Multi-stage screening and drying integrated equipment for food machining

A food processing and screening technology, applied in lighting and heating equipment, filtering, drying, etc., can solve the problems of affecting screening efficiency, low processing efficiency, occupying a large space, etc., to improve screening efficiency, screening The effect is good, and the effect of saving cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

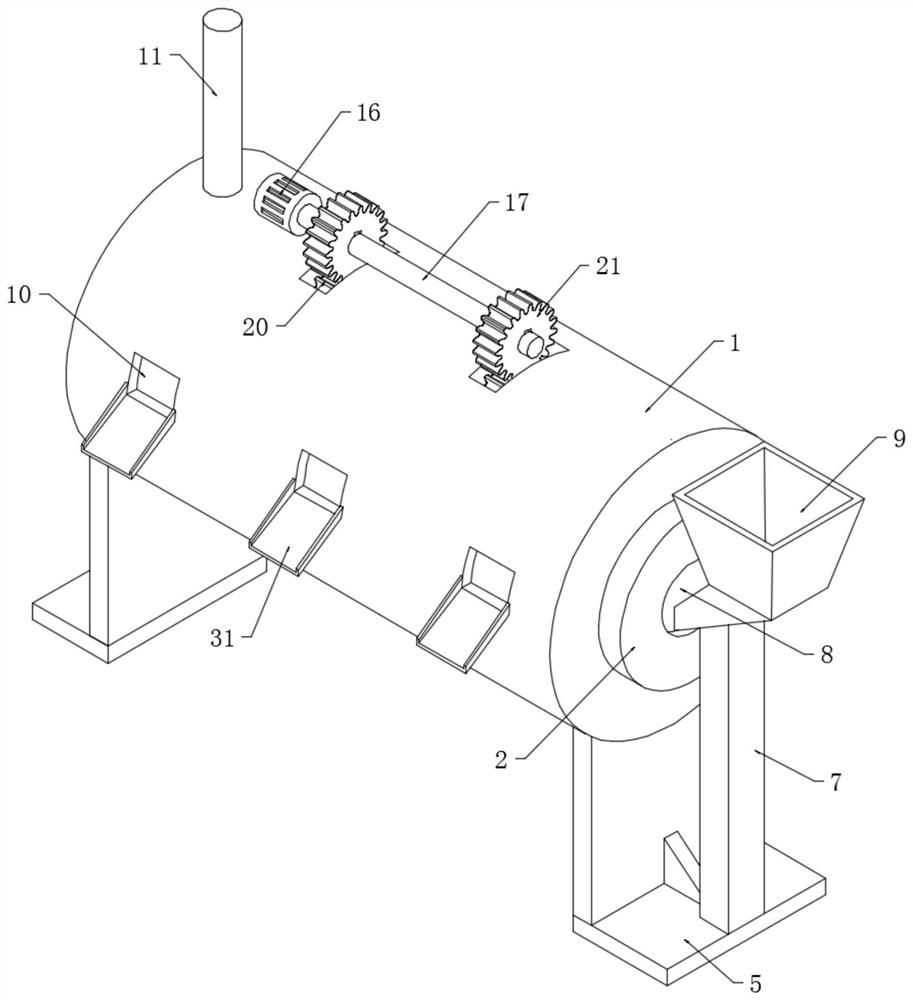

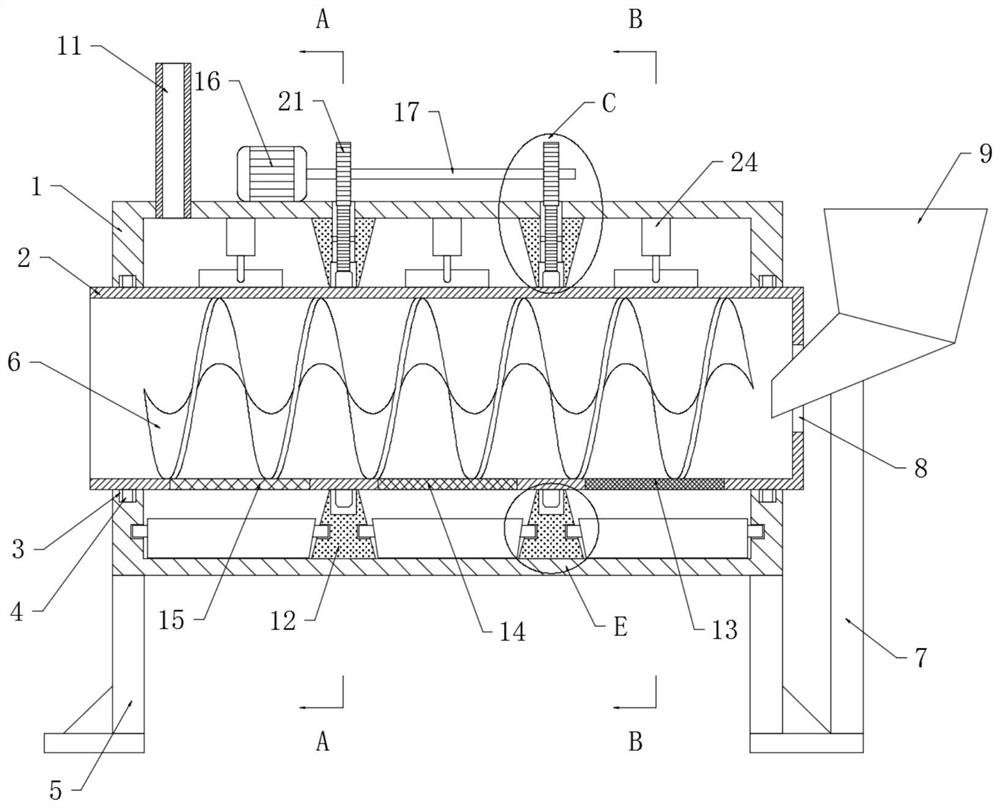

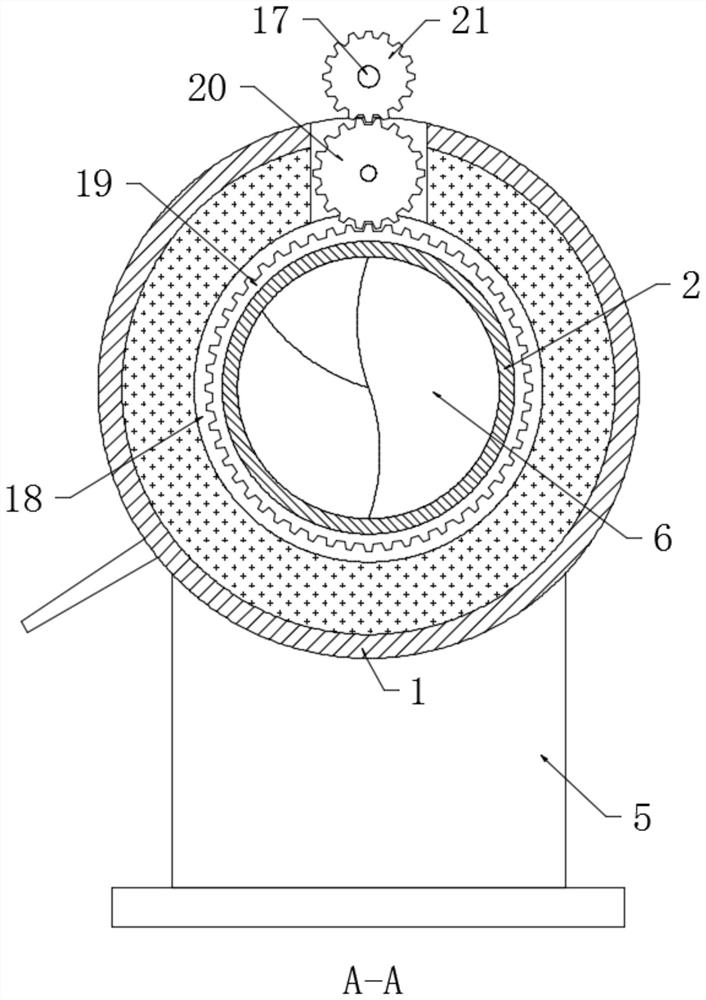

[0028] refer to Figure 1-7 , a multi-stage screening and drying integrated equipment for food processing, including a cylindrical case 1 arranged horizontally, two support feet 5 are fixedly connected to the outer wall of the bottom of the case 1, and a A cylindrical sieve box 2, the chassis 1 and the sieve box 2 are on the coaxial center line, the junction of the chassis 1 and the sieve box 2 is provided with a guide rail 3, and the outer wall of the sieve box 2 is provided with a A plurality of rollers 4, a plurality of rollers 4 are slidingly connected with the guide rail 3, and the inner wall of the sieve box 2 is fixedly connected with a material delivery blade 6, and one end of the sieve box 2 is provided with a feed inlet 8, and the The bottom of the support foot 5 is fixedly connected with a vertical fixed column 7, and the upper end of the fixed column 7 is fixedly connected with a feed cone 9, and the lower end of the feed cone 9 extends into the feed port 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com