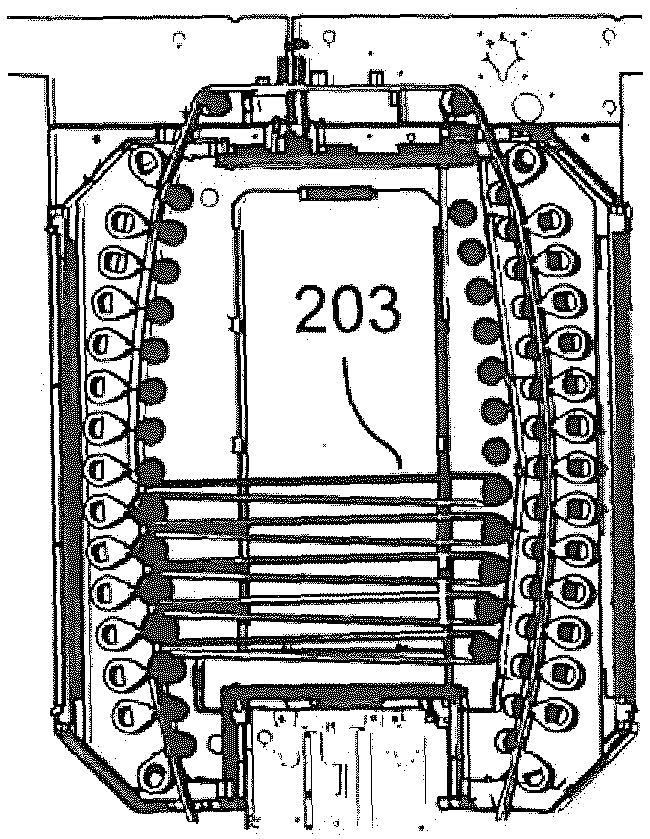

[0023] Figure 2 shows a dryer according to the invention, wherein Figure 2a , Figure 2b and Figure 2c The different web guides in the dryer are shown accordingly.

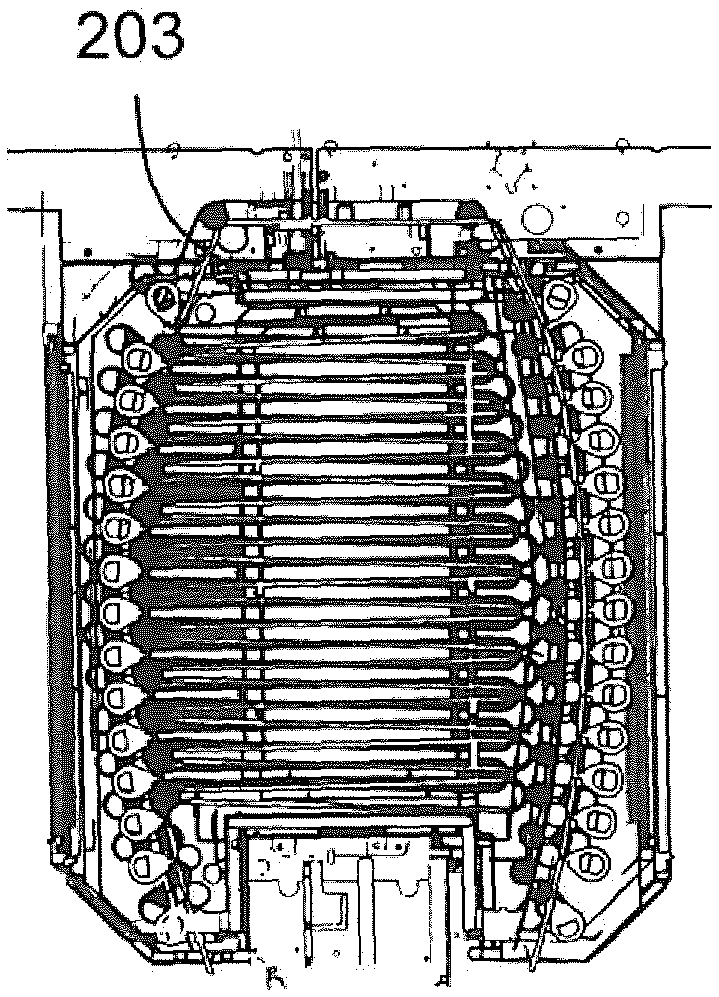

[0024] Figure 2a Firstly the web guidance of the material web 203 is shown, which is equivalent to that accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com