U-shaped channel deformation precision monitoring system based on wireless sensor network

A wireless sensor network and monitoring system technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of increased monitoring error, increased time and money costs, and reduced system sensitivity, etc., to achieve rich specifications for external expansion, flexible and diverse interfaces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solution of the U-shaped channel deformation precision monitoring system based on the wireless sensor network provided by the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

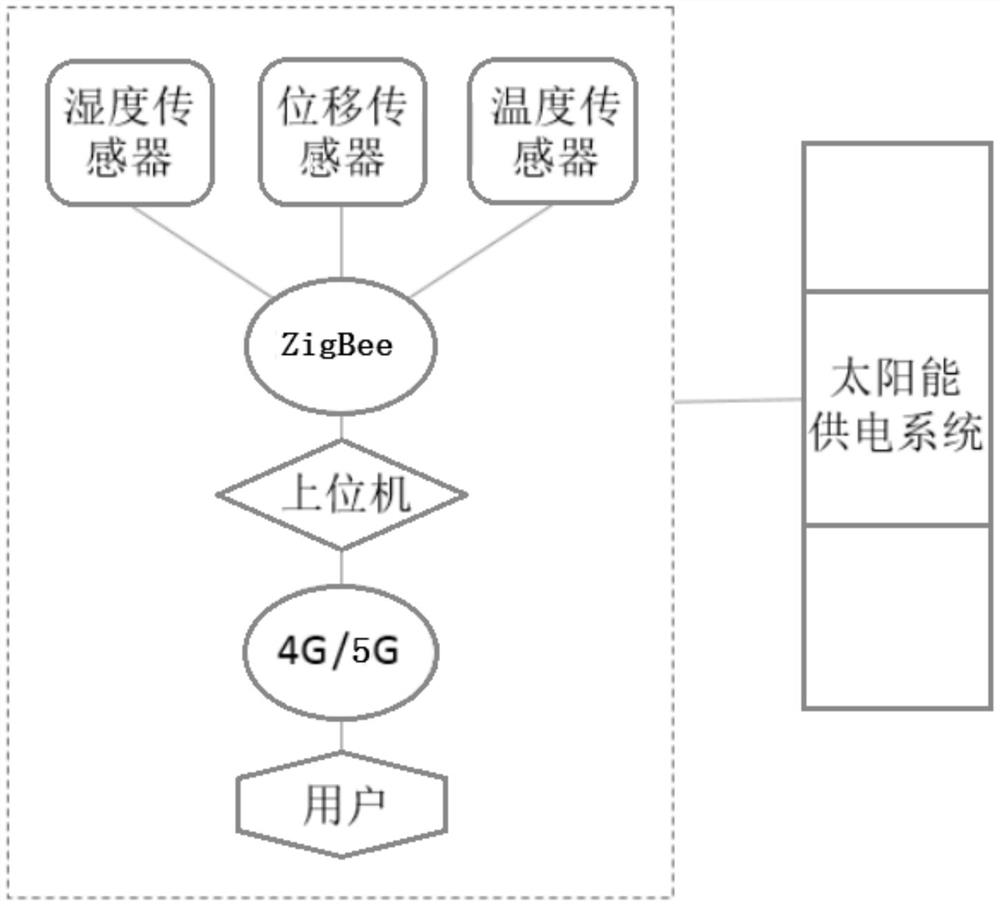

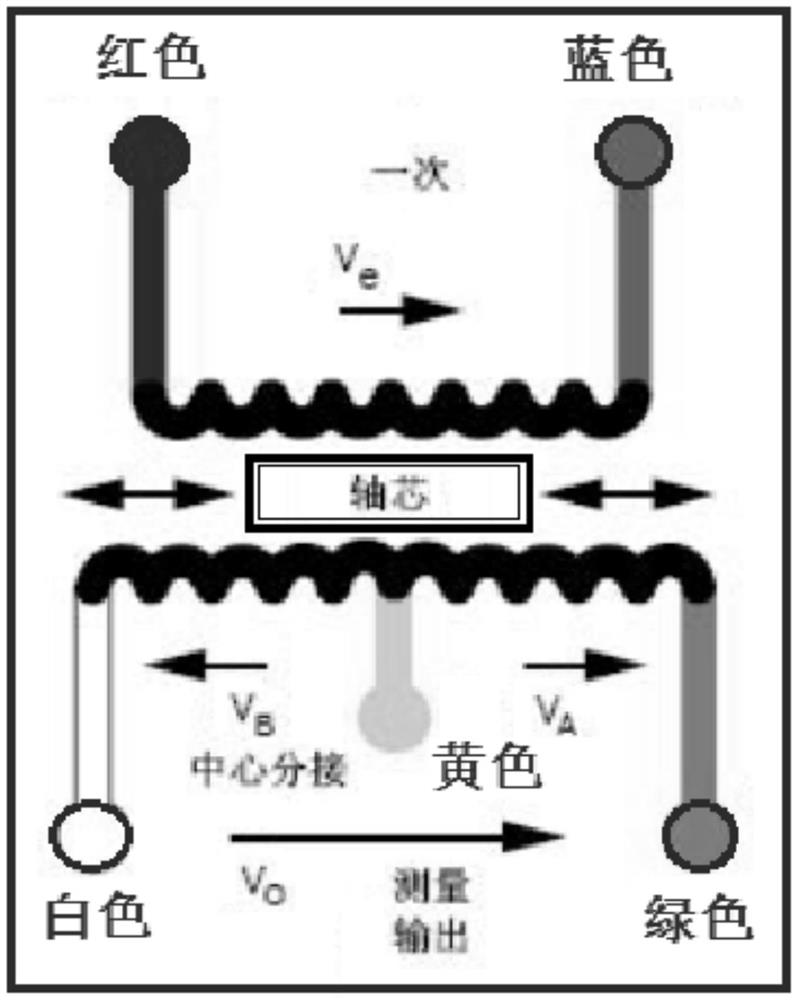

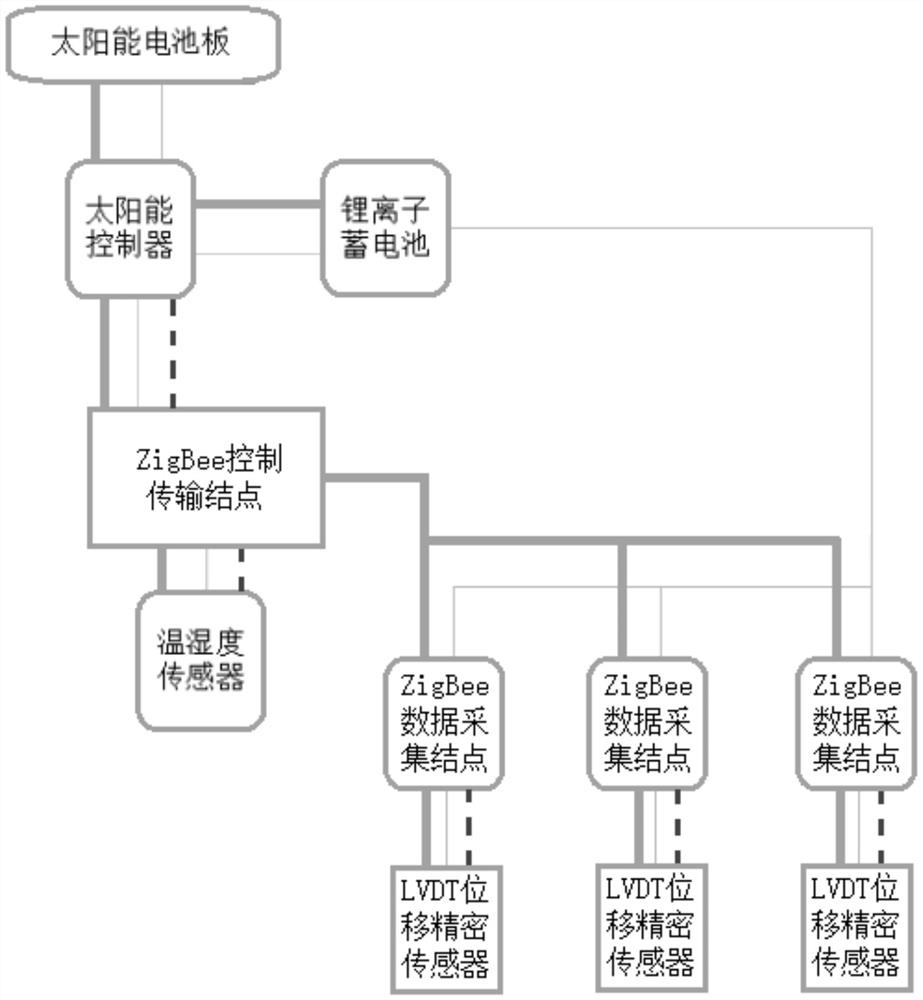

[0069] The present invention provides a set of ZigBee protocol-based wireless sensor network U-shaped canal deformation precision monitoring system, which has flexible and diverse interfaces, rich specifications for external expansion, can carry multiple types of sensors, build a wireless network by itself, and has self-repair capabilities for network failures. Install an industrial computer with data storage, processing, and collection capabilities locally, and connect to the 4G / 5G network on the industrial computer, and realize information exchange and system control with the remote control center through the mobile Internet. At the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com