A method for realizing regularization of particle size of titanium dioxide

A titanium dioxide, particle size technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problem of insufficient time, fast heating rate, and no consideration of the correlation between crystal transformation rate and crystal growth rate and temperature. different problems, so as to achieve the effect of regularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The amount of barium-containing inorganic substances required for the preparation of metatitanic acid hydrolyzed primary agglomerated particles

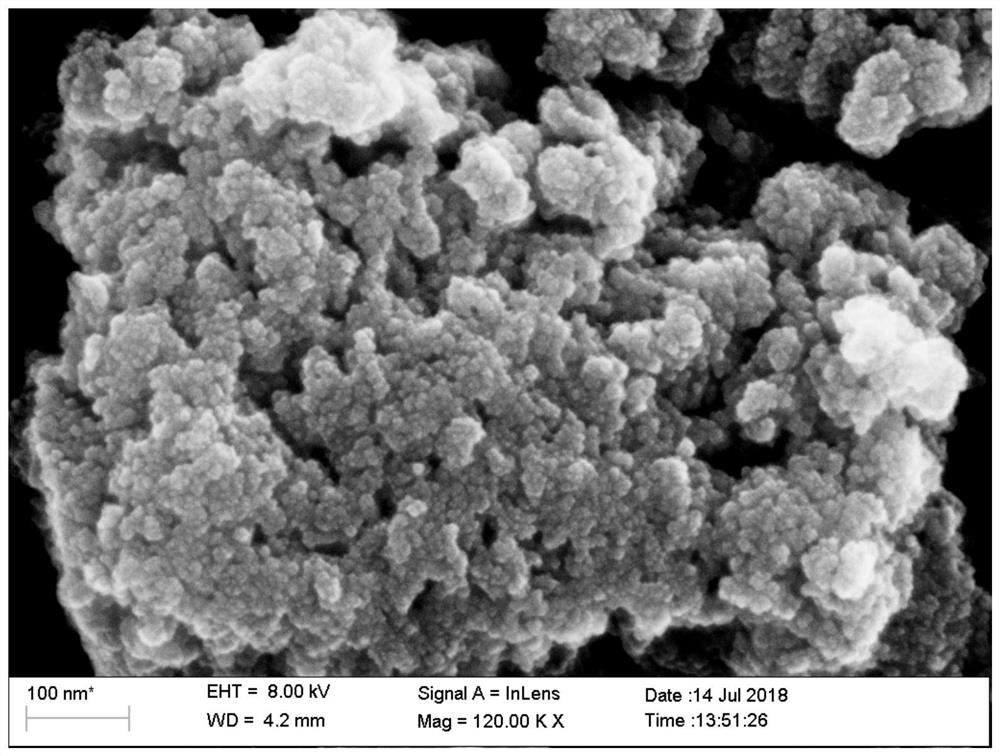

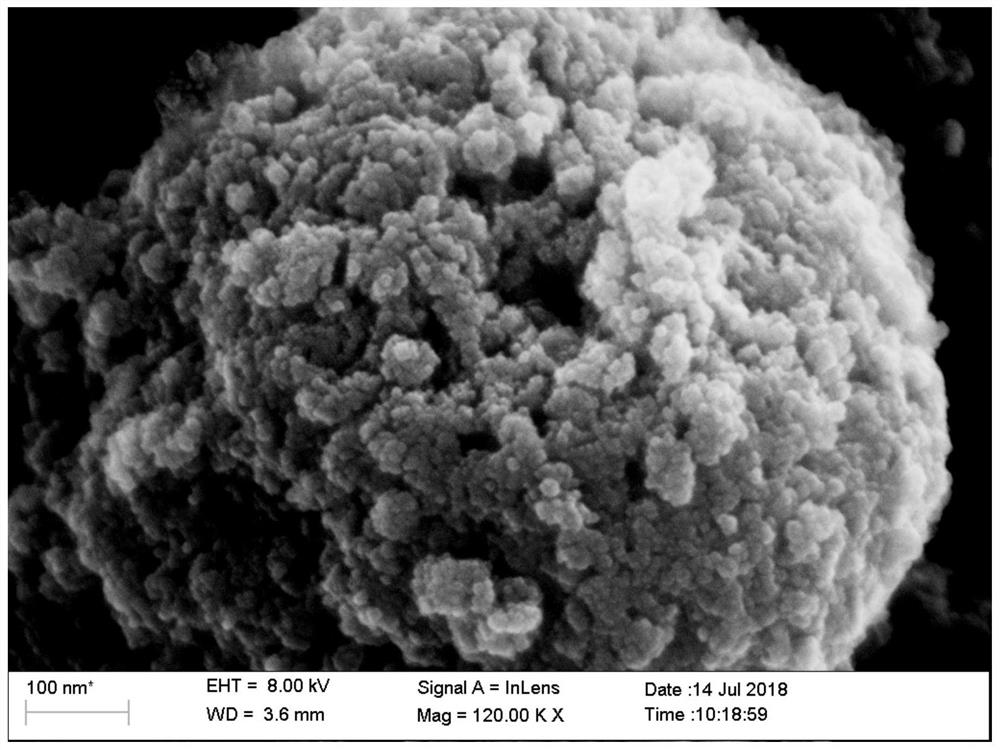

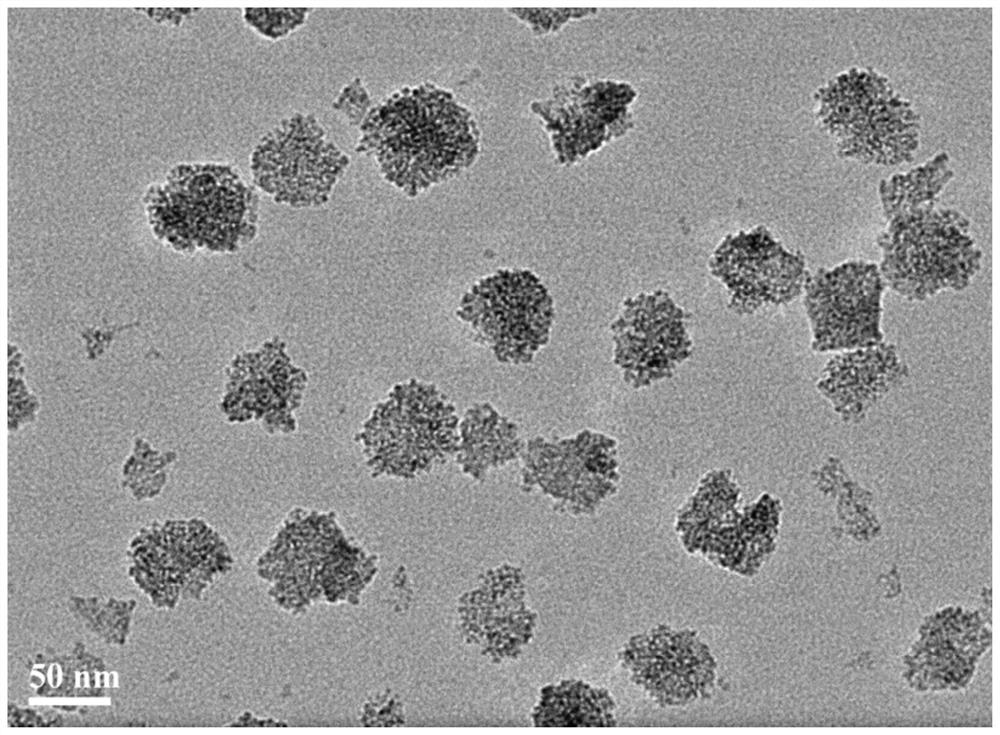

[0058]Table 1 is when the addition ratio of barium chloride (according to the ratio of sulfate radical and titanium dioxide) is 10% and 20% respectively, the high-concentration alkali of 1.5%, 2.0% and 2.5% addition neutralizes the first time of metatitanic acid hydrolysis of seed crystal The average particle size of agglomerated particles. It can be seen that 1.5%, 2.0% and 2.5% of the added amount of high-concentration alkali neutralize the average particle size of the secondary agglomerated particles of metatitanic acid hydrolysis from the original 1.722 μm, 1.688 μm and 1.837 μm to depolymerize to 54.5nm, For the primary agglomerated particles of 50.4nm and 49.65nm, when the proportion of the added barium chloride solution is increased to 20%, there is no obvious white precipitate in the primary agglomerated particle solut...

Embodiment 2

[0065] This embodiment provides a method for realizing regularization of particle size of titanium dioxide.

[0066] In this example, the particle size of metatitanic acid primary aggregate particles is combined with the temperature control of the subsequent metatitanic acid calcination process, and the metatitanic acid calcination process is regulated according to the particle size change by characterizing the metatitanic acid primary aggregate particle size The heating rate can be controlled to achieve the purpose of regulating the particle size of titanium dioxide.

[0067] Using the hydrolyzed slurry (metatitanic acid slurry) in the traditional sulfuric acid titanium dioxide production process as raw material, some hydrolyzed metatitanic acid slurry was taken for analysis.

[0068] Wherein, the measurement of the metatitanic acid primary agglomerated particles and the statistics of the average particle size of titanium dioxide after calcination are carried out according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com