Patents

Literature

33results about How to "Accuracy conforms to" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

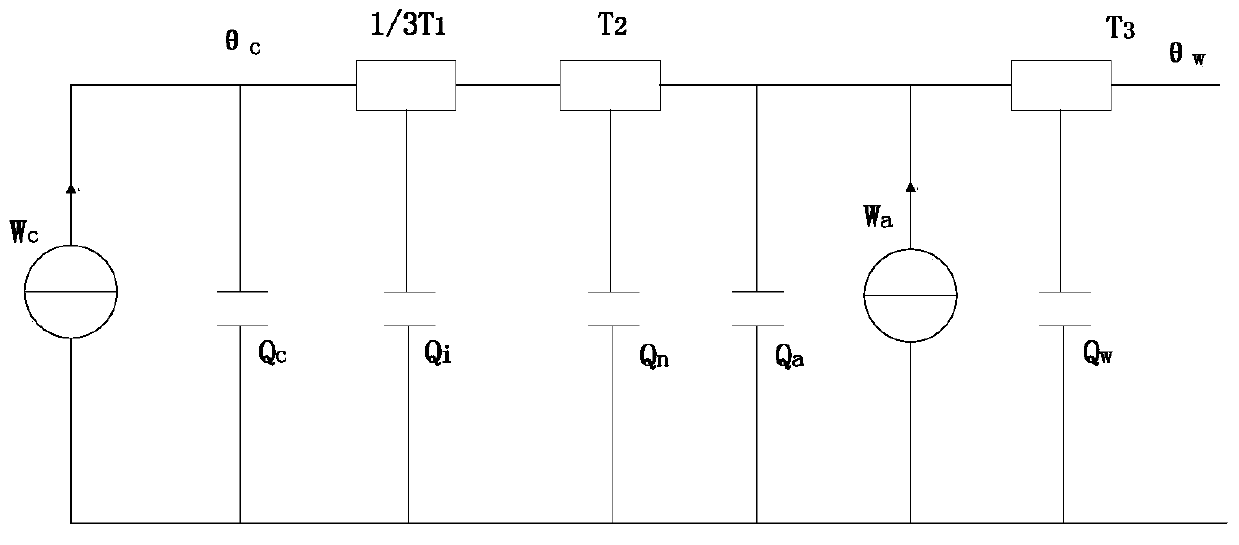

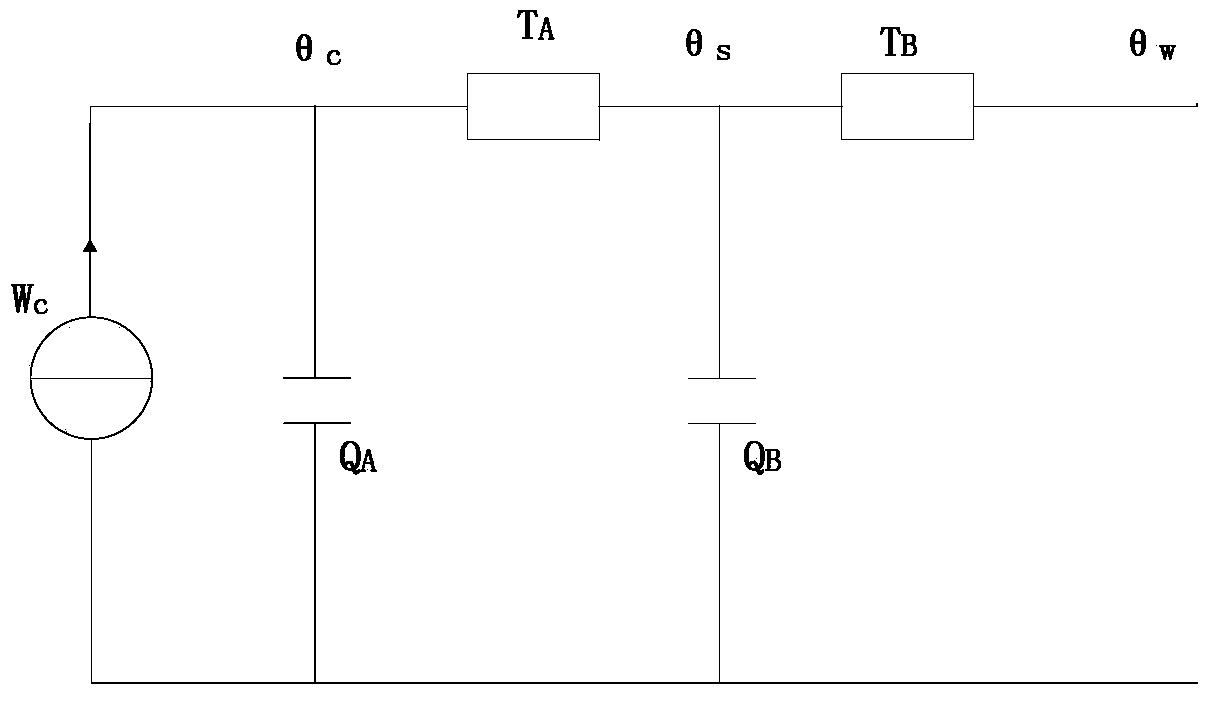

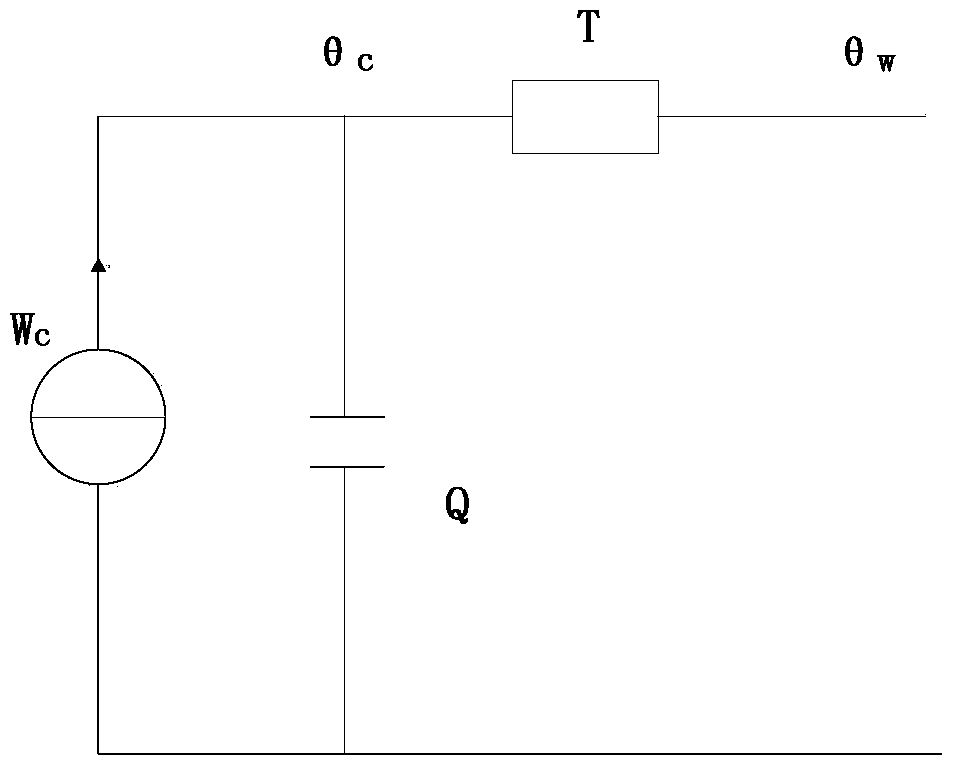

Method for calculating real-time conductor temperature of three-core cable

InactiveCN104198077AAvoid the effects of temperature calculationsSolve the technical problems of direct temperature measurementThermometers using electric/magnetic elementsUsing electrical meansCapacitanceTransient state

The invention discloses a method for calculating the real-time conductor temperature of a three-core cable. The method comprises the following steps of: (1) simplifying a complete transient-state thermal circuit model of the three-core cable into the simplest transient-state thermal circuit model only containing an equivalent thermal capacitance and an equivalent thermal resistance; (2) only considering current changes and skin temperature changes to obtain the relationship among the temperature of a conductor, a load current and a skin temperature, thus obtaining the temperature rise of the conductor caused by only considering current changes and skin temperature changes due to analogy on a first-order circuit transient response; (3) calculating the generated steady-state temperature rise and a temperature rise caused by medium losses according to a current at an initial time; (4) calculating a temperature rise caused by n times of currents and skin temperature changes in two hours (a cable thermal time constant) from the initial time; (5) summating the skin temperature at the initial time and all the temperature rises above to obtain the conductor temperature of the three-core cable currently.

Owner:SOUTH CHINA UNIV OF TECH

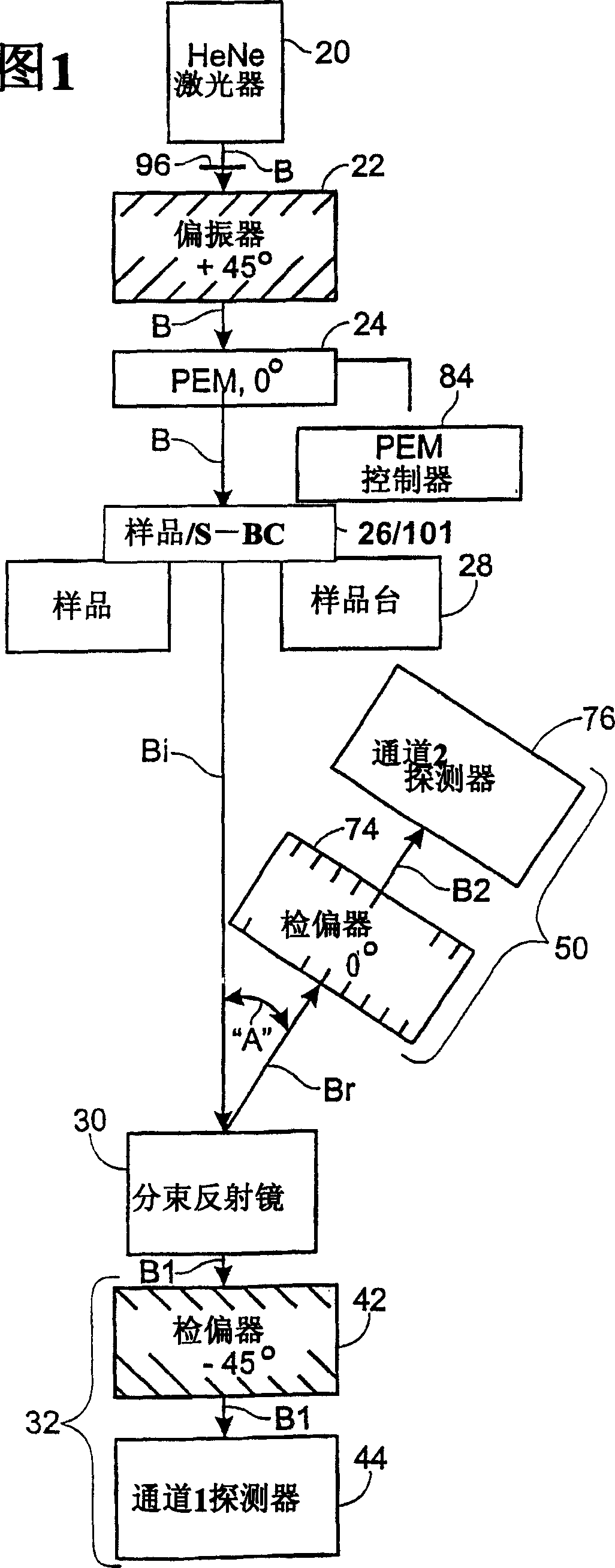

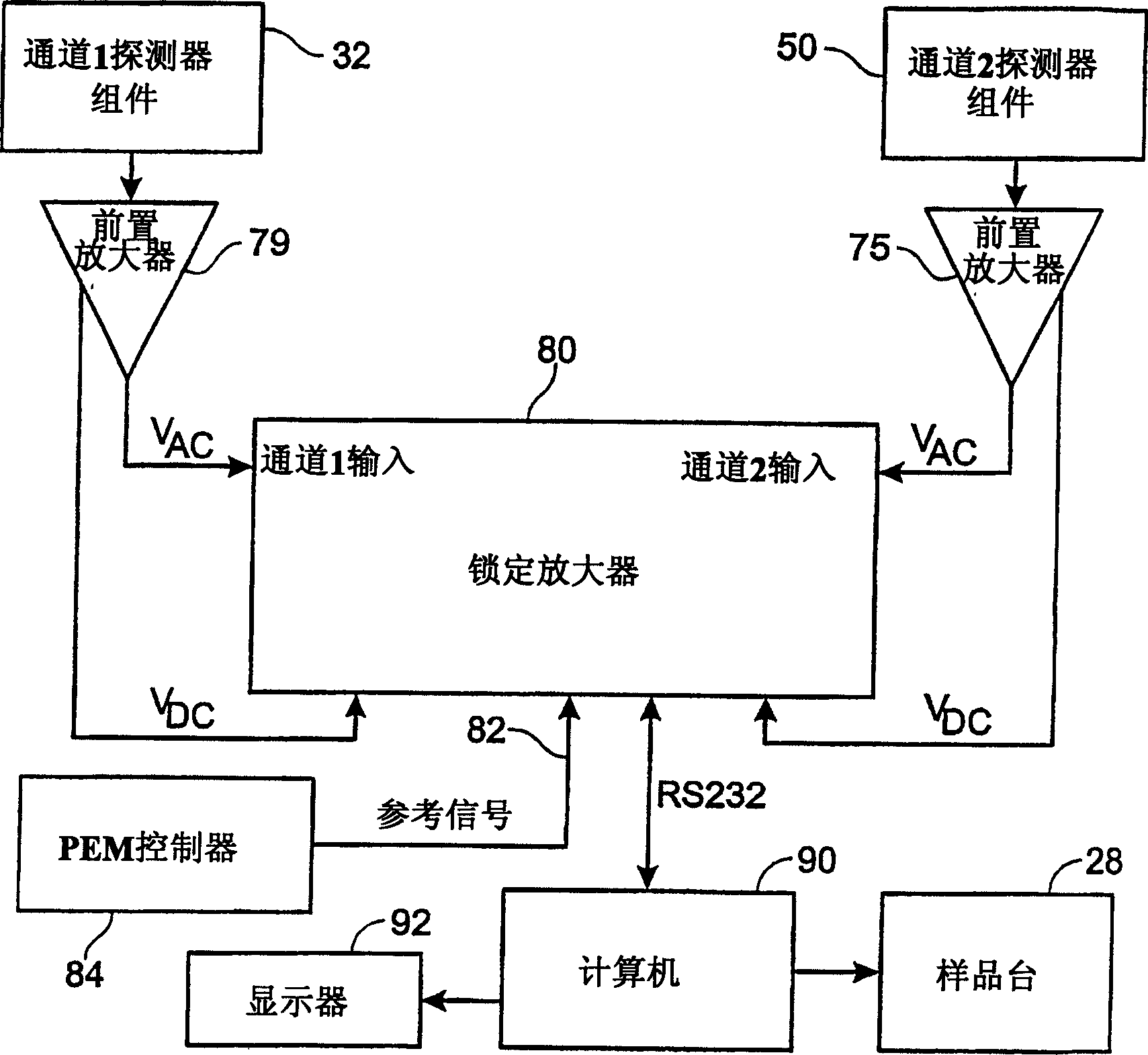

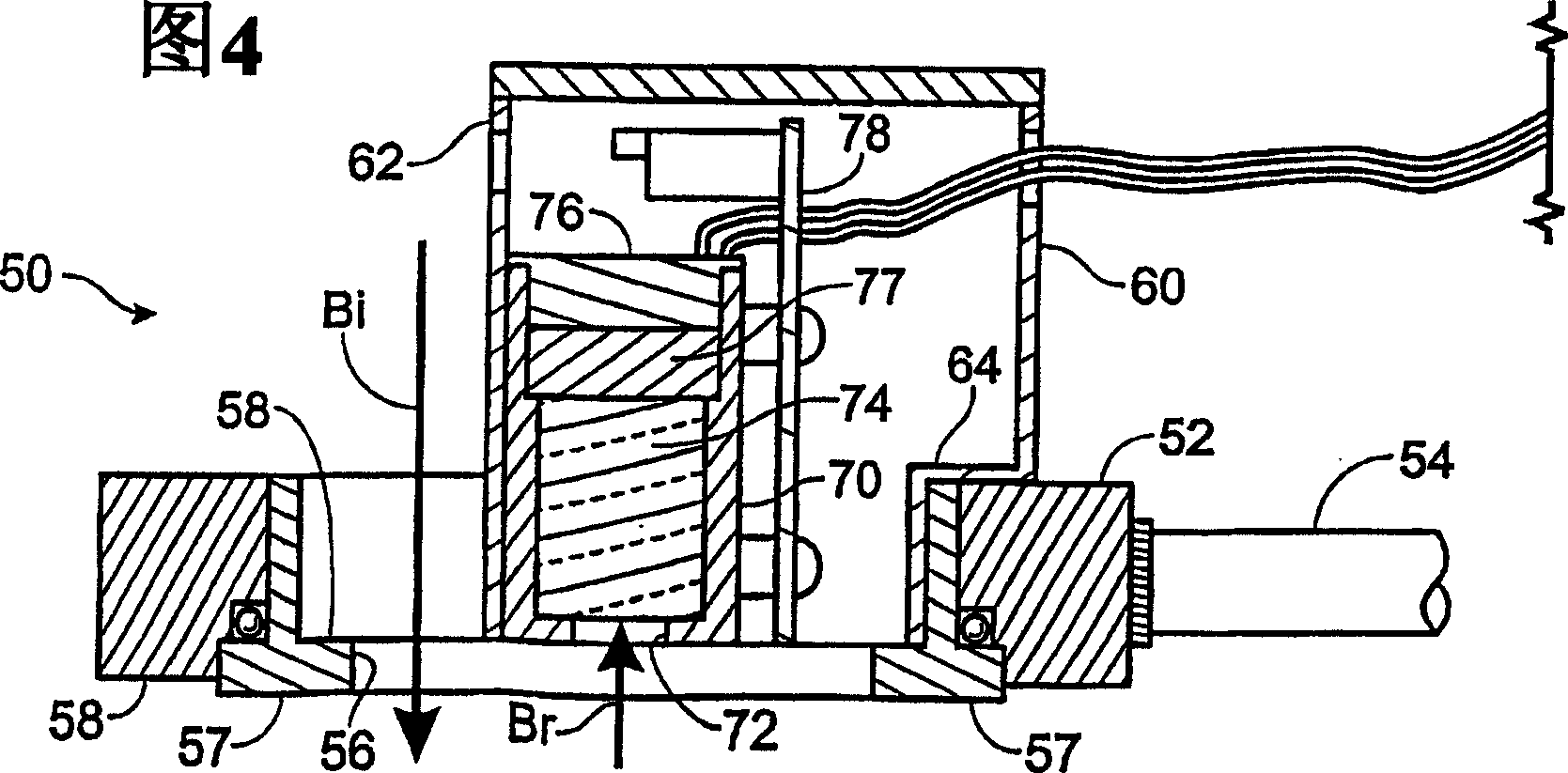

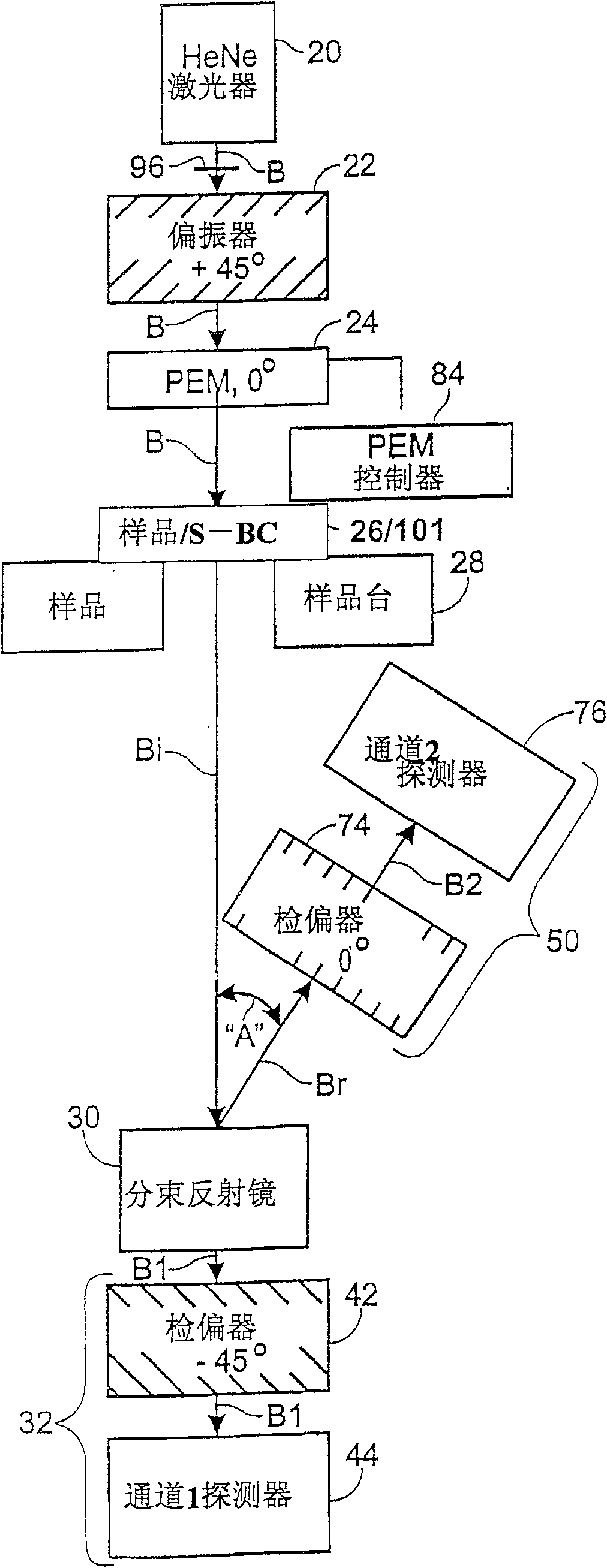

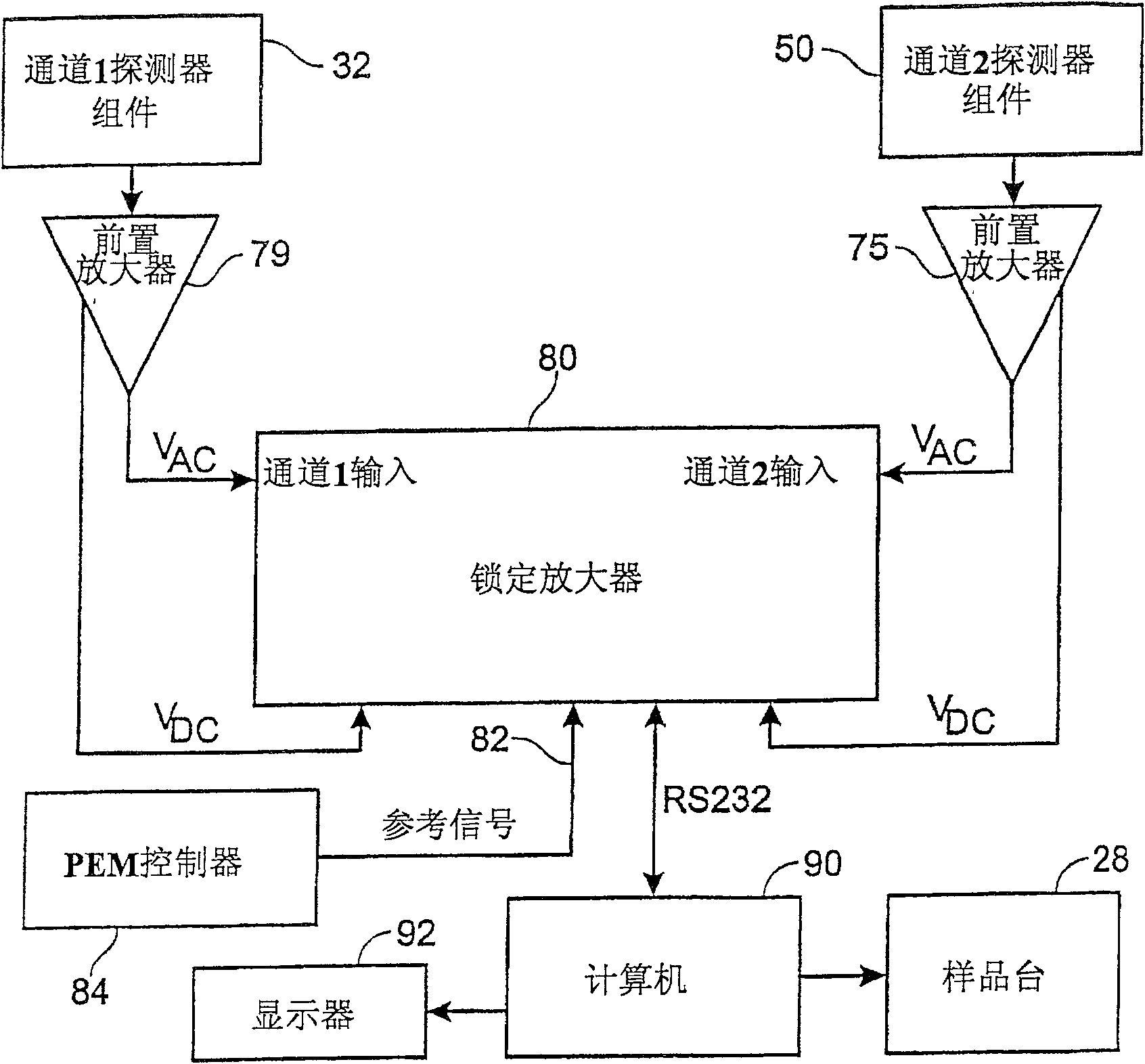

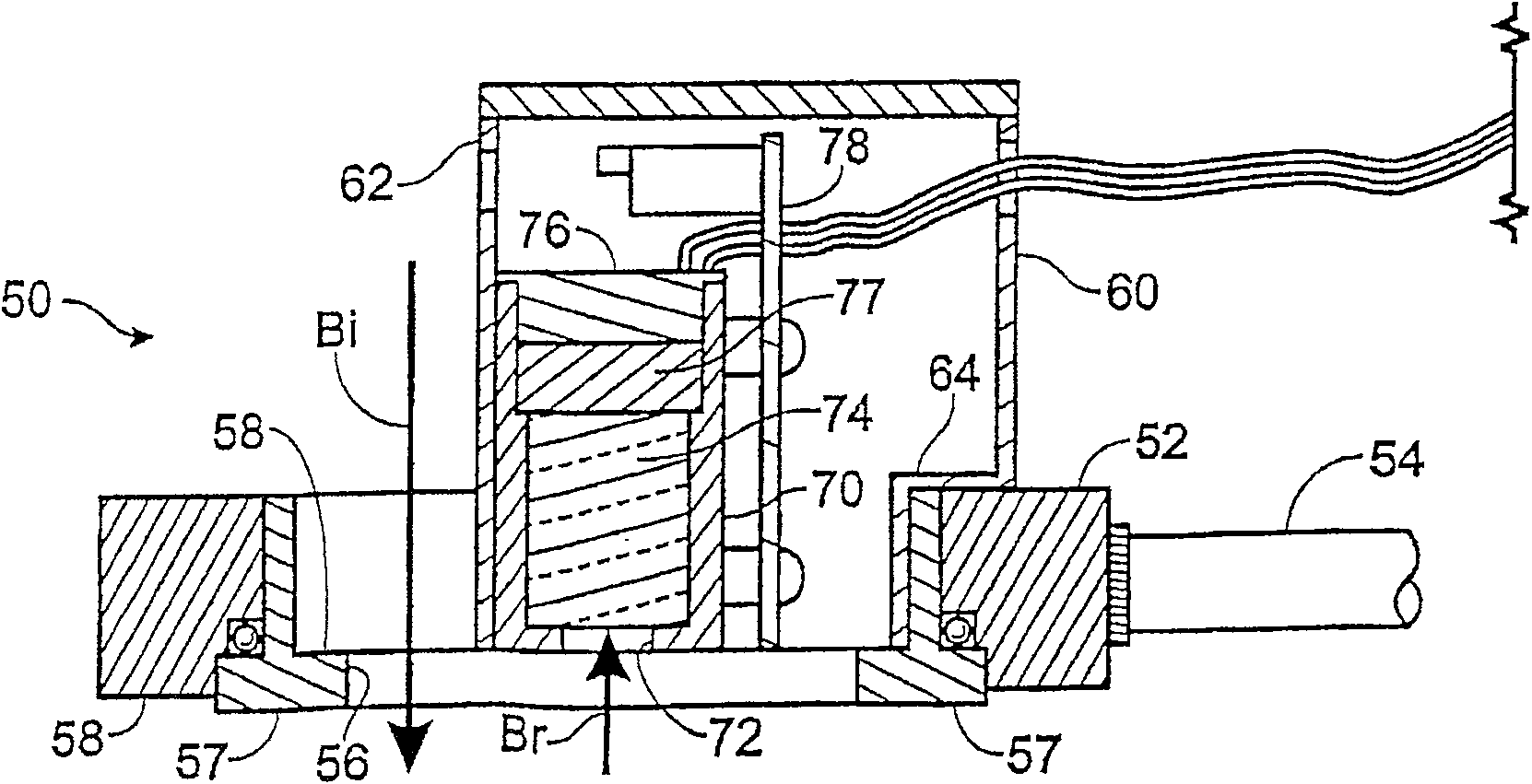

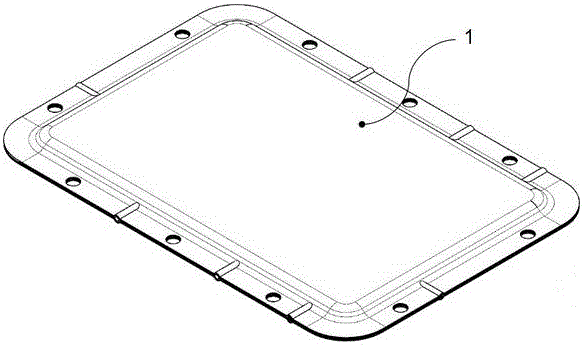

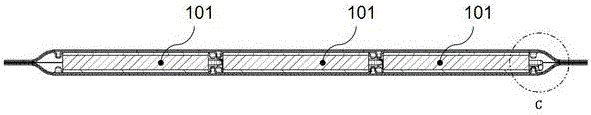

Accuracy calibration of birefringence measurement systems

InactiveCN1571918AAccuracy conforms toMaterial analysis by optical meansLight polarisation measurementLight sourceBirefringence

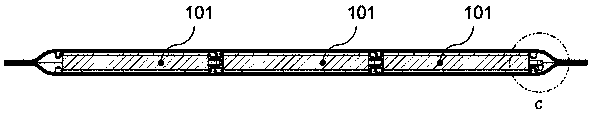

Provided are systems and methods using a Soleil-Babinet compensator (101) as a standard for calibrating birefringence measurement systems. Highly precise and repeatable calibration is accomplished by the method described here because, among other things, the inventive method accounts for variations of retardance across the surface of the Soleil-Babinet compensator (101). The calibration technique described here may be employed in birefringence measurement systems that have a variety of optical setups for measuring a range of retardation levels and at various frequencies of light sources.

Owner:HINDS INSTR

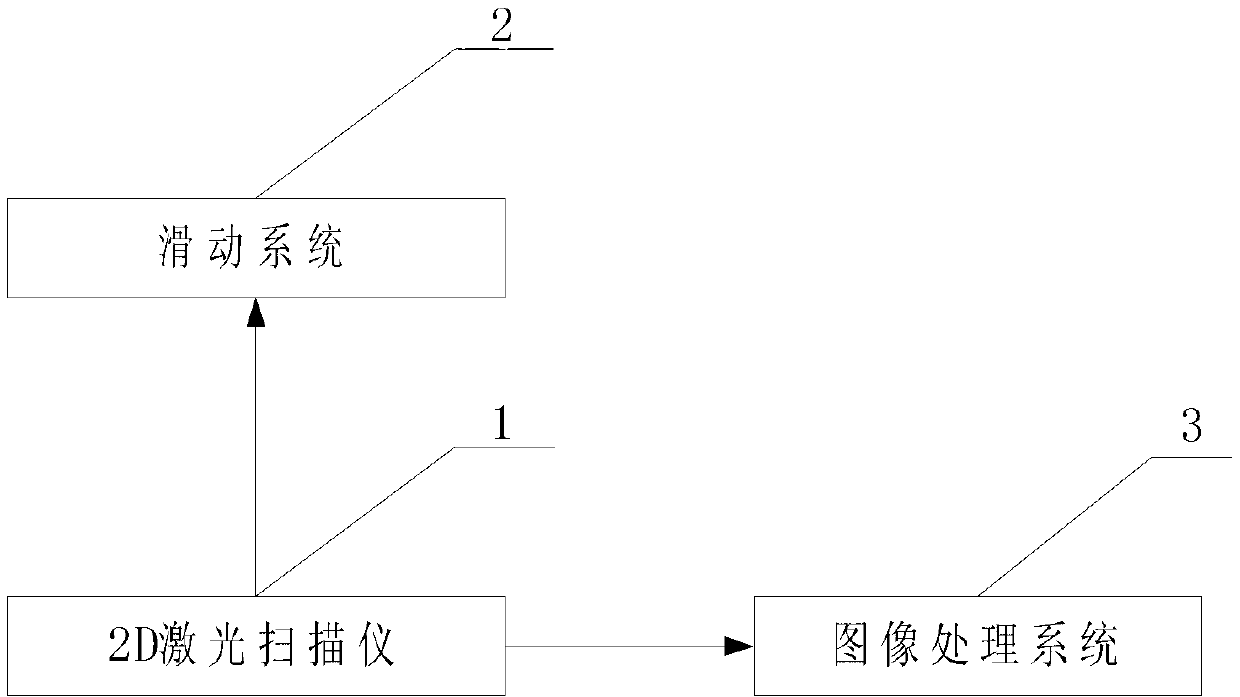

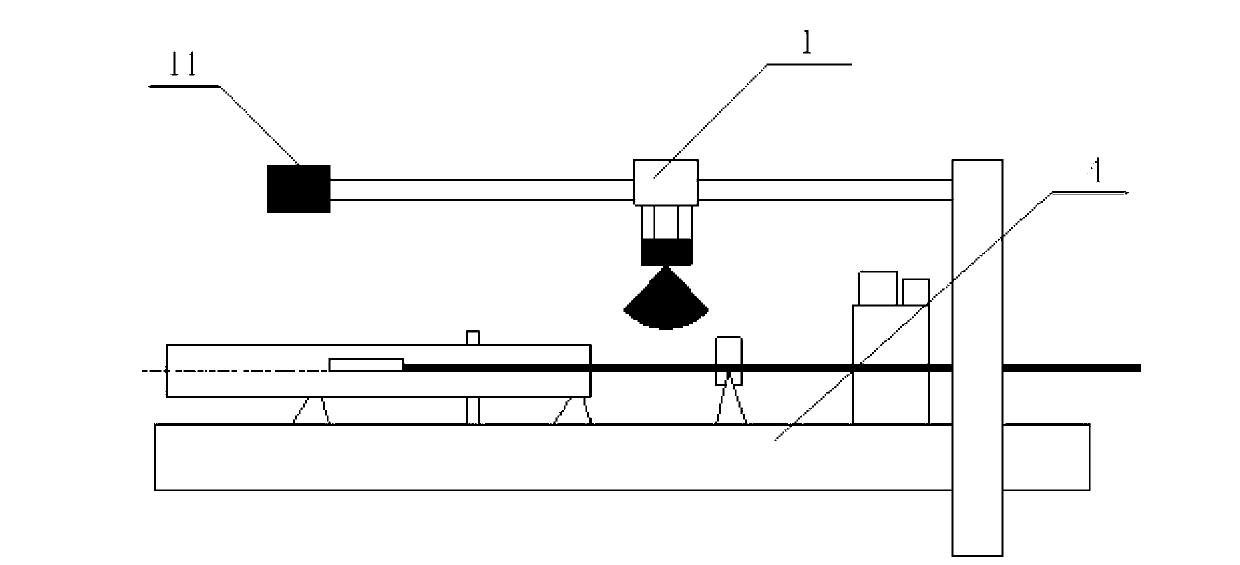

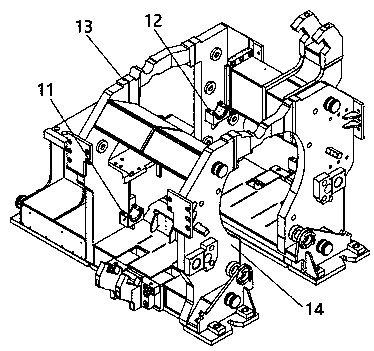

Honing machine detecting system

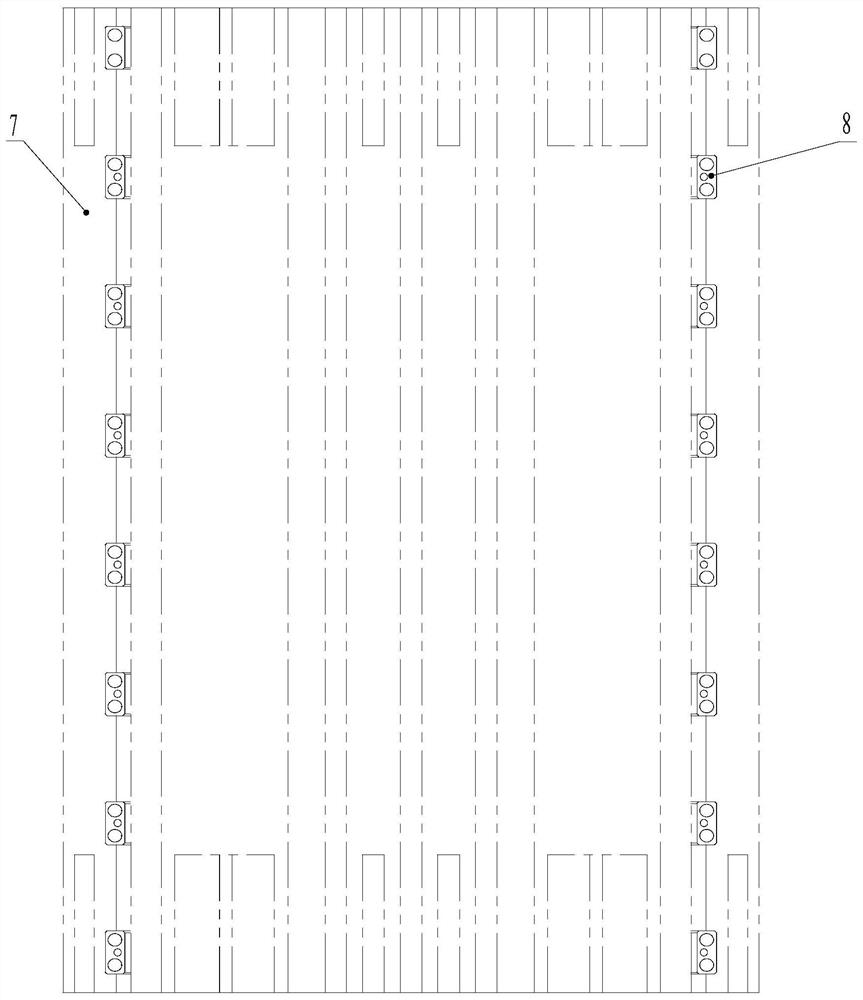

The invention discloses a honing machine detecting system which comprises a two-dimension (2D) laser scanner, a sliding system and an image processing system. The 2D laser scanner is used for transmitting laser to a guide rail and obtaining an appearance light section curve of the guide rail. The sliding system is connected with the 2D laser scanner and used for fixing and moving the 2D laser scanner. The image processing system is connected with the 2D laser scanner and used for analyzing the light section curve. The 2D laser scanner is utilized to quickly detect a large-scale horizontal type honing machine in a high-efficiency mode, a light section line image is transmitted to a digital signal processor (DSP) processing circuit by a charge-coupled device (CCD) camera, so that all parameters to be measures of each section of guide rail are obtained and compared with specified parameters of the guide rail of the honing machine to confirm whether the honing machine meets machining requirement or not, well solve the problem that accuracy of the honing machine is reduced, and conform to the requirements for being high in machining manufacturing accuracy and high in speed of modern industry. In addition, the honing machine detecting system is simple in structure, low in manufacturing cost, and obvious in practical effect, and has good application value.

Owner:NANJING UNIV OF TECH

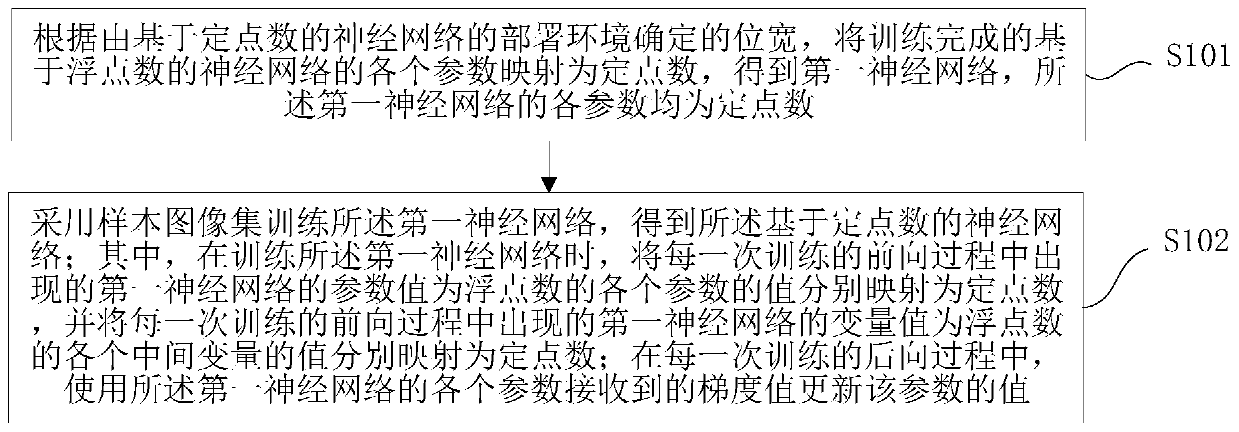

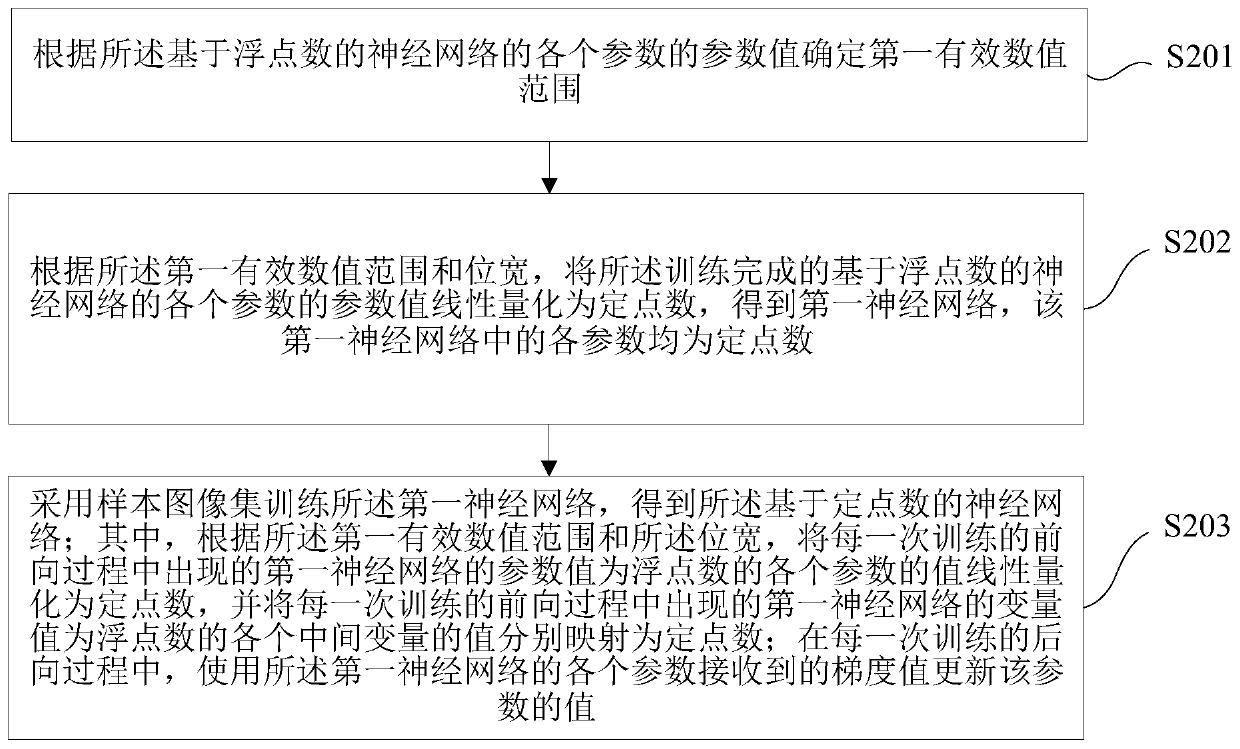

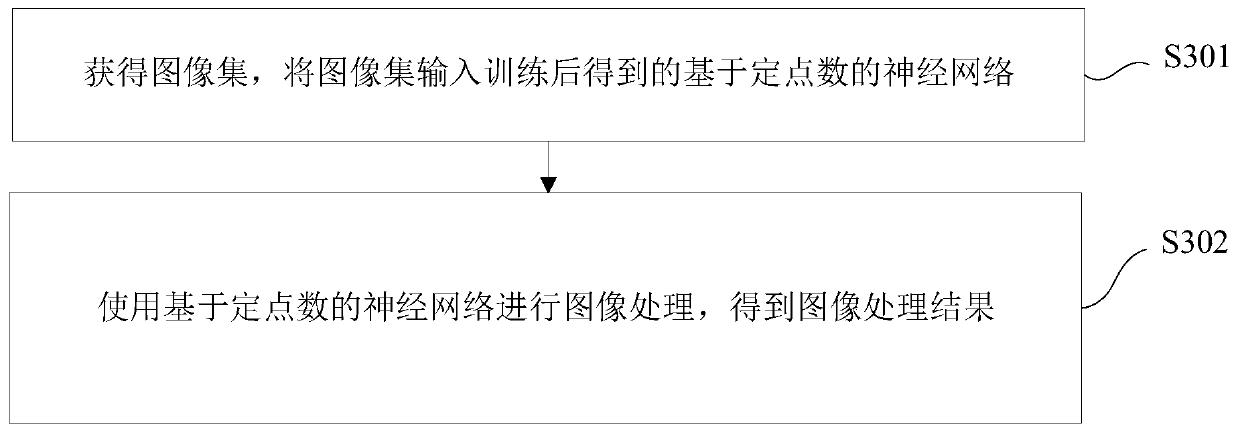

Neural network training method and device, electronic equipment and storage medium

InactiveCN110210619AReduce storageReduce operational overheadNeural learning methodsSample imageMachine learning

The invention relates to a neural network training method and device, electronic equipment and a storage medium. The method comprises the following steps: according to a bit width determined by a deployment environment of a neural network based on a fixed-point number, mapping each parameter of the trained neural network based on a floating-point number into the fixed-point number to obtain a first neural network, each parameter of the first neural network being the fixed-point number; and training the first neural network by adopting a sample image set to obtain the neural network based on the fixed-point number. By adopting the neural network based on the fixed-point number, which is obtained through mapping from the floating-point number to the fixed-point number and training, the precision of the deployment environment of the deployed electronic equipment can be met.

Owner:SHANGHAI SENSETIME INTELLIGENT TECH CO LTD

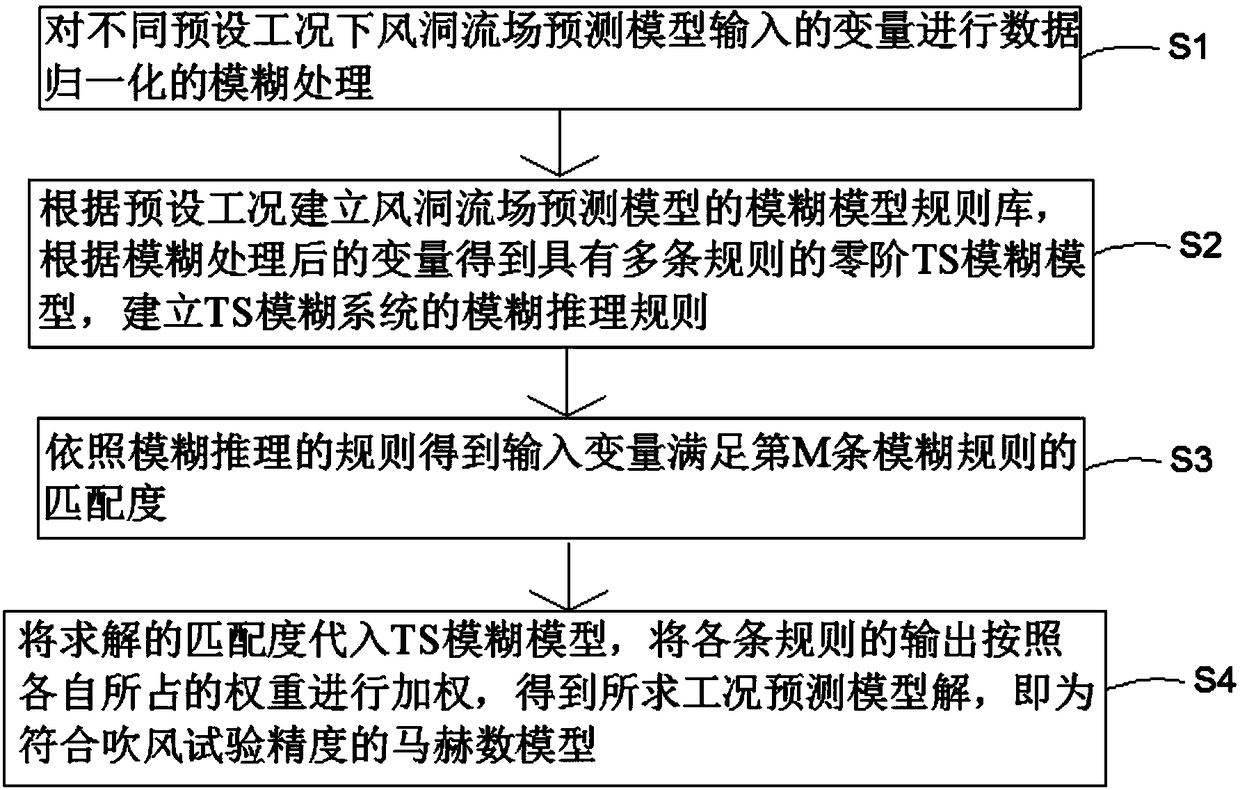

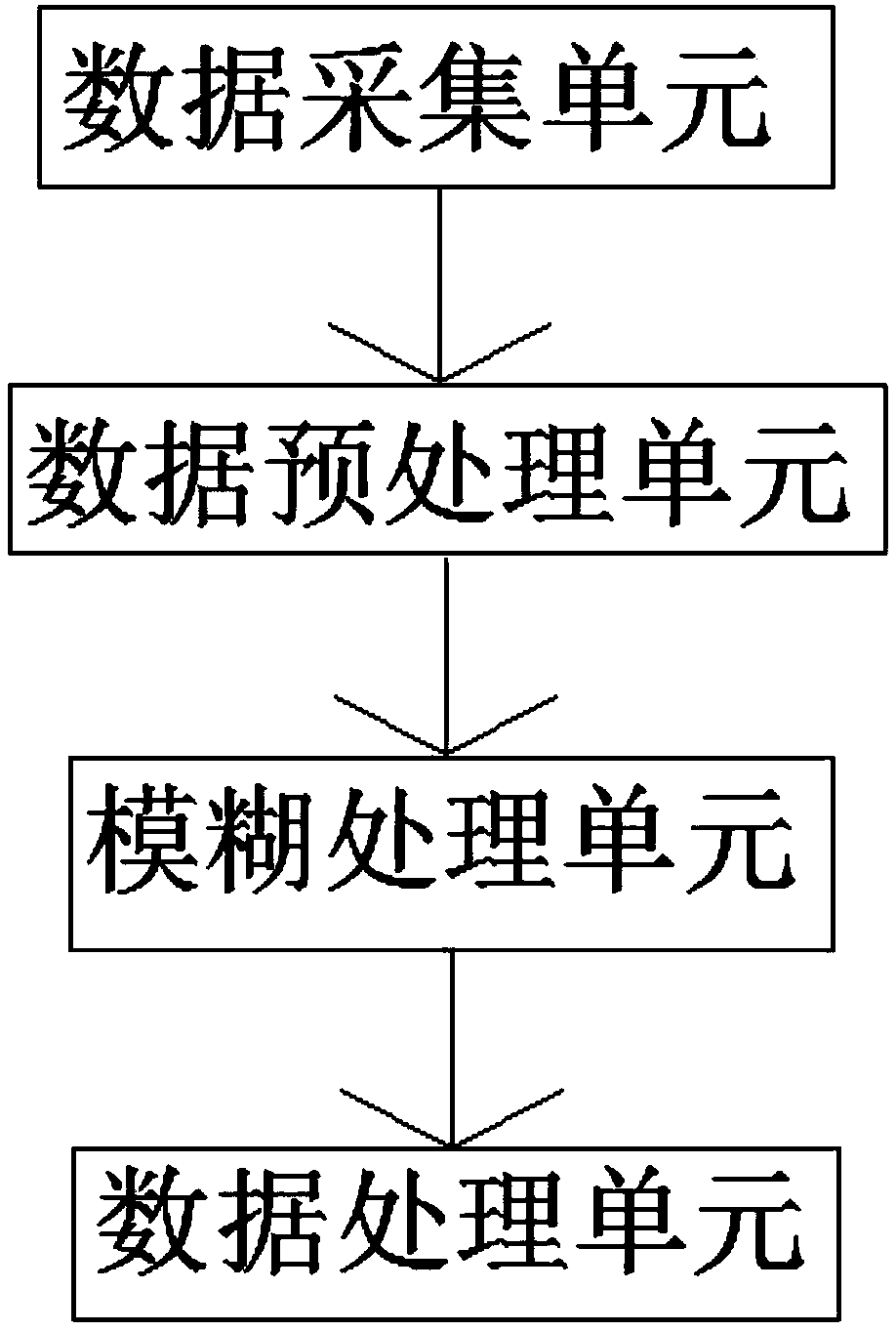

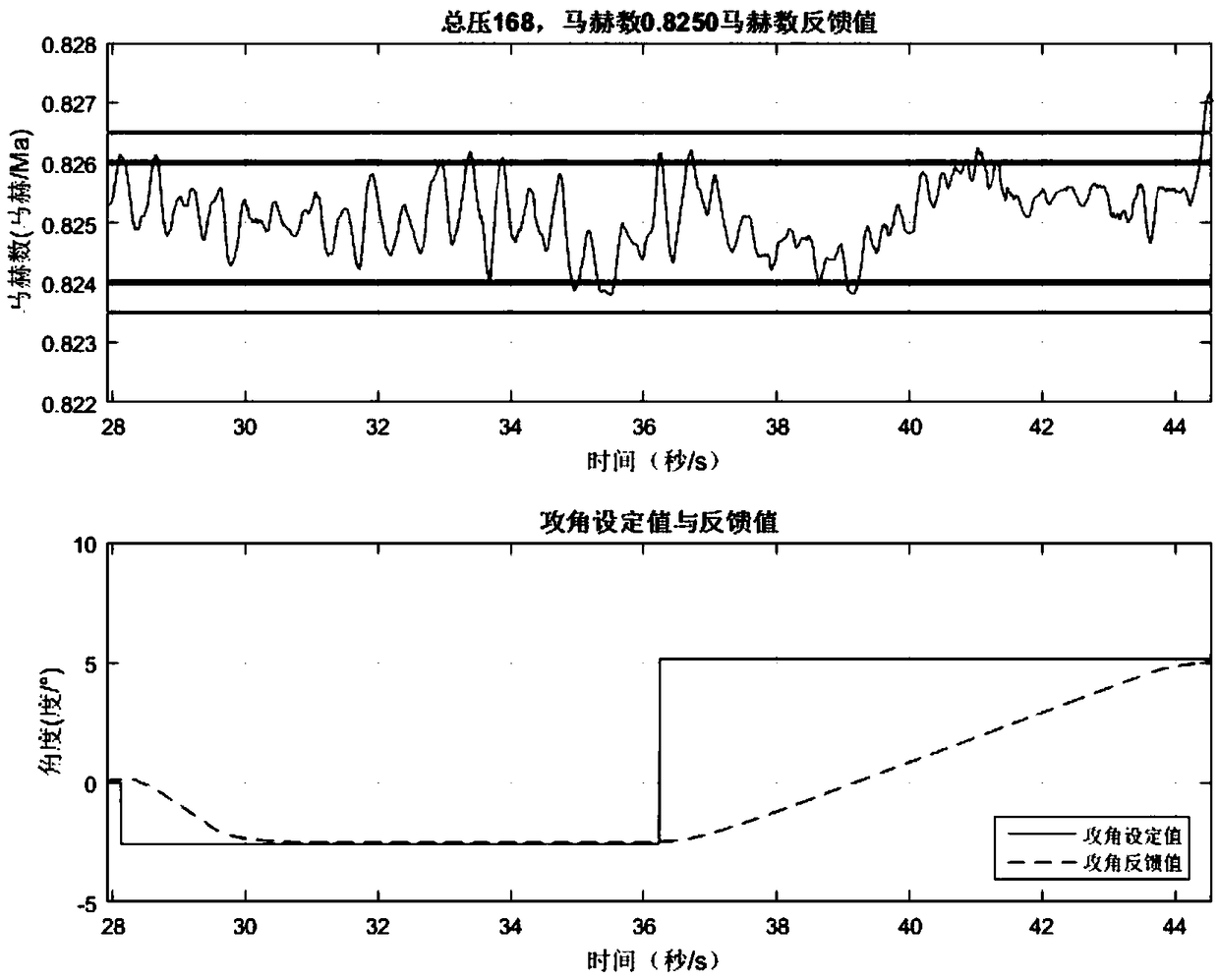

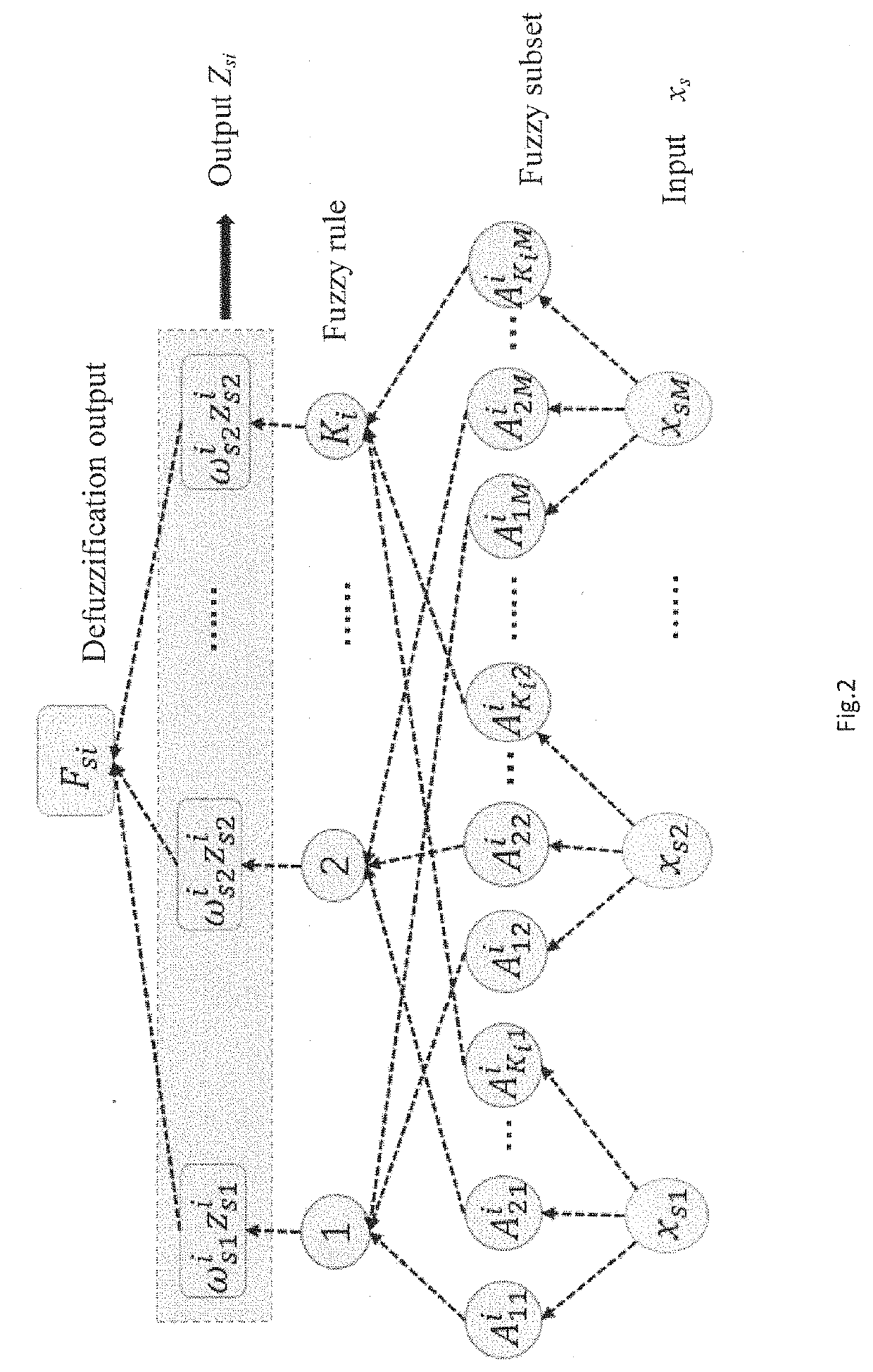

Wind speed accuracy controlling method and system of transonic-speed wind tunnel

ActiveCN109115446AAccuracy conforms toMeet the requirements of the blowing testAerodynamic testingFuzzy inference rulesFuzzy rule

The invention provides a wind speed accuracy controlling method and system of a transonic-speed wind tunnel. The method comprises the following steps: S1, performing data normalization type fuzzy processing on variables inputted by a wind tunnel flow field prediction model under different preset conditions; S2, establishing a fuzzy model rule library of the wind tunnel flow field prediction modelbased on preset working conditions, acquiring a zero-order TS fuzzy model with multiple rules according to the variables after fuzzy processing, and establishing a fuzzy inference rule of a TS fuzzy system; S3, acquiring a matching degree of meeting an Mth fuzzy rule by an input variable according to the fuzzy inference rule; and S4, substituting the calculated matching degree into the TS fuzzy model, and weighting the outputs of all rules according to respectively occupied weights to obtain a Mach number model conforming to the blowing test accuracy. According to the invention, on the basis of the mode of combination of fuzzy control with prediction condition, the accuracy of the Mach number is controlled; the blowing test accuracy is realized well; and the wind tunnel flow field prediction model based on the fuzzy model prediction meets the blowing test requirement well.

Owner:NORTHEASTERN UNIV

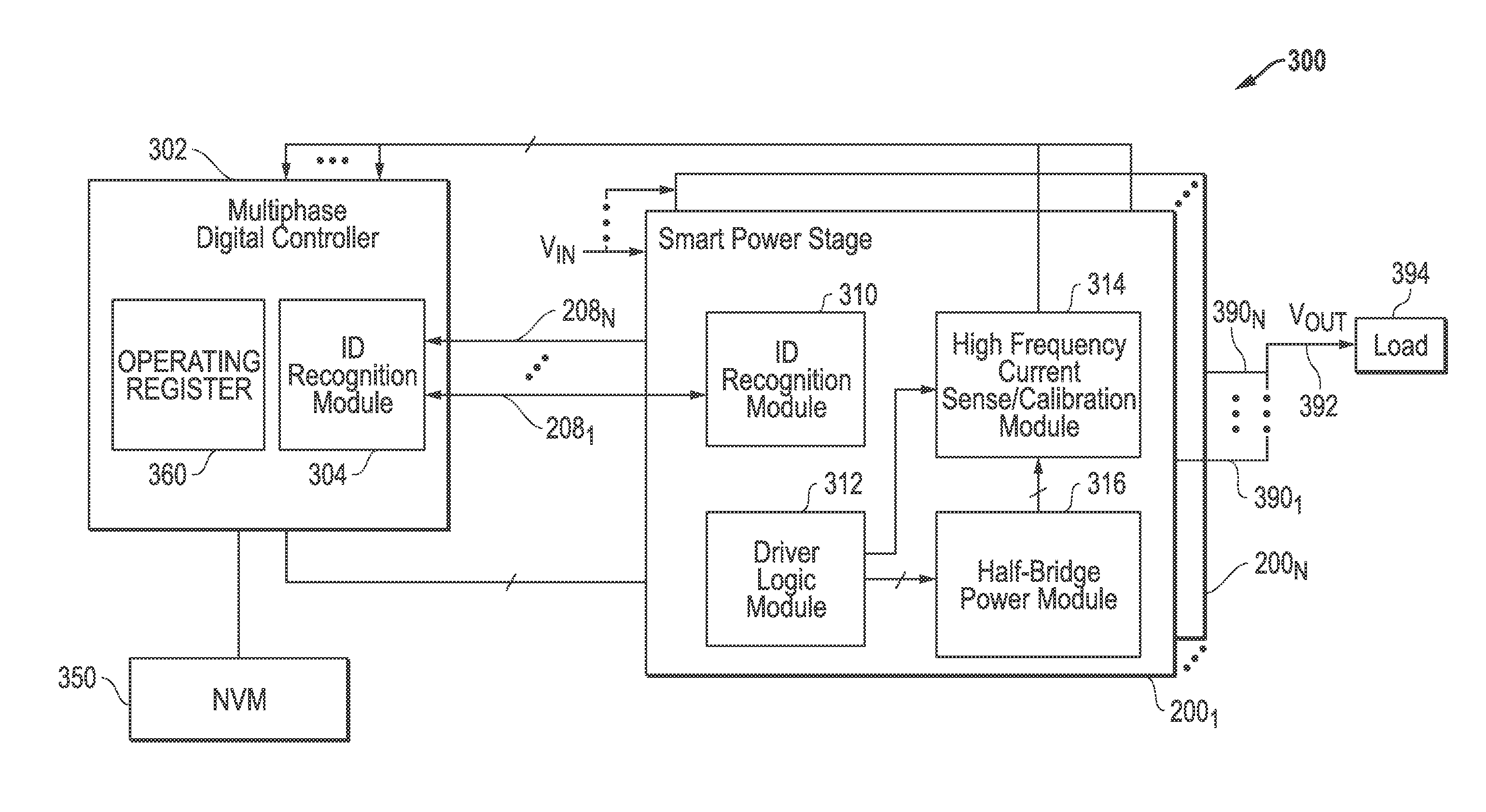

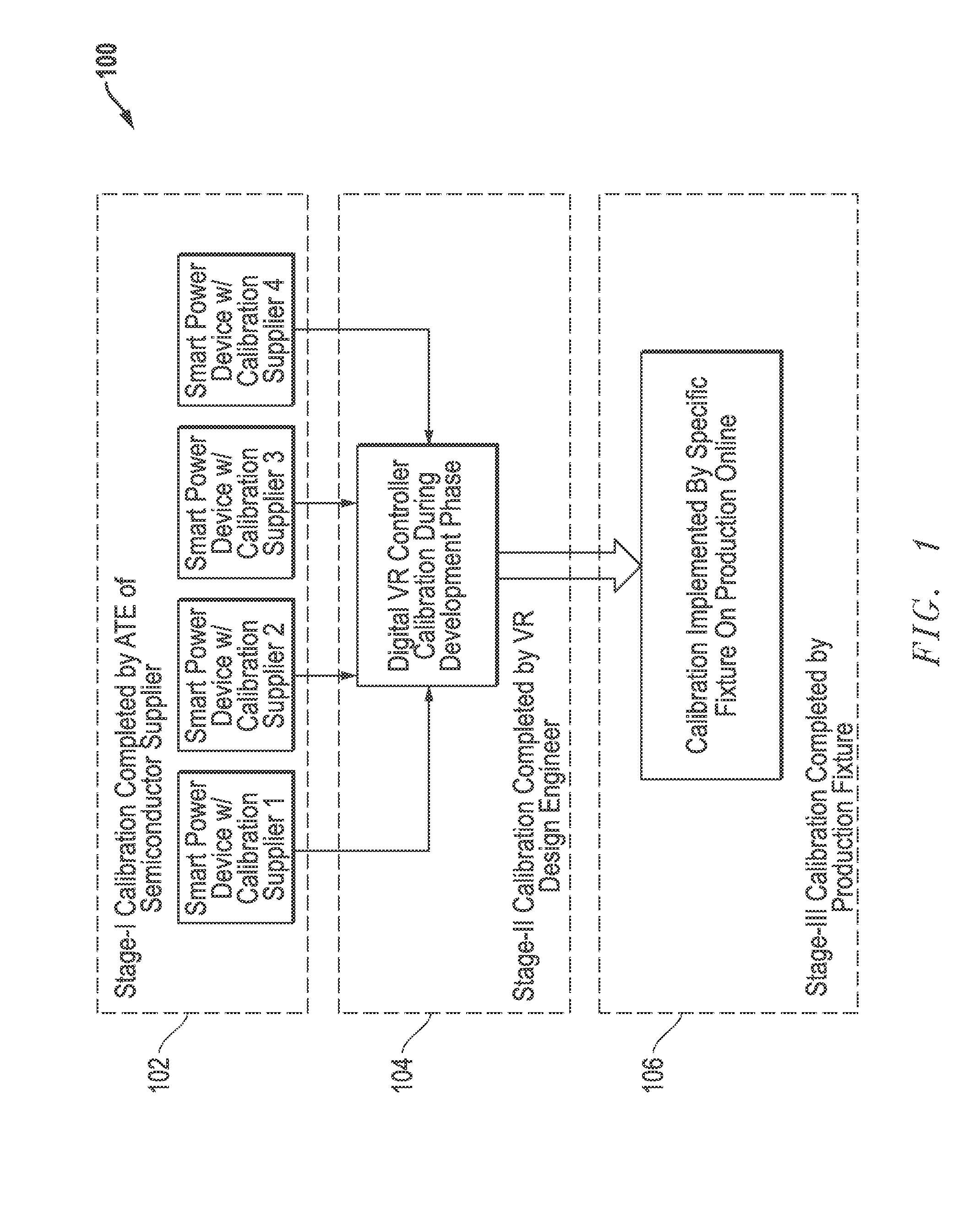

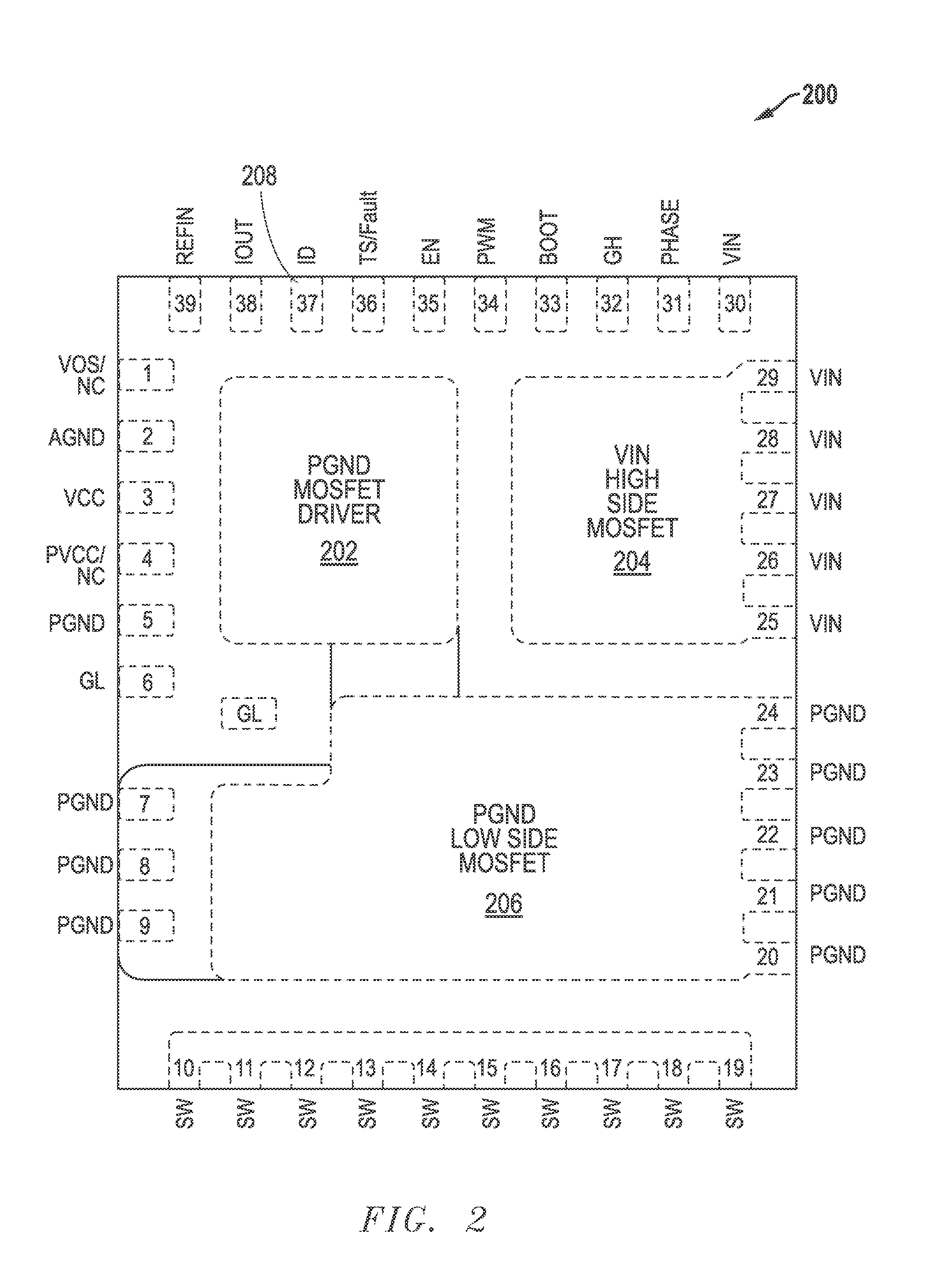

Methods and systems for calibration of voltage regulator systems with multiple types of power stages

ActiveUS20150370300A1Reducing and substantially eliminating continuity of supply (COS) concernGood power savingMemory architecture accessing/allocationMemory adressing/allocation/relocationVoltage regulationSystem configuration

Methods and systems are disclosed that may be employed to enable multi-phase voltage regulator (VR) system calibration during the development phase of a multi-phase VR system so as to meet defined accuracy targets and, in one example, to avoid the need for system level calibration in a production environment. The disclosed systems and methods may be further implemented to enable use of multiple sources for and types of integrated power stages (IPstages) in a common multi-phase VR system configuration while still achieving the required current sense accuracy, thus reducing or substantially eliminating continuity of supply (COS) concerns. The disclosed methods and systems may also be implemented to improve accuracy of current sense in a manner that improves VR system performance, power saving and reliability.

Owner:DELL PROD LP

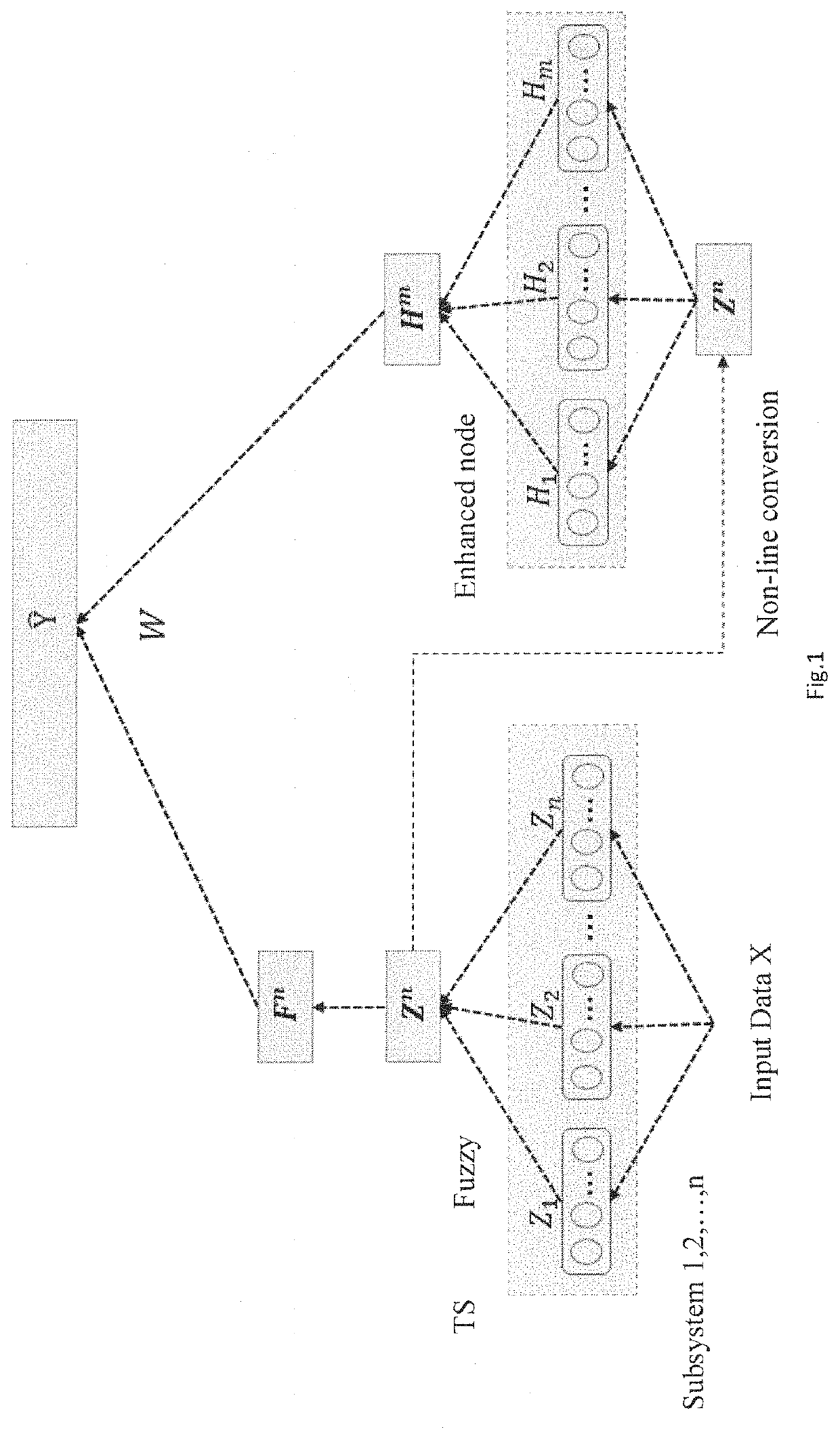

Fault monitoring method for sewage treatment process based on fuzzy width adaptive learning model

ActiveUS20220114467A1Good monitoring resultIncrease the number ofFuzzy logic based systemsTreatment control/steeringAdaptive learningSewage treatment

The invention discloses a sewage treatment process fault monitoring method based on fuzzy width adaptive learning model. Including “offline modeling” and “online monitoring” two stages. “Offline modeling” first uses a batch of normal data and 4 batches of fault data as training samples to train the network offline and label the data. After the network training is completed, the weight parameters are obtained for online monitoring. “Online monitoring” includes: using newly collected data as test data, using the same steps as offline training networks for online monitoring. The output result of online monitoring adopts one-hot encoding to realize zero-one discrimination of the output result of online monitoring, so as to realize fault monitoring. The present invention only needs to increase the number of enhanced nodes, reconstruct in an incremental manner, and does not need to retrain the entire network from the beginning. It can complete the network training in a short time and realize the rapid fault monitoring in time, which has high practical application value.

Owner:BEIJING UNIV OF TECH

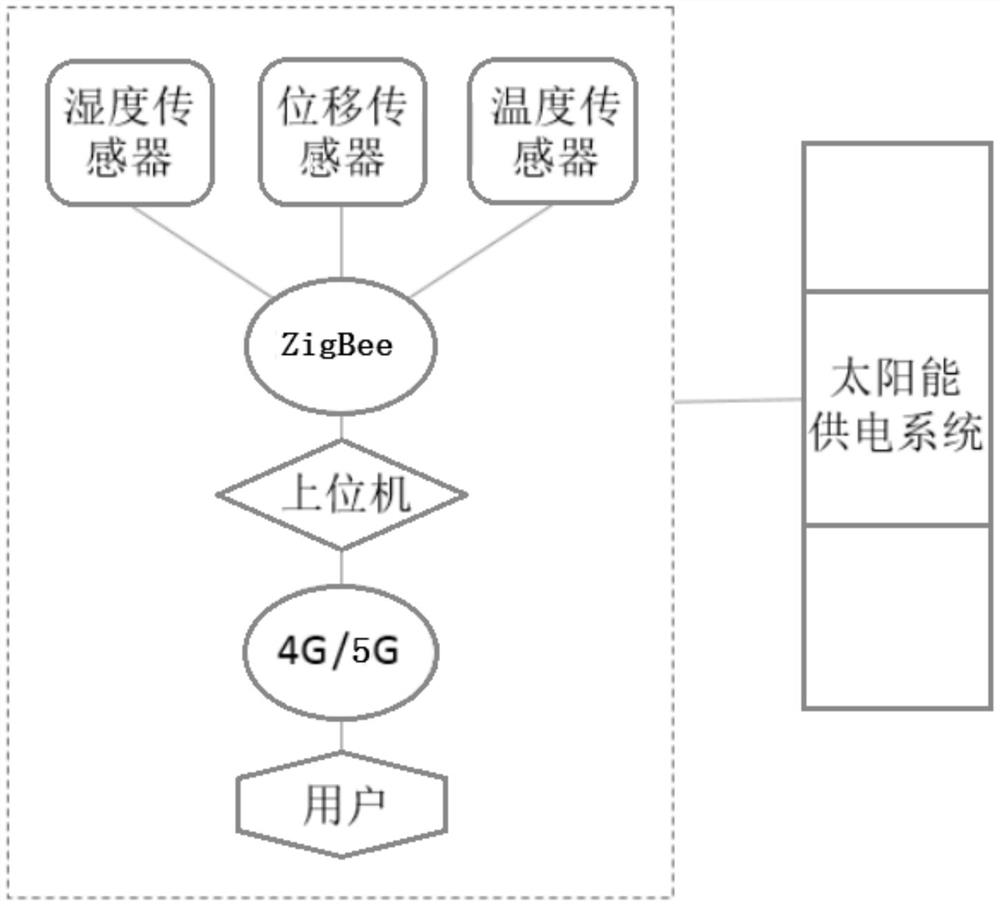

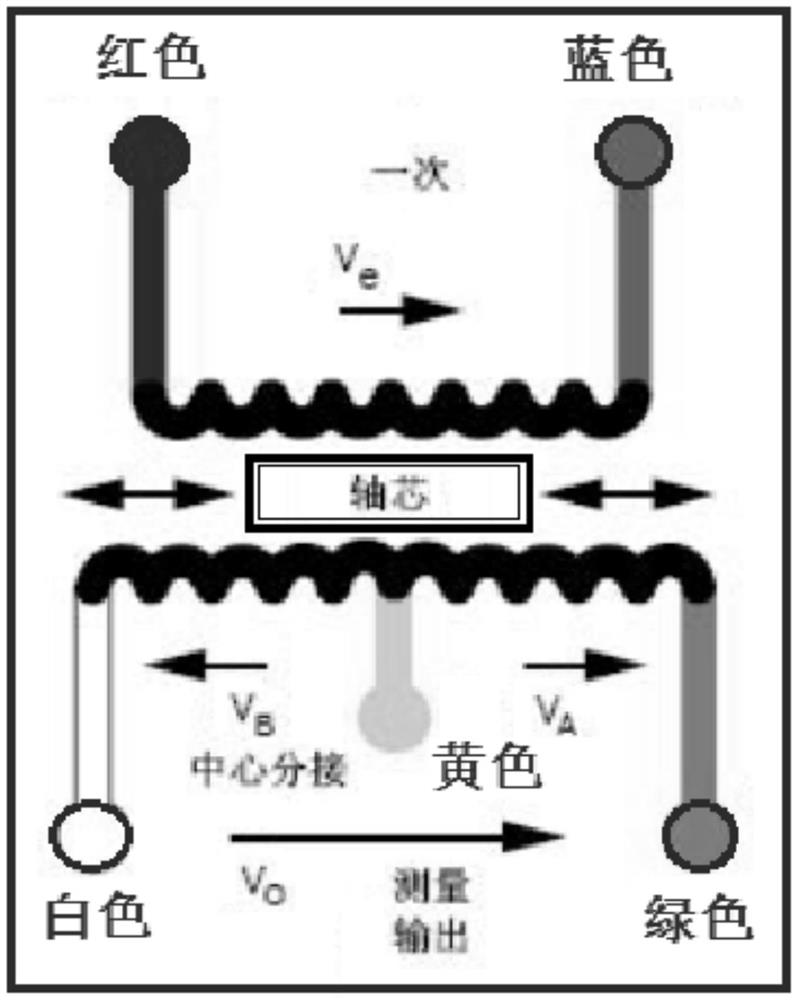

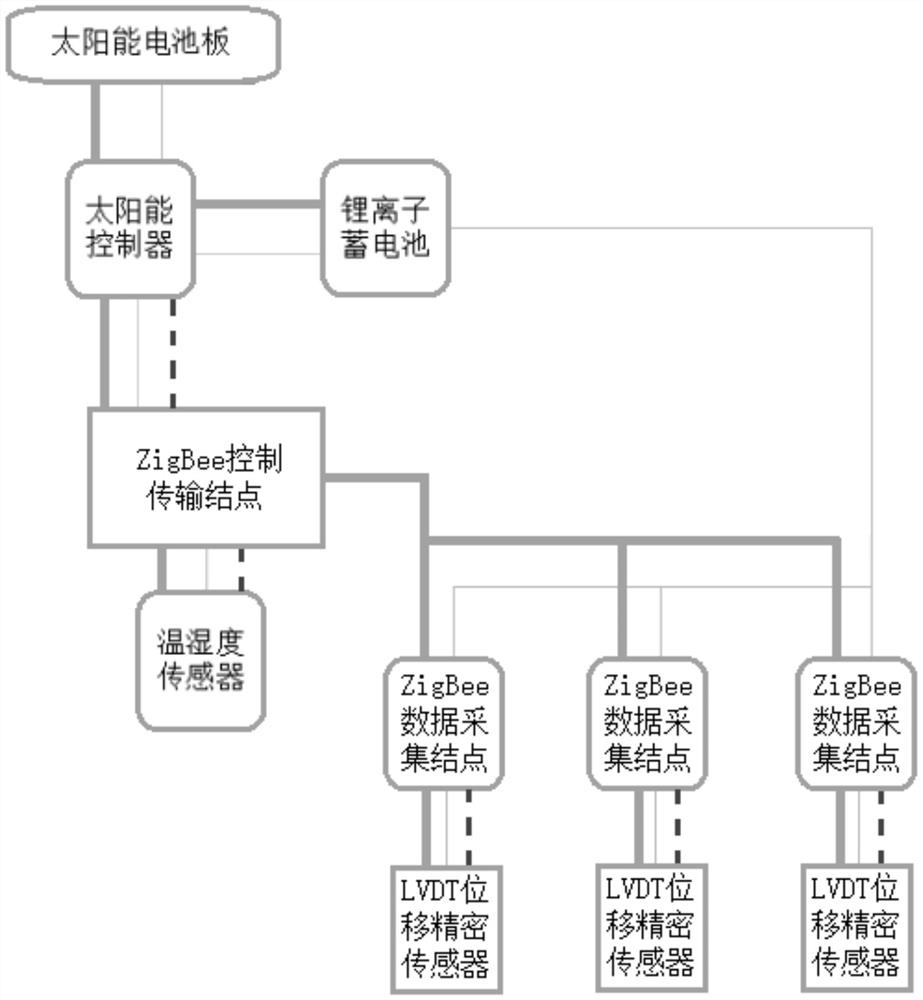

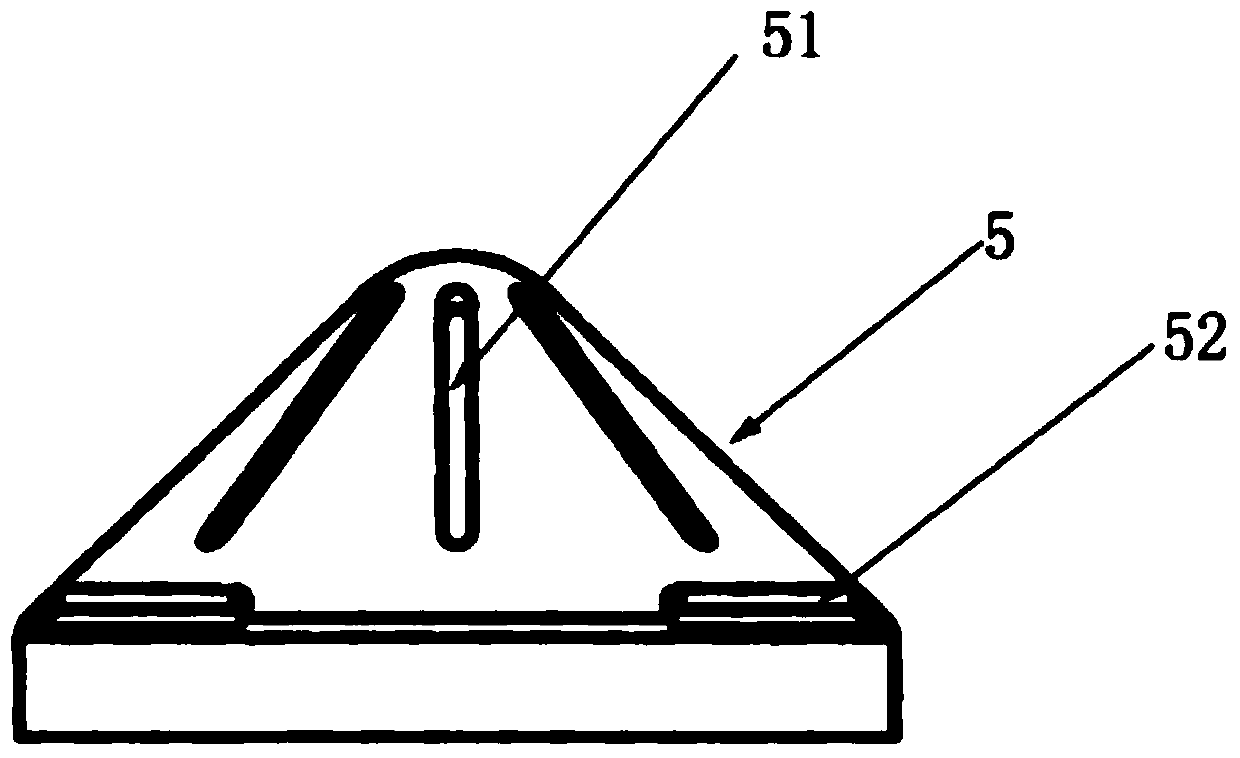

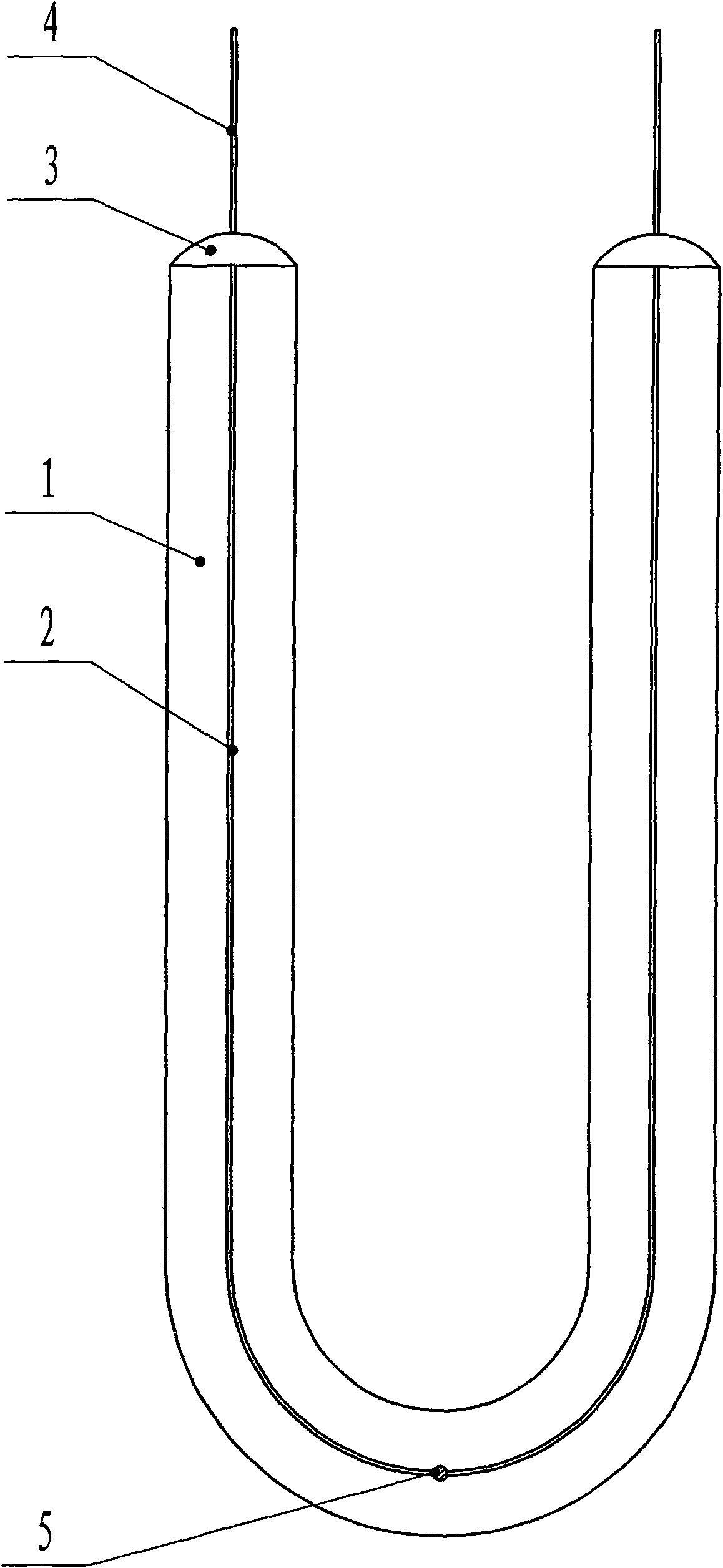

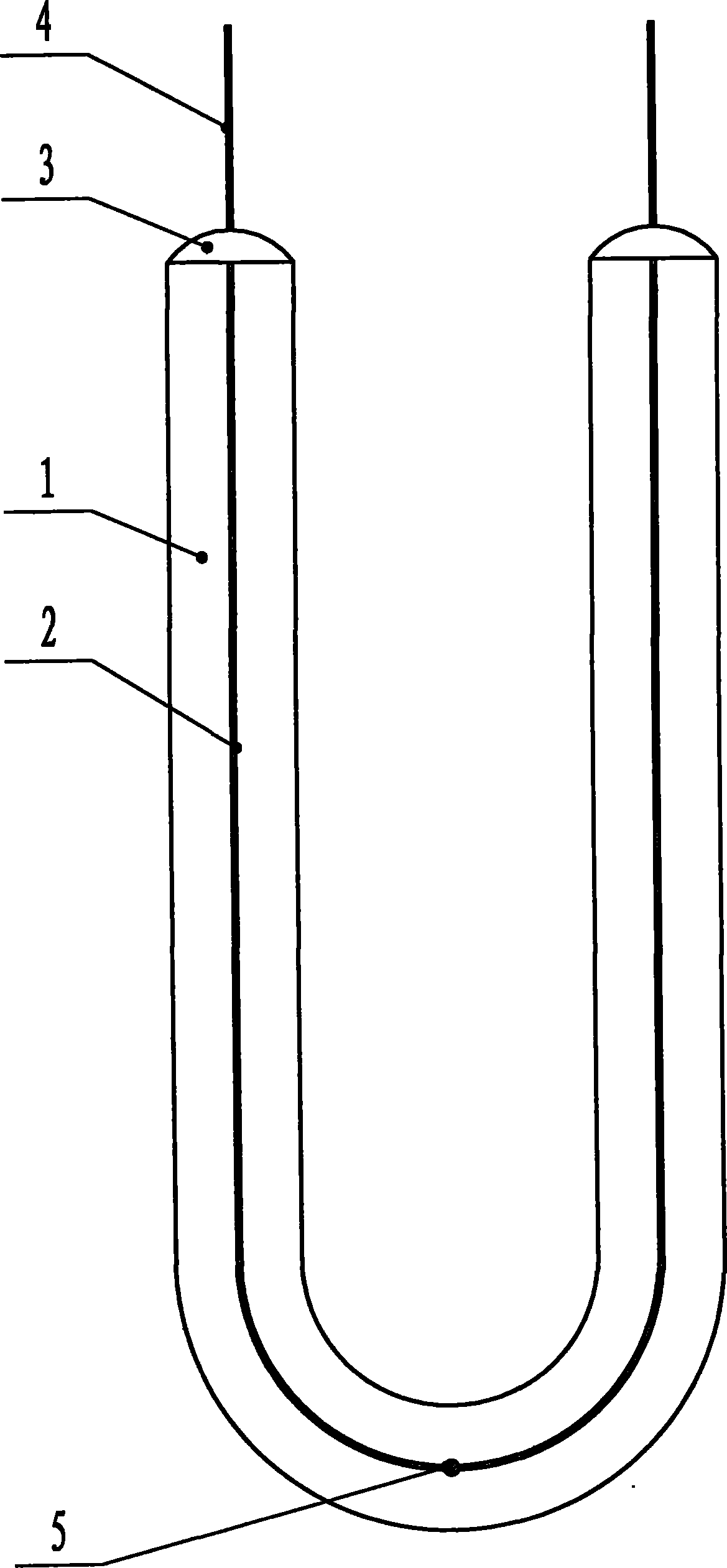

U-shaped channel deformation precision monitoring system based on wireless sensor network

PendingCN112762996AFlexible interfaceCapable of self-healing for network faultsMeasurement devicesData acquisitionSolar battery

The invention discloses an ultrasonic chromatography flow field imaging method and device. The device is mainly composed of a hardware system and a corresponding software module. The hardware system mainly comprises a ZigBee control transmission node, a ZigBee data acquisition node, a temperature and humidity sensor, a displacement precision sensor, an adaptive three-axis mounting rack, a solar panel, a matched lithium battery and an upper computer. The software module of the system is divided into two parts, one part is software corresponding to an upper computer, and the other part is a program embedded into a ZigBee node. The system can completely meet the requirement for precise monitoring of U-shaped channel deformation, is flexible and diverse in interface, is rich and standard in external expansion, can carry various types of sensors, can build a wireless network by itself, has a network fault self-repairing capability, and achieves information exchange with a remote control center and system control through the mobile internet; and meanwhile, a solar cell is carried according to the used external environment, an embedded system is developed by utilizing a single chip microcomputer to realize an energy supply management distribution strategy, and self-sufficiency of energy supply is realized.

Owner:高小翎

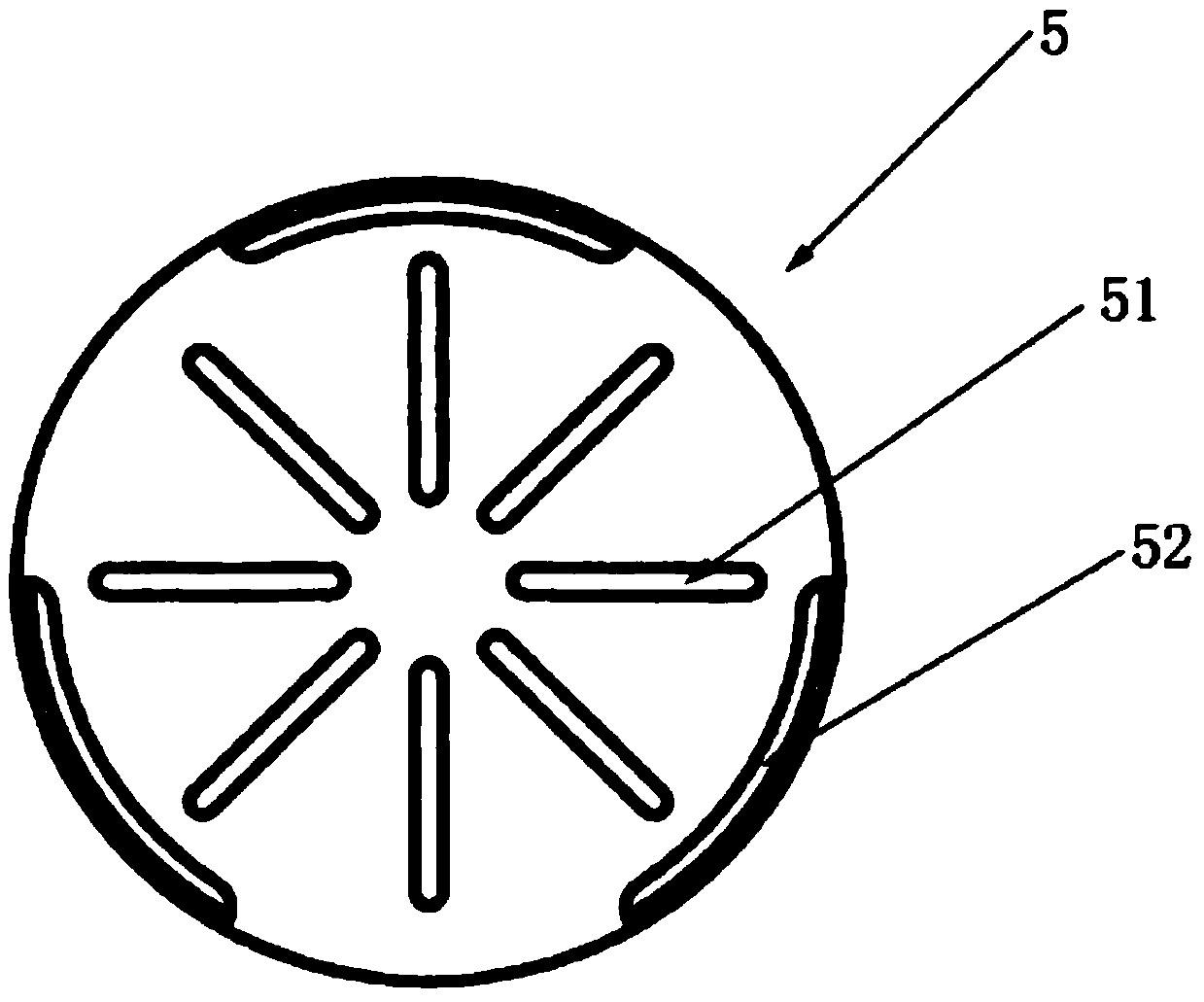

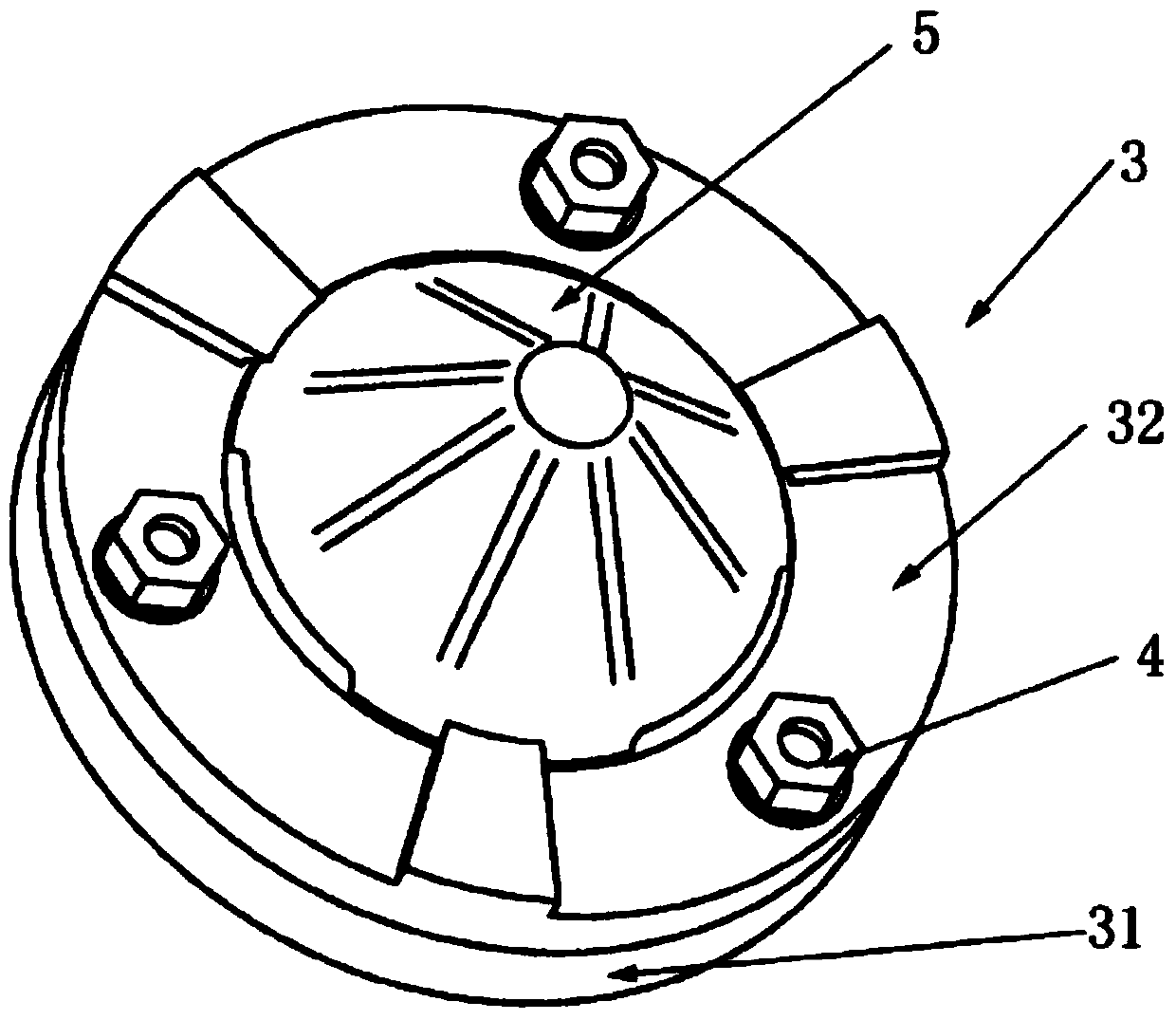

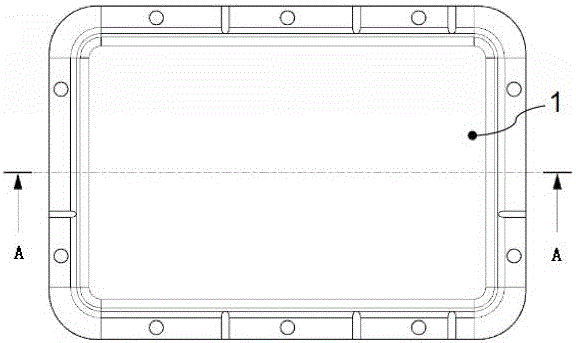

Special-shaped hole machining device and method

The invention discloses a special-shaped hole machining device used for machining special-shaped holes in a conical sheet metal part. The special-shaped hole machining device comprises an electrode mechanism and a clamping mechanism, the electrode mechanism comprises an electrode positioning seat which is provided with a plurality of electrode positioning holes corresponding to the special-shaped holes, electrodes are arranged in the electrode positioning holes, and a connecting rod is arranged on the spindle of the electrode positioning seat; the clamping mechanism comprises a tire body and an annular pressure plate, a plurality of mutually-matched screw holes are arranged in the tire body and the annular pressure plate, the conical metal part is arranged between the tire body and the annular pressure plate, and the tire body, the conical metal part and the annular pressure plate are fixedly connected through bolts. The invention further discloses a special-shaped hole machining method utilizing the special-shaped hole machining device to have the special-shaped holes in the conical metal part machined. By the special-shaped hole machining device and the special-shaped hole machining method, operation is facilitated, accuracy requirements on shape and position of the special-shaped holes in the part are guaranteed, machining cost is lowered, and production efficiency is improved.

Owner:SHENYANG AIRCRAFT CORP

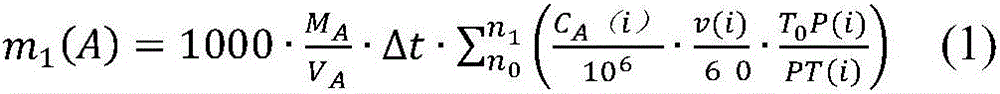

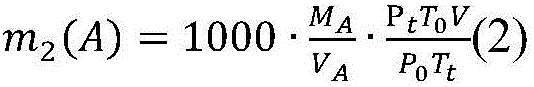

Testing method for components of combustion gas of gunpowder

ActiveCN106093298AComprehensive representationAccurate representationChemical analysis using combustionAnalysing gaseous mixturesGunpowderChemistry

The invention discloses a testing method for the components of combustion gas of gunpowder. The method can quantitatively test the mass of main gas components in a combustion product of the gunpowder under specific conditions. The method mainly comprises the following steps: 1, treating of a to-be-tested sample and adjusting the initial conditions of an enclosed combustion chamber; 2, igniting the to-be-tested sample and allowing gas produced after combustion to be fully mixed with filling gas; 3, subjecting the obtained gas mixture to pressure reduction and flow velocity adjustment, then allowing the gas mixture to pass through a sensor array, and acquiring related data including the pressure intensity of the combustion chamber, the concentrations of the gas components, flow velocity, etc.; 4, treating exhaust gas after completion of testing; 5, processing testing data and calculating the mass of the components of combustion gas produced by combustion of the to-be-tested sample per unit mass; and 6, characterizing testing results. The method provided by the invention is applicable to testing of the mass of a plurality of gas components like CO, CO2, NO, NO2, HCl and NH3 in the combustion product. The method provides a necessary technical means for research on the combustion mechanism, formula and process design of gunpowder.

Owner:XIAN MODERN CHEM RES INST

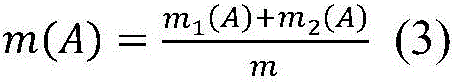

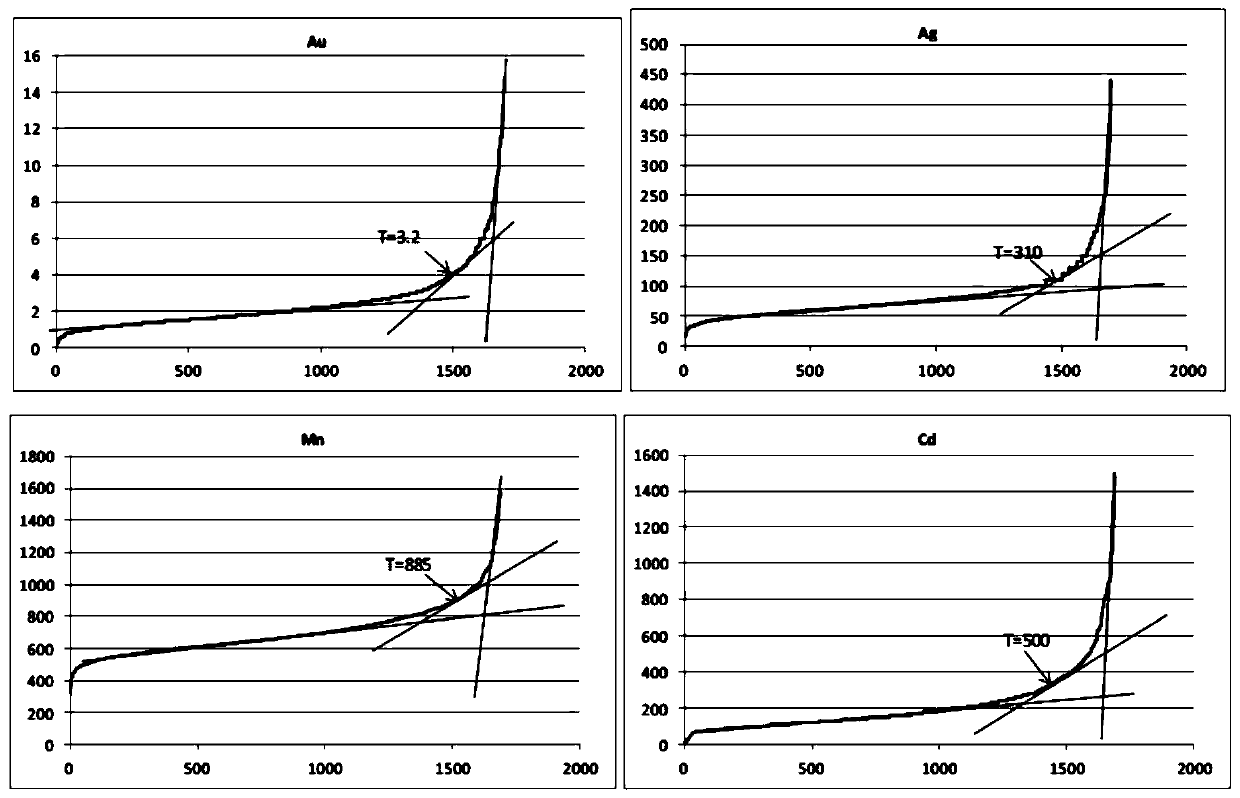

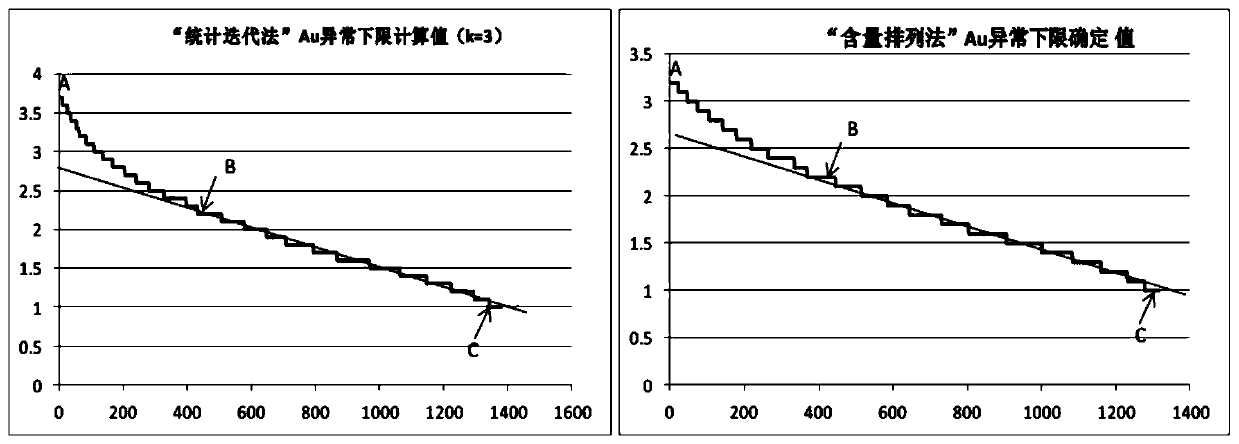

Linear approximation abnormal lower limit determination method

ActiveCN110633310AThe result is reasonableThe result is accurateDigital data information retrievalSpecial data processing applicationsLower limitSkew normal distribution

The invention relates to a linear approximation anomaly lower limit determination method, which is based on a rule that a test data background part obeys normal distribution and linear distribution must obey high normal distribution. The method comprises the following steps of writing an algorithm model to accurately separate a background part in the test digital set by using a statistical linearfitting successive approximation method through repetition (iteration) by means of a computer; wherein the upper limit and the lower limit of the separated background part are respectively the lower limit value of the positive anomaly and the upper limit value of the negative anomaly of the digital set, and the anomaly lower limit can be quickly, simply and accurately determined by the method.

Owner:甘肃省地质调查院

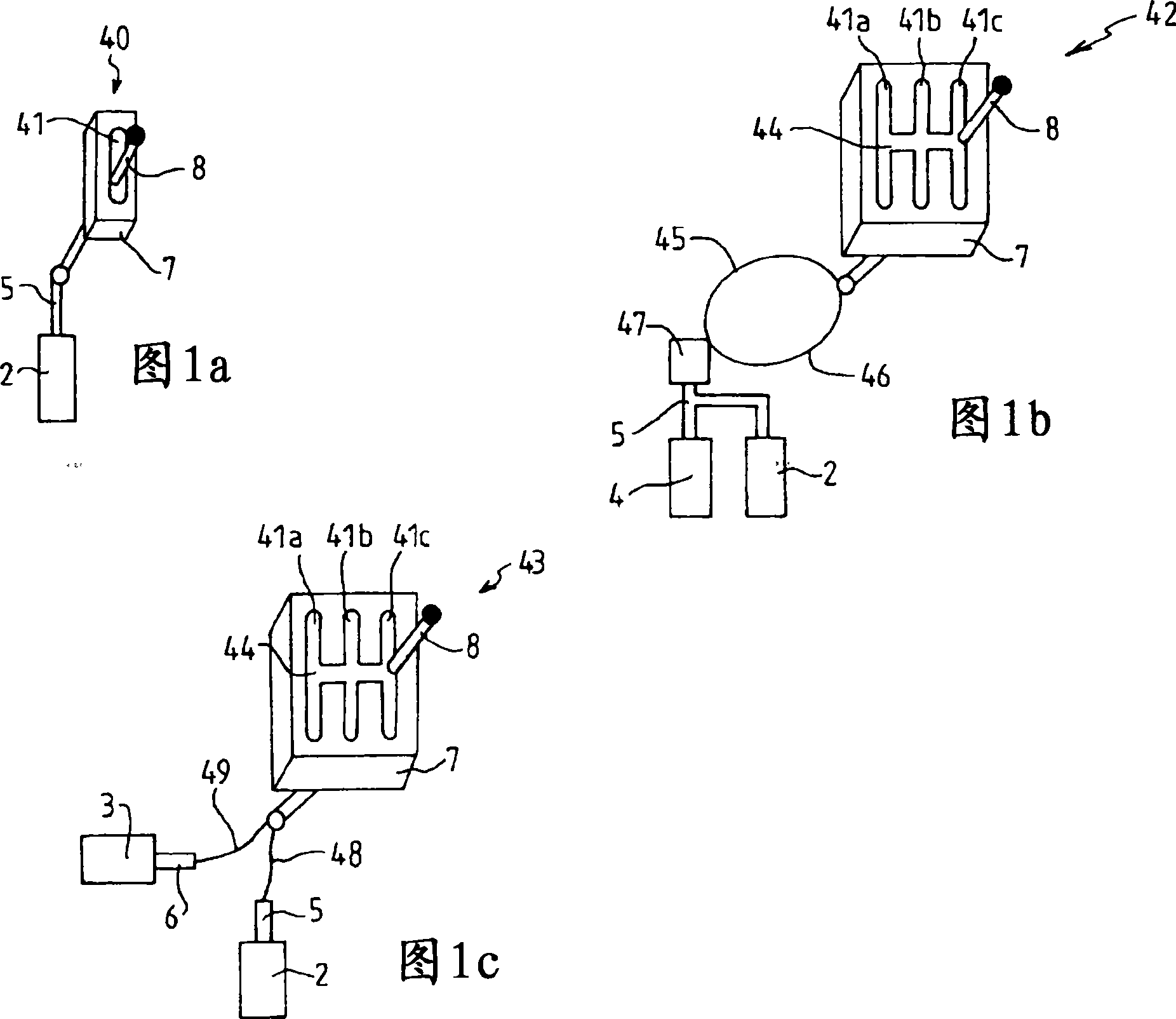

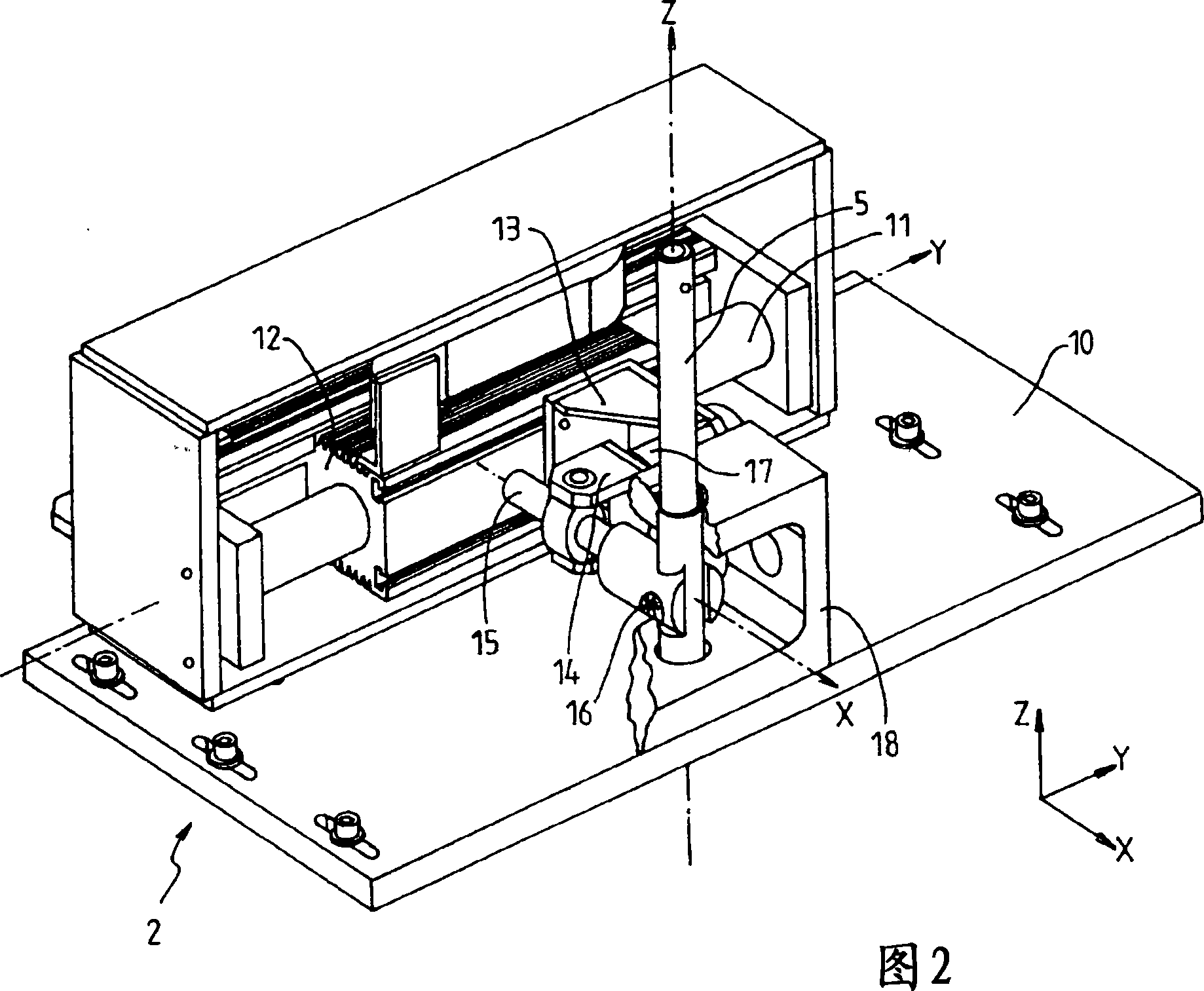

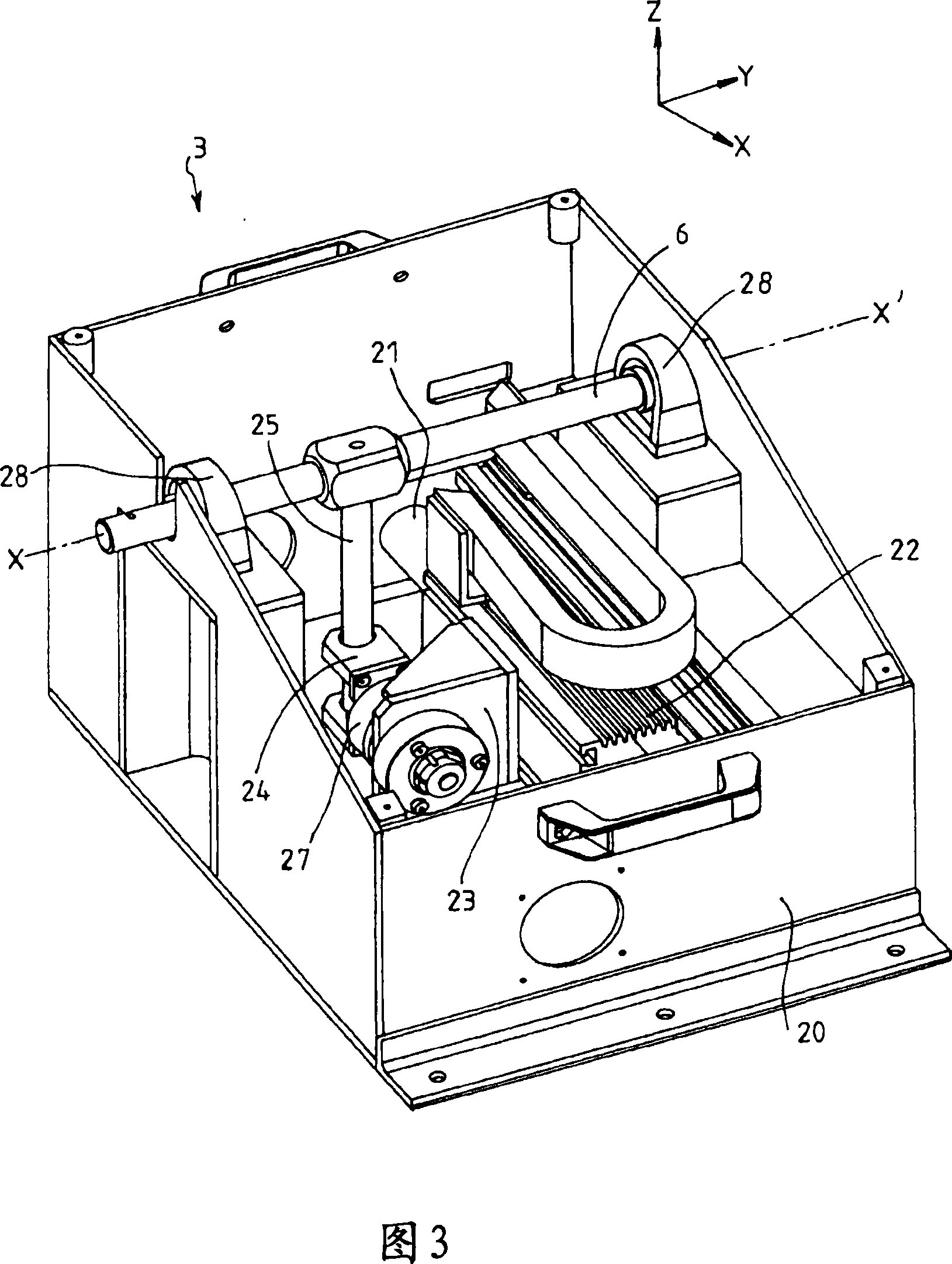

Gearbox simulation test bench

InactiveCN101142471AAccuracy conforms toEasy to moveVehicle testingMachine gearing/transmission testingLinear motionEngineering

Owner:RENAULT SA

Method for treating gelatinized thermocouple wire

InactiveCN101660954AQuality improvementAccuracy conforms toThermometers using electric/magnetic elementsUsing electrical meansDistilled waterThermocouple Wire

The invention relates to a method for treating a gelatinized thermocouple wire, comprising the following sequential steps: firstly, the gelatinized thermocouple wire penetrating through a silica tubeis thermally treated at the temperature of 400-500 DEG C for 50-70 minutes by using a thermal treatment thermocouple wire; secondly, the thermocouple wire is drawn out to cause silicon rubber losing elasticity to fall off; and thirdly, the thermocouple wire is cleaned, wherein (1) the drawn-out thermocouple wire is boiled for 25-35 minutes by using sodium hydroxide solution of 8-12 percent mass fraction, (2) the thermocouple wire treated by using alkali is boiled for 25-35 minutes by using hydrochloric acid solution of 8-12 percent mass fraction, (3) the thermocouple wire treated by using acidis repeatedly boiled by using distilled water for at least three times, each time for 25-35 minutes, and (4) the cleaned thermocouple wire is dewatered at the temperature of 60-80 DEG C; and finally,the treated thermocouple wire together with a standard thermocouple wire is examined. The method for treating the gelatinized thermocouple wire can recover thermocouple wires.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

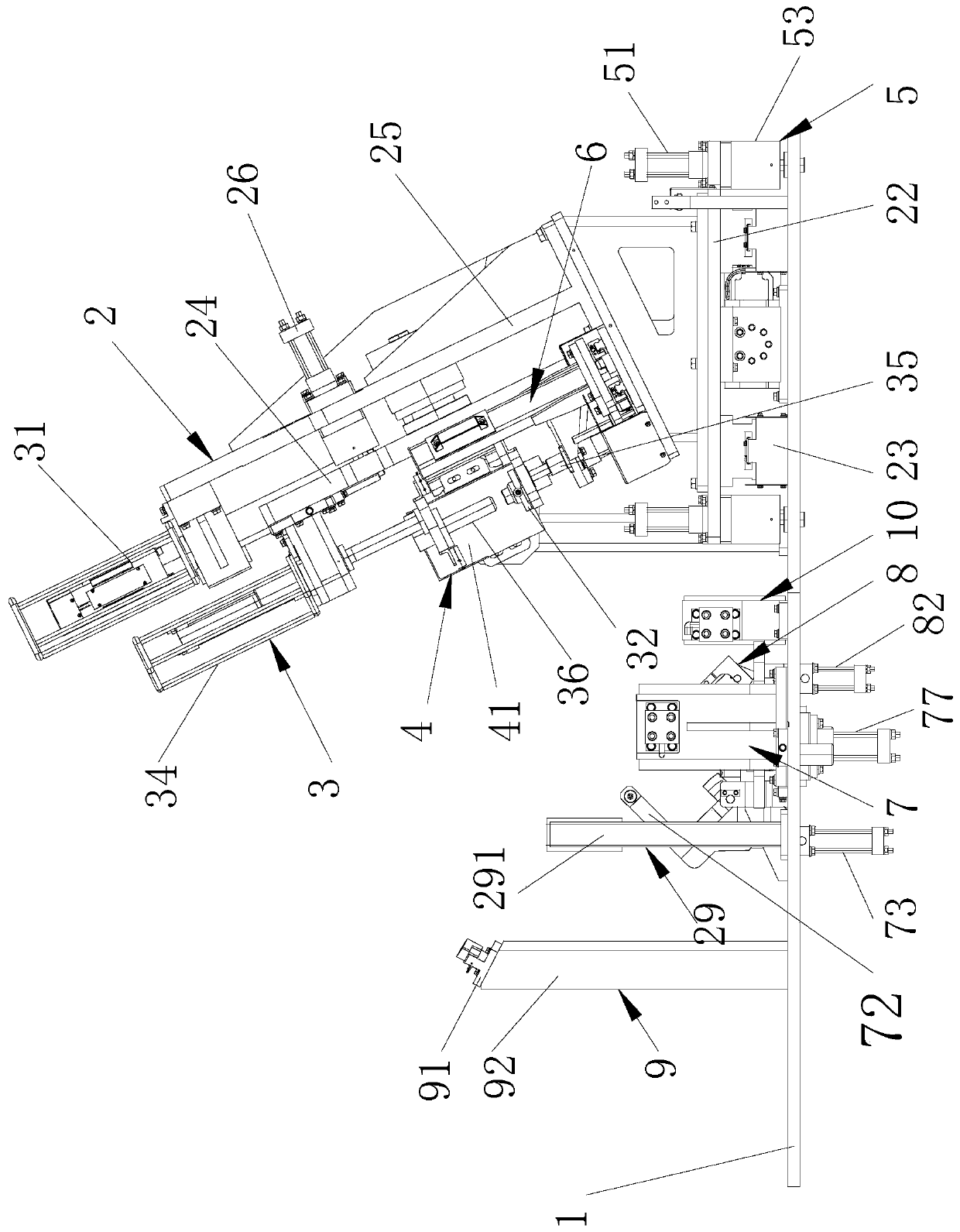

Car frame front tube shaping device

InactiveCN109834138APrevent twistingAccuracy conforms toMetal-working feeding devicesCycle equipmentsVehicle frameEngineering

The invention relates to a car frame front tube shaping device, which comprises a base, a car frame positioning assembly and a car frame front tube shaping assembly, wherein the car frame positioningassembly and the car frame front tube shaping assembly are arranged on the base. The car frame front tube shaping assembly comprises an integral deviation correction mechanism, a front tube torsion deviation correction mechanism and a front tube correction detection mechanism, the integral deviation correction mechanism comprises a first servo electric cylinder, a front tube shaping layer board, aguide rail, a torsion deviation plate, a torsion deviation base and a torsion deviation plate locking oil cylinder, the guide rail and the torsion deviation base are both arranged on the base, the front tube shaping layer board is slidably matched with the guide rail, a top rod of the first servo electric cylinder is fixedly connected with the front tube shaping layer board, the torsion deviationplate is rotatably connected with the torsion deviation base through a bearing, a locking hole is formed in the torsion deviation plate, the torsion deviation plate locking oil cylinder is installedon the torsion deviation base and driven, and a piston rod of the torsion deviation plate locking oil cylinder can be inserted in or detached from the locking hole of the torsion deviation plate. According to the car frame front tube shaping device, closed-loop correction can be formed, thus correction accuracy is high, and the correction efficiency is also high.

Owner:常州豪爵铃木摩托车有限公司

Health care ice grape beer brewed by functional water and preparation method

The invention relates to health care ice grape beer brewed by functional water and a preparation method, wherein the beer comprises the following components of raw materials by weight percent: 5-8 of malt, 2-3 of hop, 1-5 of honey, 1-2 of yeast, 15-30 of ice grape juice and the balance of water; wherein the water is active functional water. Compare with the prior art, the novel beer brewed by the active functional water and ice grape has fragrant smell, can effectively improve oxygen content of blood of the human body, activates brain tissue and cells, activates bioelectric current, improves microcirculation of the human body, improves immunity of the human body, is beneficial for the human body to absorb nutrient constituents, trace elements and rare elements, effectively complements the trace elements and beneficial rare elements which are lack in the human body, have good function of health care, meets the requirements of modern people on health care beer with low alcoholic strength, environmental protection and organism, and has a huge market potential and wide market prospect.

Owner:尤钧平

Accuracy calibration of birefringence measurement systems

InactiveCN100541149CAccuracy conforms toMaterial analysis by optical meansLight polarisation measurementLight sourceBirefringence

Systems and methods are provided for employing a Soleil-Babinet compensator (101) as a standard for calibrating a birefringence measurement system. A highly accurate and repeatable calibration can be achieved by the method described here because, among other advantages, the inventive method can calculate the different birefringence across the surface of the Soleil-Babinet compensator (101). The calibration techniques described herein can be used in birefringence measurement systems with various optics and light sources of various frequencies to measure a range of birefringence levels.

Owner:HINDS INSTR

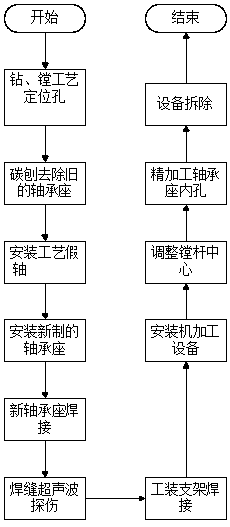

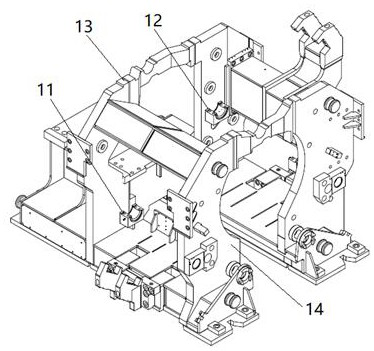

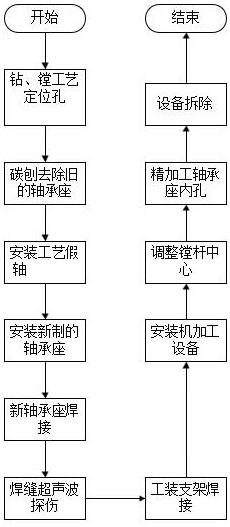

Online mounting method for bearing seats of wrapper roller frame of hot rolling coiler

ActiveCN111014299AMeet the needs of structural transformationGuaranteed concentricityMetal rolling arrangementsStructural engineeringMechanical engineering

The invention discloses an online mounting method for bearing seats of a wrapper roller frame of a hot rolling coiler. The online mounting method comprises the steps that firstly, new bearing seats are manufactured, and process positioning holes are machined at the center positions of original bearing seats at an operation side memorial archway and a transmission side memorial archway to serve aspositioning datum of mounting of the new bearing seats; the old bearing seats are demounted, process false shafts are manufactured and mounted in the process positioning holes, and the new bearing seats are mounted on the process false shafts and welded to the operation side memorial archway and the transmission side memorial archway; the process false shafts are demounted, tool brackets are welded to the inner sides and the outer sides of the transmission side memorial archway and the operation side memorial archway, boring rods of machining equipment penetrate into the tool brackets and theprocess positioning holes, and the positions of the boring rods are locked; and inner holes of the new bearing seats are machined through the machining equipment to reach the designed size, the concentricity of the bearing seats on the two sides is ensured, after machining, the machining equipment and the tool brackets are demounted, the sizes of the centers of the bearing seats are retested to meet the design precision requirements, and mounting of the new bearing seats is completed. According to the online mounting method, the structural transformation demands of the coiler are met, and theposition precision of a wrapper roller is ensured.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

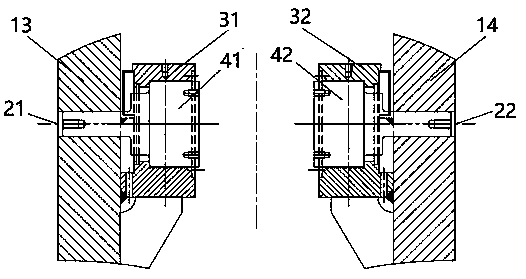

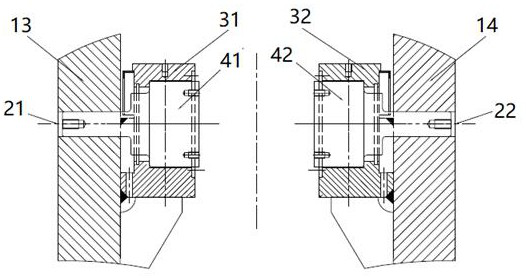

Supporting device of cylindrical lens and optical equipment

The invention discloses a cylindrical lens supporting device and optical equipment, the cylindrical lens supporting device comprises a supporting frame and a pressing assembly, the supporting frame is provided with an opening for light to pass through and a mounting hole for accommodating a cylindrical lens, the opening is communicated with the mounting hole, and the supporting frame is provided with a flexible table and three supporting tables which are all located in the mounting hole. The flexible table and the multiple supporting tables support the cylindrical lens, the multiple supporting tables define a supporting structure, the hole wall of the mounting hole abuts against the side wall of the cylindrical lens, the pressing assembly comprises flexible pressing blocks and multiple pressing blocks which are connected with the supporting frame, the number of the pressing blocks is consistent with that of the supporting tables, and the pressing blocks and the supporting tables are in one-to-one correspondence; the pressing blocks are used for pressing the cylindrical lenses on the corresponding supporting tables, and the flexible pressing blocks press the cylindrical lenses on the flexible tables. According to the supporting device, the cylindrical lens is pressed on the multiple supporting tables through the multiple pressing blocks, and the cylindrical lens is pressed on the flexible table through the flexible pressing blocks, so that multi-point press fitting is achieved, and the influence on the surface shape precision of the cylindrical lens is avoided.

Owner:JIHUA LAB

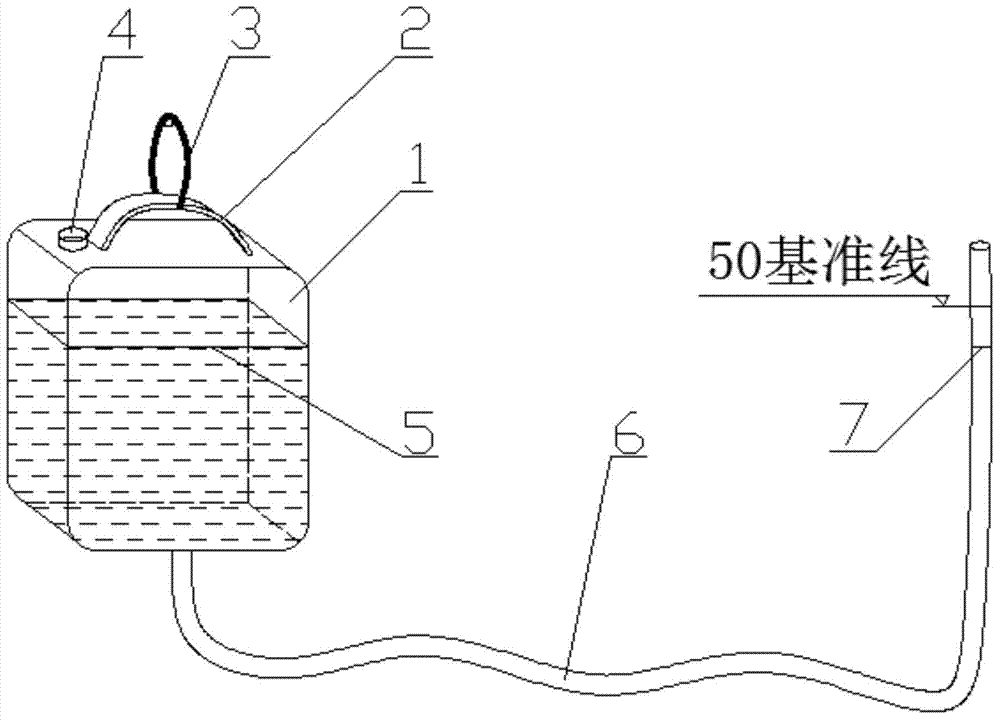

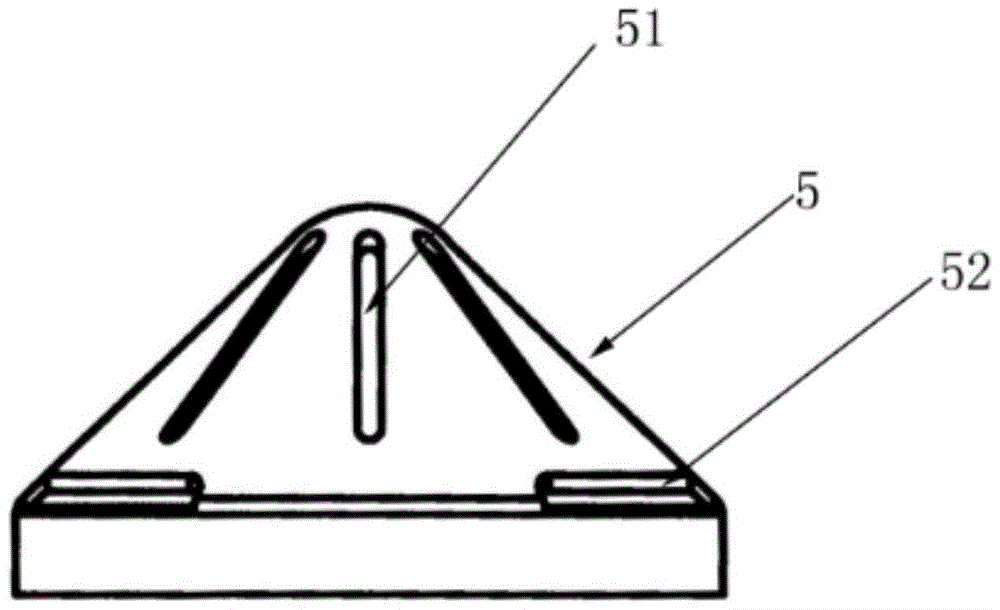

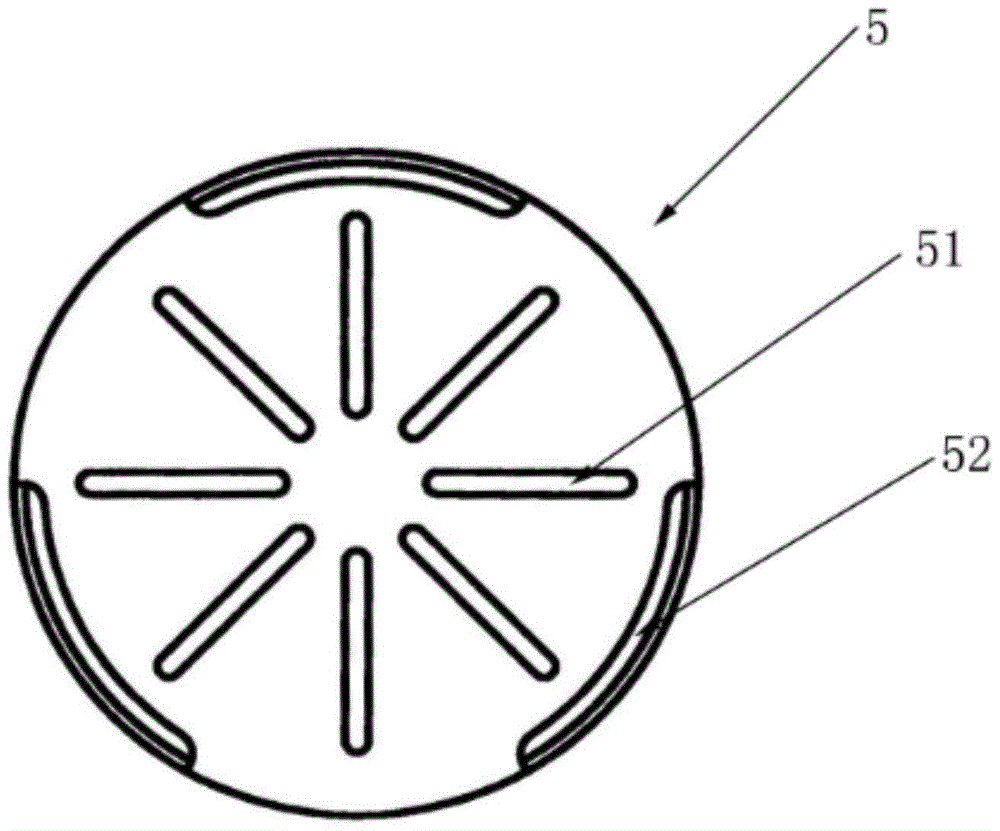

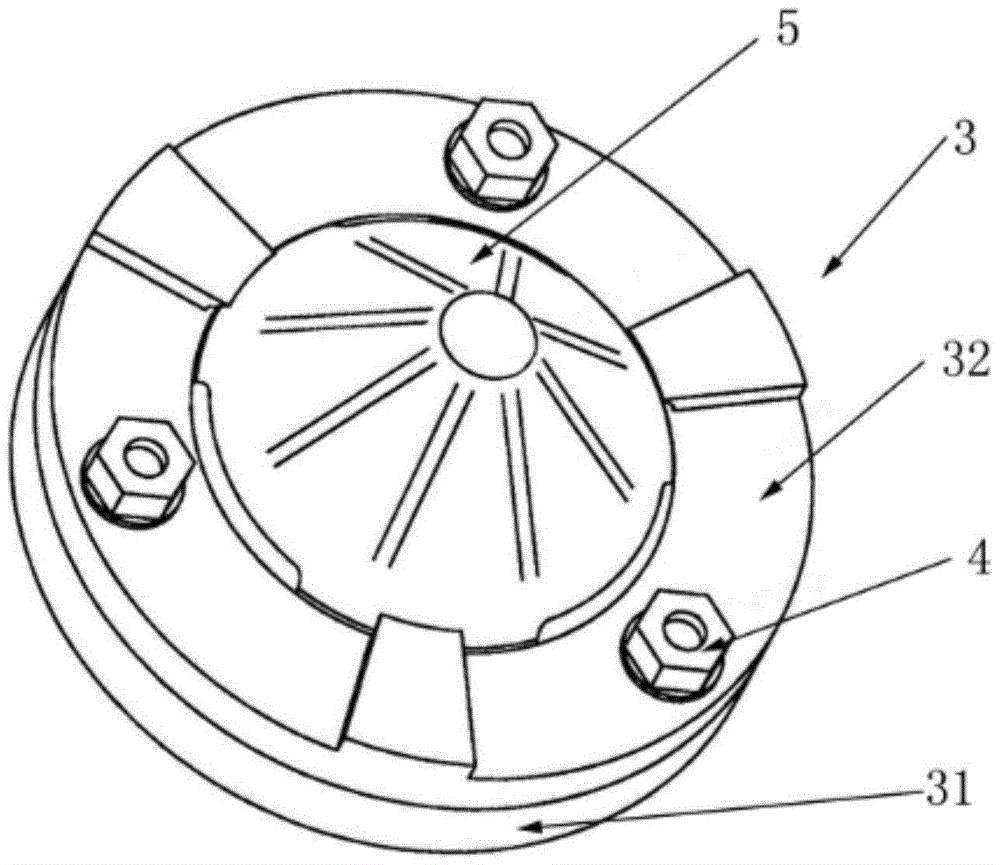

Indoor leveling device and leveling method

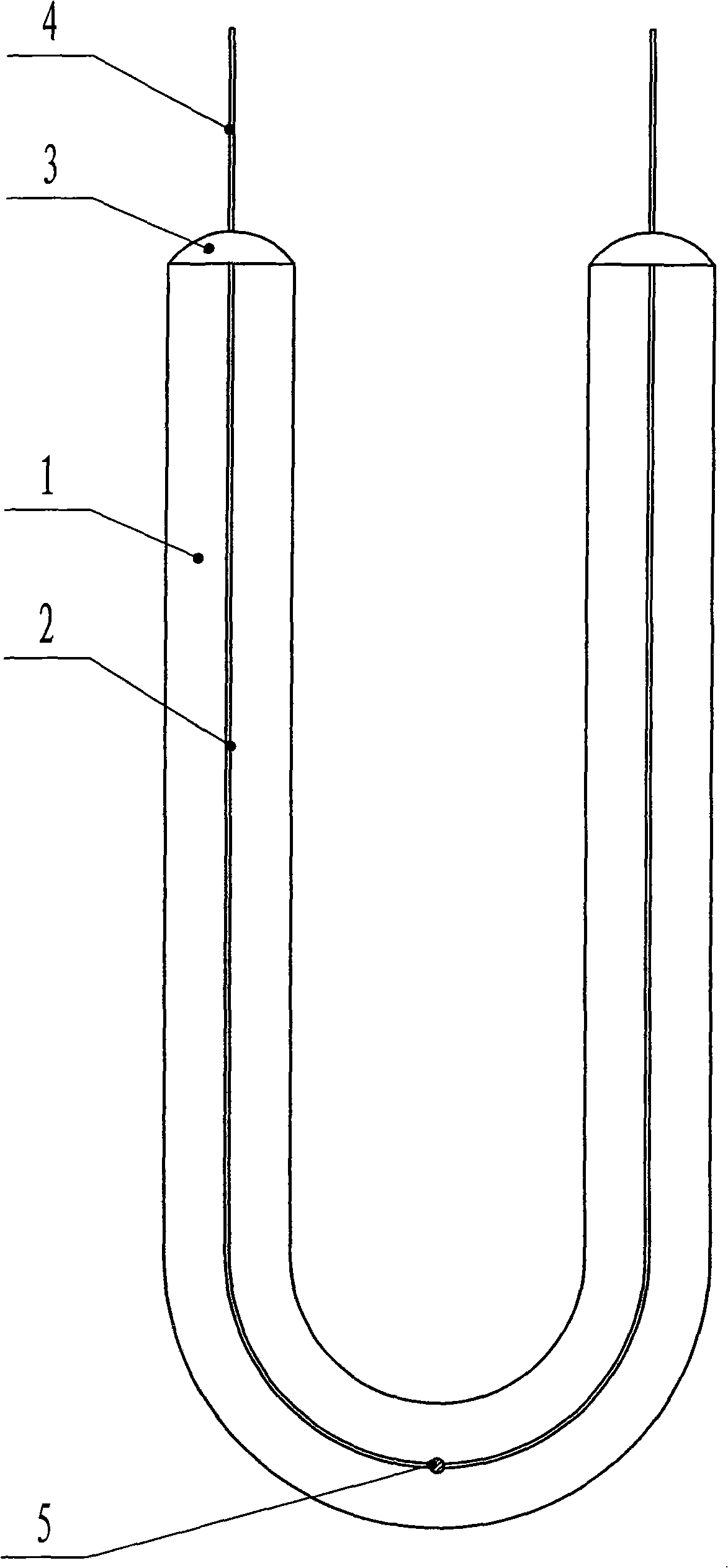

InactiveCN104501778AEasy to manufactureSimple structureIncline measurementTransverse planeEngineering

The invention discloses an indoor leveling device and a leveling method. The indoor leveling device comprises a water bucket and a flexible pipe. The top of the water bucket is provided with an inlet and the bottom of the water bucket is provided with an outlet. The outlet at the bottom of the water bucket is connected to the flexible pipe by a connector. The leveling method comprises the following steps of 1, filling the water bucket and hanging the water bucket at an object close to a 50 reference line, 2, drawing a first transverse line at the tail end of the flexible pipe aligning at the 50 reference line and drawing a second transverse line at the water bucket aligning at the water level, and 3, transferring the tail end of the flexible pipe to a position to be leveled, aligning the water level of the water bucket and the second transverse line, wherein the first transverse line is a 50 reference line of the position to be leveled, and carrying out leveling on all the positions by movement according to the 50 reference line. The indoor leveling device is prepared easily, has a simple structure, has a fast leveling rate, has a precision according with requirements, only needs one leveling operator, and is especially suitable for a narrow and small room where a level meter for leveling cannot be used.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

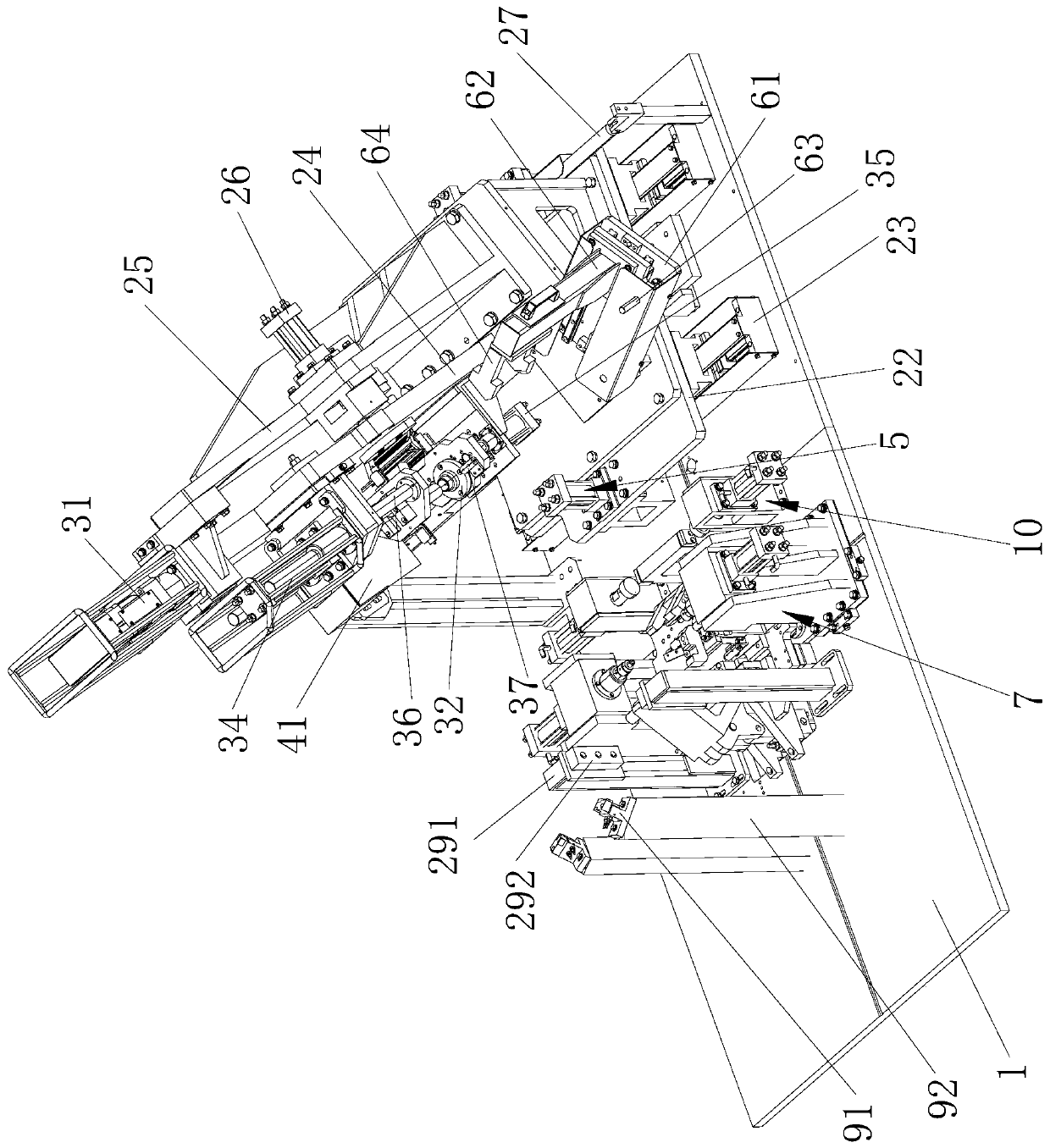

Apparatus and method for processing special-shaped holes

ActiveCN104191051BSolve processing difficultiesMeet the requirements of dimensional and position accuracyEngineeringMachining

The invention discloses a special-shaped hole machining device used for machining special-shaped holes in a conical sheet metal part. The special-shaped hole machining device comprises an electrode mechanism and a clamping mechanism, the electrode mechanism comprises an electrode positioning seat which is provided with a plurality of electrode positioning holes corresponding to the special-shaped holes, electrodes are arranged in the electrode positioning holes, and a connecting rod is arranged on the spindle of the electrode positioning seat; the clamping mechanism comprises a tire body and an annular pressure plate, a plurality of mutually-matched screw holes are arranged in the tire body and the annular pressure plate, the conical metal part is arranged between the tire body and the annular pressure plate, and the tire body, the conical metal part and the annular pressure plate are fixedly connected through bolts. The invention further discloses a special-shaped hole machining method utilizing the special-shaped hole machining device to have the special-shaped holes in the conical metal part machined. By the special-shaped hole machining device and the special-shaped hole machining method, operation is facilitated, accuracy requirements on shape and position of the special-shaped holes in the part are guaranteed, machining cost is lowered, and production efficiency is improved.

Owner:SHENYANG AIRCRAFT CORP

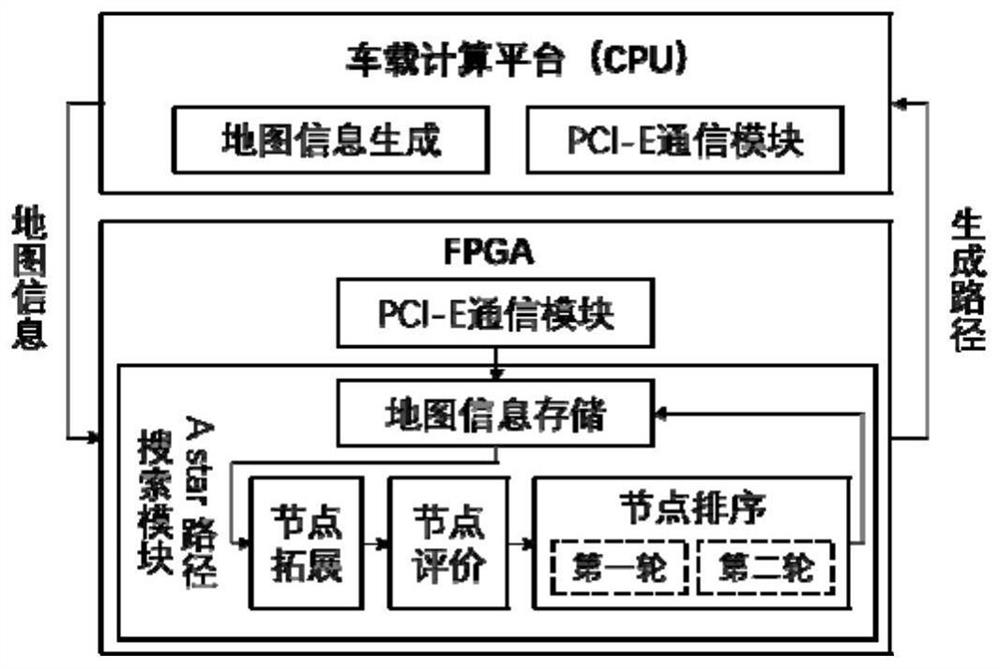

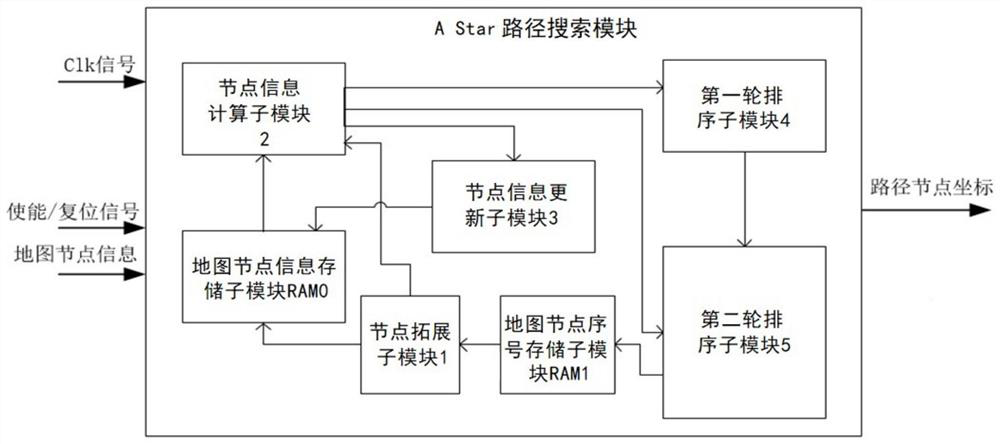

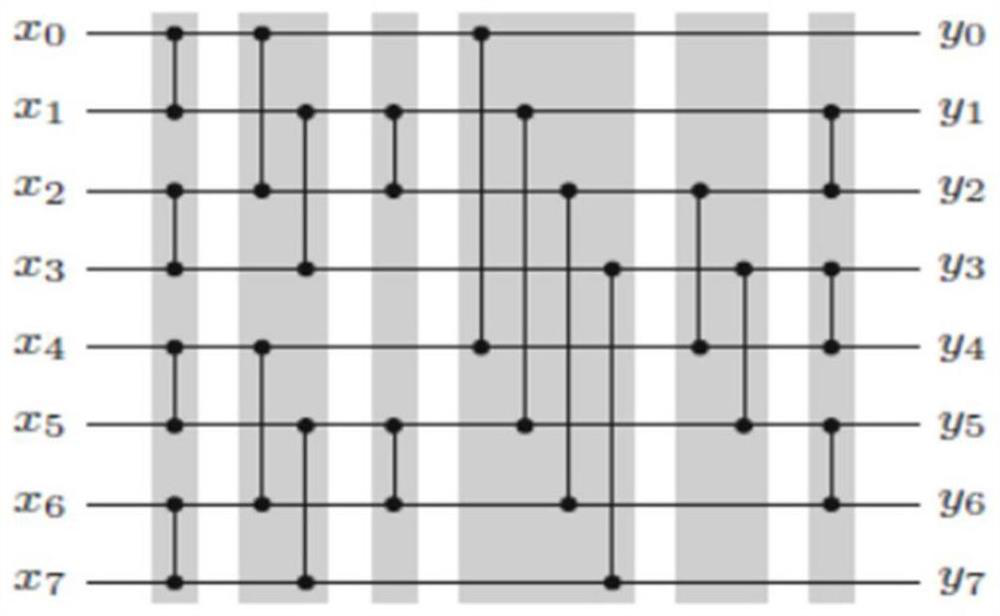

A vehicle system based on fpga design and a star path search method

ActiveCN111076736BImprove search efficiencyAccuracy conforms toInstruments for road network navigationPathPingSystems design

The invention discloses a vehicle-mounted system based on FPGA design and an A star path searching method. The vehicle-mounted system comprises a heterogeneous computing system composed of a vehicle-mounted computing platform for providing map information and an FPGA for computing a path. The FPGA design comprises the following modules: a map node information storage sub-module and a map node serial number storage sub-module used for storing map information, a node expansion module used for expanding nodes based on an evaluation function, a node information updating module used for calculatingthe relationship between the evaluation function of a newly expanded node and a father node, a first round of sorting module used for sorting newly expanded nodes based on the evaluation function value and an odd-even sorting network, and a second round of sorting module used for sorting all open nodes based on the evaluation function value and a doubly linked list. According to the method, the advantages of the FPGA in the aspect of parallel operation are brought into full play in FPGA design, the efficiency of path search can be greatly improved, and vehicle-mounted application is achievedbased on communication and system design.

Owner:TSINGHUA UNIV

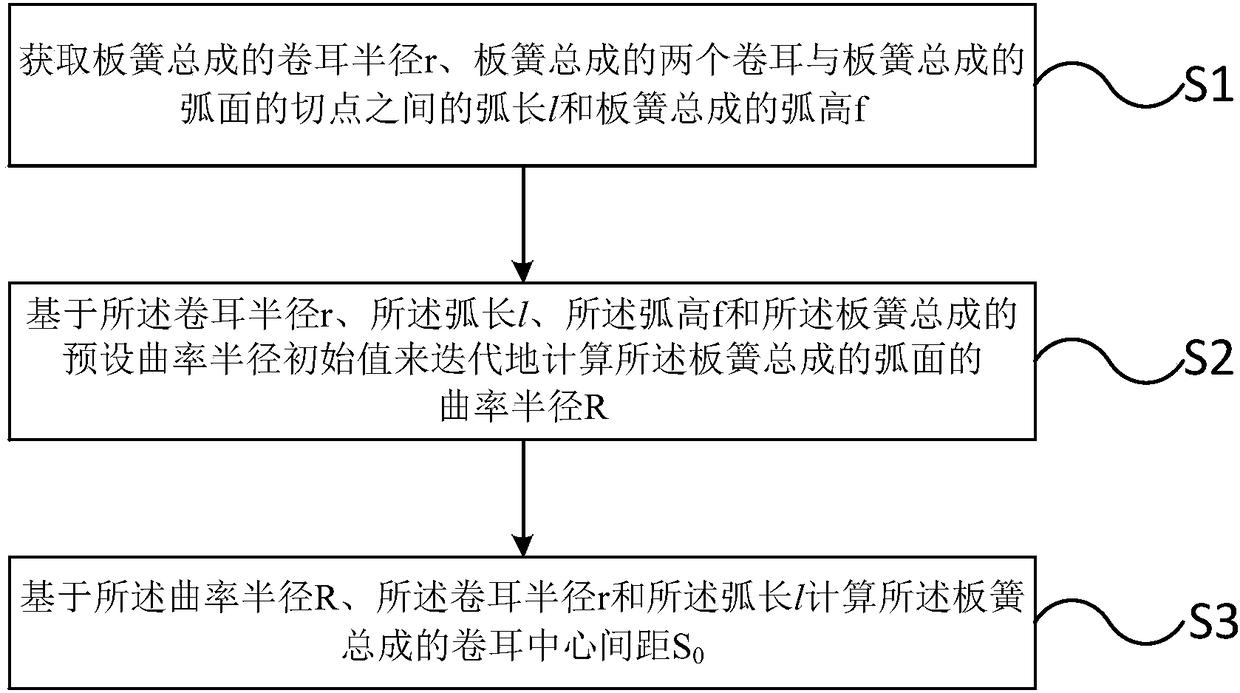

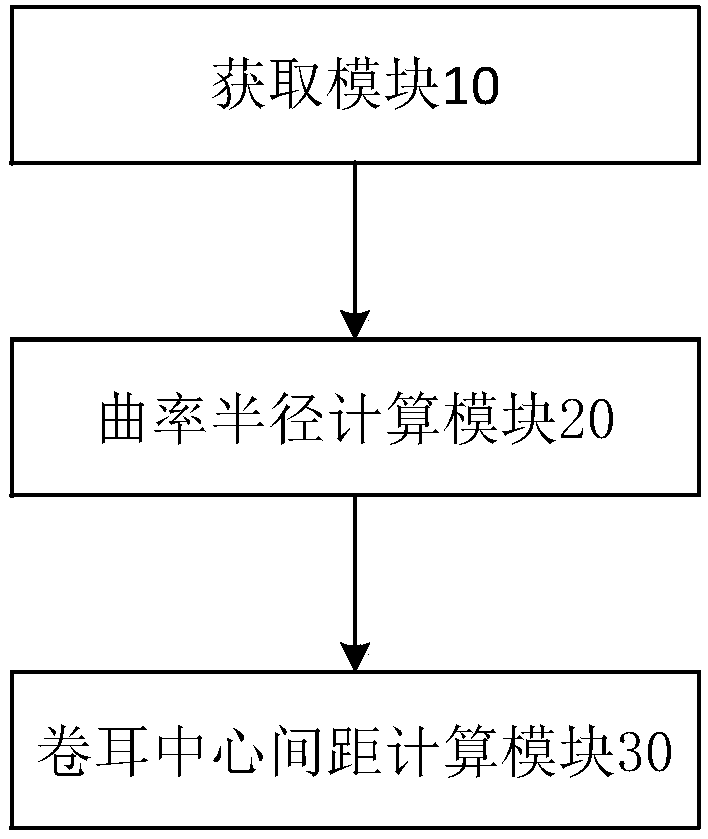

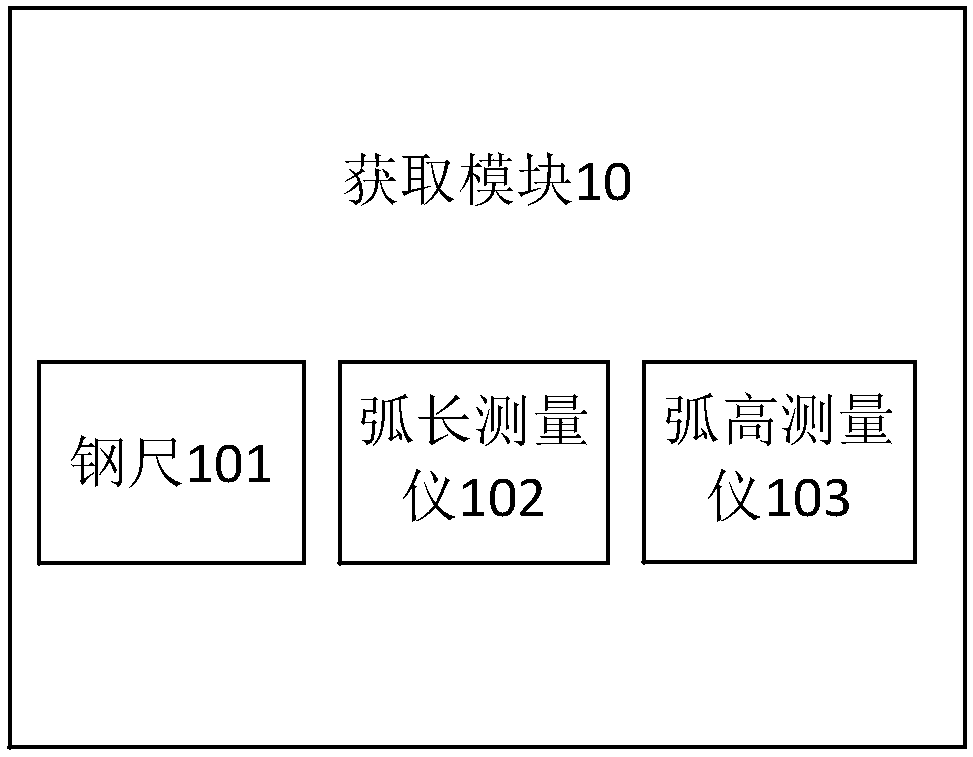

Measuring method and device for distance between lugs of leaf spring

ActiveCN106218348BImprove accuracyAccuracy conforms toSuspensionsVehicle suspension/damping testingEngineeringLeaf spring

Owner:BEIQI FOTON MOTOR CO LTD

On-line installation method for bearing seat of coiling aid roll frame of hot-rolling coiler

ActiveCN111014299BMeet the needs of structural transformationGuaranteed concentricityMetal rolling arrangementsStructural engineeringMechanical engineering

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Thermoelectric cell group

ActiveCN105957953AEffective anti-vibrationEffective impact resistanceThermoelectric device detailsWhole bodyEngineering

The invention relates to a thermoelectric cell group which comprises upper and lower shells, upper and lower shell heat transfer groups and thermoelectric cell units. The external surfaces of the upper and lower shells are provided with upper and lower shell heat transfer layers. The upper and lower shells are internally provided with a plurality of groove-shaped positioning structures capable of installing the thermoelectric cell units, and the thermoelectric cell units in a 3 by 3 arrangement, a parallel connection, a series connection or a series and parallel mixed connection can be embedded by the upper and lower shells. Each of the thermoelectric cell units is provided with positive and negative electrodes and a temperature sensor. Upper and lower buffer heat conduction shock-absorbing pads are arranged between the thermoelectric cell units and the upper and lower shells, and the upper and lower shell are connected through threaded connection or dot welding connection to form a cell group whole body. Through the above structural design, the reasonable and firm sealing and shock absorption are achieved, through sanding and polishing a working and adjusting the parallelism, the parallelism and accuracy of the working surface of the upper and lower shells are ensured, the thermal resistance is low, the production assembly is convenient, the thermoelectric cell group is convenient to use, the service life is long, and the thermoelectric cell group can be actively promoted and used.

Owner:上海松芝酷能汽车技术有限公司

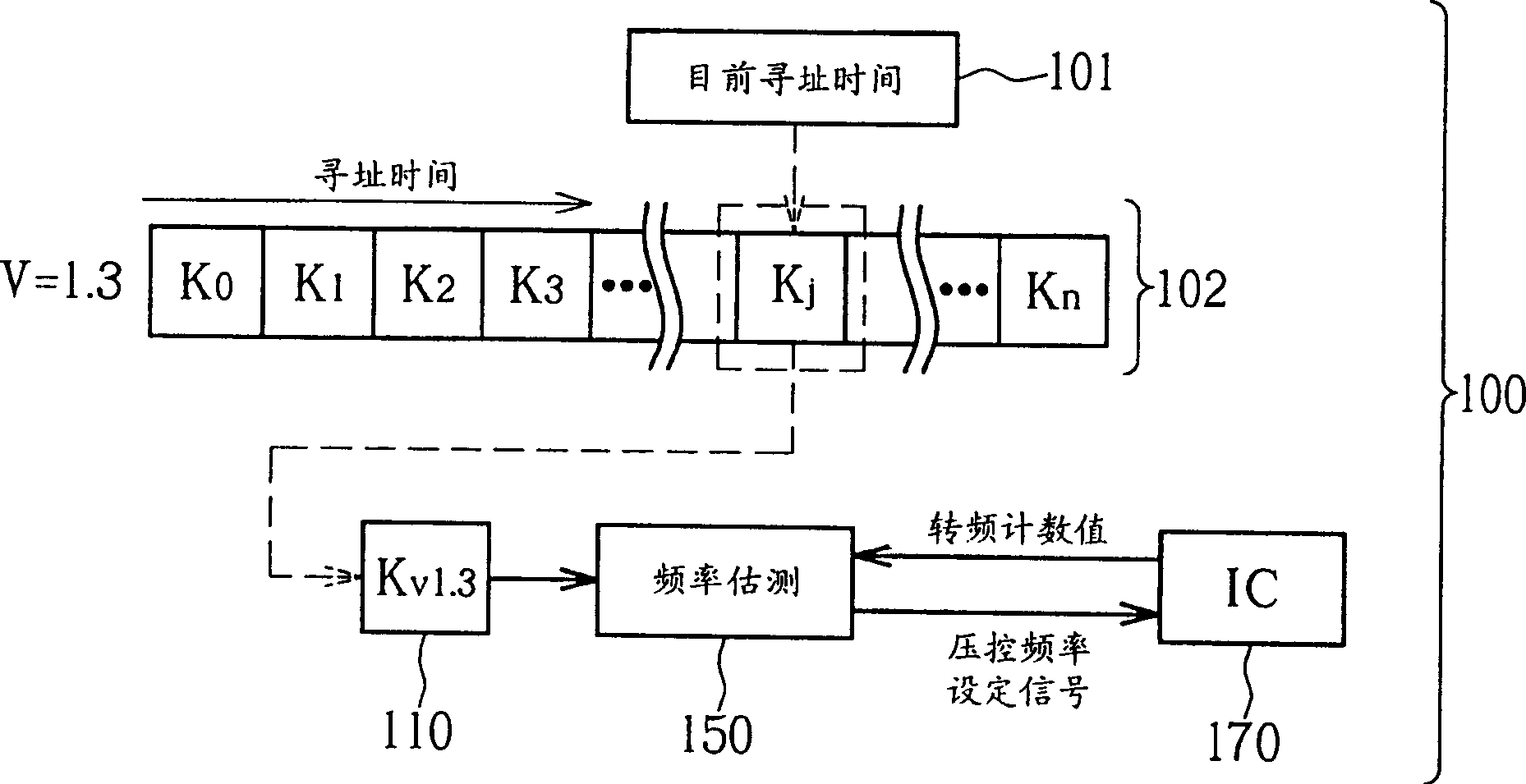

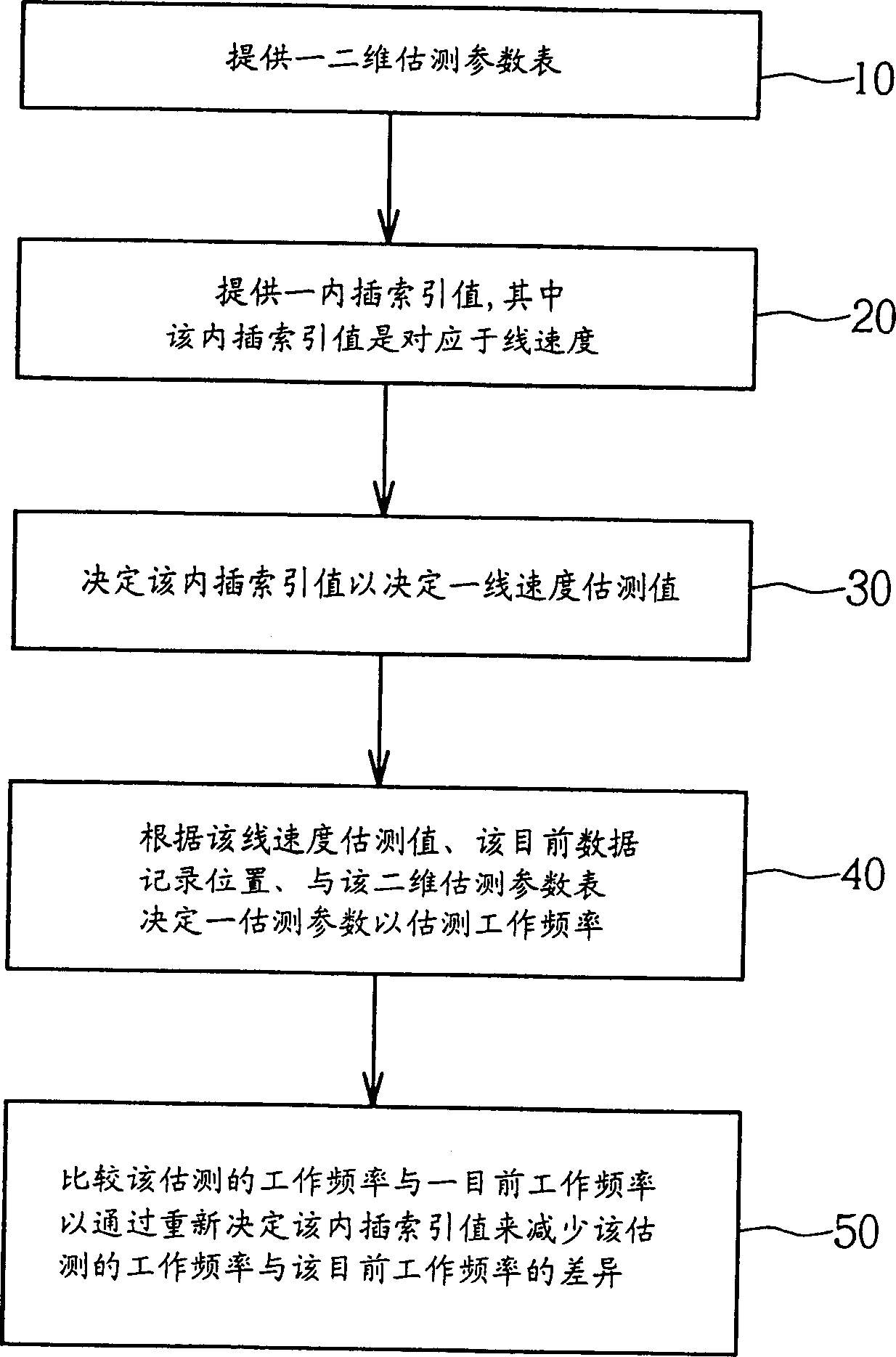

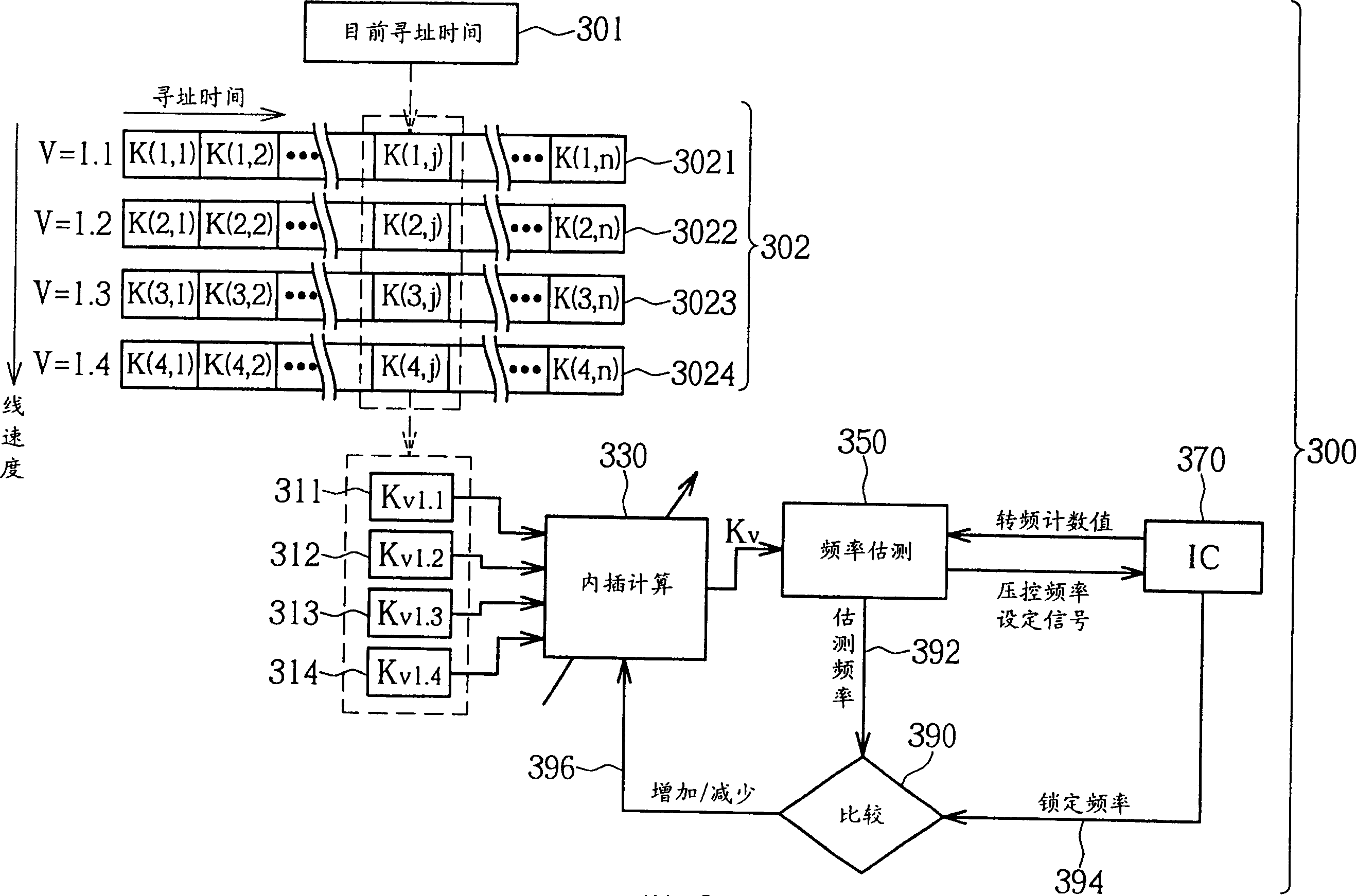

Estimation parameter adaptive adjustment method for optical storage devices

InactiveCN1282165CAccuracy conforms toQuick lockRecord information storageDigital recording/reproducingOptical storageData recording

A method for adaptive adjustment of estimated parameters of an optical storage device is used to determine an estimated parameter according to the current data recording position of an optical storage device to estimate a working frequency. The method provides a two-dimensional estimated parameter table, wherein the two-dimensional estimated parameter table has a plurality of estimated parameters corresponding to linear velocity and data recording position. The method further includes determining an estimated linear velocity; and determining an estimated parameter according to the estimated linear velocity, the current data recording position, and the two-dimensional estimated parameter table to estimate the operating frequency.

Owner:MEDIATEK INC

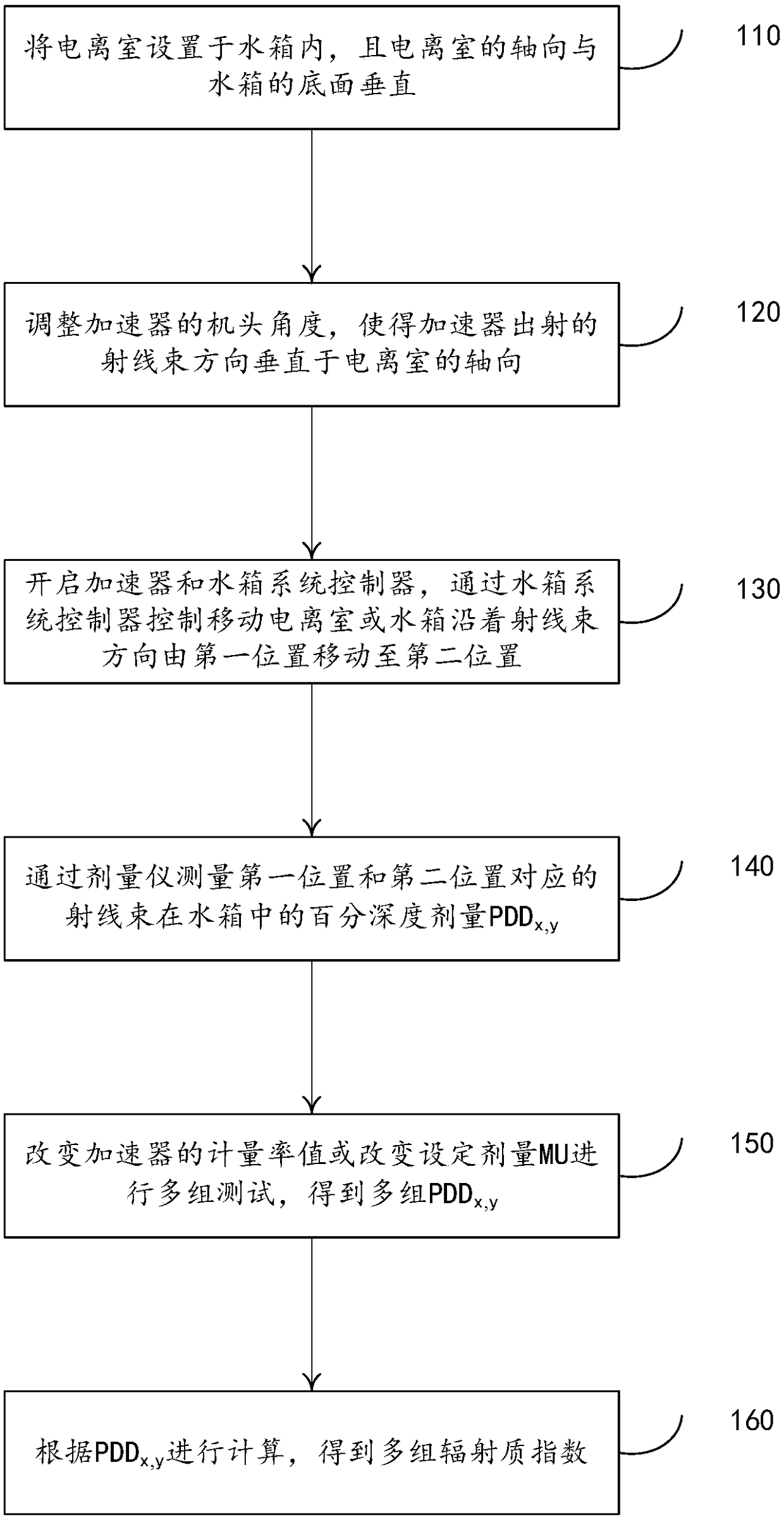

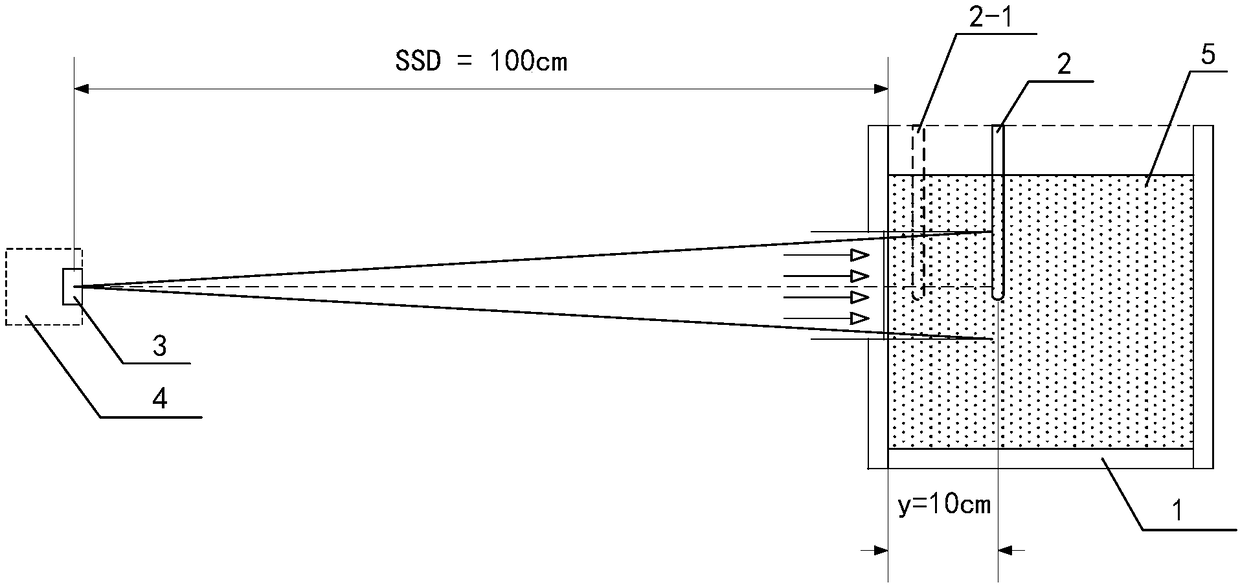

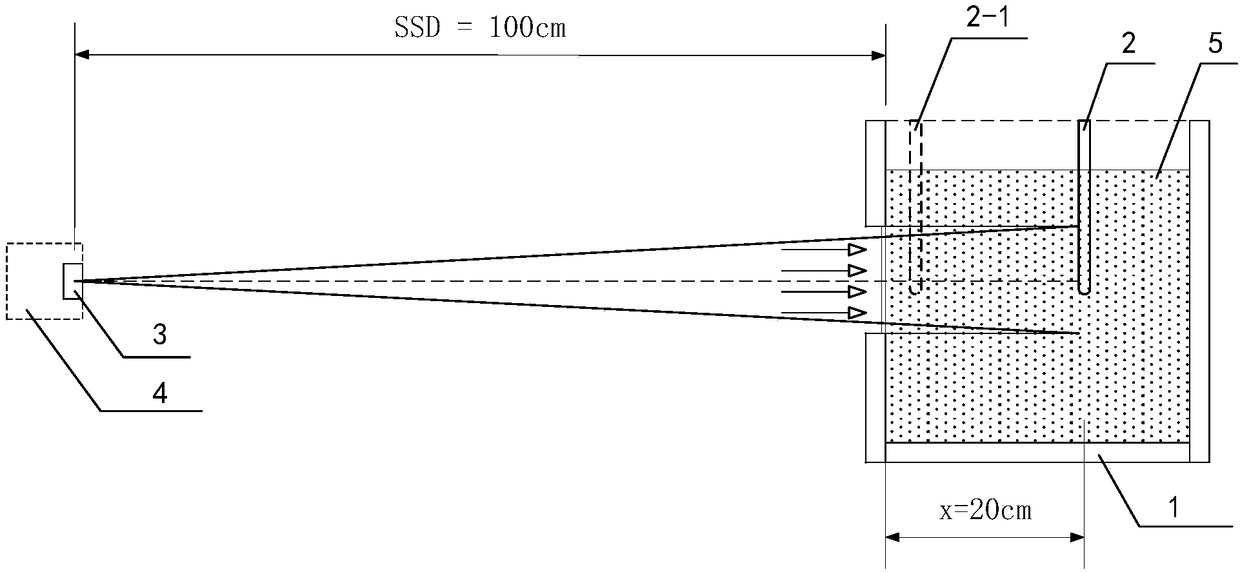

Accelerator radiant matter measurement method

InactiveCN108333621AAccuracy conforms toReduce mistakesX/gamma/cosmic radiation measurmentDosimeterDose rate

The invention relates to an accelerator radiant matter measurement method. The measurement method comprises the steps of disposing an ionization chamber in a water tank, wherein the axial direction ofthe ionization chamber is perpendicular to the bottom face of the water tank; adjusting the angle of a machine head of an accelerator, so that the direction of ray beams emitted by the accelerator isperpendicular to the axial direction of the ionization chamber; turning on the accelerator and a water tank system controller, and controlling the ionization chamber or the water tank to move from afirst position to a second position in the direction of the ray beams through the water tank system controller; measuring the percent depth dose PDDx and the percent depth dose PDDy of the ray beams corresponding to the first position and the second position in the water tank through a dosimeter, wherein x and y are thicknesses of water molds corresponding to the first position and the second position respectively; changing a dose rate value of the accelerator or changing a set dose MU for performing multiple groups of tests to obtain multiple groups of PDDx and PDDy; performing calculation according to PDDx and PDDy to obtain multiple groups of radiant matter indexes, wherein the radiant indexes are tissue phantom ratios TPRx and TPRy.

Owner:NAT INST OF METROLOGY CHINA

A thermoelectric battery pack

ActiveCN105957953BEffective anti-vibrationEffective impact resistanceThermoelectric device detailsThermodynamicsSpot welding

Owner:上海松芝酷能汽车技术有限公司

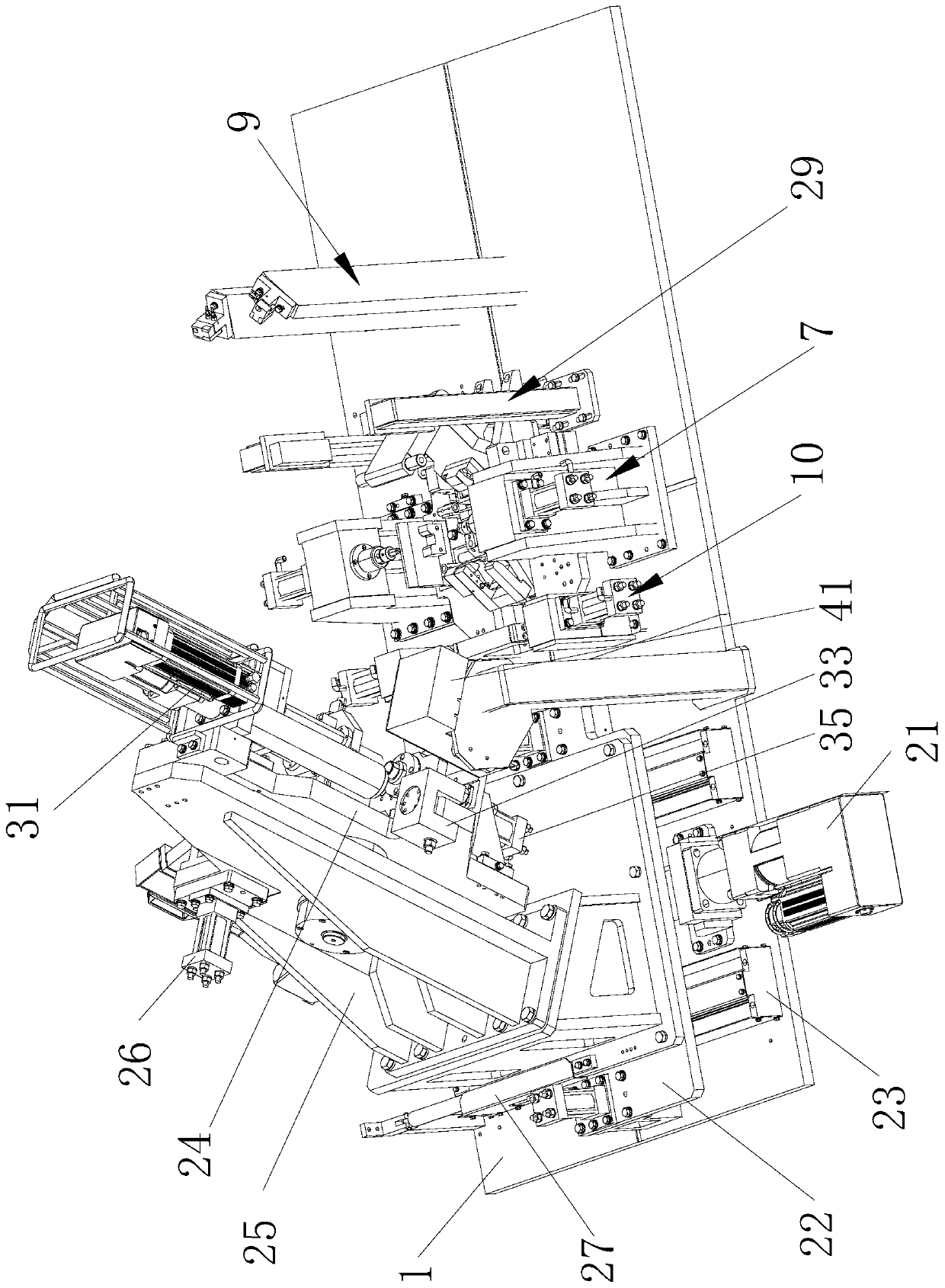

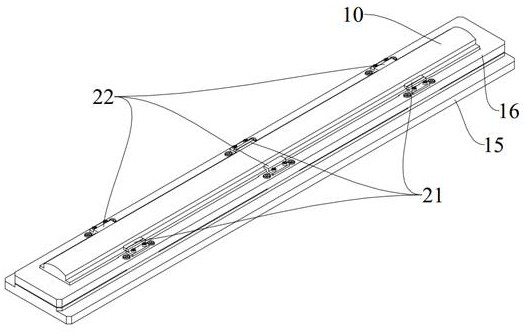

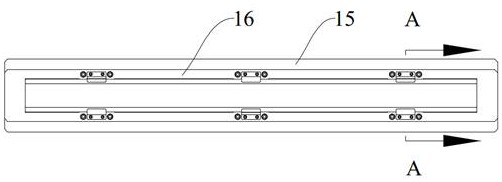

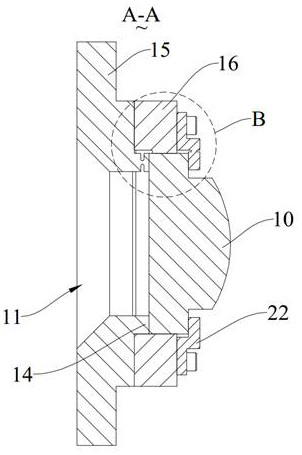

On-site processing method and equipment for generator yoke laminations

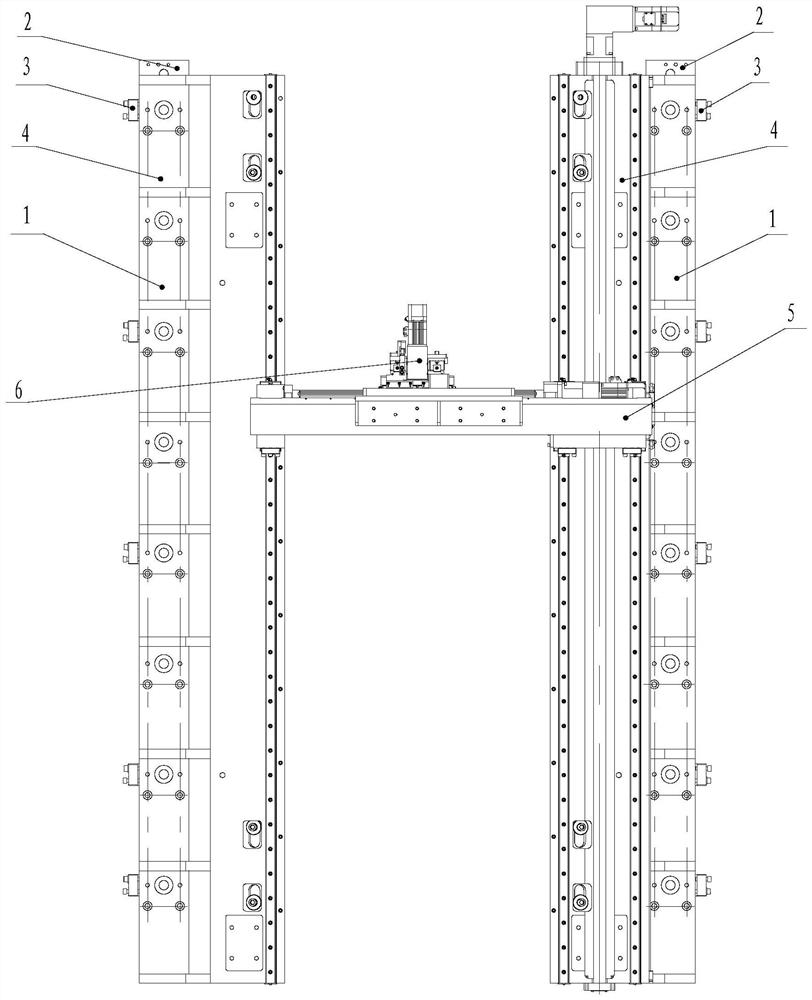

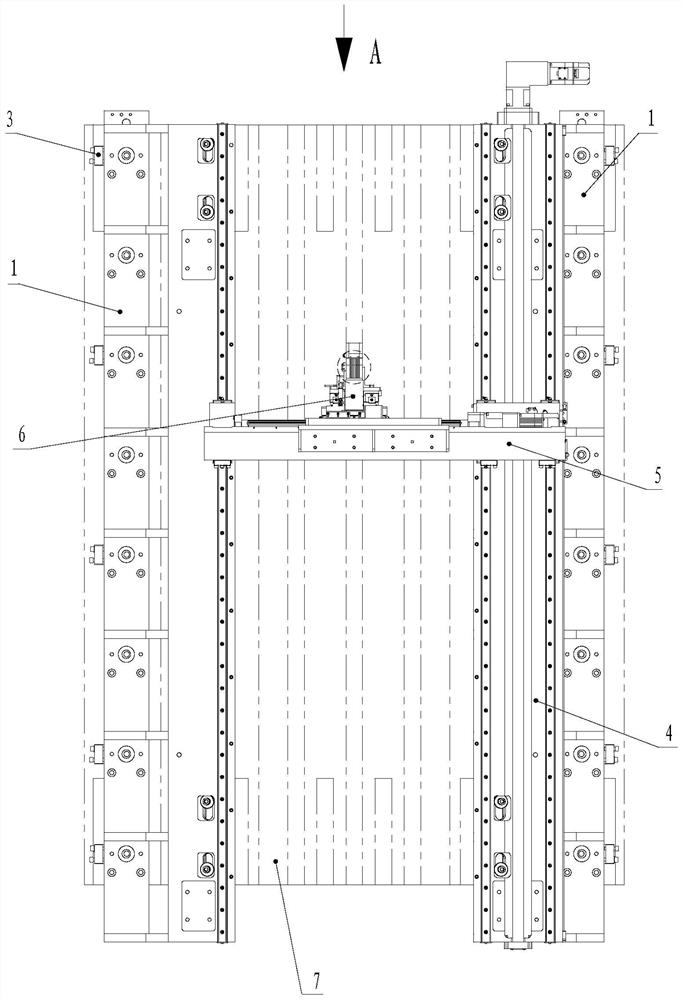

ActiveCN110890814BSolve the technical problems of processingAvoid dangerous accidentsManufacturing stator/rotor bodiesRotor magnetsMagnetic poles

The invention discloses an on-site processing method and equipment for generator magnet yoke laminations. The device mainly comprises a device foundation base, foundation bottom plates and adjusting blocks are installed on the device foundation base located on the two sides of the device and used for fixedly installing axial transmission assemblies, tangential transmission assemblies are installedon the axial transmission assemblies on the two sides, and radial transmission assemblies are installed in the middles of the tangential transmission assemblies; a plurality of basic tensioning assemblies are installed in grooves in the two sides of the to-be-machined rotor magnet yoke and used for integrally installing and fixing equipment. The beneficial effects of the invention are that the method effectively avoids the possible dangerous accidents after the dislocation of the generator rotor magnet yoke, and can achieve the high-precision restoration of the generator without the need of lifting the rotor out of the generator foundation pit; for a newly-installed generator, high-precision machining can be directly carried out on the magnet yoke on site, and the technical problem of magnet yoke machining is solved. Two V-shaped faces can be machined at the same time, and it is guaranteed that all the machined faces meet the slide precision and the surface quality of magnetic pole installation requirements after the to-be-formed groove is machined.

Owner:HANGZHOU FROMO ELECTROMECHANICAL TECH

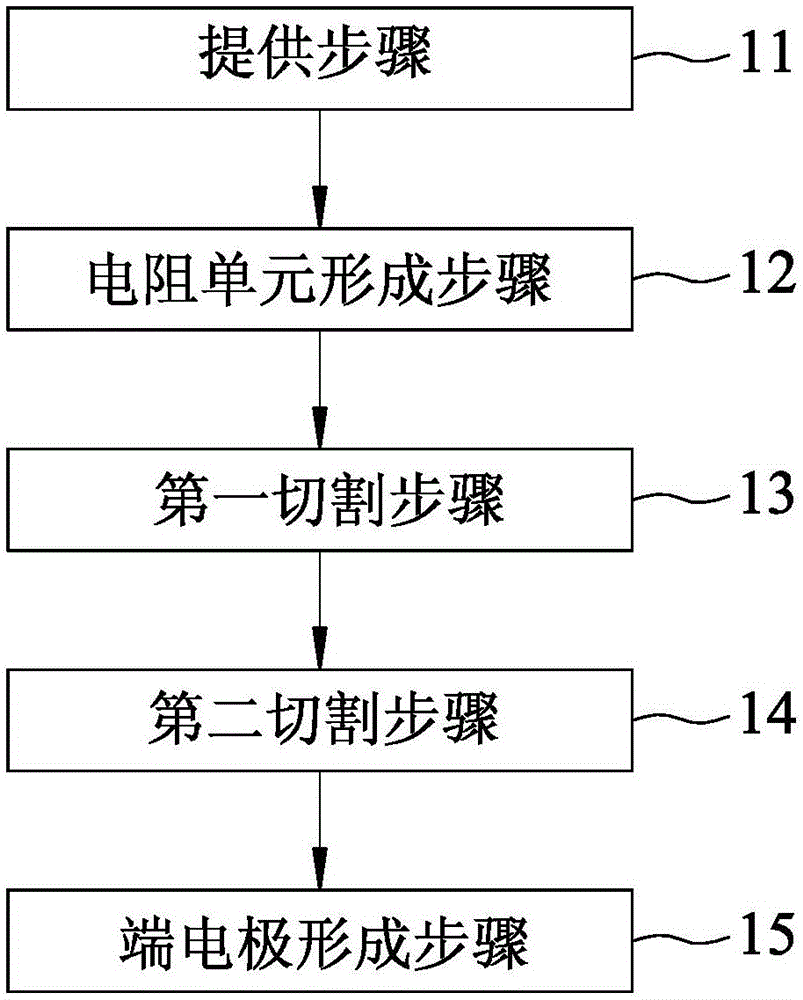

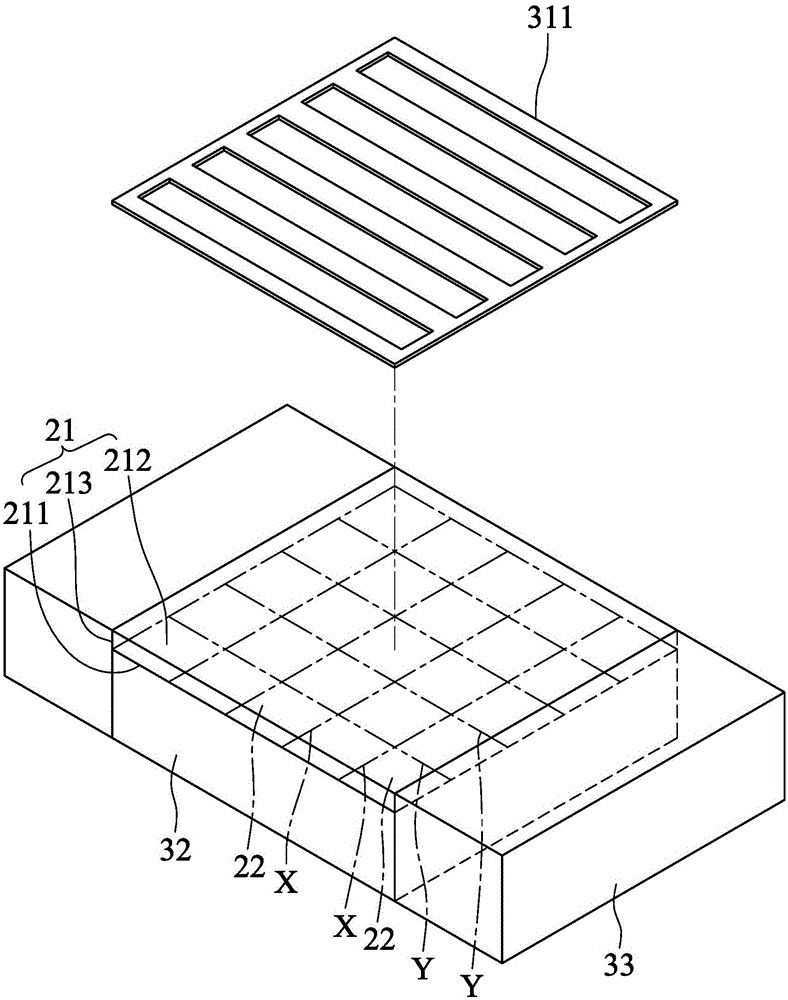

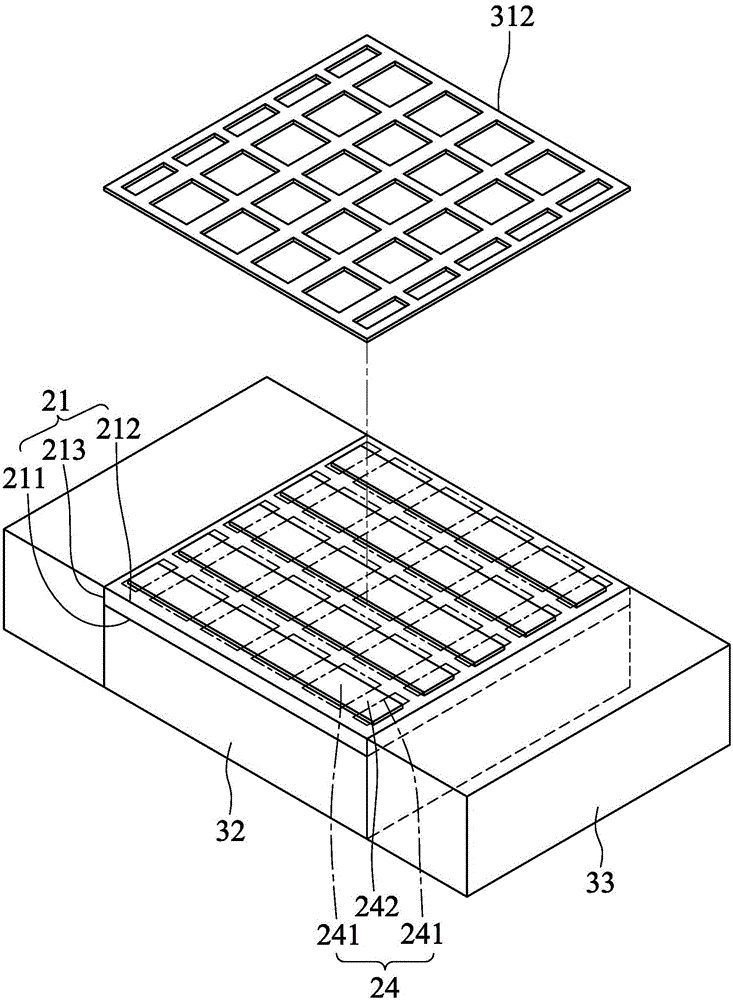

Method for manufacturing wafer type film resistor

A method for manufacturing a wafer type film resistor includes the following two steps: a providing step and a resistor unit forming step, a substrate is provided in the providing step, the substrate comprises a first surface and a second surface opposite to the first surface. The resistor unit forming step is as follows: preparing a magnetic mask having a predetermined pattern and a magnetic fixing member, and the magnetic mask and the magnetic fixing member are respectively arranged on the second surface and the first surface of the substrate, so that the magnetic mask is adsorbed and fixed on the second surface of the substrate through the magnetic fixing member, the magnetic mask masks the second surface of the substrate for sputtering for forming at least one resistor unit. In the process of sputtering deposition, the magnetic mask is attached to the substrate through the magnetic force effect so as to ensure that the shape and position of the formed resistor unit can be consistent with the accuracy.

Owner:旺詮股ふん

Method for treating gelatinized thermocouple wire

InactiveCN101660954BQuality improvementAccuracy conforms toThermometers using electric/magnetic elementsUsing electrical meansDistilled waterThermocouple Wire

The invention relates to a method for treating a gelatinized thermocouple wire, comprising the following sequential steps: firstly, the gelatinized thermocouple wire penetrating through a silica tube is thermally treated at the temperature of 400-500 DEG C for 50-70 minutes by using a thermal treatment thermocouple wire; secondly, the thermocouple wire is drawn out to cause silicon rubber losing elasticity to fall off; and thirdly, the thermocouple wire is cleaned, wherein (1) the drawn-out thermocouple wire is boiled for 25-35 minutes by using sodium hydroxide solution of 8-12 percent mass fraction, (2) the thermocouple wire treated by using alkali is boiled for 25-35 minutes by using hydrochloric acid solution of 8-12 percent mass fraction, (3) the thermocouple wire treated by using acid is repeatedly boiled by using distilled water for at least three times, each time for 25-35 minutes, and (4) the cleaned thermocouple wire is dewatered at the temperature of 60-80 DEG C; and finally, the treated thermocouple wire together with a standard thermocouple wire is examined. The method for treating the gelatinized thermocouple wire can recover thermocouple wires.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com