Machining method for special-shaped structure sealing groove of angular contact bearing

A technology for angular contact bearings, machining methods, used in metalworking equipment, manufacturing tools, boring/drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] 1. The technical route of the bearing ring.

[0018] Turning → heat treatment → initial grinding cycle → first additional tempering → fine grinding cycle → second additional tempering → return to the car seal groove → final grinding cycle → superfinishing.

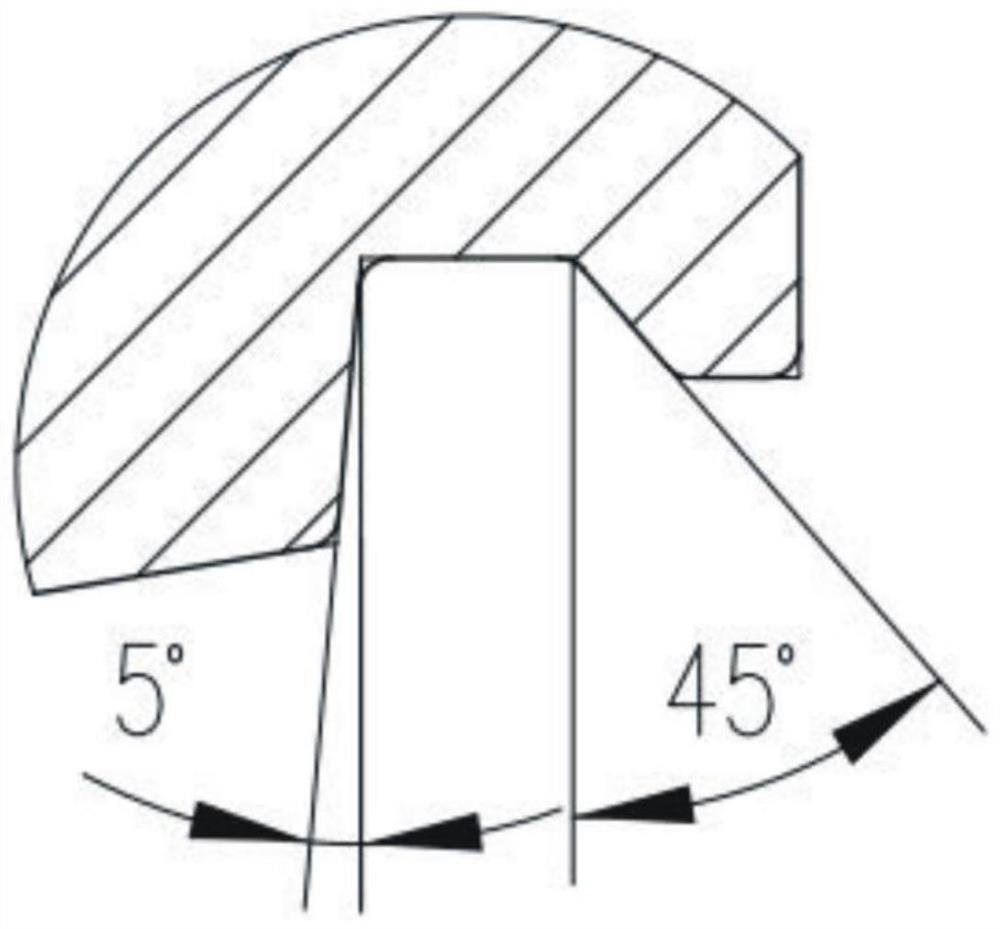

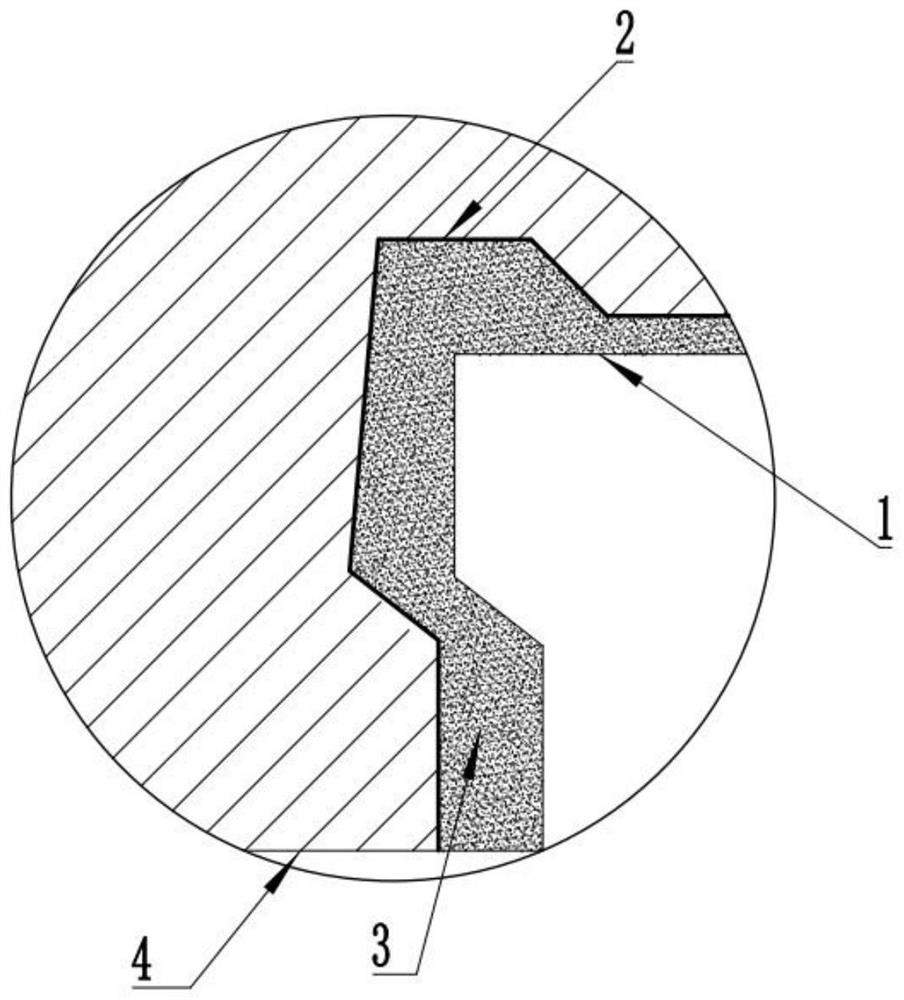

[0019] Two, reference image 3 , when the bearing ring is turned, two inner steps are symmetrically processed on both sides, that is, the processing contour 1 before heat treatment and the required sealing groove contour 2.

[0020] 3. The processing of the return seal groove includes the following steps.

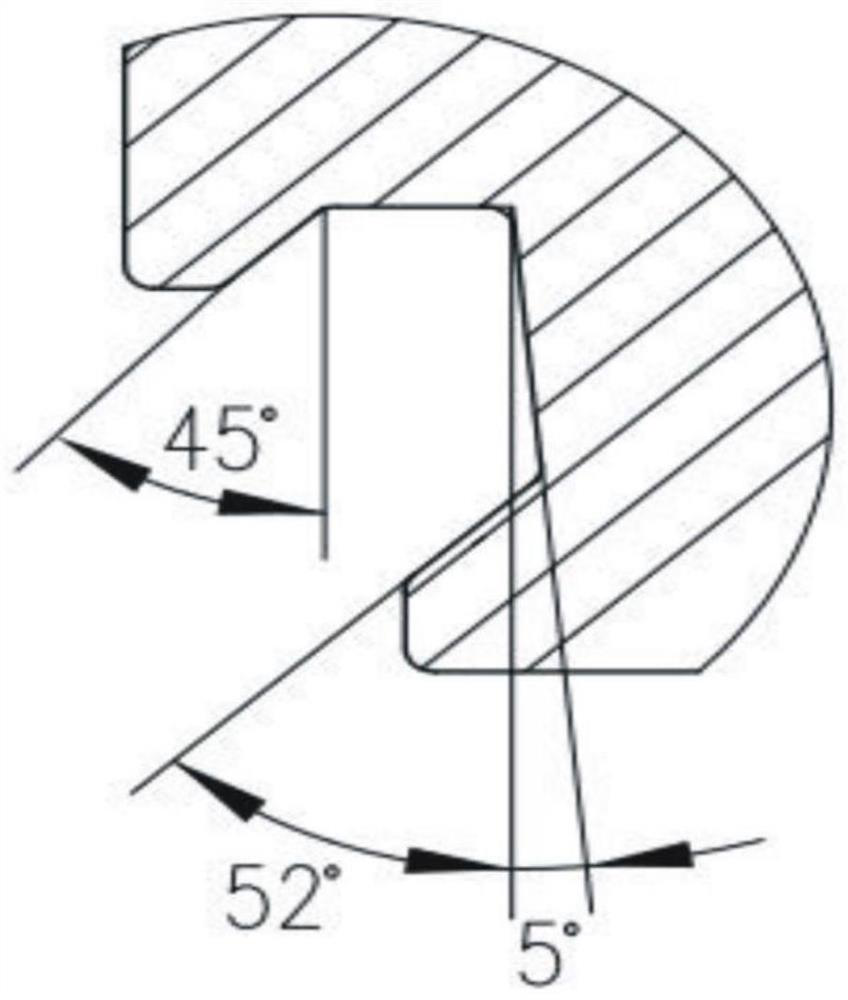

[0021] 1. Reference Figure 4 , the first step is to install a 35° rhombic blade 8 on the boring tool bar 5 with a 93° lead angle to process the end face in the inner diameter direction of the sealing groove. Allowance to avoid interference in post-process processing.

[0022] 2. Reference Figure 5 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com