A heat treatment device for a battery pack and a manufacturing method of a phase change material

A technology for heat treatment devices and battery packs, applied to heat exchange materials, secondary batteries, chemical instruments and methods, etc., can solve problems such as poor effect and unfavorable heat dissipation of high energy density power batteries, and improve work performance, flow and The flow rate is controllable and reasonable, and the effect of prolonging the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

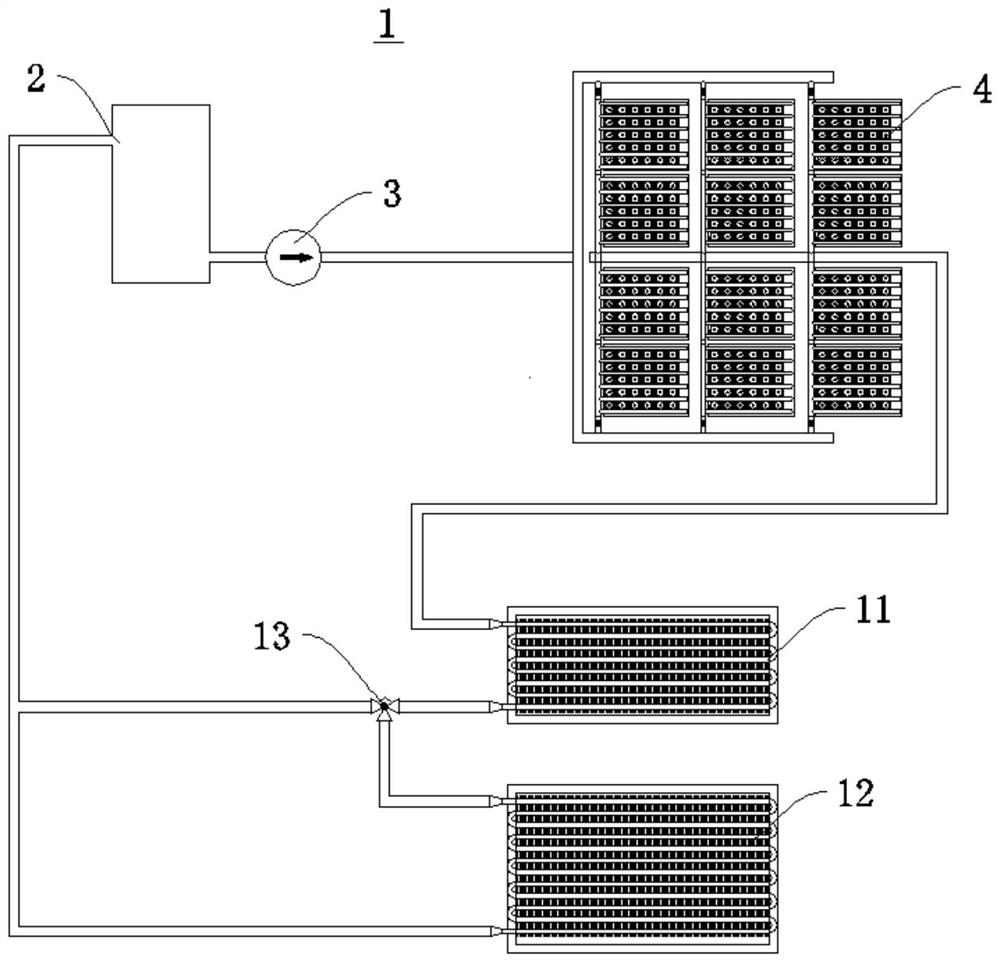

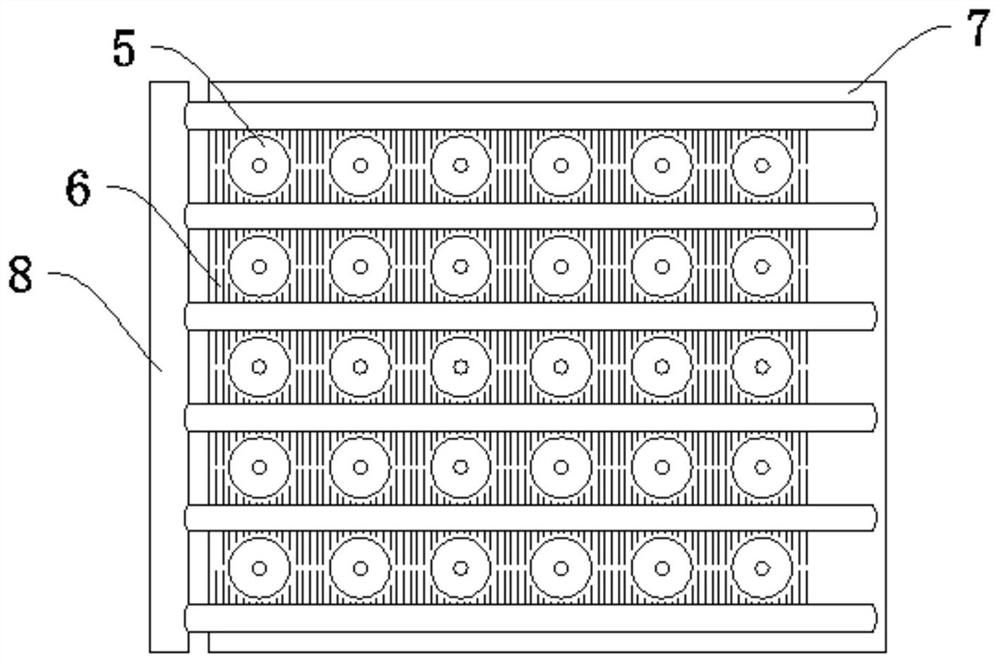

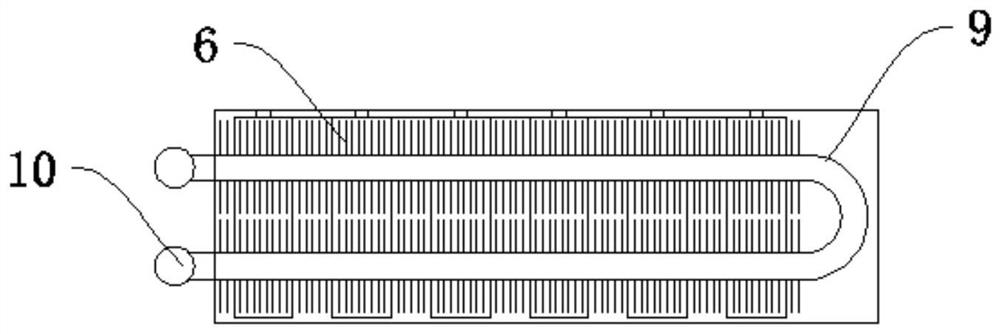

[0060] Please refer to figure 1 , with reference to Figure 2 to Figure 3 , the present application provides a battery pack heat treatment device 1, including a coolant tank 2, a variable frequency electric pump 3, a power battery 5 mechanism, and a heat dissipation mechanism, and the power battery 5 mechanism includes a liquid supply pipeline, a plurality of liquid cooling components 4, and a plurality of batteries 5 and the phase change structure 6, the heat dissipation mechanism includes a temperature control valve 13, at least two first radiators 11 and second radiators 12 with different heat dissipation areas; wherein, the coolant tank 2 is equipped with a The cooling liquid for cooling the battery pack, which communicates with the variable frequency electric pump 3 through the connecting pipe; the variable frequency electric pump 3 is used to transport the cooling liquid in the coolant tank 2 to the liquid cooling assembly 4 to cool the battery pack, Moreover, the frequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com