A thermoelectric battery pack

A technology of thermoelectric batteries and battery packs, which is applied in the direction of thermoelectric device components, etc., can solve the problems of limiting the application range of thermoelectric battery modules, inconvenient installation and use, surface insulation, and limiting the use range of thermoelectric batteries, etc., to achieve low thermal resistance and long working life , The effect of convenient production and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

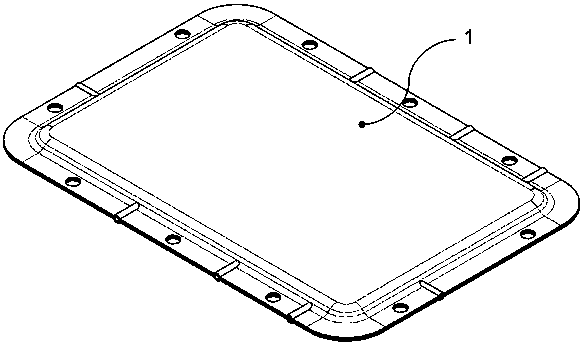

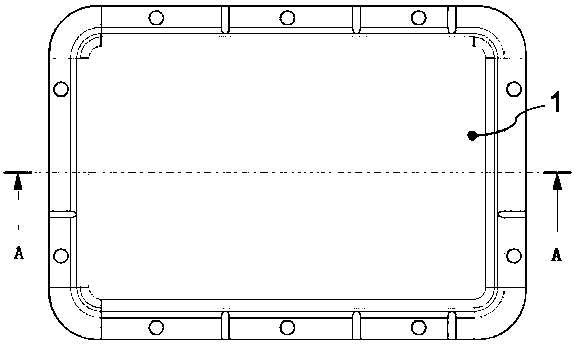

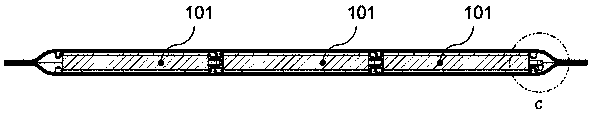

[0046] see Figure 1-4. A thermoelectric battery pack 1, comprising a thermoelectric battery unit 101, an upper case 2, an upper case heat transfer layer 3, a lower case 4, a lower case heat transfer layer 5, an upper and lower case heat insulation pad 6, an upper buffer heat conduction layer Shock-absorbing pad 7, lower buffer heat-conducting shock-absorbing pad 8. The thermoelectric battery unit 101 is the smallest structural unit of the thermoelectric battery pack, and its working surface is made of ceramic materials; the shape of the thermoelectric battery unit 101 is round or square, and its height is between 3 and 6 mm. The width is between 10 and 80mm. The upper case 2 and the lower case 4 adopt stamping structural parts or die-casting structural parts, and a number of positioning slots corresponding in size and capable of installing the thermoelectric battery unit 101 are provided inside the upper case 2 and the lower case 4 Shaped structures 401, 402 can limit the ...

Embodiment 2

[0055] see Figure 7-8 . A thermoelectric battery pack, the components of which are basically the same as those in Example 1. The difference is that the arrangement methods of the upper shell heat transfer layer 3 and the lower shell heat transfer layer 5 are different.

[0056] The specific method of embodiment 2 is: first attach the upper casing heat transfer layer 3 with an area smaller than the outer surface of the upper casing 2 to the outer surface (working area) of the upper casing 2, and place the non-working layer on the outer surface of the upper casing 2 There is no upper shell heat transfer layer 3 in the area; then the lower shell heat transfer layer 5 with an area smaller than the outer surface of the lower shell 4 is pasted on the outer surface of the lower shell 4 (working area), and on the outer surface of the lower shell 4 The non-working area has no lower shell heat transfer layer 5; the edge of the upper shell 2 without the upper shell heat transfer layer...

Embodiment 3

[0059] see Figure 9-15 . A thermoelectric battery pack, the components of which are basically the same as those in Embodiment 1. The difference is:

[0060] The hole structure for installation and positioning provided around the upper casing 2 and the lower casing 4 and the through-hole structure that facilitates the wiring of the positive pole 9, the negative pole 10 and the temperature sensor 11 of the thermoelectric battery unit 101 are more obvious (see Figure 10 , 11 ).

[0061] The arrangement methods of the upper case heat transfer layer 3 and the lower case heat transfer layer 5 are different. The specific method of embodiment 3 is: first attach the upper shell heat transfer layer 3 with an area smaller than the outer surface of the upper shell 2 to the outer surface (working area) of the upper shell 2, and place the non-working layer on the outer surface of the upper shell 2 There is no upper shell heat transfer layer 3 in the area; then the lower shell heat tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com