Testing method for components of combustion gas of gunpowder

A test method and combustion gas technology, which is applied in chemical analysis by combustion, analysis of gas mixture, and measurement devices, etc., can solve the problem of test environment, test conditions are greatly affected, the initial conditions of test sample combustion are not easy to control, and the gas generated by combustion is not stable. Stability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is further explained and illustrated by the following examples.

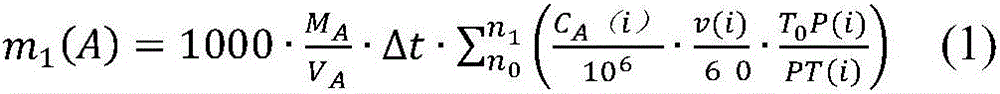

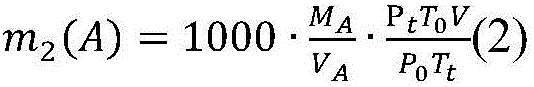

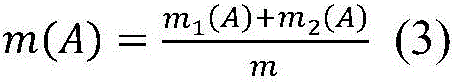

[0048] According to the characteristics of propellant combustion gas composition quality testing, the method includes the determination of test samples, the preparation of initial combustion conditions, the combustion of test samples and gas mixing, the measurement of the concentration of gas components in the mixed gas and related parameters, the preservation of test data and the treatment of test tail gas, and the test There are seven steps in data processing and measurement result characterization.

[0049] Step one, test sample preparation. Weigh a certain mass of gunpowder test sample, place the test sample on the sample bracket of the bearing bracket in the closed combustion chamber, pass the ignition wire through the test sample and fix it on the ignition terminals on both sides of the sample bracket, and fix the bearing bracket At the bottom of the closed combustion chamber,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com