Method for drying and desolventizing cottonseed meal and special drying and desolventizing equipment of method

A desolvation and cottonseed technology, applied in drying, dryer, lighting and heating equipment, etc., can solve the problems of unstable cottonseed protein, high dissolution consumption, high residual oil, etc., to ensure the quality of cottonseed protein. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

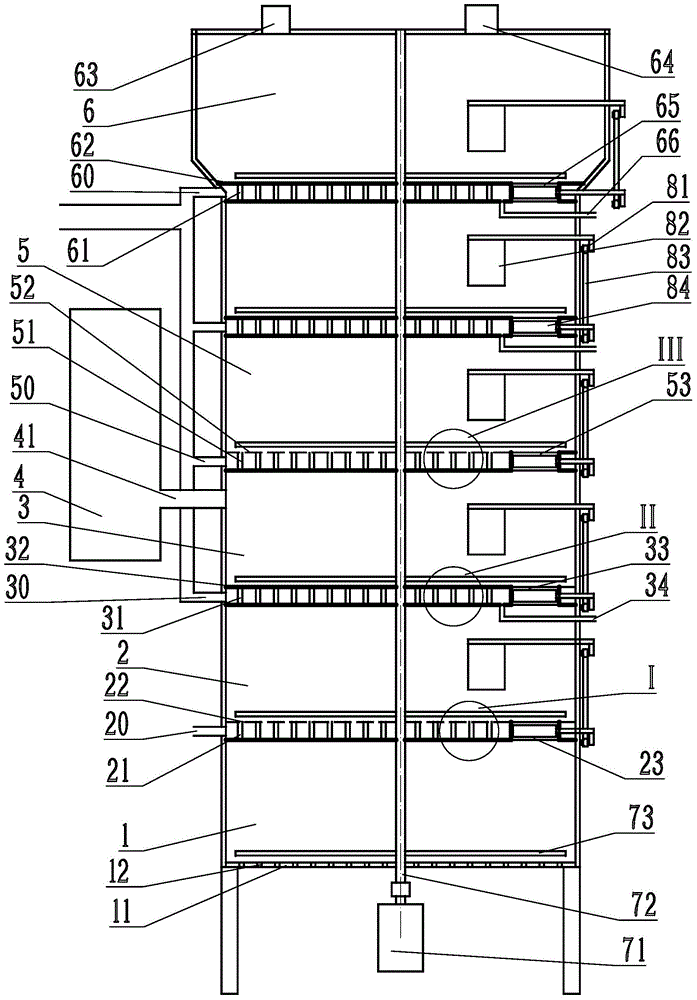

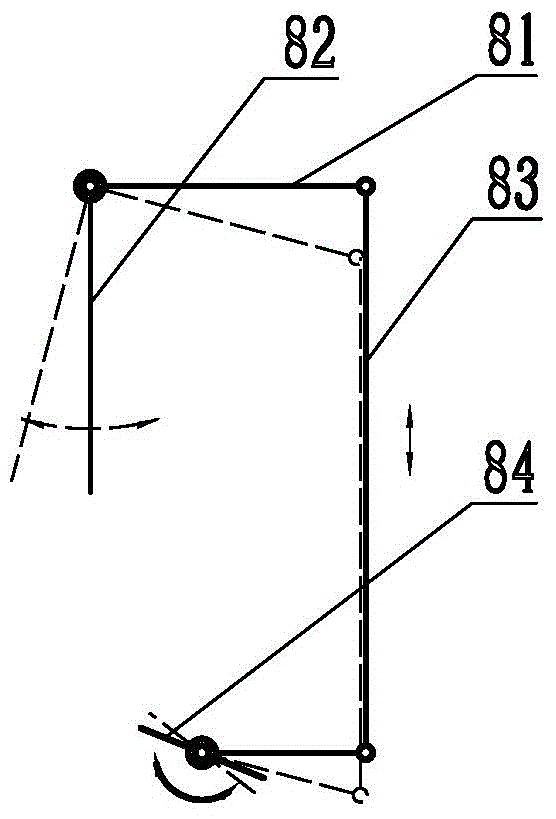

[0036] Example 1: refer to Figure 1~5 , is a schematic structural diagram of the drying tower in Example 1 of the present invention, the drying tower includes a cylindrical tower body and a stirring mechanism, the stirring mechanism includes a motor (71), a stirring shaft (72) and a stirring fin (73) , the space in the tower body consists of 6 layers, from bottom to top are discharge layer (1), cooling layer (2), drying layer (3), air-permeable layer (5), drying layer and pre-desolvation layer (6 ), the lower part of each layer is provided with a sieve-shaped partition, and the stirring fins (73) are arranged above the sieve-shaped partition, and in each layer, the partitions are provided with densely distributed feeding holes, Make the partitions sieve-like.

[0037] The partitions under the cooling layer (2), drying layer, breathable layer (5) and pre-desolvation layer (6) are interlayer hollow plates.

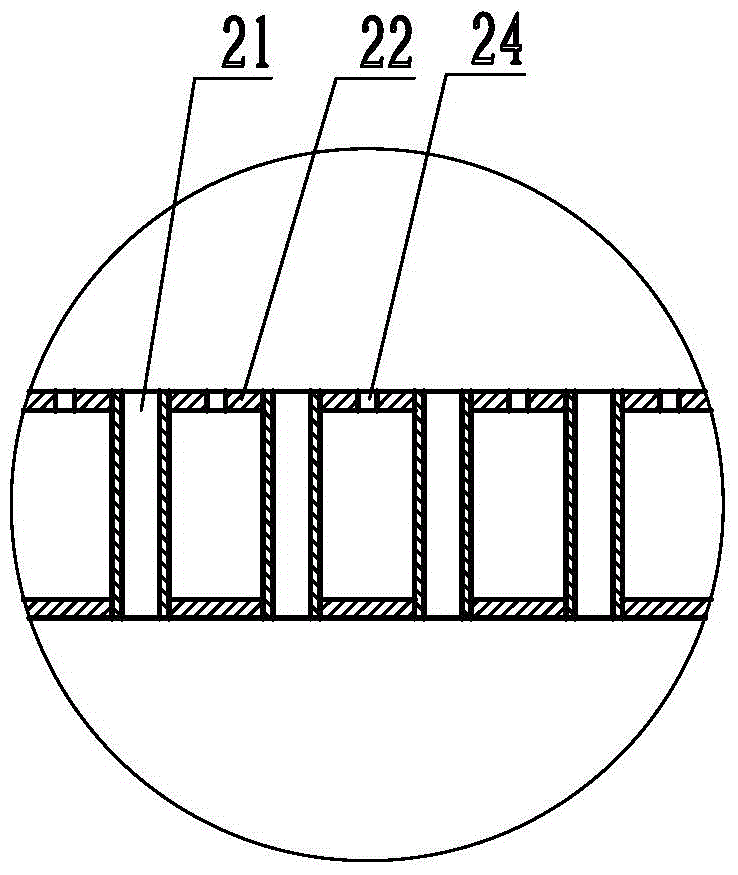

[0038] The cooling layer (2) includes a sandwich hollow plate body...

Embodiment 2

[0046] Example 2: refer to Figure 6 , is a schematic structural diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is: the air outlet A (24) of the cooling layer (2) [or the air outlet of the air-permeable layer (5) C (54)] The outlet is not facing upwards, and it is realized by setting a side-opening tower cap on the air outlet A (24) [or air outlet C (54)] to prevent the material from flowing out of the air outlet A (24) ) [or air outlet C (54)] channel into the cavity of the sandwich hollow plate.

Embodiment 3

[0047] Example 3: refer to Figure 7 , is a schematic structural diagram of Embodiment 3 of the present invention. Compared with Embodiment 2, the difference of this embodiment is: the air outlet A (24) of the cooling layer (2) [or the air outlet of the air-permeable layer (5) C (54)] is realized by setting a multi-pass tubular body on the air outlet A (24) [or air outlet C (54)].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com