Dense phase transport bed reactor

A transport bed and reactor technology, applied in chemical/physical/physicochemical fixed reactors, etc., can solve problems such as low reaction efficiency, difficult adjustment of reaction time, inability to use fixed bed reactors, etc., and achieve easy reaction time , smooth flow, easy concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

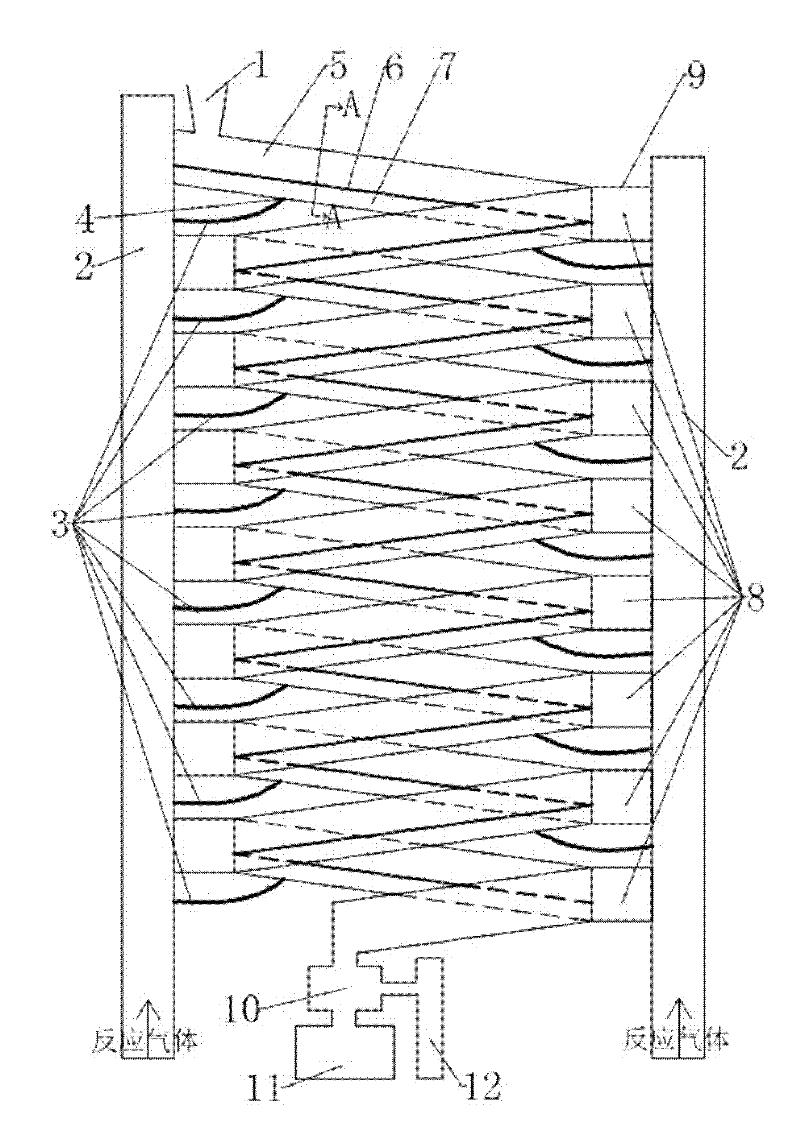

[0014] The principle, specific structure and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

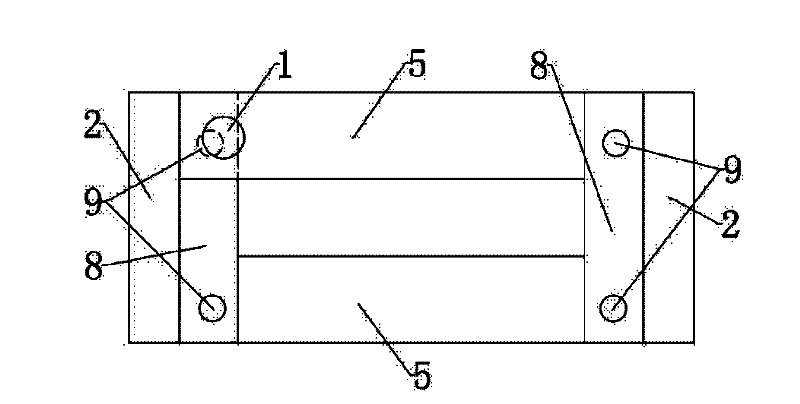

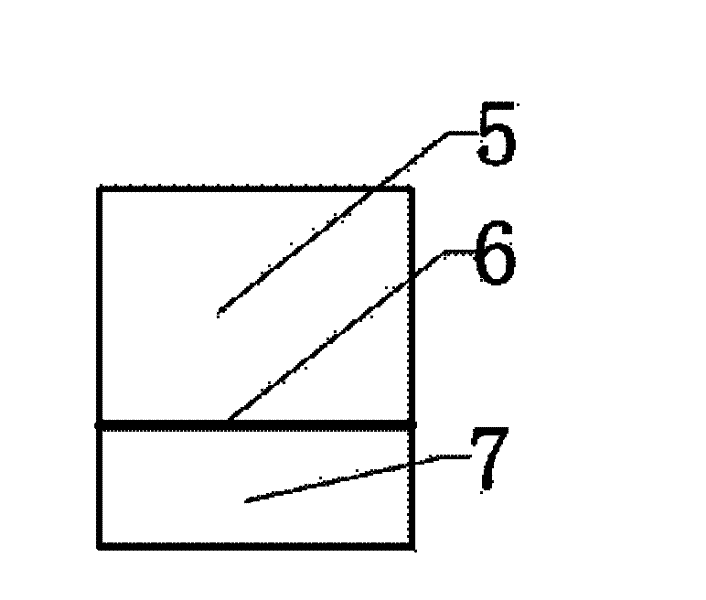

[0015] figure 1 It is a schematic diagram of the dense phase transport bed reactor provided by the present invention. The reactor comprises a top feed port 1 , a gas delivery channel 2 , a transport bed, a separator 10 , a solids collector 11 and a gas collector 12 . The transport bed consists of multiple stages, usually 8 to 16 stages; each stage of the transport bed is composed of a transport trough 5, an air distribution plate 6 and an air chamber 7 arranged at the lower part of the transport trough, and is arranged inclined downwards, with an inclination angle It can be changed within the range of 7°~20°. The transportation bed adopts the layout method of cross-drop (that is, the first-level transportation bed is inclined to the lower right direction, and the second-level transportation bed is incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com