Final polycondensation reactor for preparing polycarbonate(PC)

A technology of polycarbonate and final polycondensation, which is applied in the field of polycarbonate, can solve the problems of unstable vacuum degree, difficult control of material residence time, and easy occurrence of side reactions, so as to prevent overheating side reactions, improve reaction effects, and prevent side effects. The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

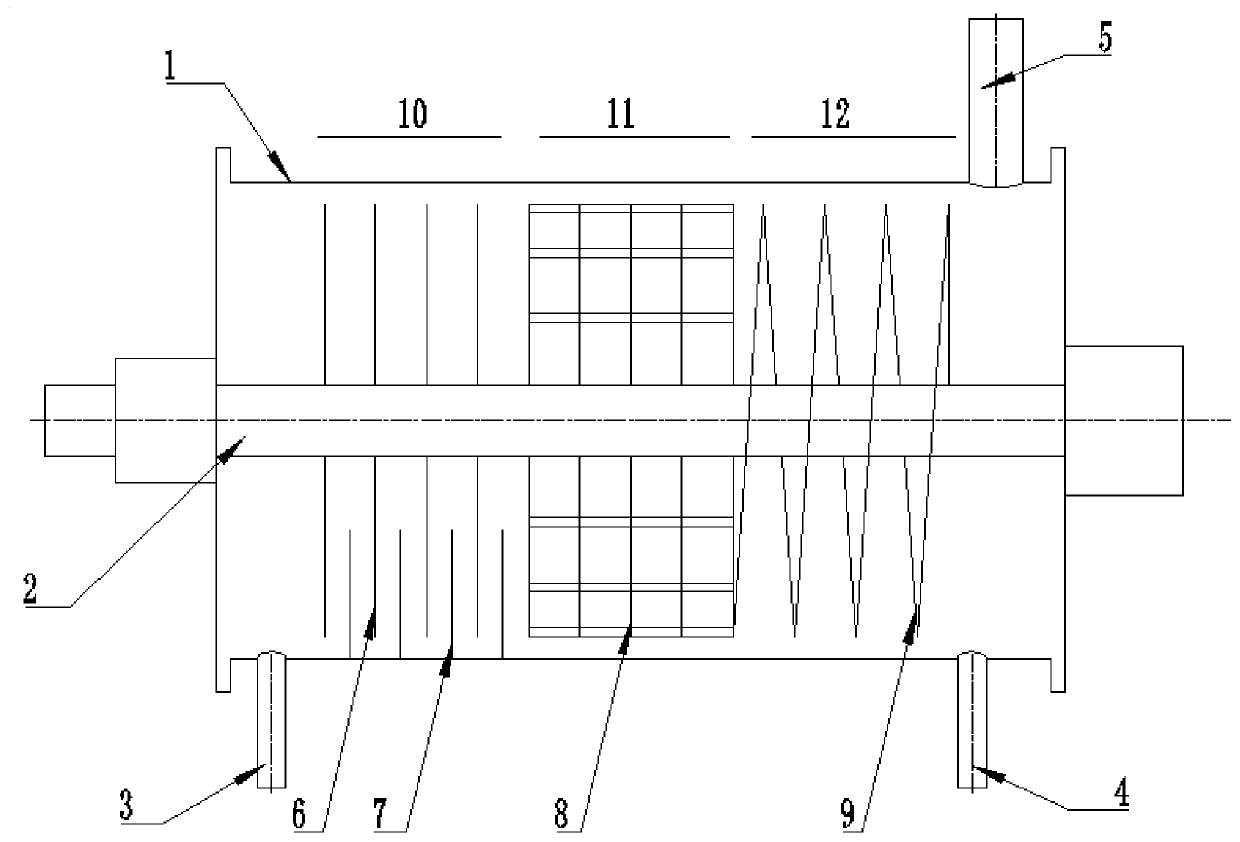

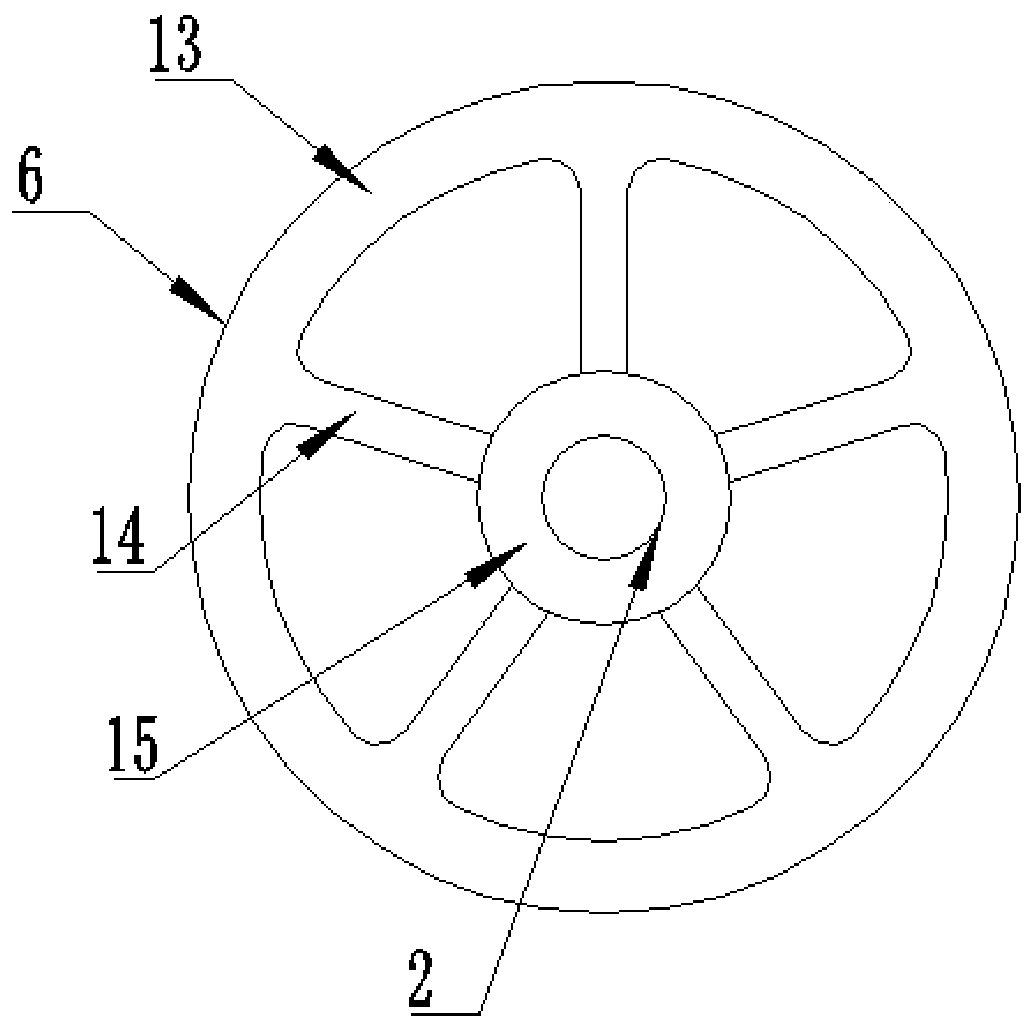

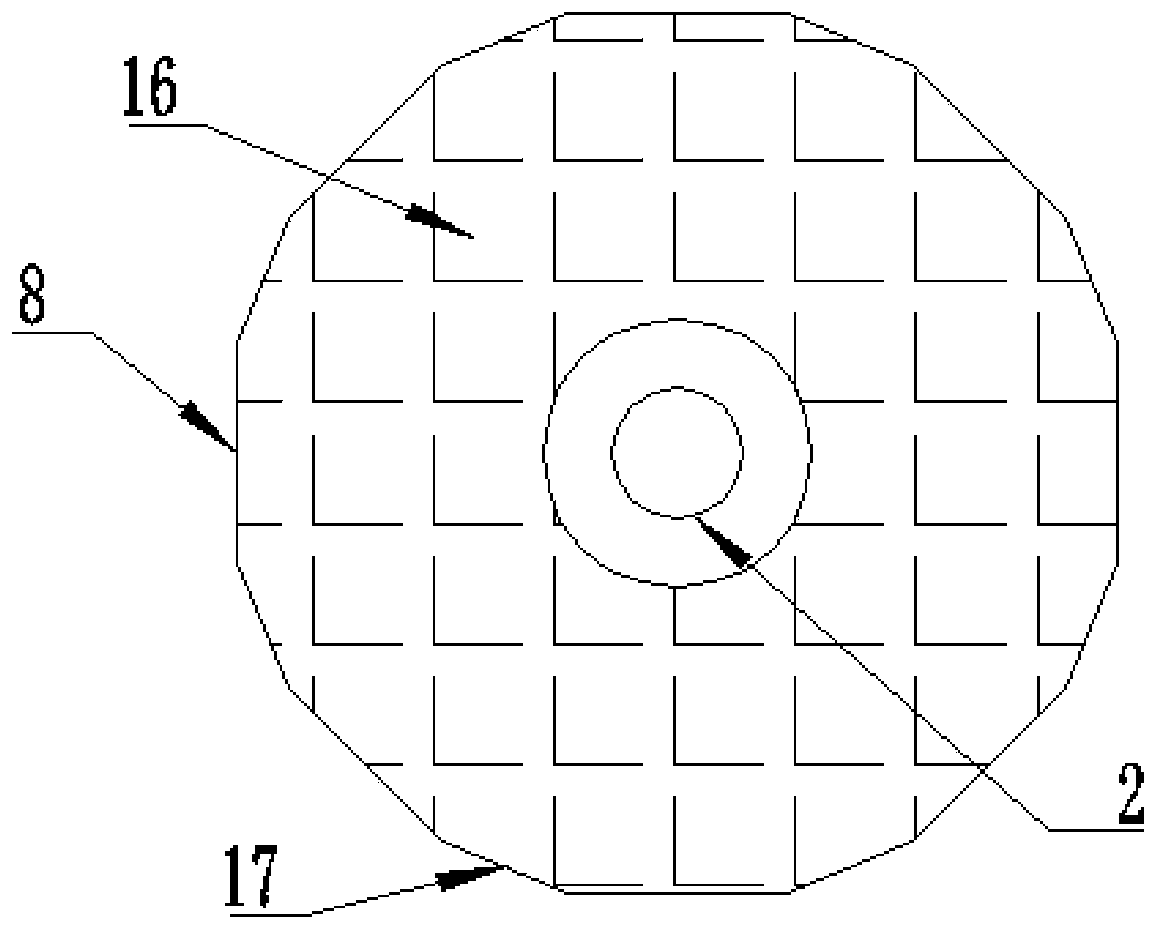

[0032] Such as figure 1 As shown, a final polycondensation reactor for preparing polycarbonate includes a horizontal cylindrical shell 1, a feed port 3, a discharge port 4 and a vacuum port 5, and the horizontal cylindrical shell 1 is provided with a drive shaft 2. A low-viscosity zone 10, a medium-viscosity zone 11 and a high-viscosity zone 12 are arranged in the horizontal cylinder 1 from the feed port 3 to the discharge port 4, and the drive shaft 2 is equipped with a disc paddle 6 , net-frame paddle 8 and screw ring-type paddle 9, described disc paddle 6 is positioned at low-viscosity zone 10, is provided with dividing plate 7 between disc paddle 6, enhances mass transfer; Net-frame paddle The blade 8 is located in the medium-viscosity zone 11 , and the spiral ribbon ring paddle 9 is located in the high-viscosity zone 12 .

[0033] The radial section of the horizontal cylinder 1 can be circular or approximately elliptical. When the section is circular, the drive shaft 2 i...

Embodiment 2

[0041] Such as Figure 4As shown, a final polycondensation reactor for preparing polycarbonate, the horizontal cylindrical barrel 1 is also provided with a vacuum sealing device, the vacuum sealing device is arranged at the vacuum port 5, including the horizontal cylindrical barrel 1 The fixed seat I1-1 on the outer wall and the fixed seat II1-2 on the inner wall, the fixed seat I1-1 is provided with a vacuum elbow 1-3, the vacuum elbow 1-3 is set through the vacuum port 5, and the vacuum elbow A vacuum sealing head 1-4 is provided outside the tube 1-3, a support cover 1-5 is provided outside the vacuum sealing head 1-4, a vent hole 1-6 is provided on the support cover 1-5, and a vent hole 1-6 is provided on the vent hole 1-6. There are vacuum hoods 1-7.

[0042] The fixing seat I1-1 of the present invention is placed outside the horizontal cylinder body 1, the fixing seat II1-2 and the vacuum sealing head 1-4 are placed inside the horizontal cylinder body 1, and the elbow mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com