Wind speed accuracy controlling method and system of transonic-speed wind tunnel

A precision control, transonic technology, applied in the field of aerospace, can solve the problem of wasting train trips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

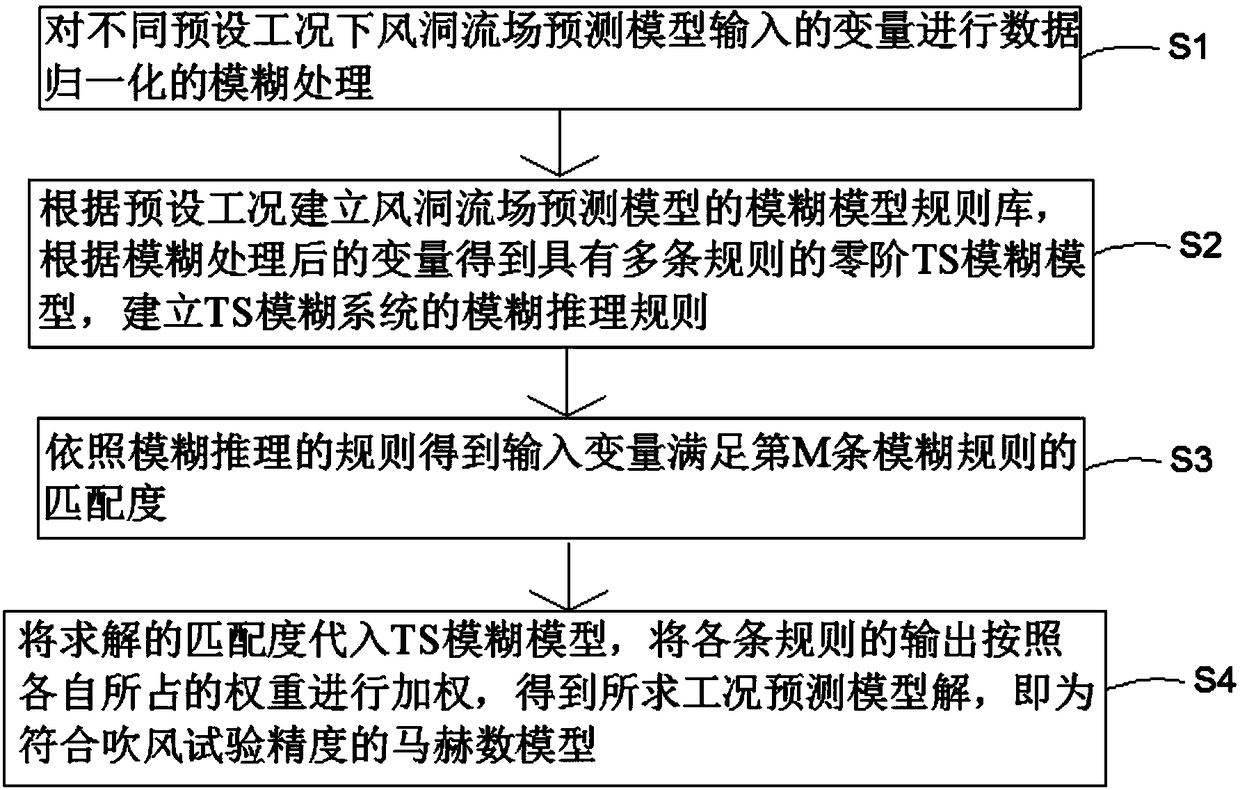

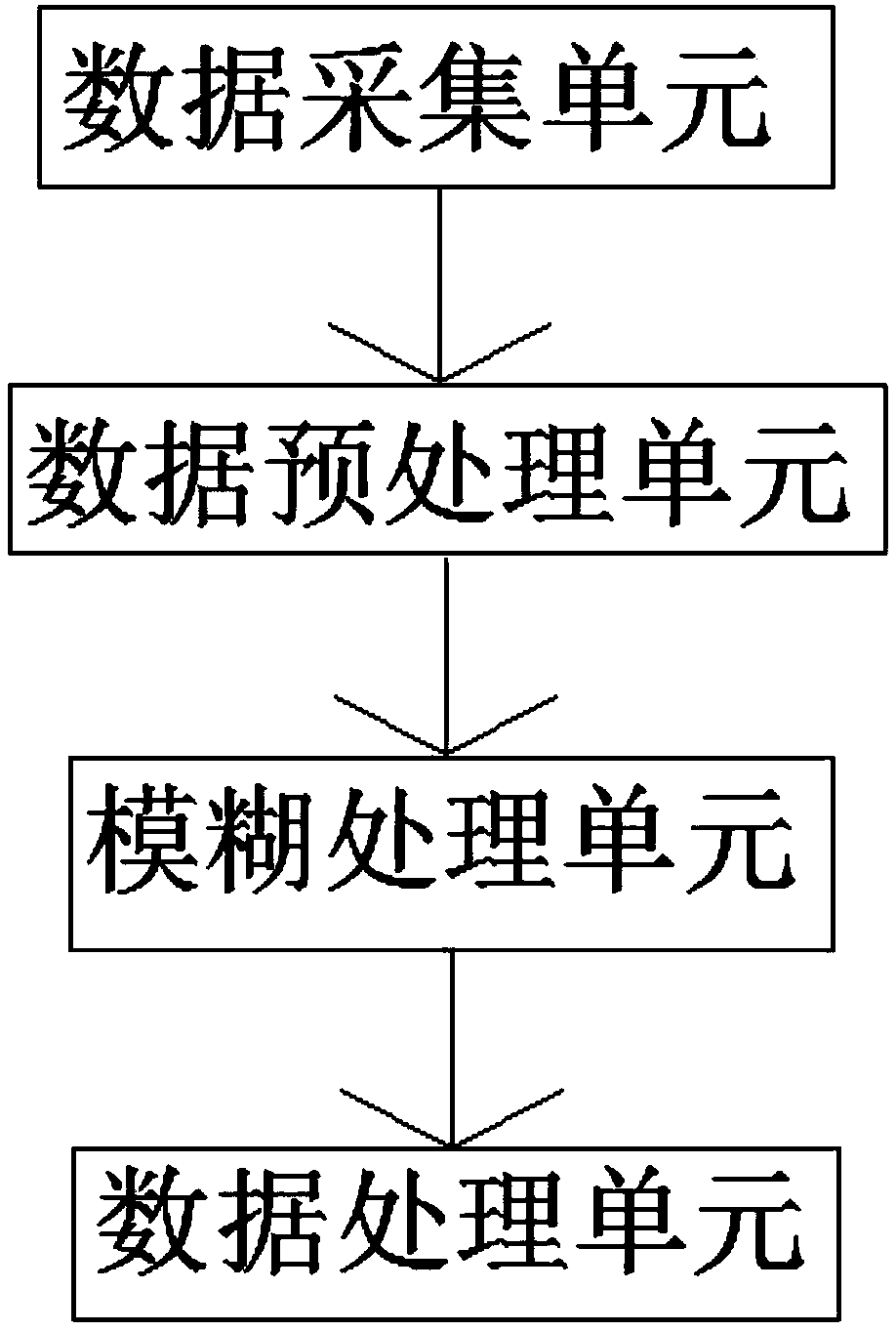

Method used

Image

Examples

Embodiment 1

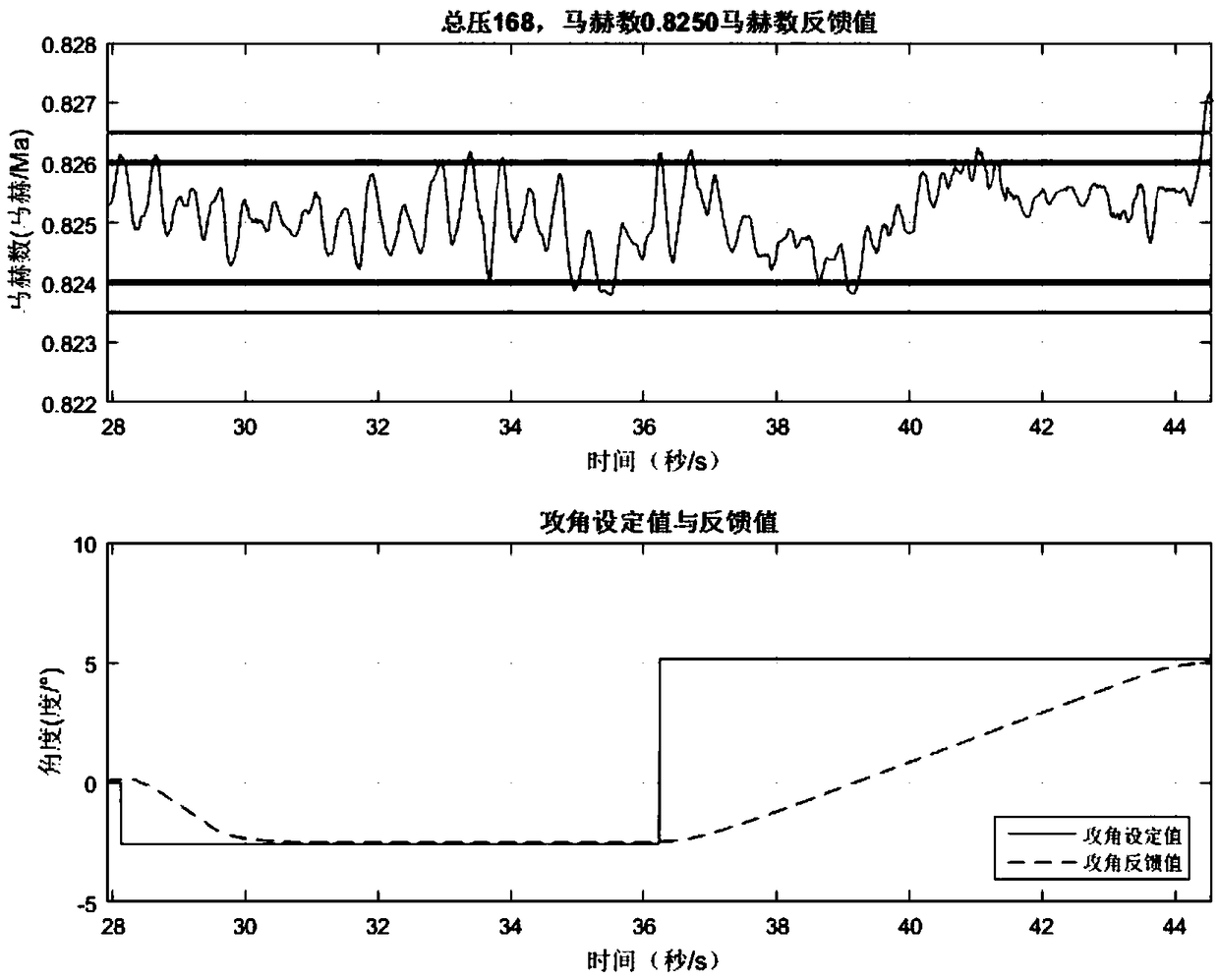

[0090] According to the rule base model, it is estimated that the total pressure / static pressure is 168KPa, and the new working condition of Mach number is 0.825. The input eigenvector of the new case is described as X m ={168,0.8250,520,-23.25,2}, from the above method, it can be obtained that the estimated new working condition prediction model solution is y 0 .

[0091] In order to verify the practicability of the estimated model, the dynamic matrix control method based on the estimated model is used to control the wind tunnel flow field, and the control effect is as follows image 3 shown.

[0092] During the blowing test, the angle of attack was continuously changed from 0° to -2.5° to 5°, and the Mach number was basically kept within the error band of 0.002. The test performance indicators are shown in Table 1

[0093]

[0094] Table 1

[0095] It can be seen from the test performance indicators that the average value of the Mach number is stable at 0.8253 during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com