Surface treatment method of Mg alloy

A surface treatment, magnesium alloy technology, applied in the field of magnesium alloy surface treatment, can solve the problems of heavy social and land cost load, environmental pollution around users, heavy metal pollution and fluorine diffusion, etc., to achieve good adhesion, uniform surface roughness, The effect of increasing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

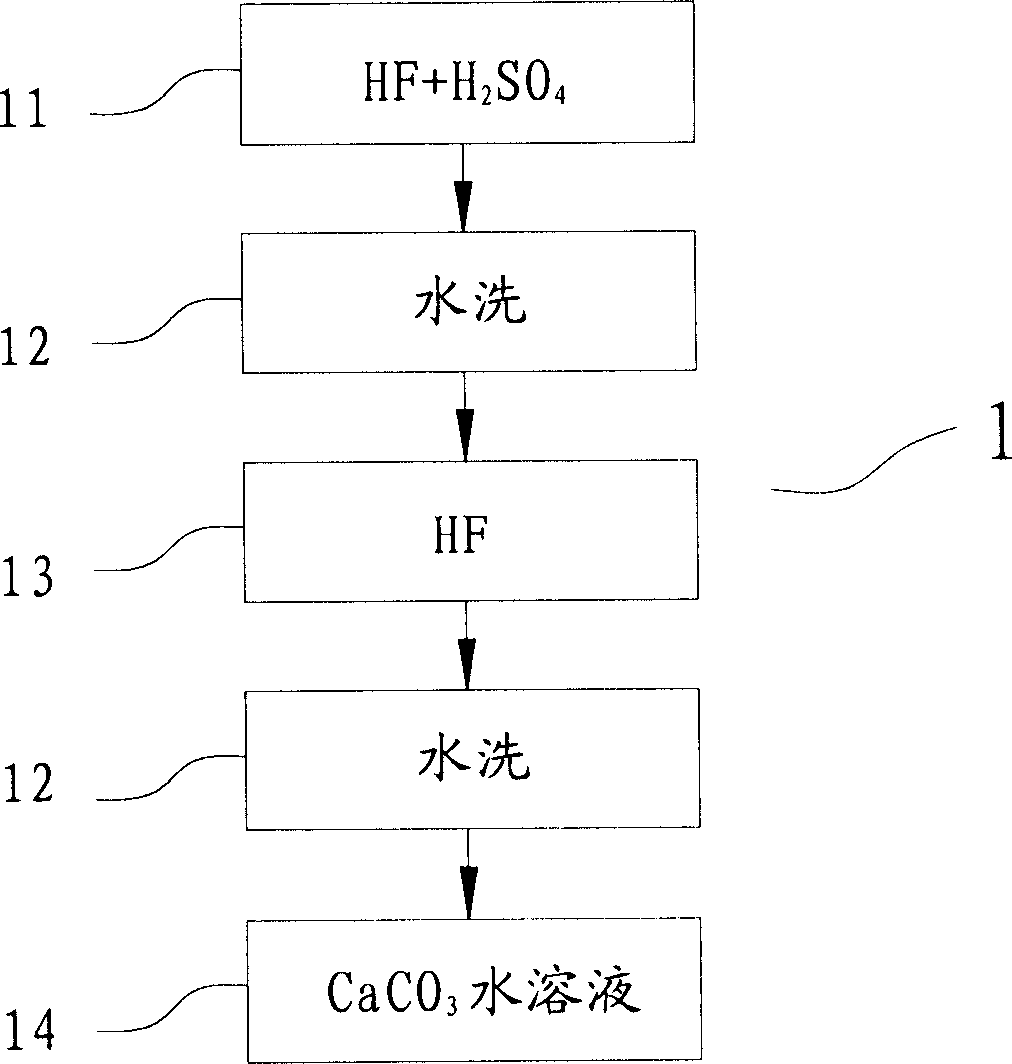

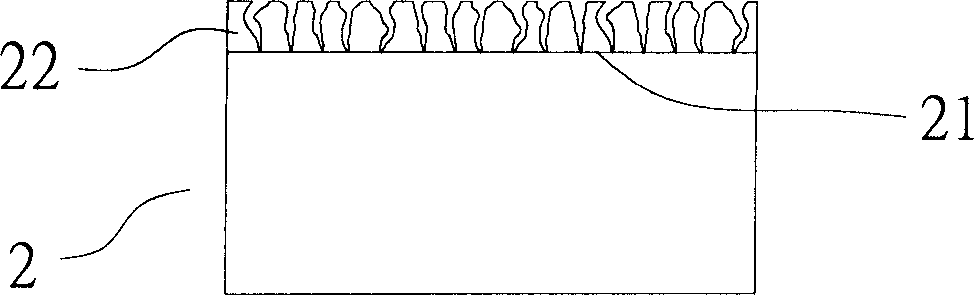

[0074] The material is subjected to [hydrofluoric acid (HF) + sulfuric acid (H 2 SO 4 )] 11 and hydrofluoric acid (HF) 13 solution treatment, observed its surface morphology by scanning electron microscope (SEM) (please refer to Figure 4 shown) is similar to the appearance of the film, so it can achieve the effect of increasing the adhesion of the coating; and the measurement of the surface roughness (please refer to Figure 5 Shown) its surface can also achieve a similar roughness to facilitate subsequent painting. Figure 5 Among them, Lt: measuring length (mm); Lc: one point per unit length (mm); in experiment No. ①, the test piece just finished die-casting was used without any treatment (as-diecast).

Embodiment 2

[0076] The magnesium alloy surface treatment method of the present invention finds through electrochemical experiment result, after [hydrofluoric acid+sulfuric acid] 11 and hydrogen hydrofluoric acid 13 solution treatment, its corrosion current can drop significantly, and corrosion current can be from about 300 microamperes / square centimeter (μA / cm 2 ) down to 10 microamps / square centimeter (μA / cm 2 ) below, such as Figure 6 and shown in Table 2. The result is similar to that of chromic acid and non-chromic acid series chemical film treatment.

[0077] Table two, the test piece that implements through specific ratio [hydrofluoric acid (HF)+sulfuric acid (H 2 SO 4 )] and comparison of corrosion current before and after treatment with hydrofluoric acid (HF) solution.

[0078]

[0079] The magnesium alloy surface treatment method of the present invention is through the analysis result of X-ray diffractometer, as Figure 7 As shown, the symbol ① in the figure indicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com