Lattice cell, fuel assembly positioning grid and fuel assembly

A technology for positioning grids and fuel assemblies, applied in the directions of reactor fuel elements, fuel element assembly, nuclear power generation, etc., can solve problems such as increasing workload, and achieve the effects of avoiding damage, preventing up and down movement, and fully contacting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

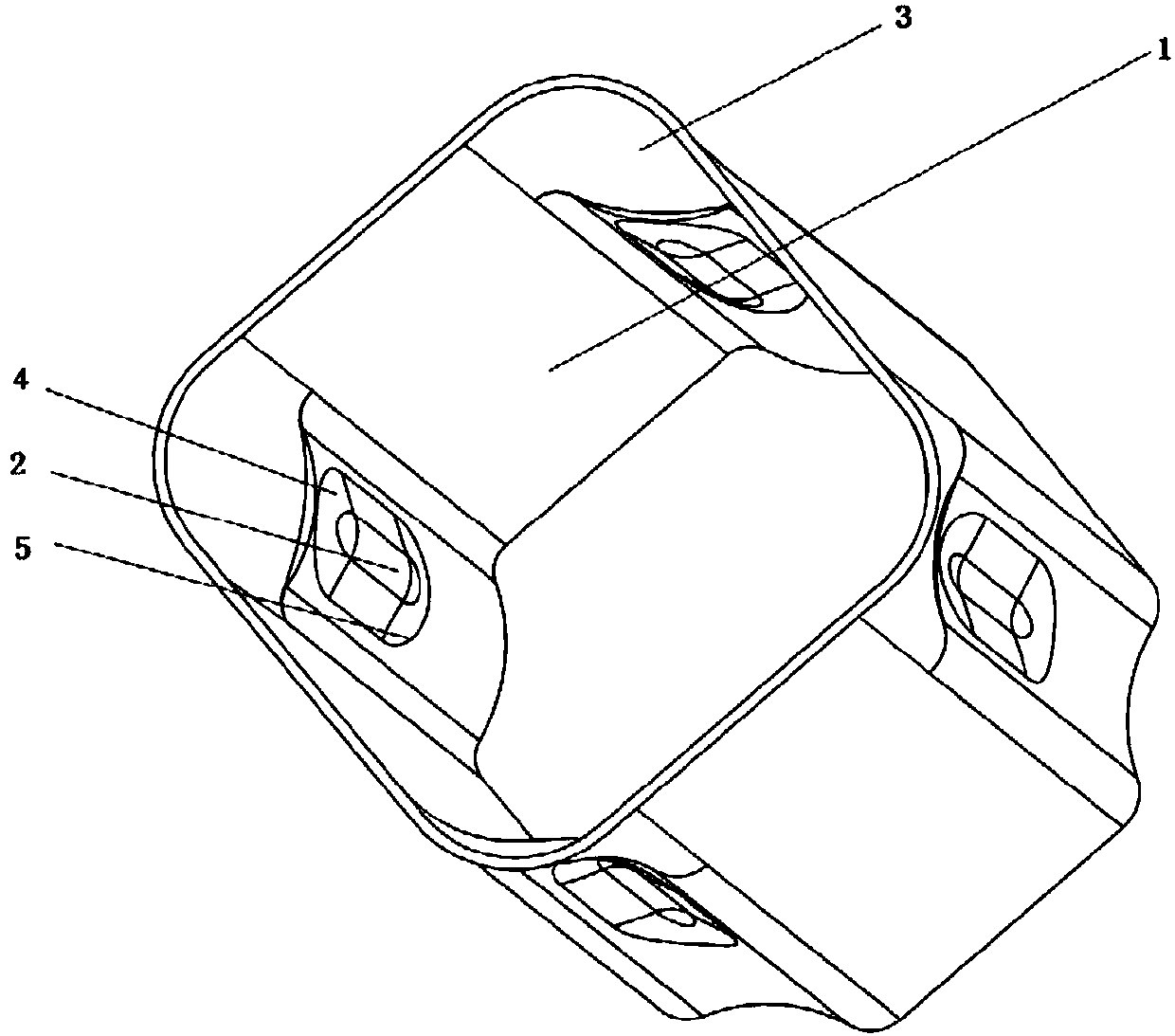

[0056] like figure 1 As shown, cell 1 is a four-sided cylinder, including cylinder corners and cylinder walls, and a plane is processed at the cylinder corners. Rigid protrusions 2 are provided on the cylinder angle plane of the cell 1 .

[0057] The rigid protrusions 2 are elliptical and protrude toward the inner side of the cell 1 along the height direction of the cell 1 to form a line contact with the fuel element.

[0058] An inclined upper guide surface 4 is provided above the rigid protrusion 2, and an inclined lower guide surface 5 is provided below the rigid protrusion 2 to make a smooth transition between the rigid protrusion 2 and the cell wall of the cell 1, and facilitate the insertion of fuel elements.

[0059]An upper convex portion 3 is provided above the upper guide surface 4 for controlling the flow rate of the coolant and producing a certain mixing effect on the coolant. The raised portion 3 protrudes toward the outside of the cell 1 . The protruding range...

Embodiment 2

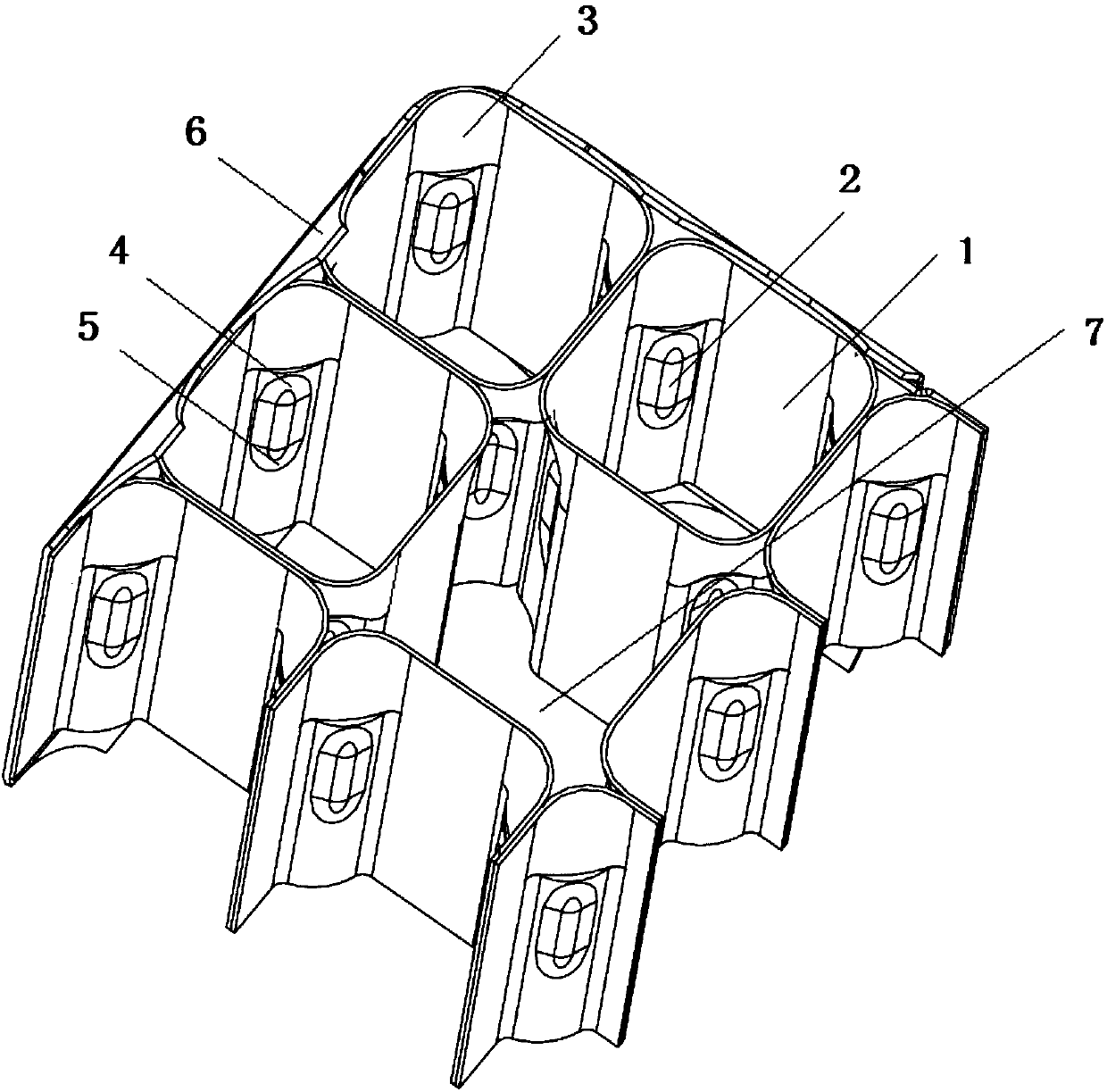

[0066] Cell 1 is a four-sided cylinder, including cylinder corners and cylinder walls, and a plane is processed at the cylinder corners. Rigid protrusions 2 are provided on the cylinder angle plane of the cell 1 .

[0067] like Figure 4 As shown, the rigid protrusion 2 is elliptical and protrudes toward the inner side of the cell 1 along the height direction of the cell 1 to form a line contact with the fuel element.

[0068] An inclined upper guide surface 4 is provided above the rigid protrusion 2, and an inclined lower guide surface 5 is provided below the rigid protrusion 2 to make a smooth transition between the rigid protrusion 2 and the cell wall of the cell 1, and facilitate the insertion of fuel elements.

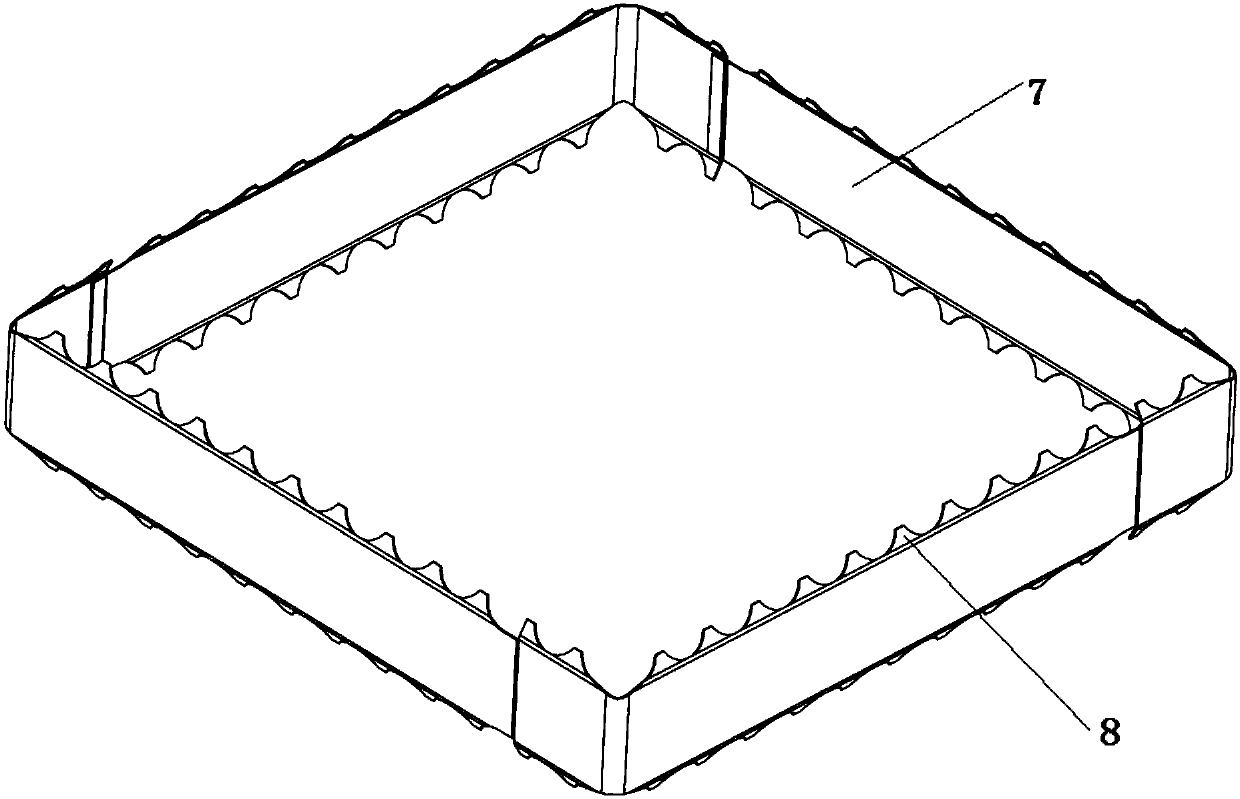

[0069] A cell-type fuel assembly positioning grid is composed of cell 1 arrays. The cells 1 are connected in pairs and fixed by spot welding to form a 3x3 positioning grid.

[0070] Take out the cell 1 at the center of the cell arrangement, and use the vacant p...

Embodiment 3

[0075] Cell 1 is a four-sided cylinder, including cylinder corners and cylinder walls, and a plane is processed at the cylinder corners. Rigid protrusions 2 are provided on the cylinder angle plane of the cell 1 .

[0076] The rigid protrusions 2 are elliptical and protrude toward the inner side of the cell 1 along the height direction of the cell 1 to form a line contact with the fuel element.

[0077] An inclined upper guide surface 4 is provided above the rigid protrusion 2, and an inclined lower guide surface 5 is provided below the rigid protrusion 2 to make a smooth transition between the rigid protrusion 2 and the cell wall of the cell 1, and facilitate the insertion of fuel elements.

[0078] An upper convex portion 3 is provided above the upper guide surface 4, and a lower convex portion 9 is arranged symmetrically with the upper convex portion 3 below the lower guide surface 5, which is used to control the flow rate of the coolant and generate a certain amount of mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com