On-site processing method and equipment for generator yoke laminations

A yoke lamination and on-site processing technology, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve problems such as enterprise losses, quality accidents, generator yoke lamination misalignment, etc., and achieve the goal of avoiding dangerous accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Embodiment: As shown in the accompanying drawings, the method for on-site processing of generator yoke laminations includes the following steps:

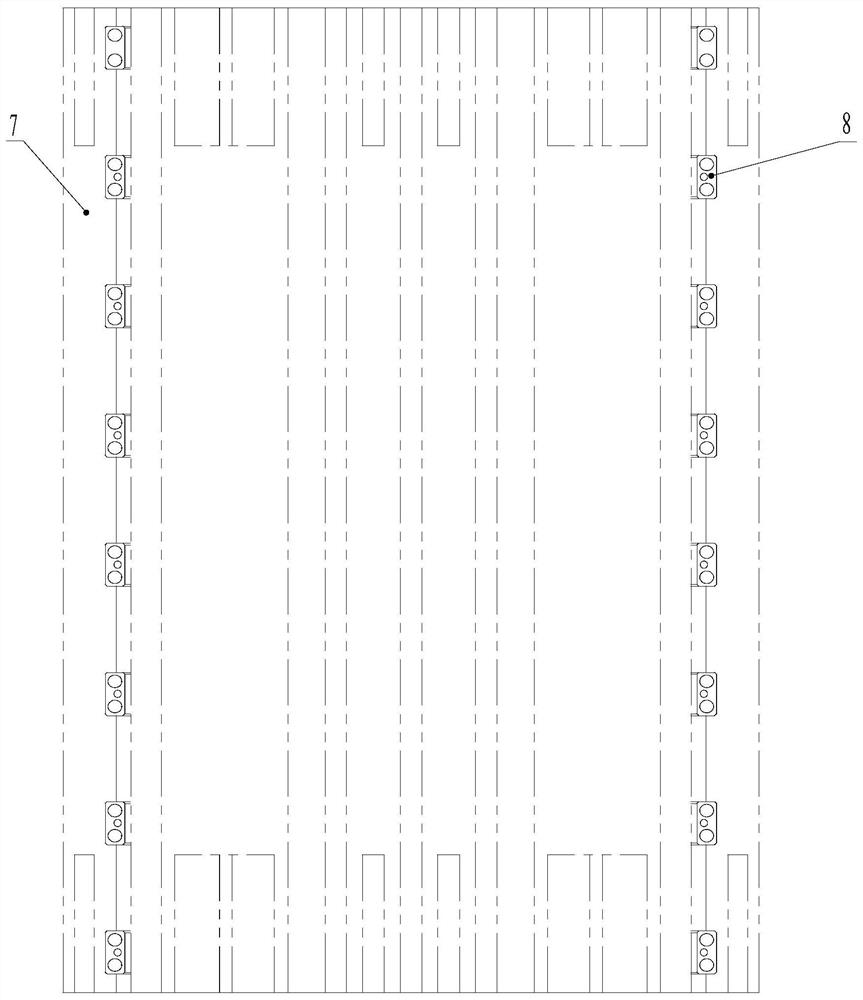

[0025] Step 1: Foundation installation: Remove all magnetic poles of the generator rotor to be processed to facilitate the processing of the equipment in the foundation pit, select the position to be processed of the rotor yoke 7 to be processed, and groove 7-1 on both sides of the rotor yoke 7 to be processed A certain number of foundation tensioning components 8 are installed inside, as attached figure 1 As shown, in the present embodiment, 8 pieces are evenly distributed on each side;

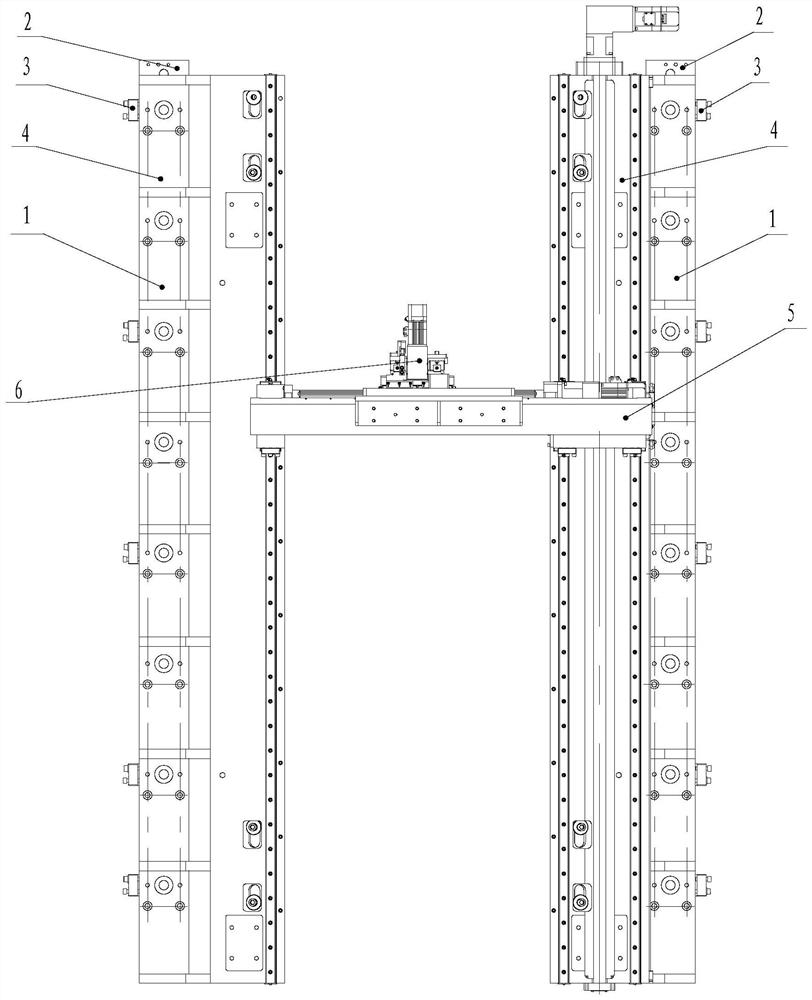

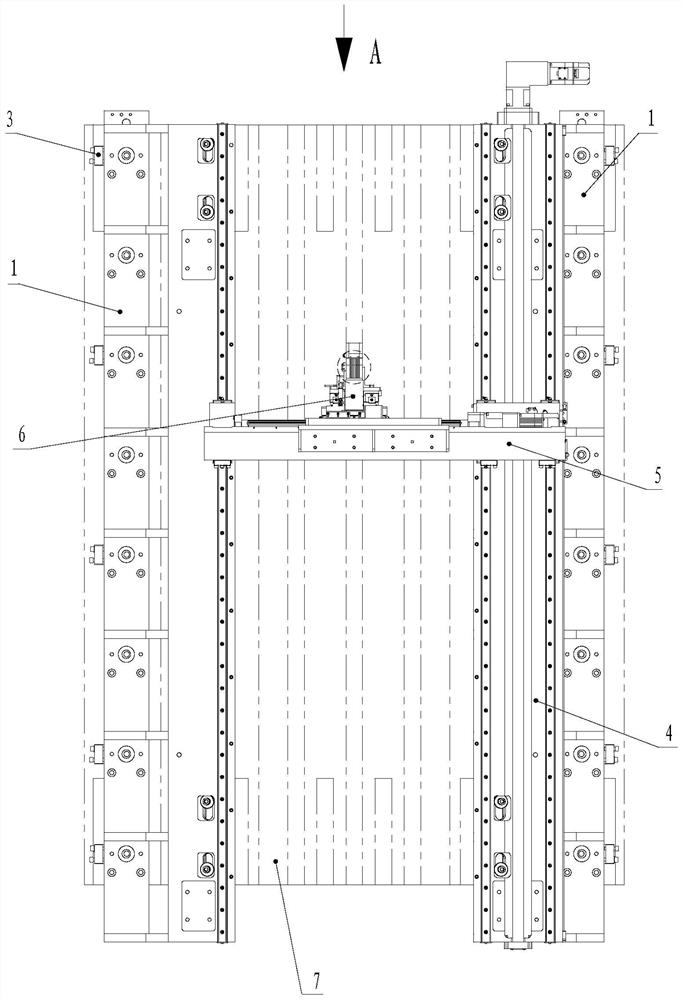

[0026] Step 2: Component installation: Install the base plate 2 and the adjustment block 3 on both sides of the equipment base 1 outside the generator foundation pit in advance, and integrate with the axial transmission component 4 on the equipment base 1; A tangential transmission assembly 5 is installed on the axial transmission assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com