Car headlamp reflector die

A reflective mirror and concave mold technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as thinning, insufficient effective control of material flow, inaccurate focusing of reflective mirrors, etc., to achieve improved tearing, Height adjustment is convenient and quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

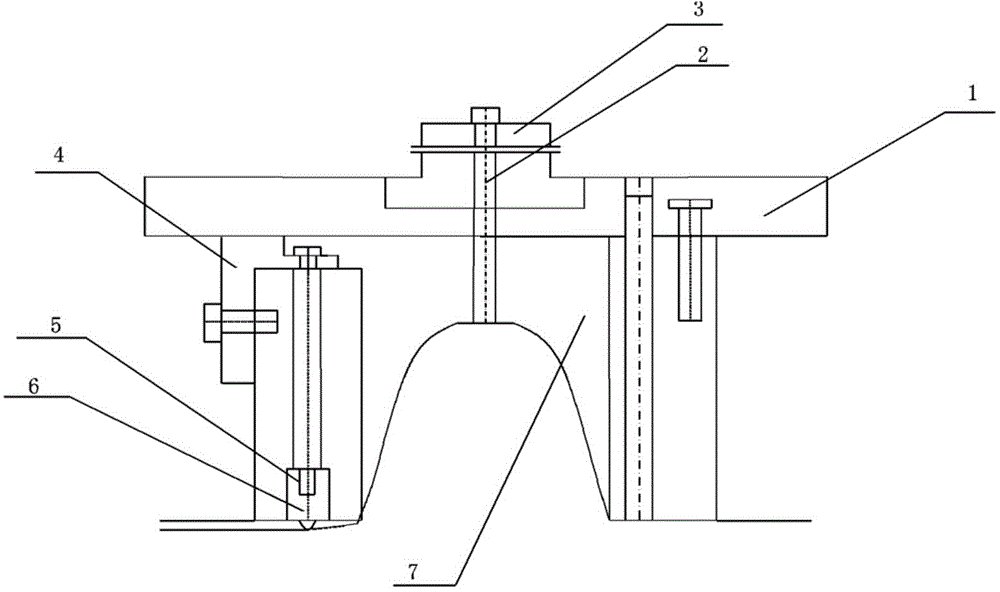

[0013] The electric vehicle headlight reflector die includes a die main body 7, an upper template 1, a handle 3, a feeder 2 and a drawbead assembly, and the drawbead assembly includes a drawbead 6 and a drawbead The positioner 4 and the adjusting spacer 5, the drawbead positioner 4 placed on the lower side of the upper template 1 positions one end of the drawbead 6, and the other end of the drawbead 6 is adjusted in height through the adjustment spacer 5.

[0014] The beater 2 and the mold handle 3 are fixedly installed in the middle of the upper template 1 .

[0015] The thickness of the drawn rib 6 is 7mm, and the length is 30mm. The drawn height is 3mm, and then the spacer 4 is adjusted according to the actual situation of the electric vehicle headlight.

[0016] In the process of adjusting the height of the drawbead 6, only need to take down the drawbead positioner 4, and then take out the drawbead 6, without disassembling the whole mold, the thickness of the adjusting gas...

Embodiment 2

[0019] The electric vehicle headlight reflector die includes a die main body 7, an upper template 1, a handle 3, a feeder 2 and a drawbead assembly, and the drawbead assembly includes a drawbead 6 and a drawbead The positioner 4 and the adjusting spacer 5, the drawbead positioner 4 placed on the lower side of the upper template 1 positions one end of the drawbead 6, and the other end of the drawbead 6 is adjusted in height through the adjustment spacer 5.

[0020] The beater 2 and the mold handle 3 are fixedly installed in the middle of the upper template 1 .

[0021] The thickness of the drawn rib 6 is 10mm, and the length is 45mm. The drawn height is 5mm, and then the spacer 4 is adjusted according to the actual situation of the electric vehicle headlight.

[0022] In the process of adjusting the height of the drawbead 6, only need to take down the drawbead positioner 4, and then take out the drawbead 6, without disassembling the whole mold, the thickness of the adjusting ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com