Compound spinning assembly with replaceable sand cavity inner sleeve and application thereof

A composite spinning and component technology, which is applied in the direction of spinneret assembly, filament forming treatment, textiles and papermaking, etc., can solve the problems of inability to spin fibers of different specifications, reduced supply, melt degradation, etc., and achieve reduction Difficulty in process adjustment, cost saving, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

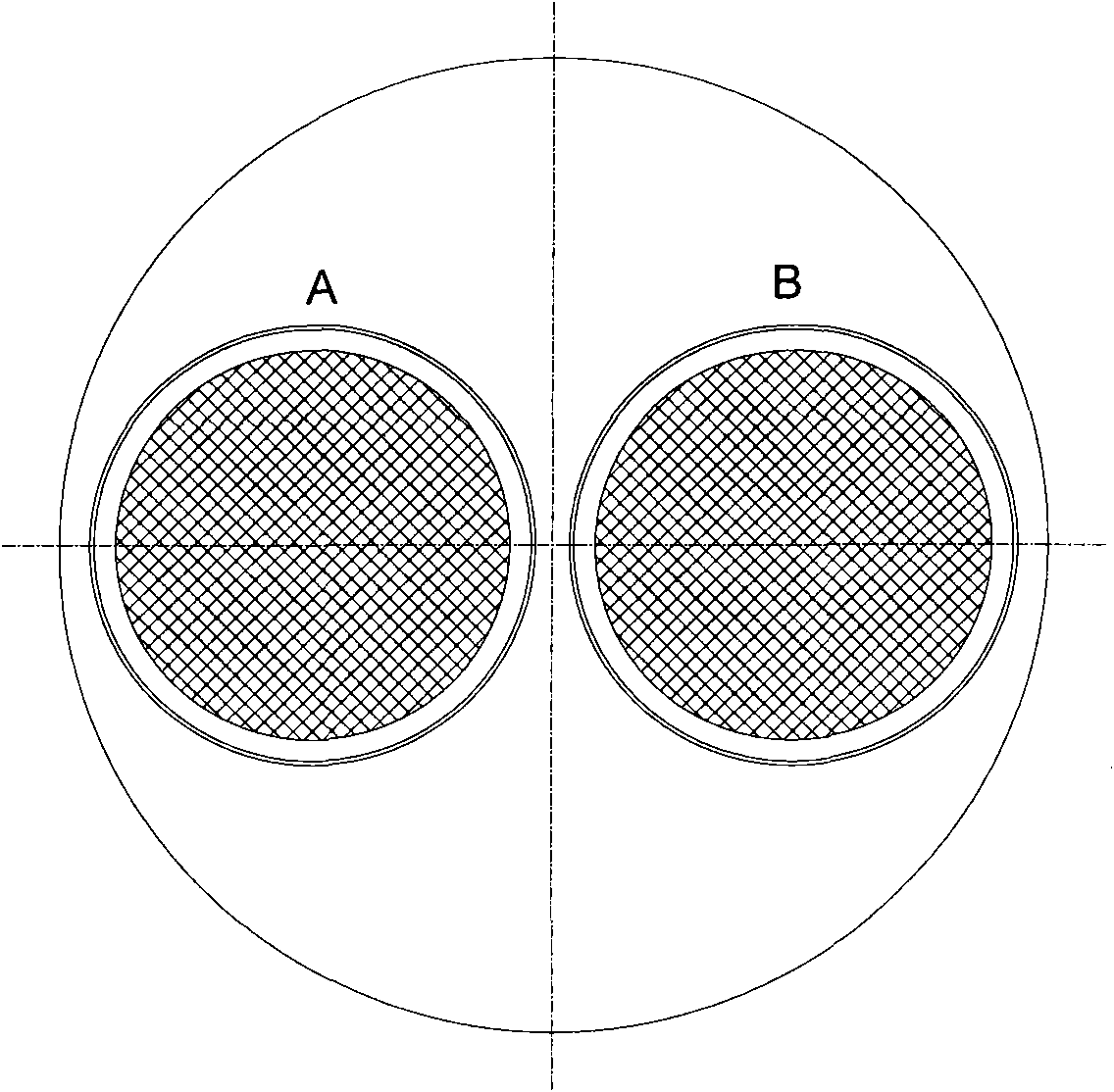

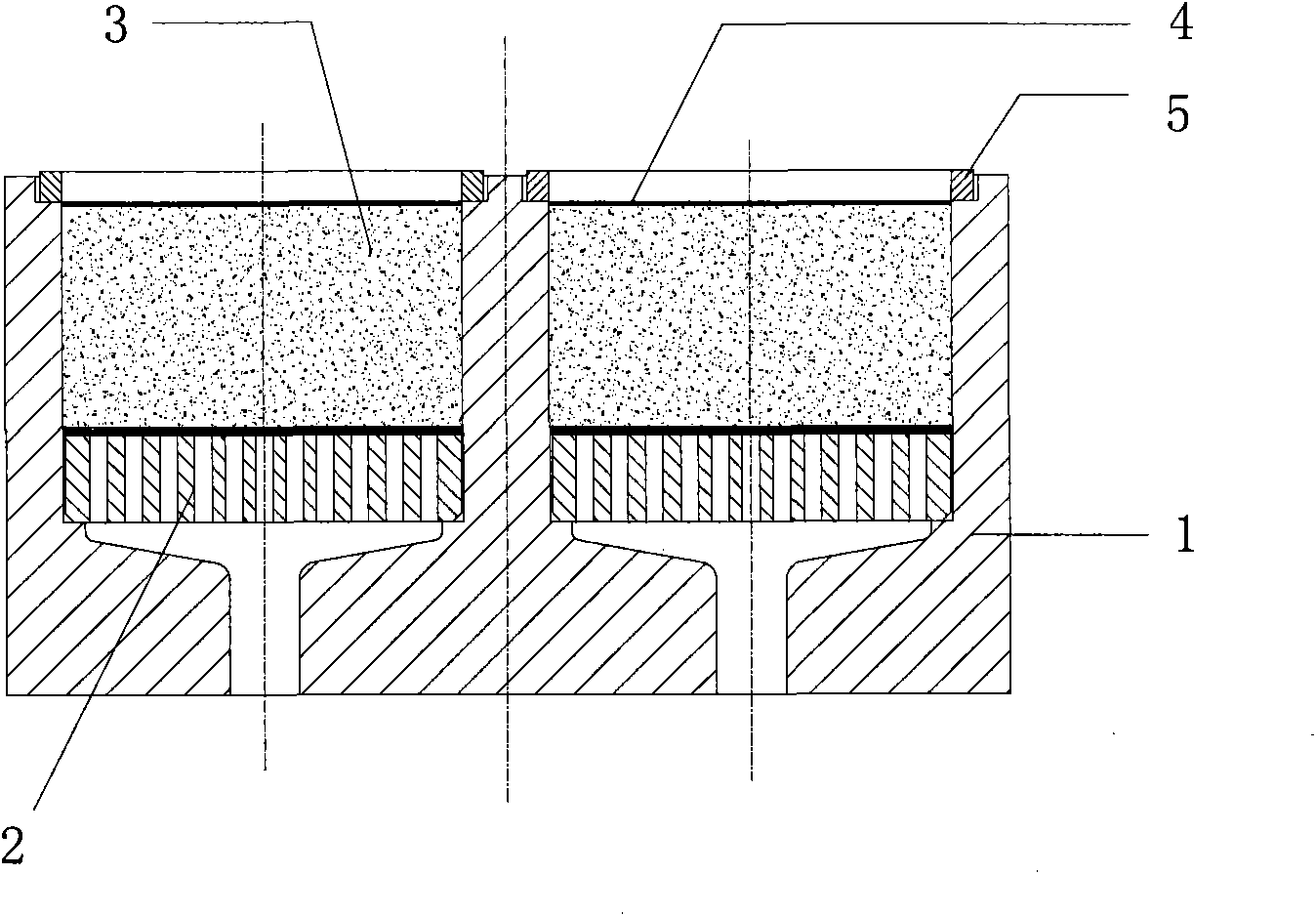

[0073] Such as Figure 4 As shown, the composite spinning assembly with a replaceable sand chamber inner sleeve of the present invention is mainly composed of a sand chamber body 1, a distribution block 2 in the sand chamber, a metal filter sand 3, a metal filter screen 4 and a metal sealing ring 5. The composite spinning assembly described therein also includes a movable sand chamber inner cover 6, the described sand chamber body 1 includes a component A sand cavity and a B component sand cavity, and the movable sand cavity inner cover 6 is connected with the B group The sand sub-chambers cooperate with each other, and the metal sealing ring 5 is preferably a copper sealing ring.

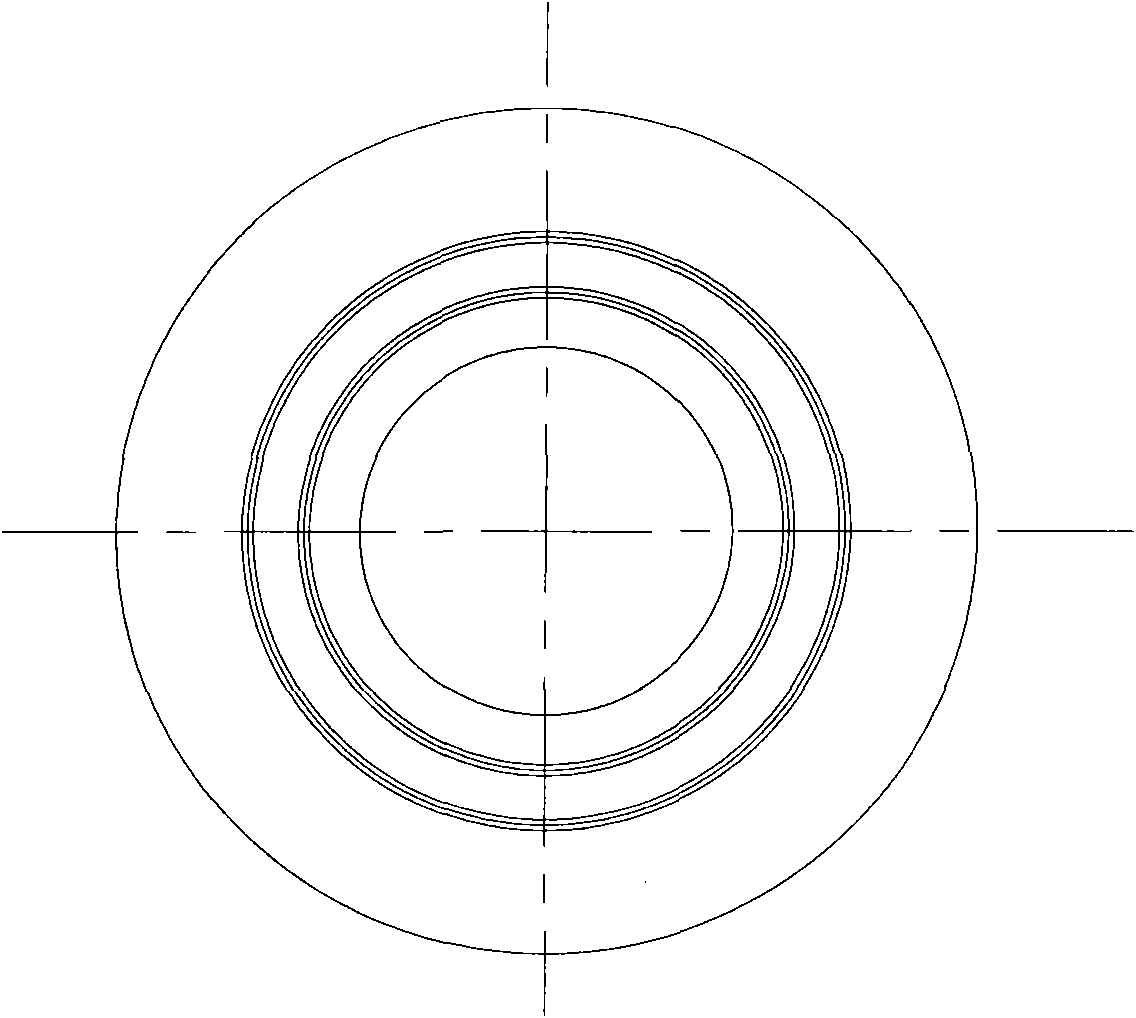

[0074] Figure 2-A and Figure 2-B A bottom view and a sectional view of the movable sand chamber inner sleeve of the present invention are shown. The inner casing of the movable sand chamber is made of stainless steel, and the material is preferably 1Cr18Ni9, more preferably SUS630. The value ...

Embodiment 2

[0076] In order to cooperate with the original seal, so that the melt does not cross-feed in the sand chamber, on the basis of the composite spinning assembly provided in Example 1, the upper and lower surfaces of the movable sand chamber inner sleeve 6 are further A metal gasket 7 is provided, preferably a copper gasket or an aluminum gasket, more preferably an aluminum gasket. The upper surface of the aluminum sealing gasket 7 is 0.5-1.5 mm higher than the upper surface of the copper sealing ring, preferably 0.7-1 mm. Figure 3-A and Figure 3-B A bottom view and a cross-sectional view of the aluminum gasket of the present invention are shown. The aluminum sealing gasket is made of aluminum alloy, and the material is preferably L3-M; the value of its outer diameter c is 2-5mm smaller than the value of the outer diameter a of the inner casing of the movable sand chamber, preferably 2.5-3.0mm; the value of the inner diameter d is It is larger than the inner diameter b of the...

Embodiment 3

[0078] Such as Figure 4 As shown, the composite spinning assembly of the present invention with a replaceable sand chamber inner sleeve also includes an overflow cover 8 . There is a gap of 0.5 mm to 1.5 mm between the overflow cover 8 and the copper sealing ring 5 , preferably 0.7 mm to 1 mm. After fastening, the overflow cover and the copper sealing ring are in close contact to achieve sealing. At the same time, the upper and lower aluminum gaskets also play a sealing role, so that the melt will not form a dead angle in the sand chamber. In this way, the component A sand chamber is still sealed with the original copper sealing ring, while the copper sealing ring of the component B sand chamber plays the role of sealing and supporting the overflow cover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com