Method for treating gelatinized thermocouple wire

A technology of thermocouple wire and processing method, which is applied in the direction of using thermometers that are directly sensitive to heat electrical/magnetic components, measuring heat, using electrical devices, etc., can solve problems such as waste and scrap, and achieve the effect of eliminating serious waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

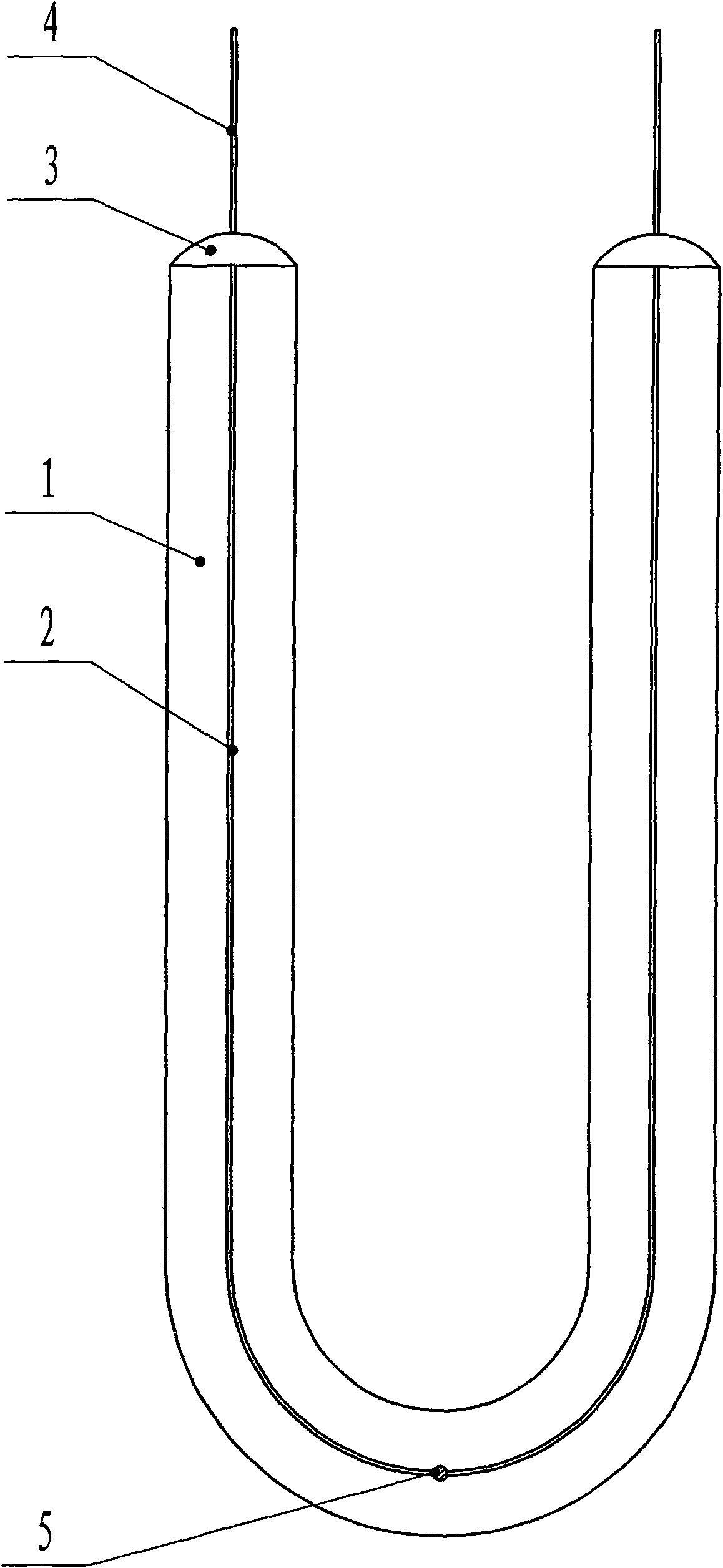

Image

Examples

Embodiment 1

[0038] The processing method embodiment of this gluing thermocouple wire is the following sequential steps:

[0039] A heat-treated galvanic wire

[0040]Put 400 glue-coated galvanic wires through quartz tubes into a quartz glass container, and place them in a constant temperature furnace at 450°C for heat treatment for 60 minutes.

[0041] Two, pull out the galvanic wire

[0042] The heat-treated quartz glass container and the glued galvanic wire are taken out of the constant temperature furnace, and the silicone rubber is pinched into yellow powder with fingers to make it fall off, and the galvanic wire is pulled out of the quartz tube.

[0043] Three cleaning galvanic wire

[0044] (1) Put the extracted galvanic wires together into a 200 ml beaker, pour 150 ml of sodium hydroxide alkaline water with a mass fraction of 10% into the beaker and submerge the galvanic wires, heat and boil in an electric furnace for 30 minutes.

[0045] (2) Pour out the remaining alkaline wate...

Embodiment 2

[0052] The processing and cleaning method embodiment of this glue-coated thermocouple wire is the following sequential steps:

[0053] A heat-treated galvanic wire

[0054] Put 400 glue-coated galvanic wires through quartz tubes into a quartz glass container, and place them in a constant temperature furnace at 440°C for heat treatment for 60 minutes.

[0055] Two, pull out the galvanic wire

[0056] The heat-treated quartz glass container and the glued galvanic wire are taken out of the constant temperature furnace, and the silicone rubber is pinched into yellow powder with fingers to make it fall off, and the galvanic wire is pulled out of the quartz tube.

[0057] Three cleaning galvanic wire

[0058] (1) Put the extracted galvanic wires together into a 200 ml beaker, pour 150 ml of sodium hydroxide alkaline water with a mass fraction of 10% into the beaker and submerge the galvanic wires, heat and boil in an electric furnace for 30 minutes.

[0059] (2) Pour out the rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com