Halogen-free low-splash solder wire and preparation method of halogen-free low-splash solder wire

A solder wire and solder technology, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of welding efficiency tin wire splashing, smoke and dust harm to human body, etc., and achieve the effect of improving welding efficiency, low odor, and improving splash characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Solder wire ratio: flux 2%, Sn-3.0Ag-0.5Cu rod (φ100mm) solder 98%

[0027] Among them, the flux mass percentage ratio is: 35% hydropine, 35% polymerized rosin, 12% rubber, 2% benzotriazole, 2% methylimidazole, 0.5% oxalic acid, 3% oxalate, Succinic acid 3%, antioxidant oil 3%, compound AK218 active agent 4.5%.

[0028] Preparation:

[0029] Step 1. Flux preparation: evenly heat the rosin in the flux formula to 170±5°C. After it is completely melted, add the rest of the flux materials and stir until all the materials are dissolved and the appearance is uniform and clear liquid. The heating time cannot exceed 120±5 minutes, otherwise the flux will not be used. Filter after heating, filter the heated and melted solder paste with a 100-mesh filter and pour it into the flux barrel of the wire extruder to keep it warm at 90-100°C, and the air pressure setting range is 0.1-0.4MPa;

[0030] Step 2. Extrusion: install the selected rod-shaped solder on the extruder, set the e...

Embodiment 2

[0034] Tin wire ratio: flux 1.8%, Sn-0.7Cu rod (φ100mm) solder 98.2%

[0035] Among them, the flux mass percentage ratio is: 32% hydrogenated rosin, 35% polymerized rosin, 15% rubber, 2% phenylacryltriazole, 2% ethylimidazole, 1.5% oxalic acid, 3% oxalate, Succinic acid 3%, antioxidant oil 3%, compound AK218 active agent 3.5%;

[0036] No small pull is needed in the preparation method, and others are the same as in Example 1.

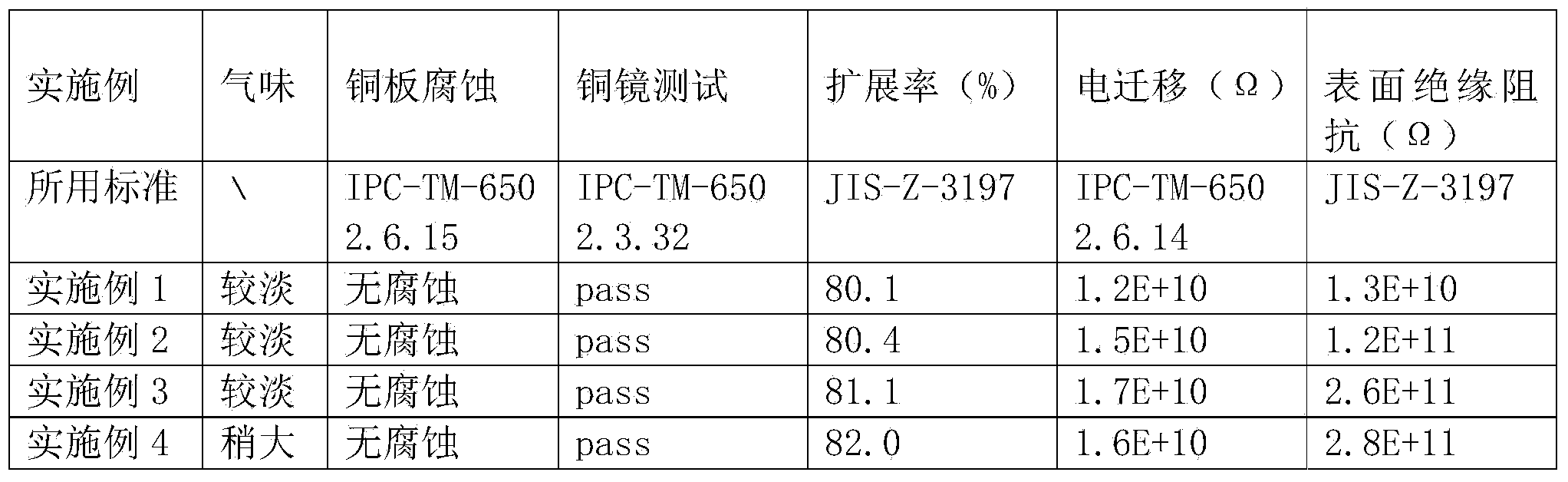

[0037] The various test indexes of the solder wire obtained in this embodiment are shown in Table 1 and Table 2. Compared with Example 1, due to the increase of the formula rubber content, the surface insulation resistance after welding is improved.

Embodiment 3

[0039] Tin wire ratio: flux 2%, Sn-0.3Ag-0.7Cu rod (φ100mm) solder 98%

[0040] Among them, the flux mass percentage ratio is: 32% of hydrogenated rosin, 31% of polymerized rosin, 19% of rubber, 2% of benzotriazole, 2% of ethylimidazole, 1.5% of oxalic acid, 3% of oxalate, Succinic acid 3%, antioxidant oil 3%, compound AK218 active agent 3.5%;

[0041] No small pull is needed in the preparation method, and others are the same as in Example 1.

[0042] The various test indicators of the solder wire obtained in this embodiment are shown in Table 1 and Table 2, and its splash effect is as follows: figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com