Fondant milling degree regulating device of milling extrusion pressing granulation machine group

An adjustment device and mixing technology, applied in the direction of mixers, mixer accessories, dissolution, etc., can solve the problems of high design and manufacturing costs, inconvenient adjustment and testing, and large mechanisms, and achieve reduced maintenance costs, novel structure, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

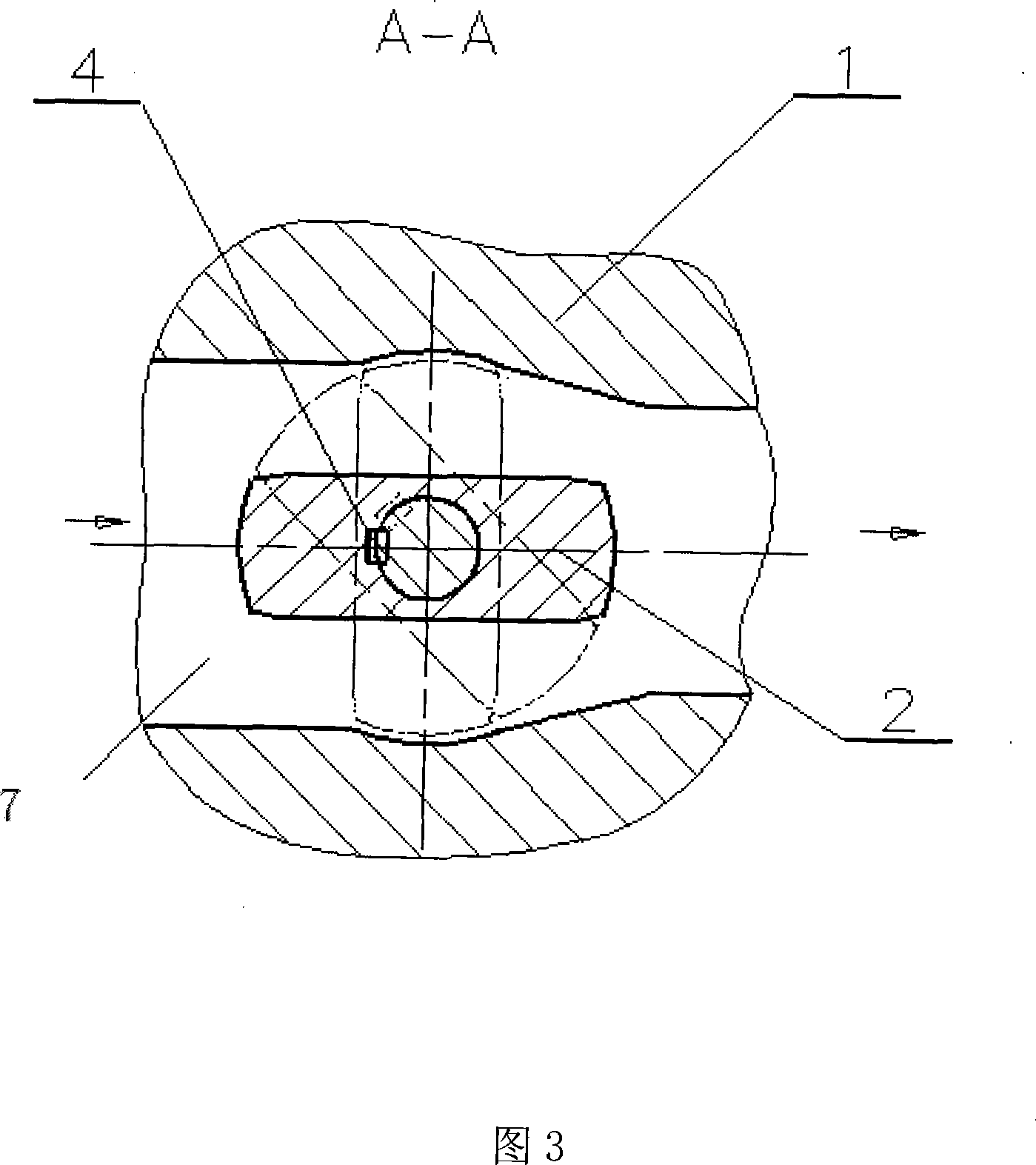

[0017] As shown in Figures 2 and 3, the melt mixing degree adjustment device of the mixing and granulation unit has a material flow channel 7 in the alloy steel valve body 1 with a wear-resistant and corrosion-resistant surface, and a rotating device is installed in the material flow channel. Axis 3, the rotating shaft is fixed with a wear-resistant and corrosion-resistant alloy steel valve core 2 or valve plate through keys 4 or pins. The flow area of the material flow channel varies with the rotation angle, and the connection diagram of the rotating shaft is not Drives drawn, such as electric, hydraulic or manual drives. The rotating shaft is not in direct contact with the valve body, and is connected by supporting bushings 6 at both ends.

[0018] In order to ensure the sealing effect of the valve, sealing covers 5 are installed on both sides of the rotating shaft bushing, and the sealing cover on one side is fitted with the valve body 1 to seal the molten material; the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com