Patents

Literature

86results about How to "Comprehensive representation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

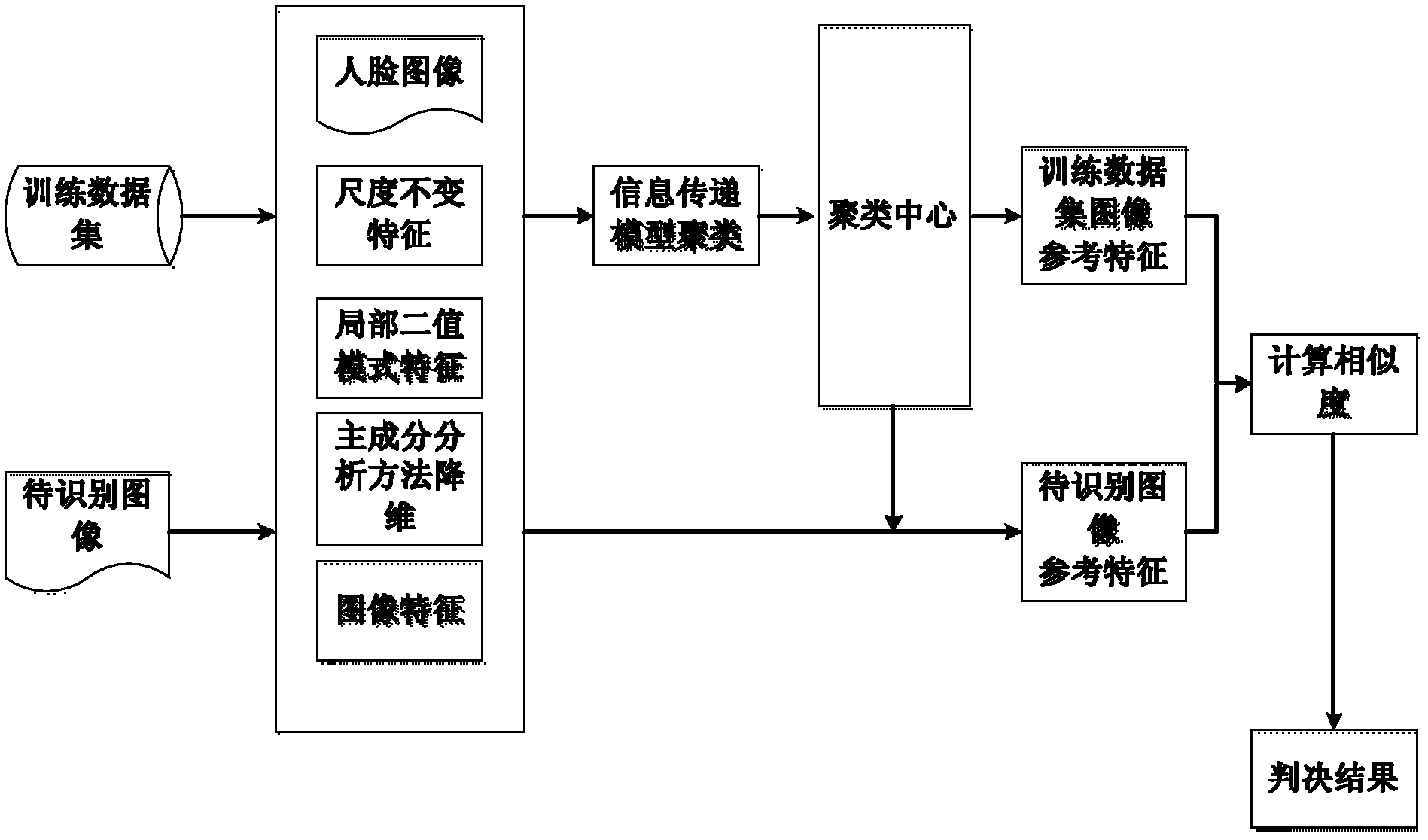

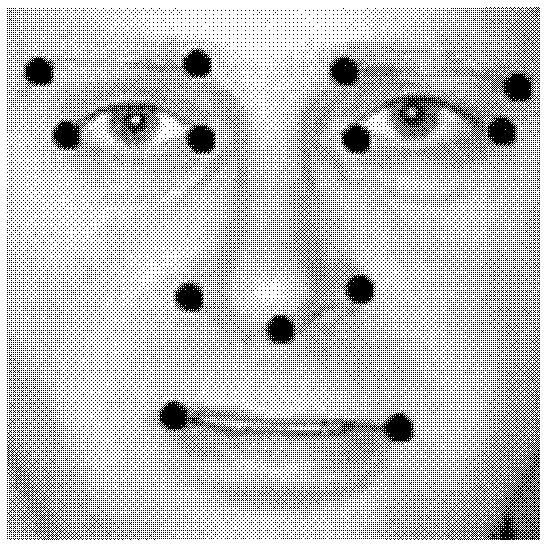

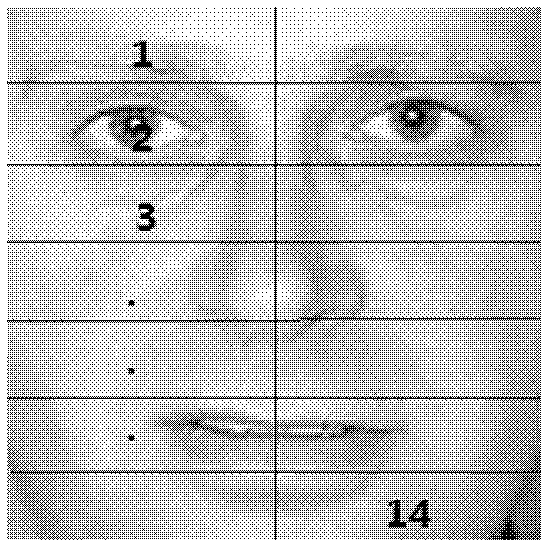

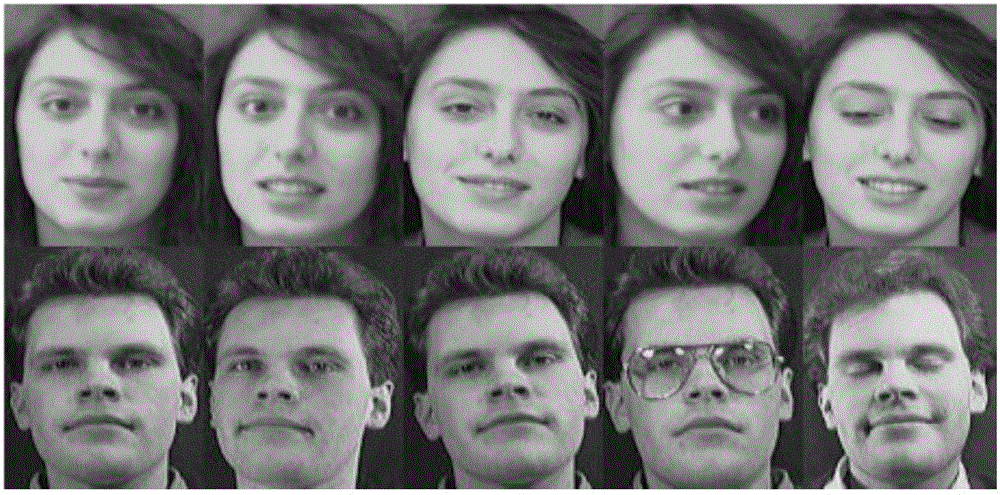

Face recognition method based on reference features

ActiveCN102637251AComprehensive representationSimplify the feature extraction processCharacter and pattern recognitionKernel principal component analysisPrincipal component analysis

The invention discloses a face recognition method based on reference features. The method comprises the following steps that: scale invariant features and local binary pattern features of a face image to be recognized are extracted; a principal component analysis method is utilized for dimensionality reduction to obtain the image features of the face image to be recognized; the similarity of the image features to a cluster center is calculated by utilizing the obtained image features to obtain the reference features of the face image to be recognized; and the similarity of the reference features of the face image to be recognized and the reference features of training data concentration is calculated to obtain an analysis result. The reference features of the face image provided by the invention comprise texture information and structure information of the face image, so that the method provided by the invention can more comprehensively represent the face compared with the method in the prior art, which only represents the texture information or the structure information of the face. The process of feature extraction is simple and easy to realize; the recognition result is highly precise; high recognition rate of different facial gestures of the same person is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

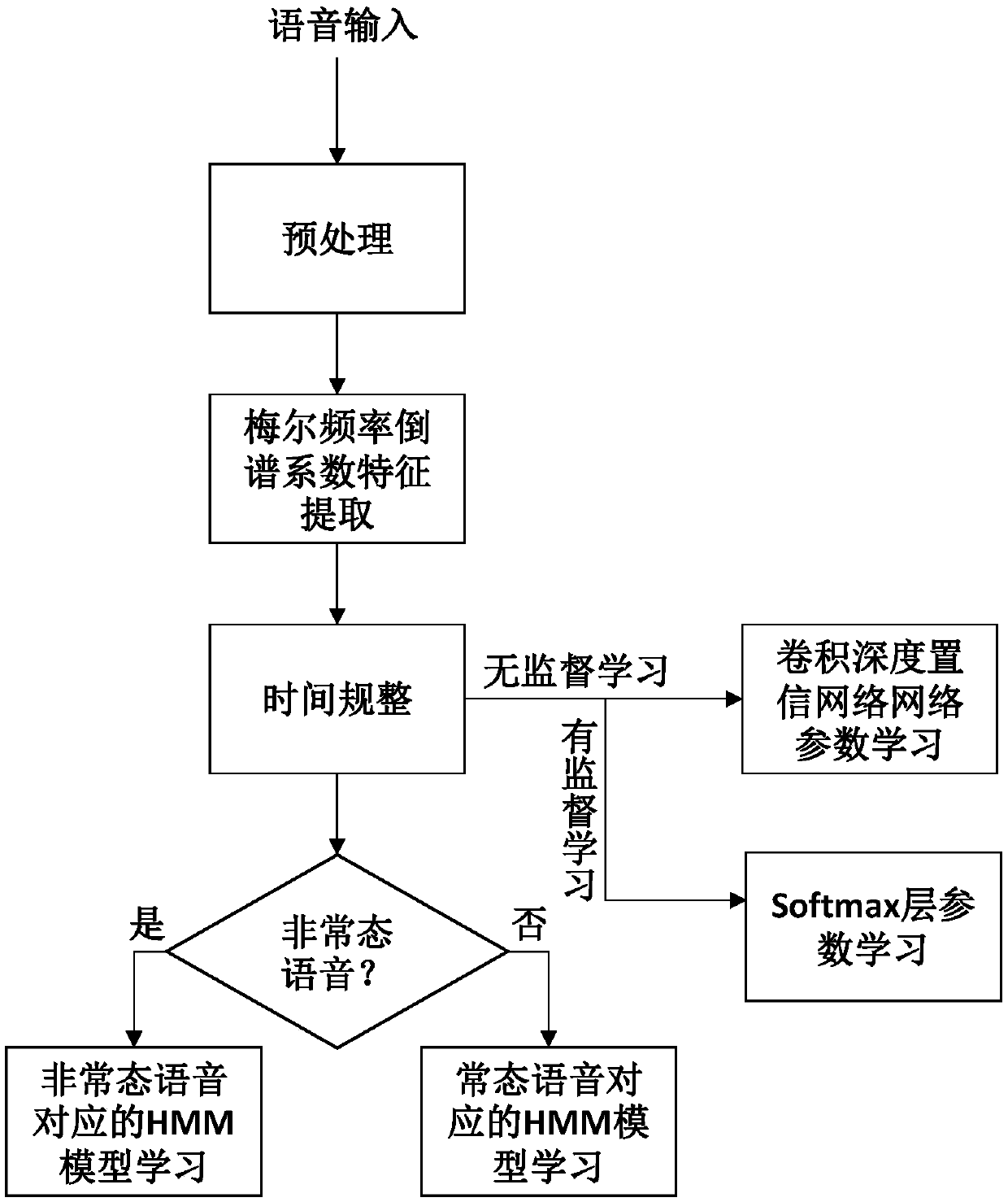

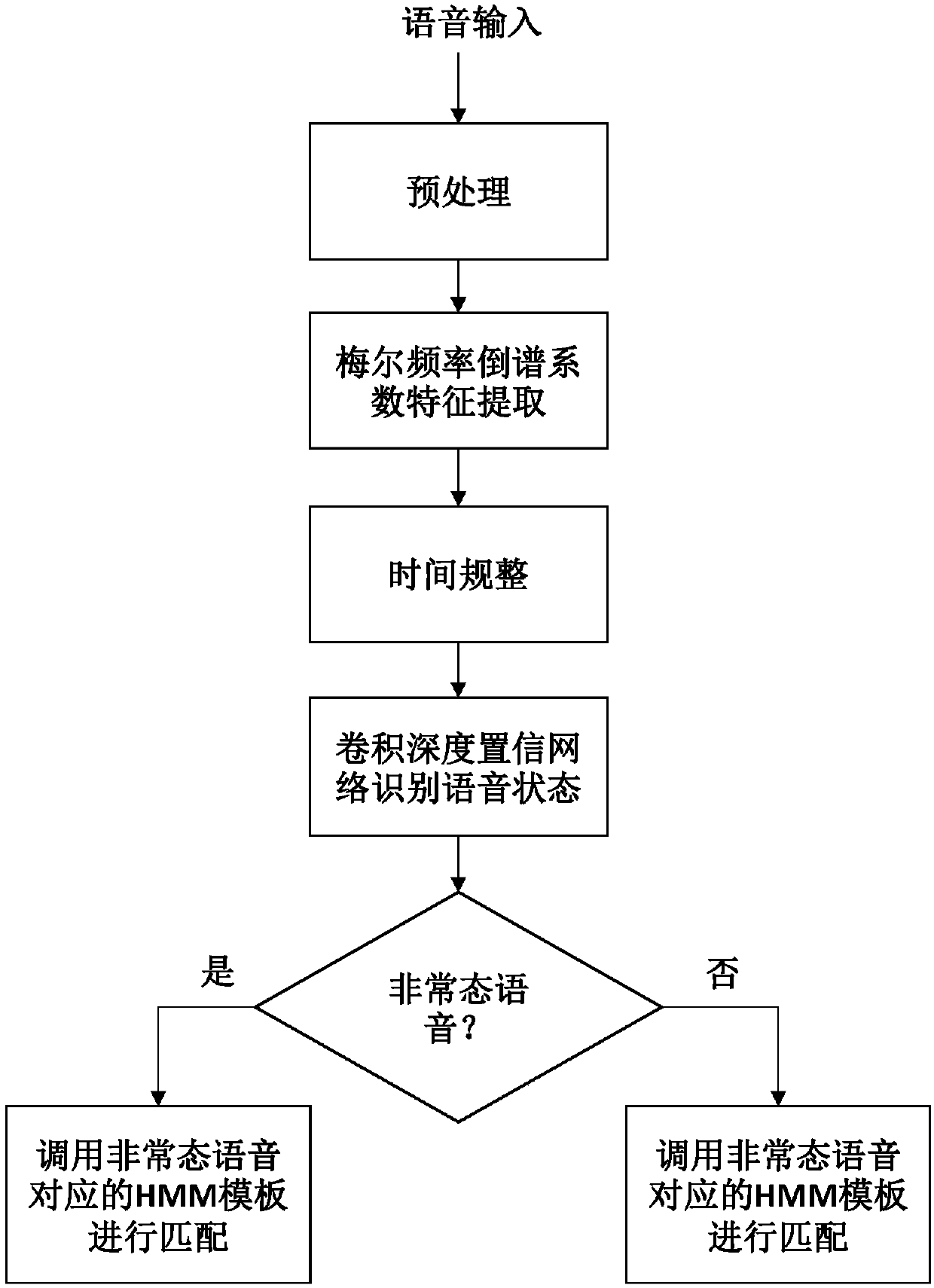

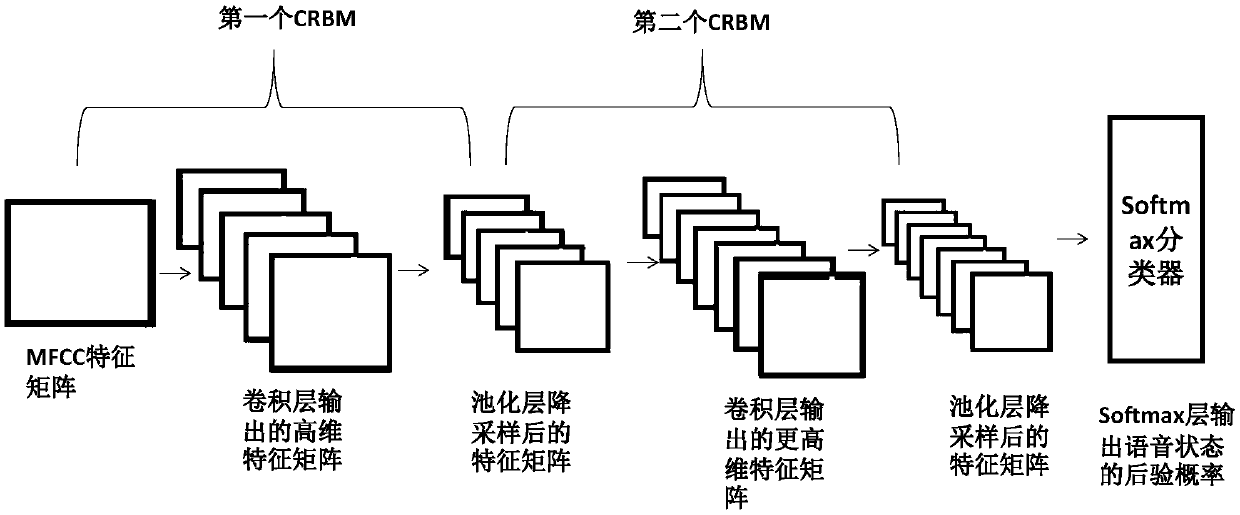

Deep learning-based unusual speech distinguishing method

ActiveCN108766419AComprehensive representationImprove recognition accuracySpeech recognitionTemplate matchingHide markov model

The invention discloses a deep learning-based unusual speech distinguishing method. The method comprises the following steps: input speech is acquired, resampling, pre-emphasis and framing and windowing preprocessing are carried out on the input speech, and preprocessed speech is obtained; a mel-frequency cepstral coefficient (MFCC) characteristic vector is extracted for the preprocessed speech; the speech segments with different frames are regularized to a fixed number of frames, and each speech segment obtains a corresponding mel-frequency cepstral coefficient characteristic vector; a convolutional depth confidence network is built; the mel-frequency cepstral coefficient characteristic vectors are inputted to the convolutional depth confidence network for training, and the states of input speech are classified; and according to a classification result, a hidden Markov model is called for template matching and a speech recognition result is obtained. Multiple nonlinear transform layers of the convolutional depth confidence network are used, the inputted MFCC characteristics are mapped to higher-dimensional space, the hidden Markov model is then used to carry out modeling on different states of speech, and the speech recognition accuracy is improved.

Owner:SOUTH CHINA UNIV OF TECH

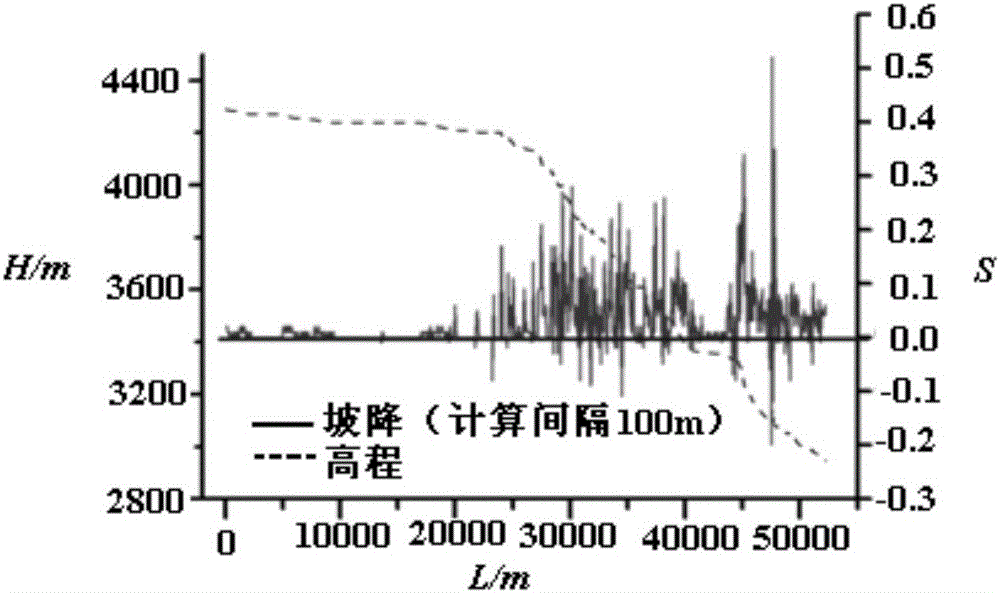

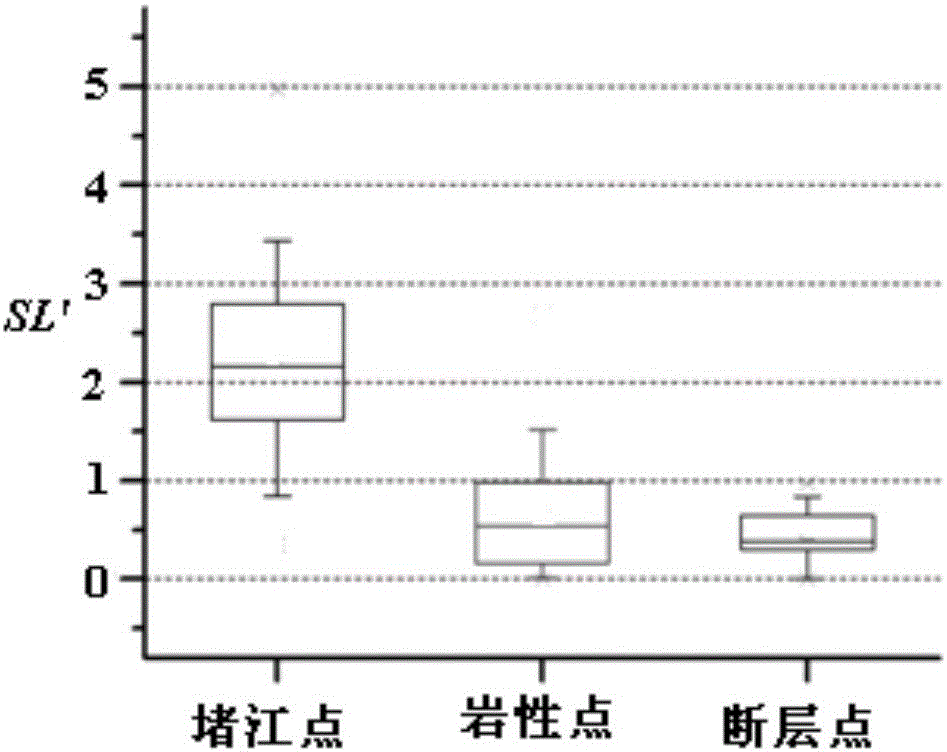

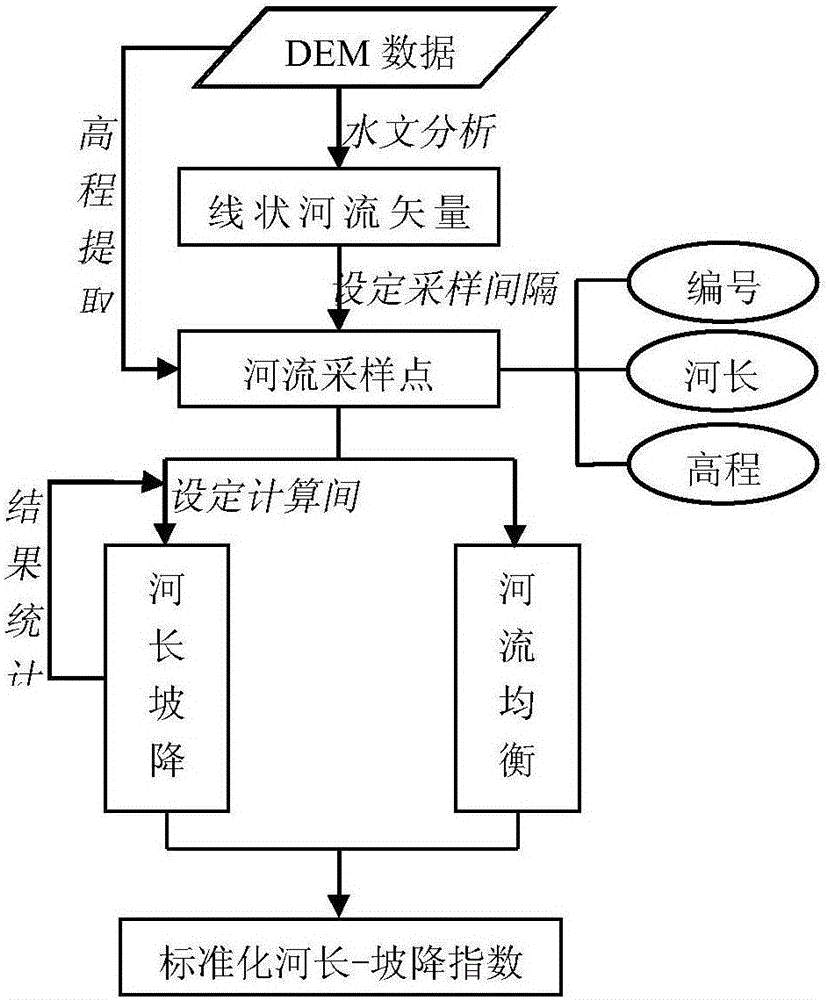

Automatically extracting method for river-valley morphological parameters based on DEM

InactiveCN105740464AGeometric meaning representation is clearEasy to analyzeImage enhancementImage analysisTerrainInterference factor

The invention discloses an automatically extracting method for the river-valley morphological parameters based on DEM, and relates to the field of digital geomorphology analysis. The automatically extracting method includes the steps that DEM data for analyzing a river-valley drainage basin is obtained; all rivers belonging to the river-valley drainage basin are obtained and numbered, and sampling points of a longitudinal section are taken at a certain sampling interval a; the morphological parameters of the longitudinal section of a river valley and the morphological parameters of the transverse section of the river valley are calculated. By means of the automatically extracting method, river-valley geomorphology and subsection difference can be represented in the microscopic view, and the whole terrain of the river valley can be analyzed; representation is comprehensive; the calculated parameters are small in interference factor and high in accuracy and operation efficiency.

Owner:CHINA AERO GEOPHYSICAL SURVEY & REMOTE SENSING CENT FOR LAND & RESOURCES

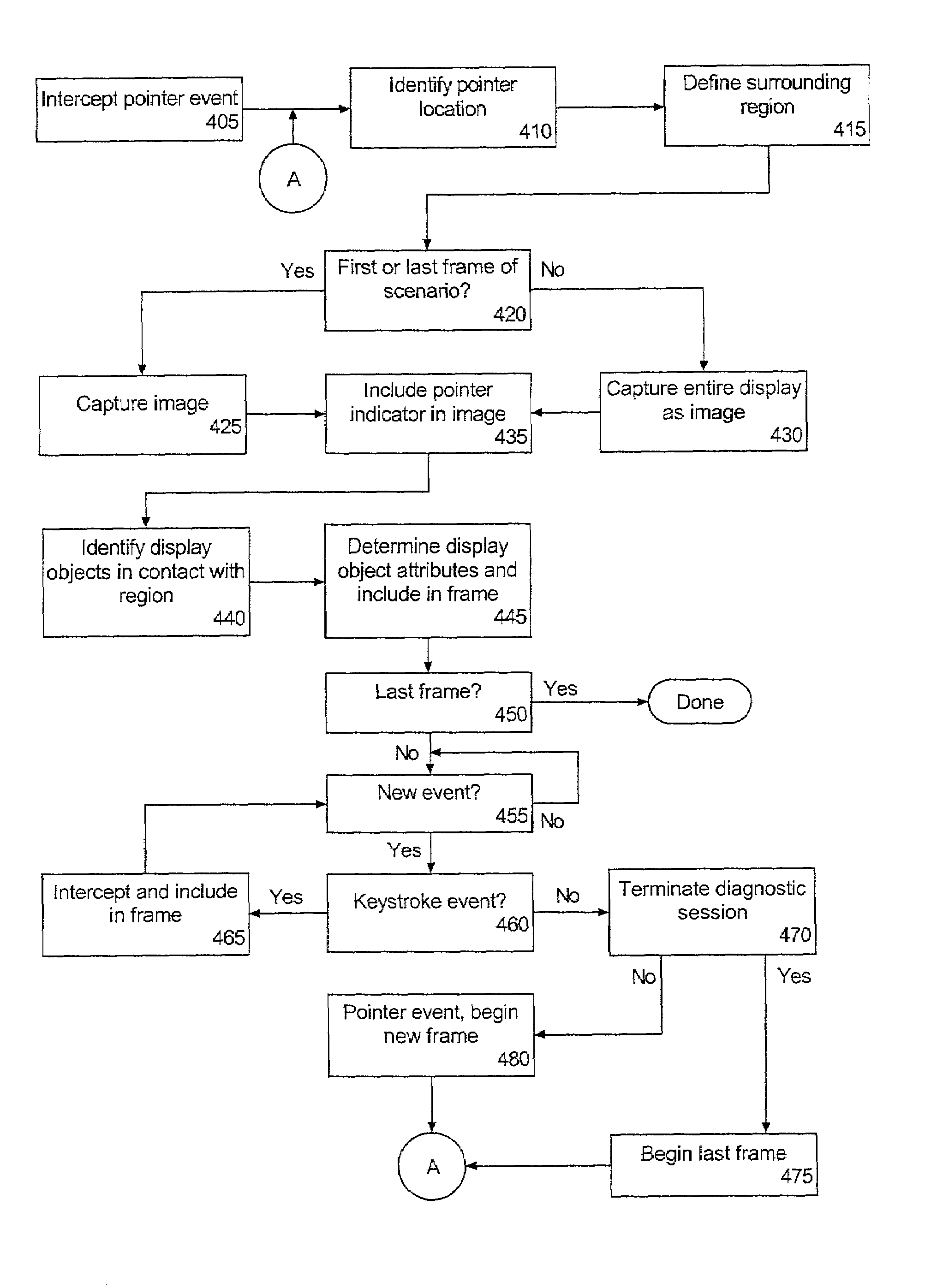

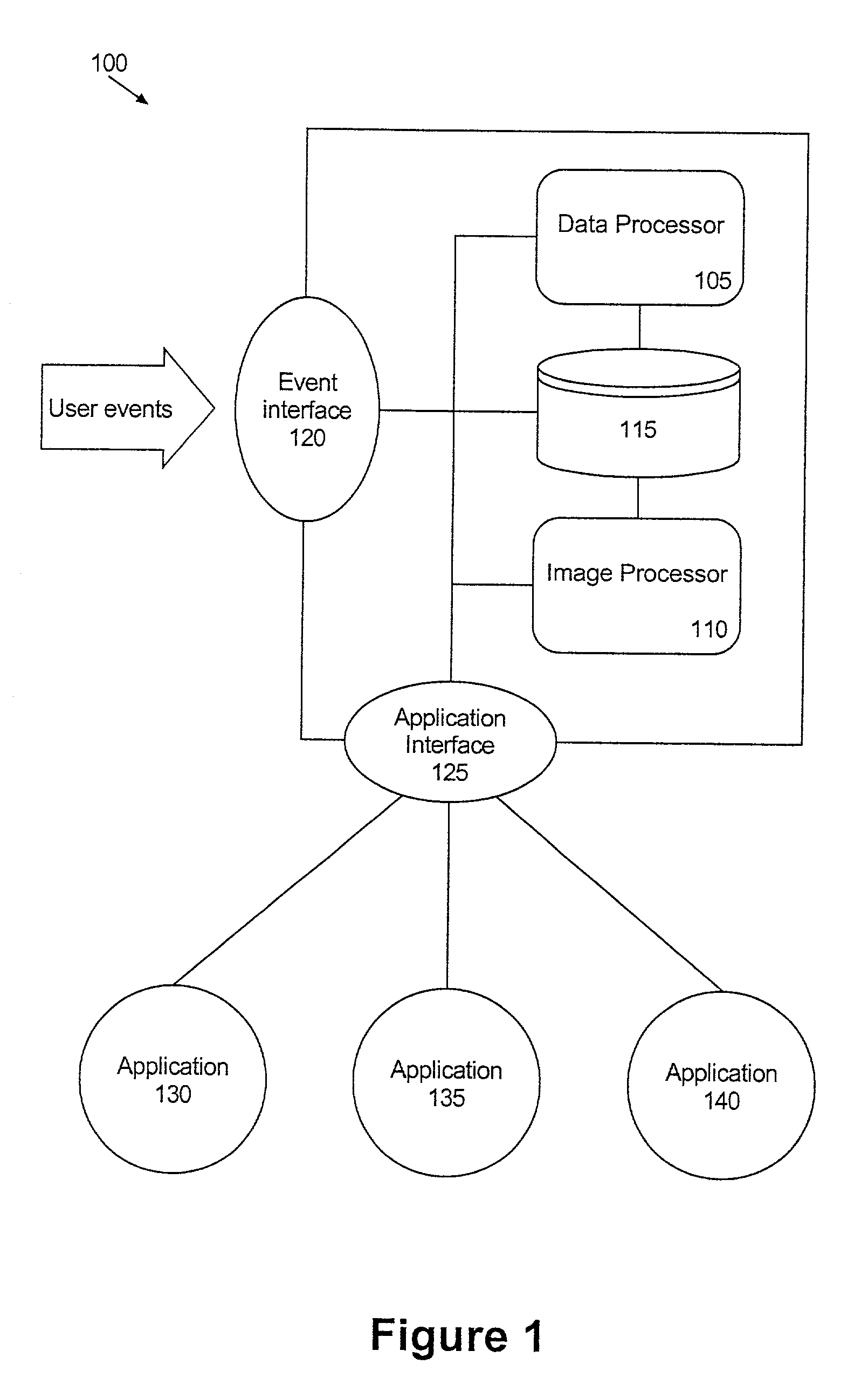

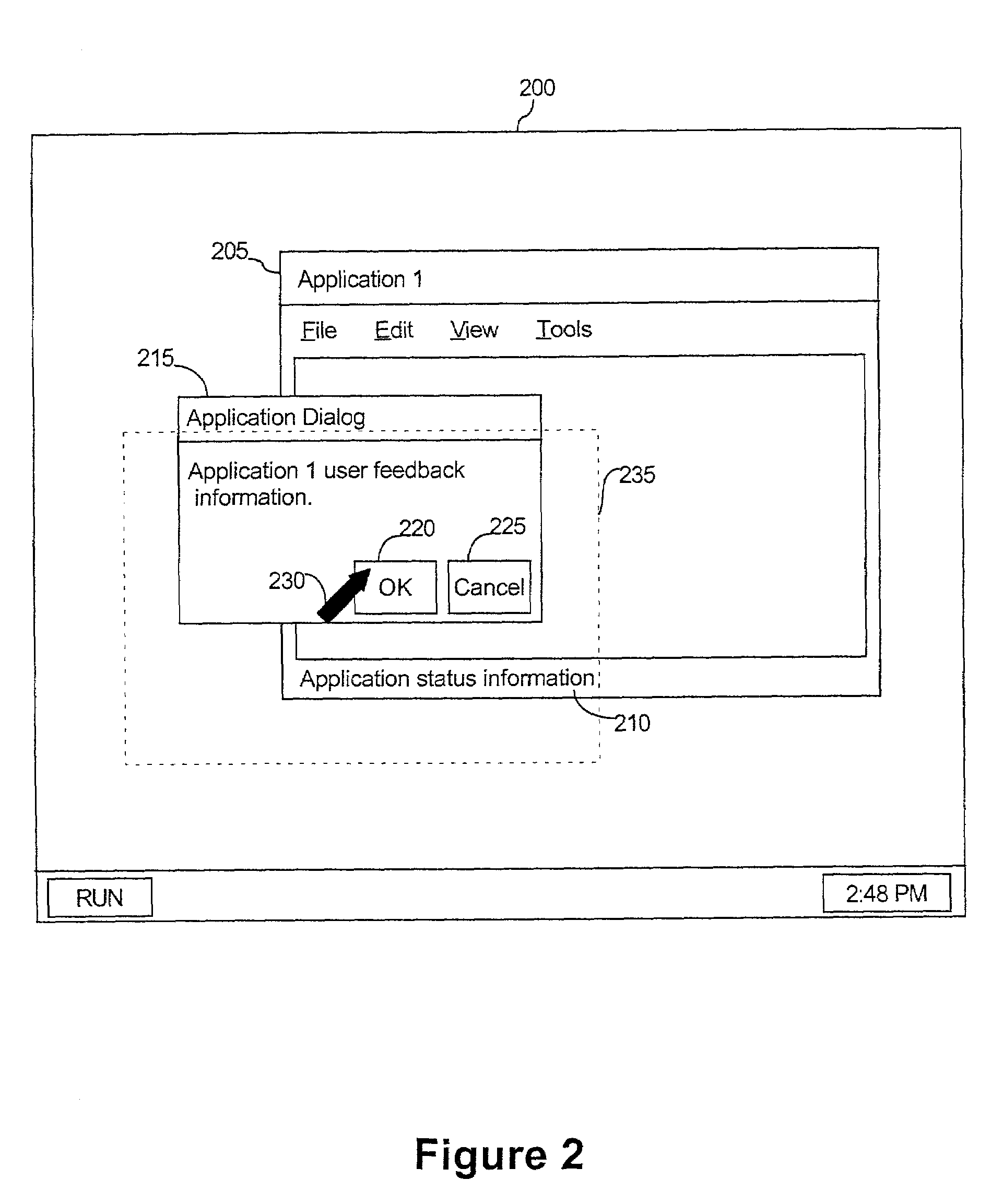

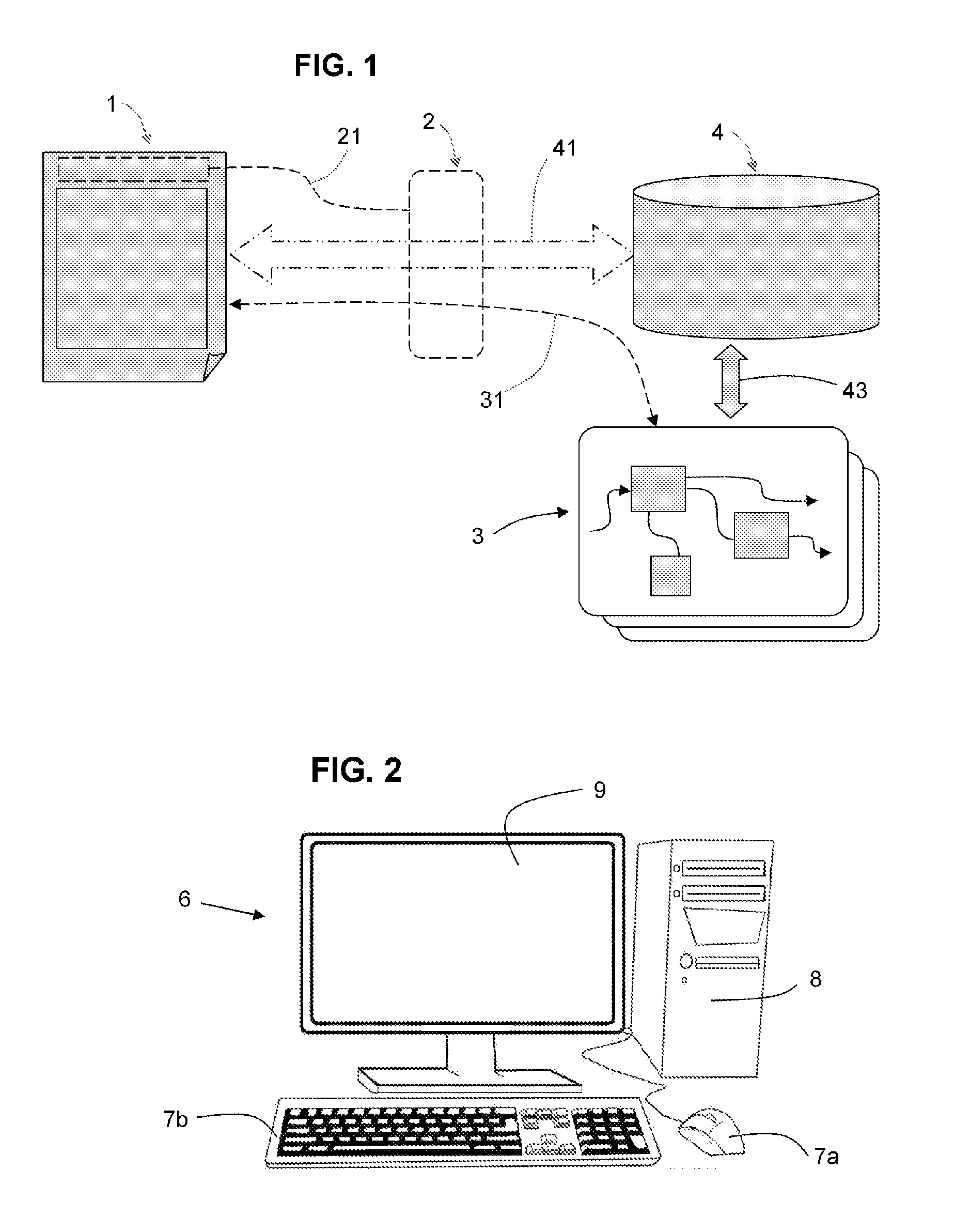

Simple scenario builder

InactiveUS7043669B2Improve the level ofDiagnosing application faultsSoftware testing/debuggingUser inputData mining

A method of constructing a diagnostic scenario can include intercepting at least one user input event, capturing an image of a region surrounding the user input event, and generating a diagnostic frame specifying the image and text representing attributes of the intercepted user input event.

Owner:IBM CORP

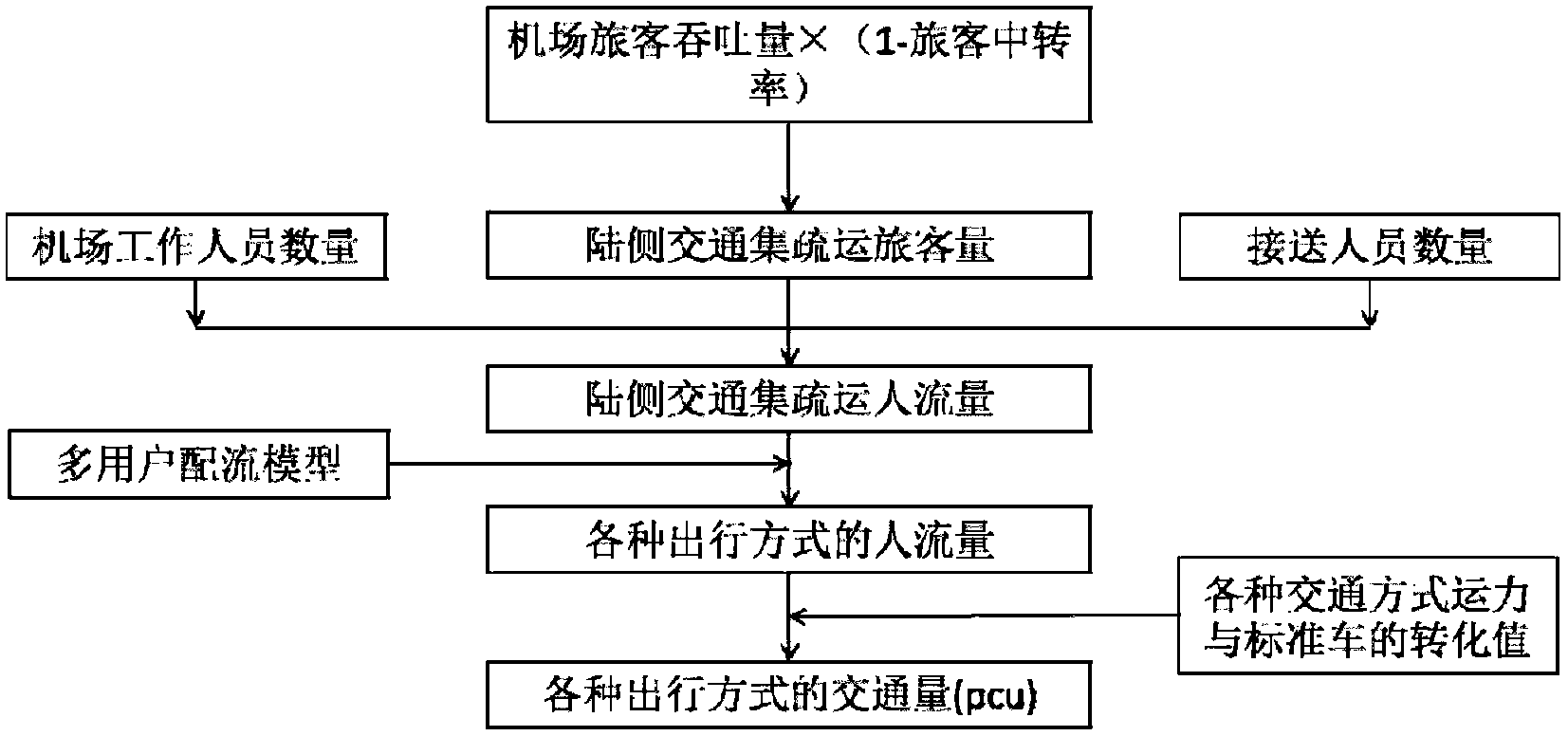

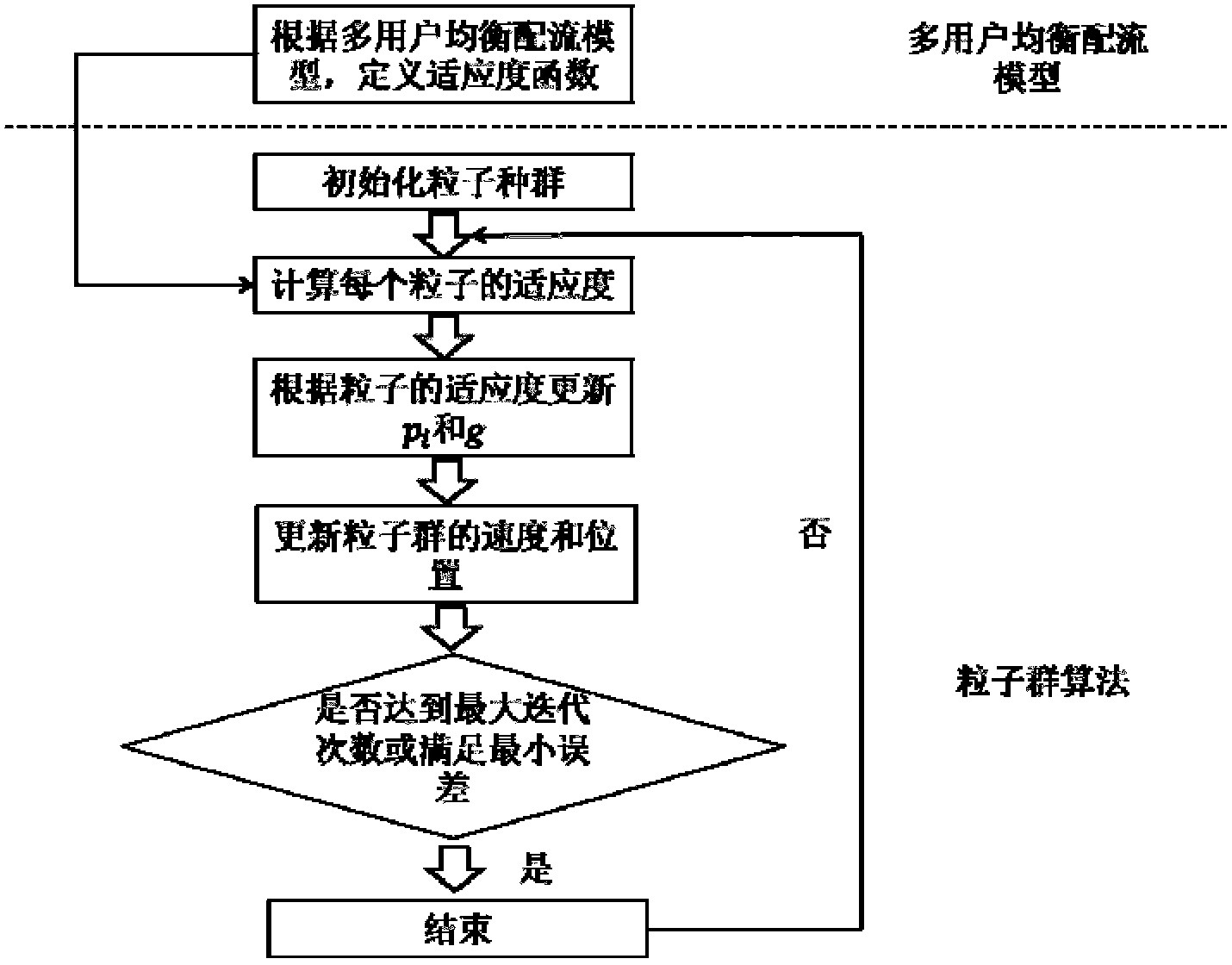

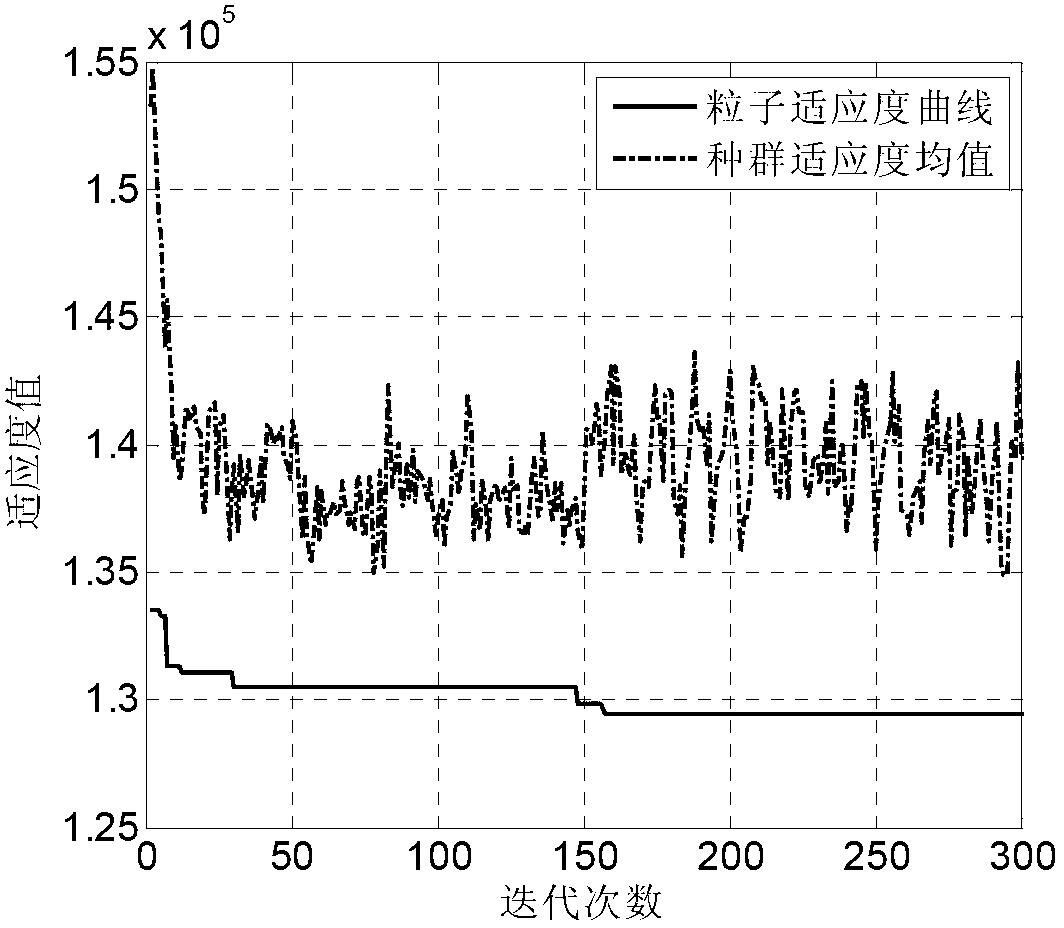

Airport collecting and distributing traffic volume determination method based on multi-user assignment model

ActiveCN103226801AClose to the actual situationComprehensive representationData processing applicationsMode of transportAerodrome

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

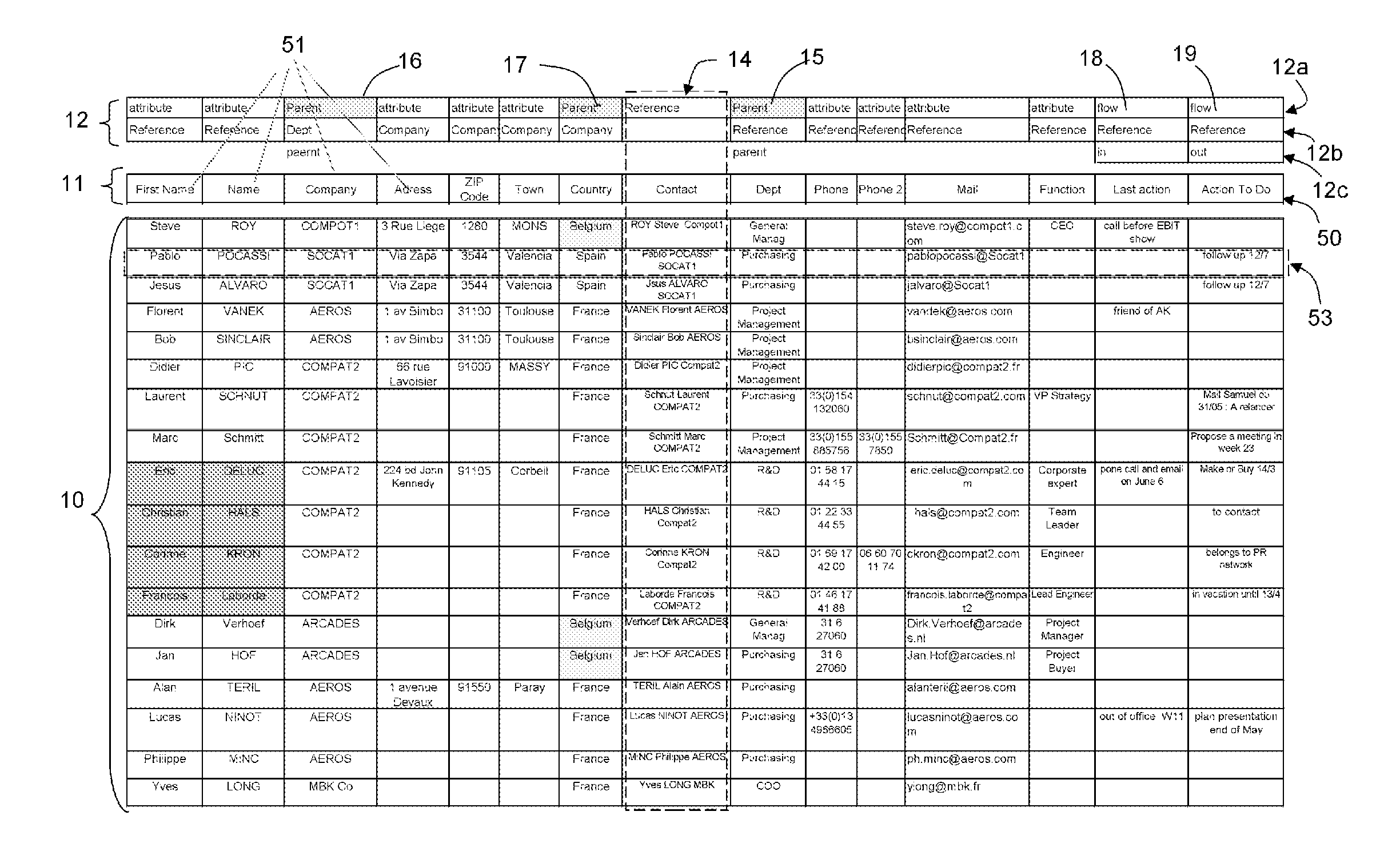

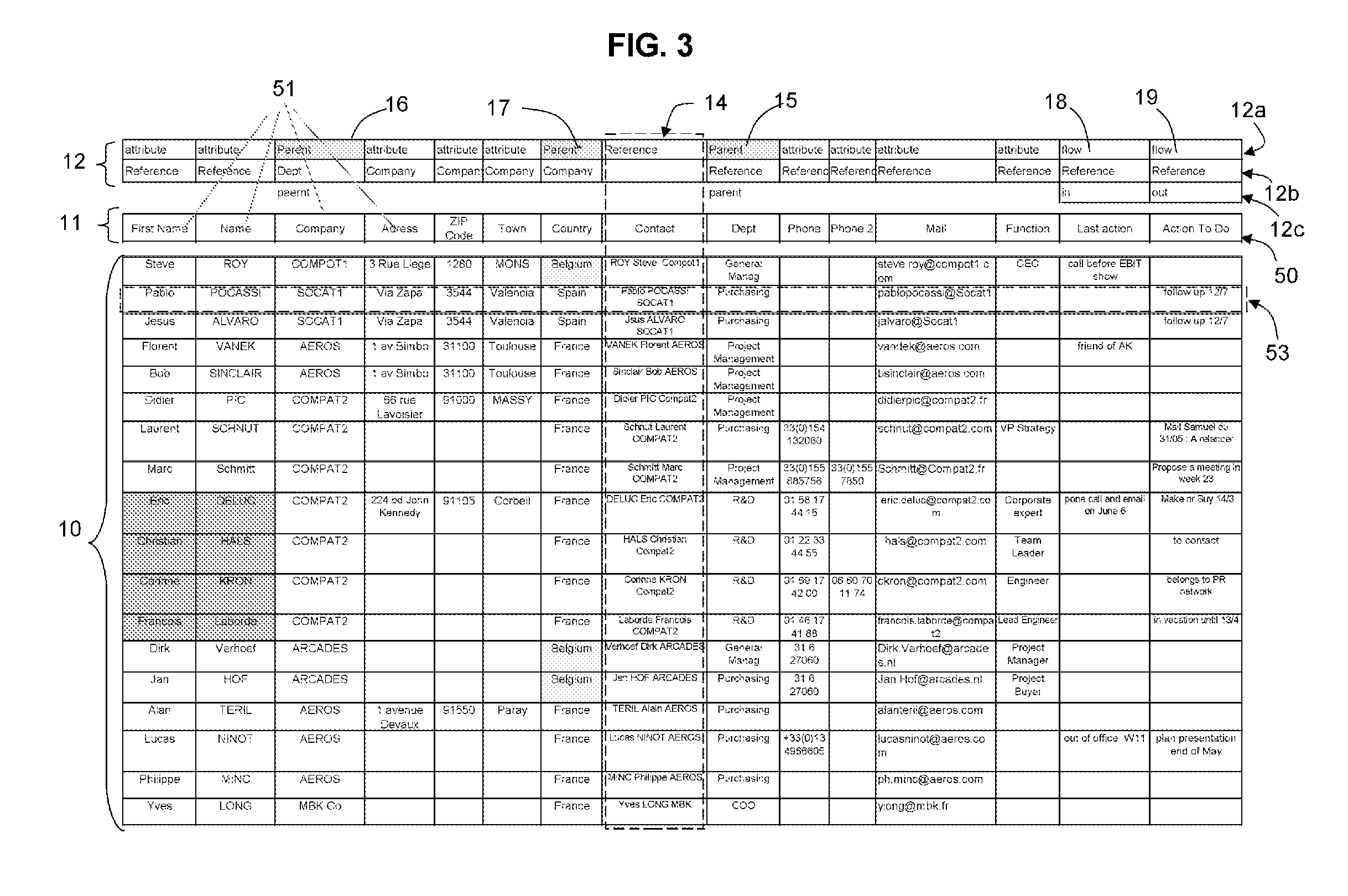

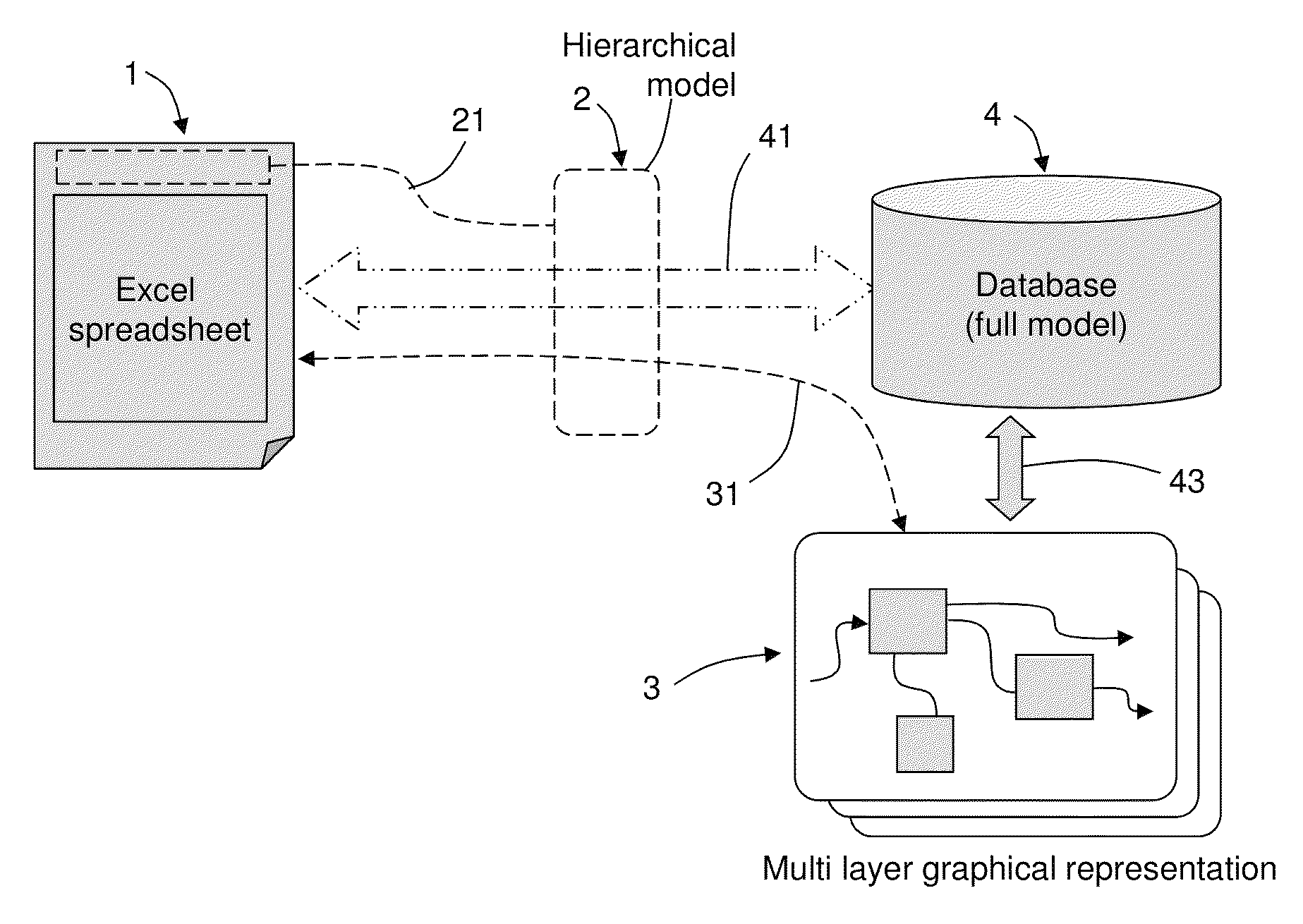

Spreadsheet data processing method and system

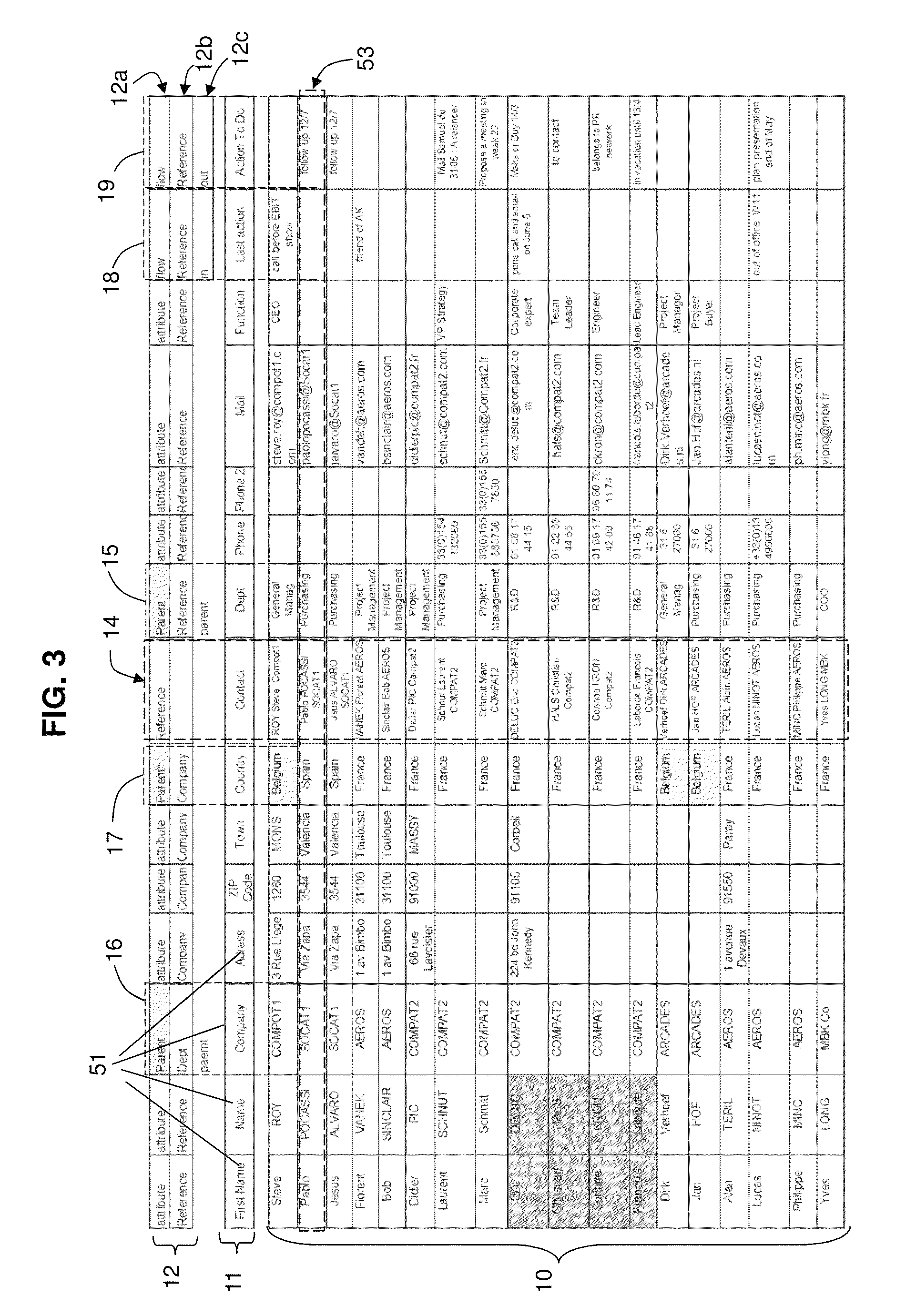

InactiveUS20130117648A1Frequent access can be avoidedComprehensive representationText processingSpecial data processing applicationsGraphicsReference field

A Method carried out in a computer system including a spreadsheet file having a sheet with lines and columns, wherein columns represent fields, the sheet having a header portion having a designation line with a field designation for each column, a data portion, wherein each line includes a record, the method including: / a / identifying a single reference field, / b / allocating a field type to fields other than the reference field, the field type belonging to a set of field type including attribute, parent, and flow, / c / defining a link, for each field with a type, which establishes a link with another linked field, in particular a parent / child link, / d / building a hierarchical model representing the parent / child links, / f / generating a graphical hierarchical multilevel representation of the sheet content, with graphical views showing one or more hierarchical levels and displaying the representation on the display.

Owner:KNOWLEDGE INSIDE

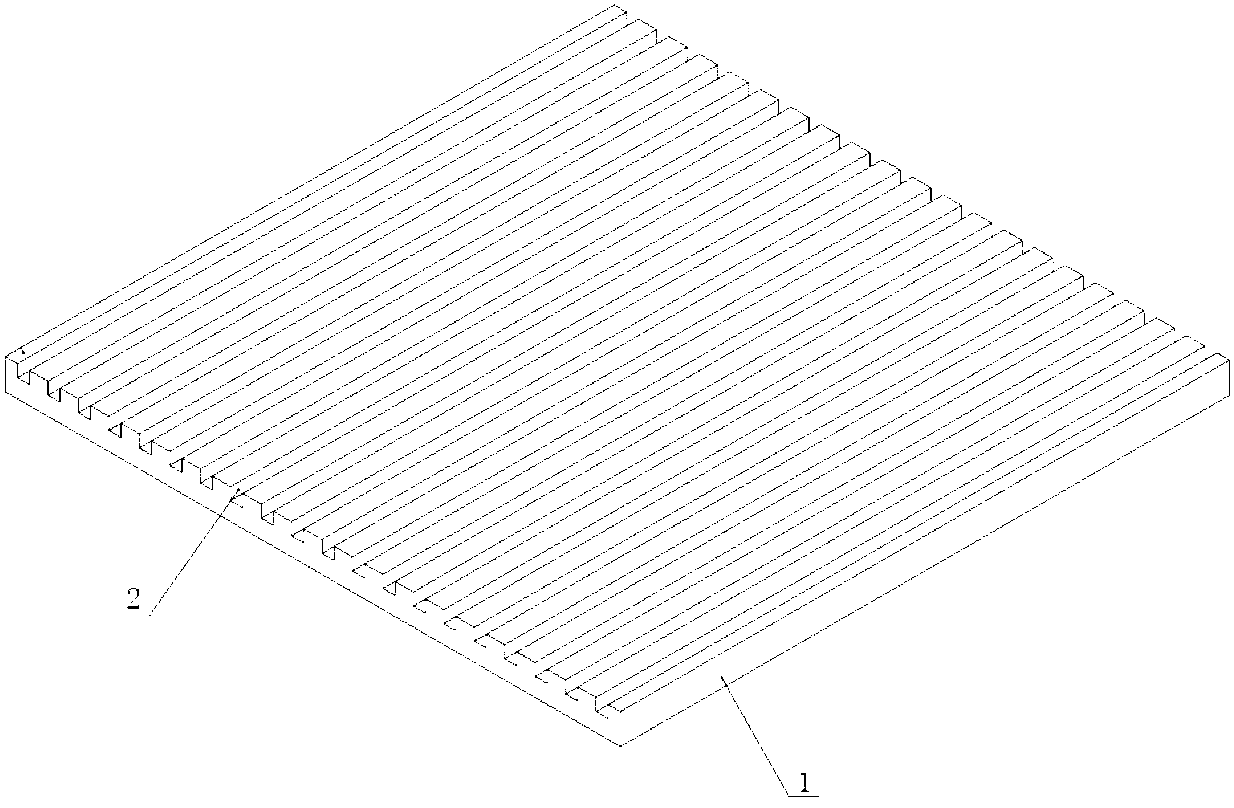

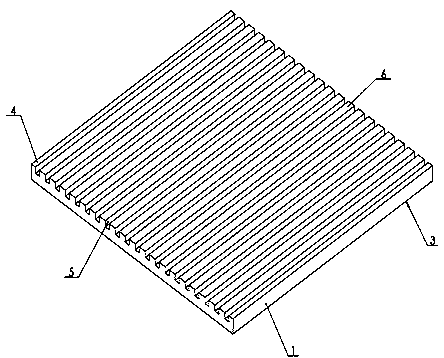

Dedicated cushion plate for measuring friction stir welding temperature field

InactiveCN103212783AComprehensive measurementComprehensive representationThermometers using electric/magnetic elementsUsing electrical meansFriction weldingPlastic materials

The invention discloses a dedicated cushion plate for measuring a friction stir welding temperature field. The dedicated cushion plate for measuring the friction stir welding temperature field comprises a cushion body main body and a groove formed in the lower surface of the cushion plate main body. Multiple through holes are formed in the groove. Thermoelectric couples are arranged in the through holes. Temperature measuring ends of the thermoelectric couples penetrate through the through holes and arranged at temperature measuring points of a welded workpiece. Under the condition that the requirements for clamping of trial plates of different thickness and size are met, measuring the temperature field in a friction stir welding process is achieved and the requirements of different temperature measuring points are met so that achieving comprehensive, reliable and accurate measuring of the friction stir welding temperature field and surface features are possible. The problem that welding joint is not well formed due to sagging of plastic materials at a butt joint of welding parts in the welding process is effectively solved so that welding quality is ensured. The dedicated cushion plate for measuring the friction stir welding temperature field is simple in structure, convenient to manufacture, strong in practicality and suitable for friction stir welding of different materials and different welding sizes and measuring of the friction stir welding temperature field under the condition that size matching is ensured.

Owner:JIANGSU UNIV OF SCI & TECH

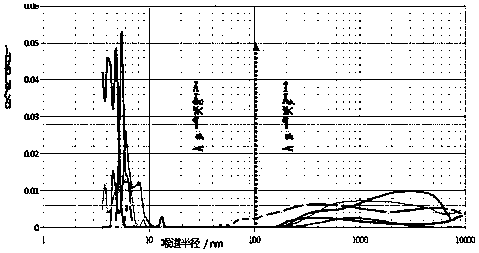

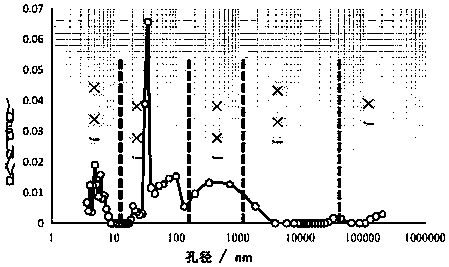

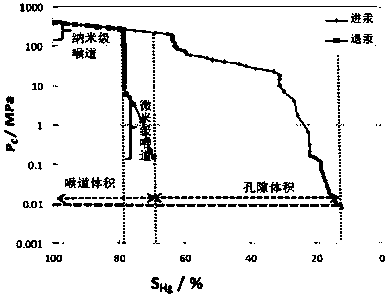

Method for multi-scale representing of dense reservoir pore throat characteristics based on high-pressure mercury intrusion

ActiveCN109632594AAvoid damageIncrease authenticityPermeability/surface area analysisMaterial analysis by measuring secondary emissionThroatPorosity

The invention provides a method for multi-scale representing of dense reservoir pore throat characteristics based on high-pressure mercury intrusion. The method comprises the following steps that thepermeability K and the porosity phi of a rock core are determined under the original stratum covering condition; a high-pressure mercury intrusion experiment is carried out on the rock core to obtainthe external mercury inlet pressure Pi, the hole throat radius ri in the case of the mercury inlet pressure Pi, and the mercury inlet saturation increment delta Si in the case when the mercury inlet pressure is changed from Pi-1 to Pi; the relevant new parameters of pores and throats of stages, and pore throats of stages are calculated, then correlation analysis with the porosity phi and the permeability K are conducted, and main control factors of the permeability of a reservoir are determined; and the real existence of the pore throats of stages is verified by the aid of a scanning electronmicroscope, the width of hole diameters of the pore throats is measured, and the width is compared with the hole diameter distribution obtained by the above algorithm. According to the method, mathematical, physical and other theoretical formulas are applied for processing relevant mercury intrusion data based on data provided by the high-pressure mercury intrusion, so that a new algorithm is formed to represent micro-pore throat characteristics and the permeability of fluid in a micro-pore throat.

Owner:NORTHEAST GASOLINEEUM UNIV

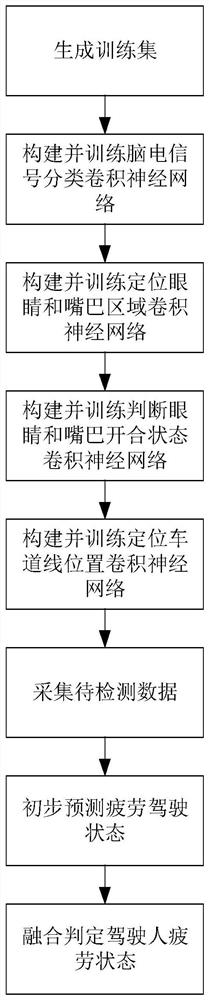

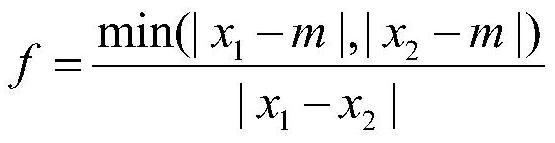

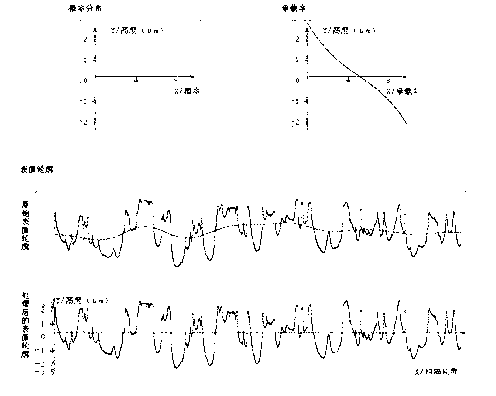

Fatigue driving detection method based on multi-modal information fusion

PendingCN112528815AOvercoming the problem of being easily disturbed by the external environmentImprove detection accuracyCharacter and pattern recognitionSensorsSignal classificationEngineering

The invention discloses a fatigue driving detection method based on multi-modal information fusion. The method comprises the steps: collecting electroencephalogram signals, facial images and vehicle driving lane images at the same time, constructing and training convolutional neural networks respectively, collecting and inputting to-be-detected data into the trained convolutional neural networks for preliminary prediction, and judging whether a driver is in a fatigue state or not by integrating preliminary prediction results. The method comprises the following specific steps: generating a training set, respectively constructing and training electroencephalogram signal classification, positioning eye and mouth areas, judging opening and closing states of eyes and mouth, positioning a convolutional neural network of lane line positions, collecting to-be-detected data, preliminarily predicting a fatigue driving state, and fusing and judging a fatigue state of a driver. According to the method, the problems of single driver fatigue state judgment basis mode and incomplete representation of the driver fatigue state are solved, the method has good robustness and stability, and the fatigue driving detection precision is improved.

Owner:XIDIAN UNIV

Method and device for measuring topography functional characteristic parameters of roller and strip steel three-dimensional surface

The invention discloses a method and a special device for measuring topography functional characteristic parameters of a roller and a strip steel three-dimensional surface. The method is used for reading the original outline value and can carry out data processing in the following steps of;(1) eliminating a shape error; (2) eliminating a waviness error; (3) correcting a singular point; (4) calculating a two-dimensional outline height distribution probability; (5) calculating a three-dimensional outline height distribution probability; and (6) obtaining an outline load-carry duty curved line according to the integral of the three-dimensional outline height distribution probability, and calculating a topography functional characteristic parameter of the three-dimensional surface according to loaded region distributed data. The method provided by the invention can measure the topography functional characteristic parameters of the roller and the strip steel three-dimensional surface in a production field, and the accuracy of a characterization roller and a strip steel pattern is improved; the method can fully represent the surface property of the characterization roller and the strip steel, an exactly moving objective table does not need, the measured time is short, and the device can resist the large interfere influencing the measurement.

Owner:武汉钢铁有限公司 +1

Multidirectional SLGS characteristic description and performance cloud weight fusion face recognition method

ActiveCN106056059AAvoid one-sidednessAvoid precisionCharacter and pattern recognitionCross processingFace perception

The invention discloses a multidirectional SLGS characteristic description and performance cloud weight fusion face recognition method. The face recognition method comprises the following steps: 1, an existing SLGS algorithm is extended from a perspective of directions, and textural features of a human face in different directions are obtained; 2, base classifiers are constructed based on the texture features by utilizing a layered cross-processing mode, a performance cloud is formed according to recognition stability and reliability of the base classifiers on different regions, and weight values are obtained; and 3, discrimination and classification for a to-be-measured human face are achieved through a weight fusion for the base classifiers. The method can use a multidirectional SLGS algorithm to fully describe a human face image, and can use the weight values, obtained based on the performance cloud, of the base classifiers to improve recognition performance of a system and obtain the high recognition rate.

Owner:HEFEI UNIV OF TECH

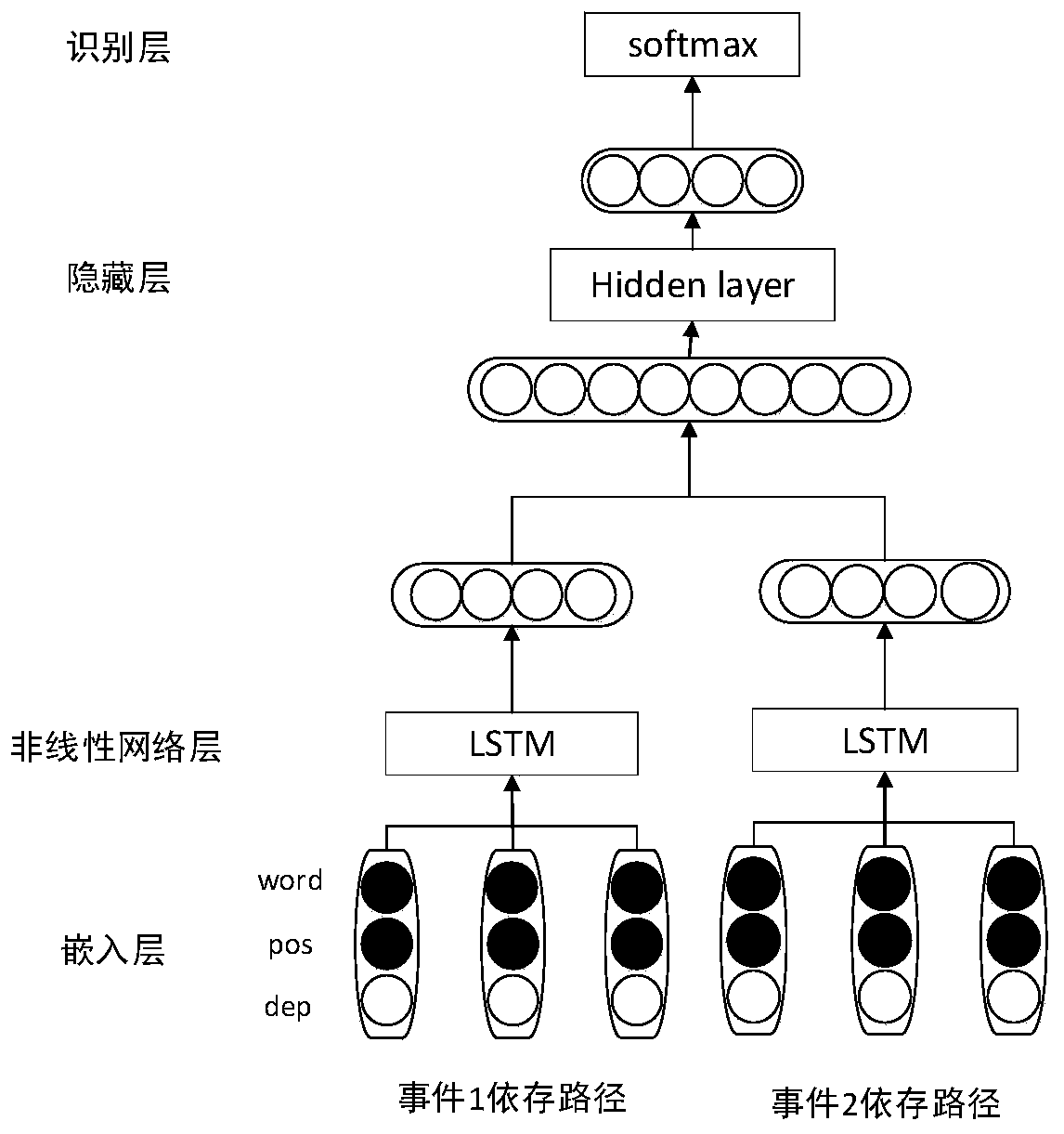

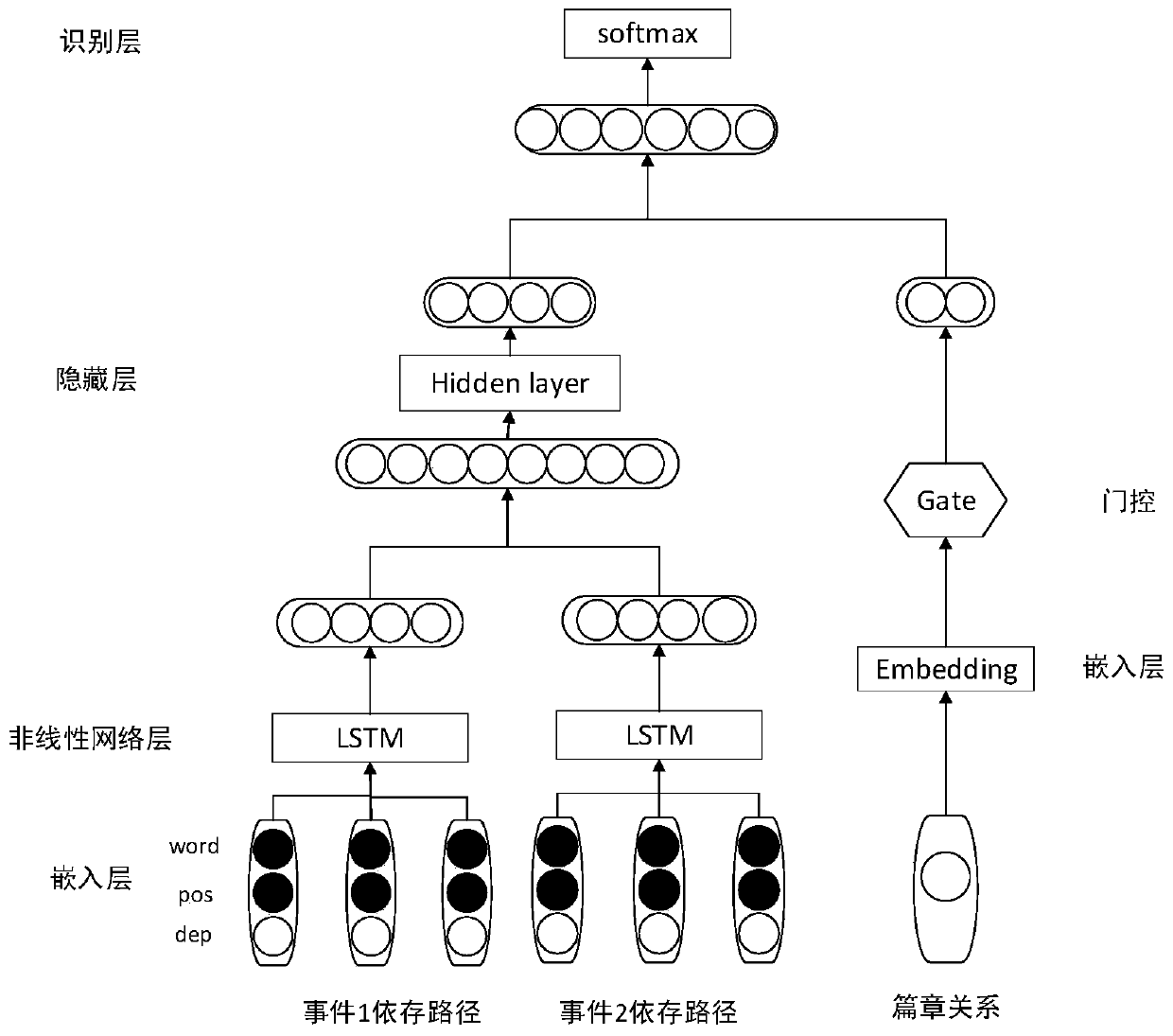

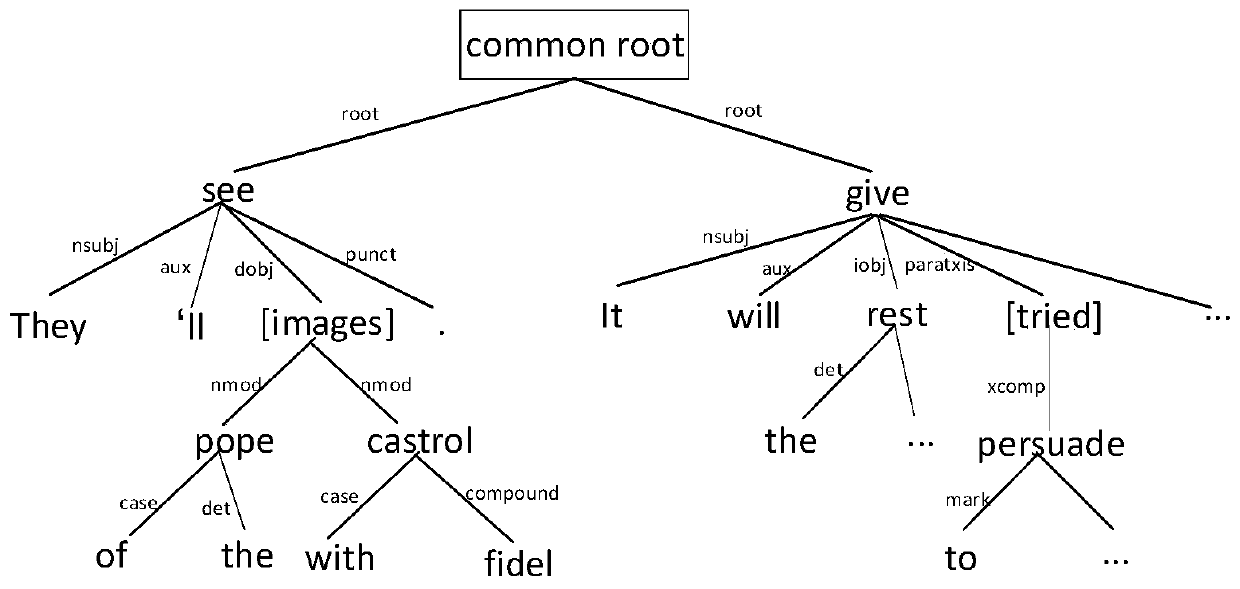

Event time sequence relation identification method fusing dependency relation and chapter rhetoric relation

ActiveCN110069636AMake up for missing problemsComprehensive representationNatural language data processingText database indexingReference modelData mining

The invention discloses an event time sequence relation identification method fusing a dependency relation and a chapter rhetoric relation. The method is characterized by comprising the following steps of giving event pairs e1 and e2, and extracting the aspect of a shortest dependency path; in consideration of a complex syntax structure of the dependency syntax tree, adding a heuristic rule to enrich event related information; adding the child nodes into the dependency path, and finally sorting the extracted words according to the sequence of event sentences; and enabling the obtained event pair dependency path to pass through an embedded layer, a bidirectional LSTM layer and a hidden layer according to the same processing method as the reference model to obtain a vector representation Y'.The method has the beneficial effect that the information codes of the chapter tree are added into the model, the incidence relation between events is characterized by being divided into two parts: one part is dependency path information of sentences where the events are located.

Owner:SUZHOU UNIV

Spreadsheet data processing method and system

InactiveUS9053082B2Comprehensive representationFrequent access can be avoidedText processingSpecial data processing applicationsGraphicsReference field

A method carried out in a computer system having thereon a spreadsheet file with lines and columns, the columns representing fields and each line representing a record, the sheet also having a header portion with a designation line with a field designation for each column, wherein the method identifies a single reference field, allocates a field type to fields other than the reference field, defines a link for each field with a field type and thereby link with another linked field, builds a hierarchical model representing the links, and generates a graphical hierarchical multilevel representation of the sheet content, with graphical views showing one or more hierarchical levels and displaying this representation on a display.

Owner:KNOWLEDGE INSIDE

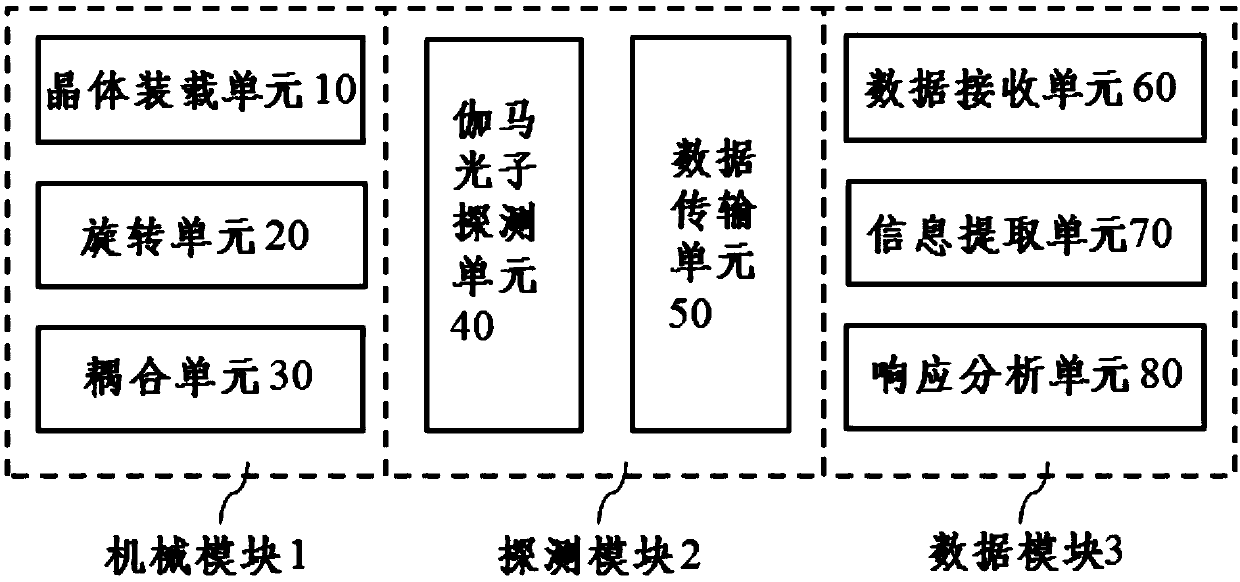

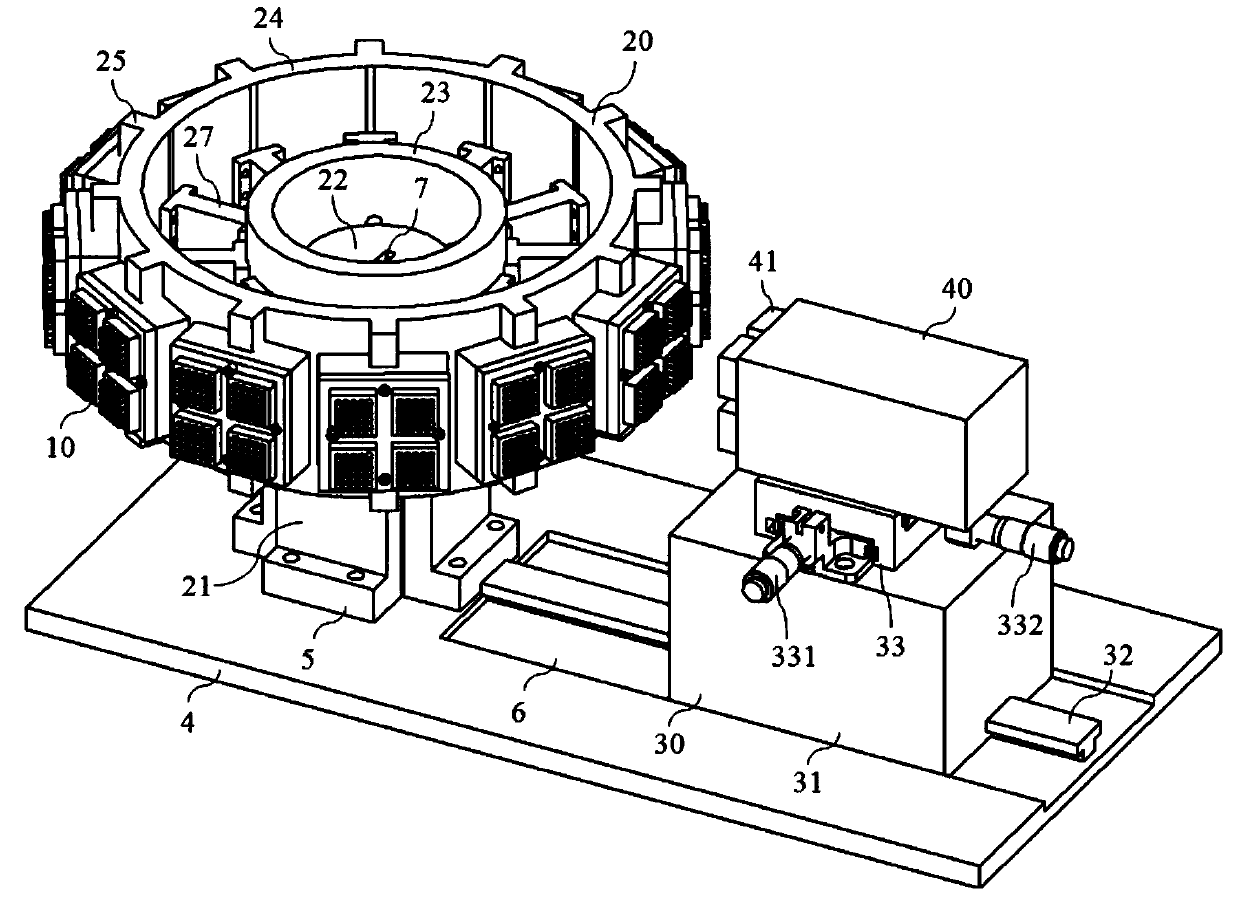

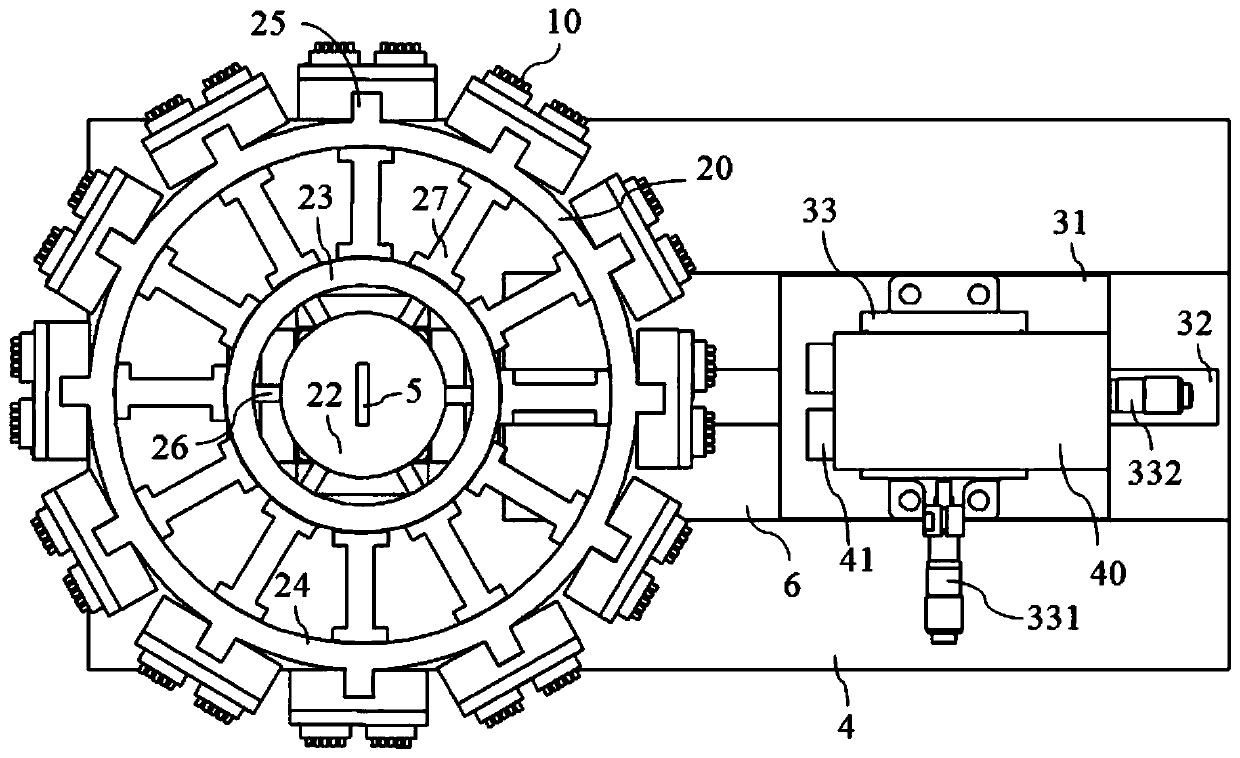

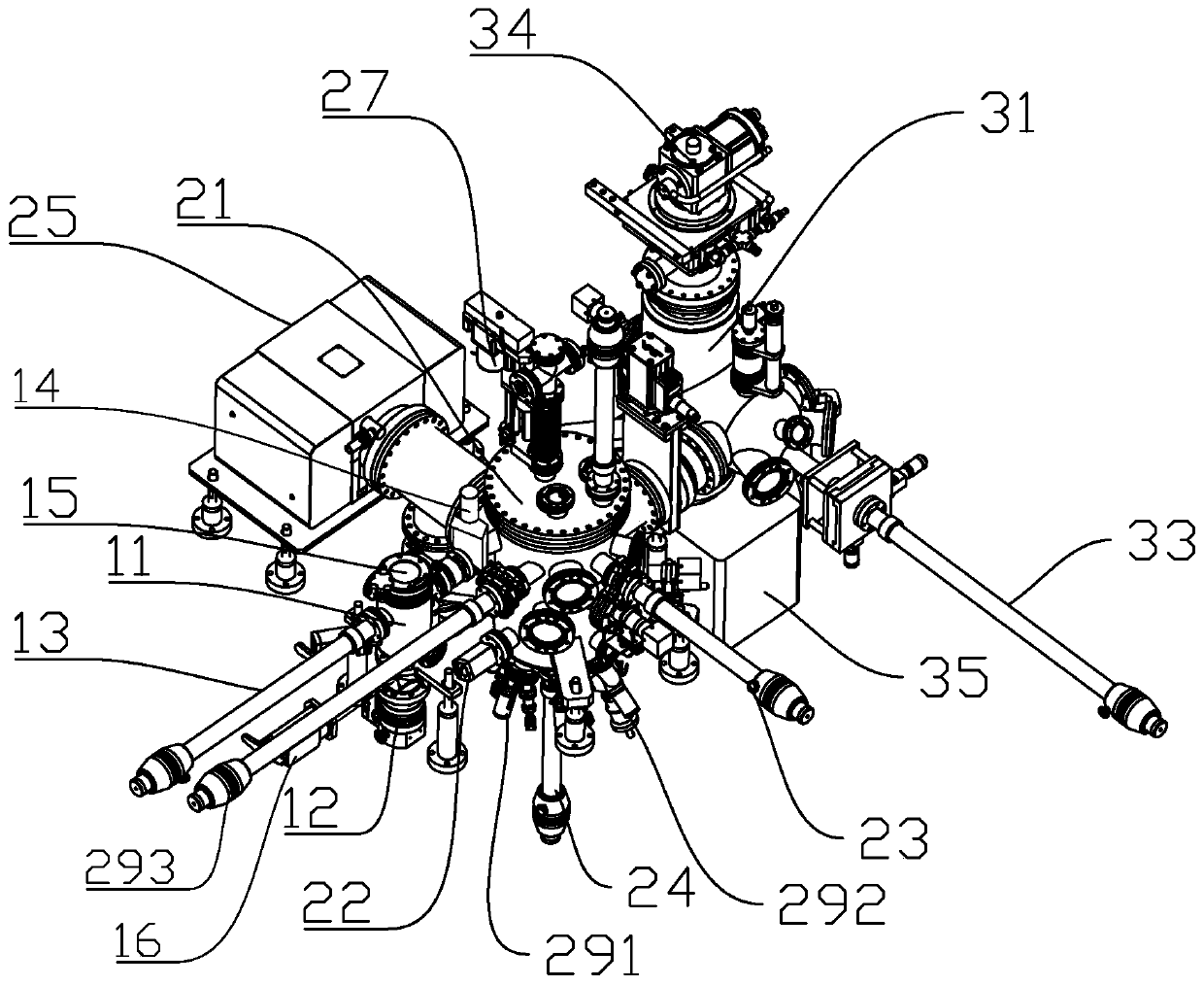

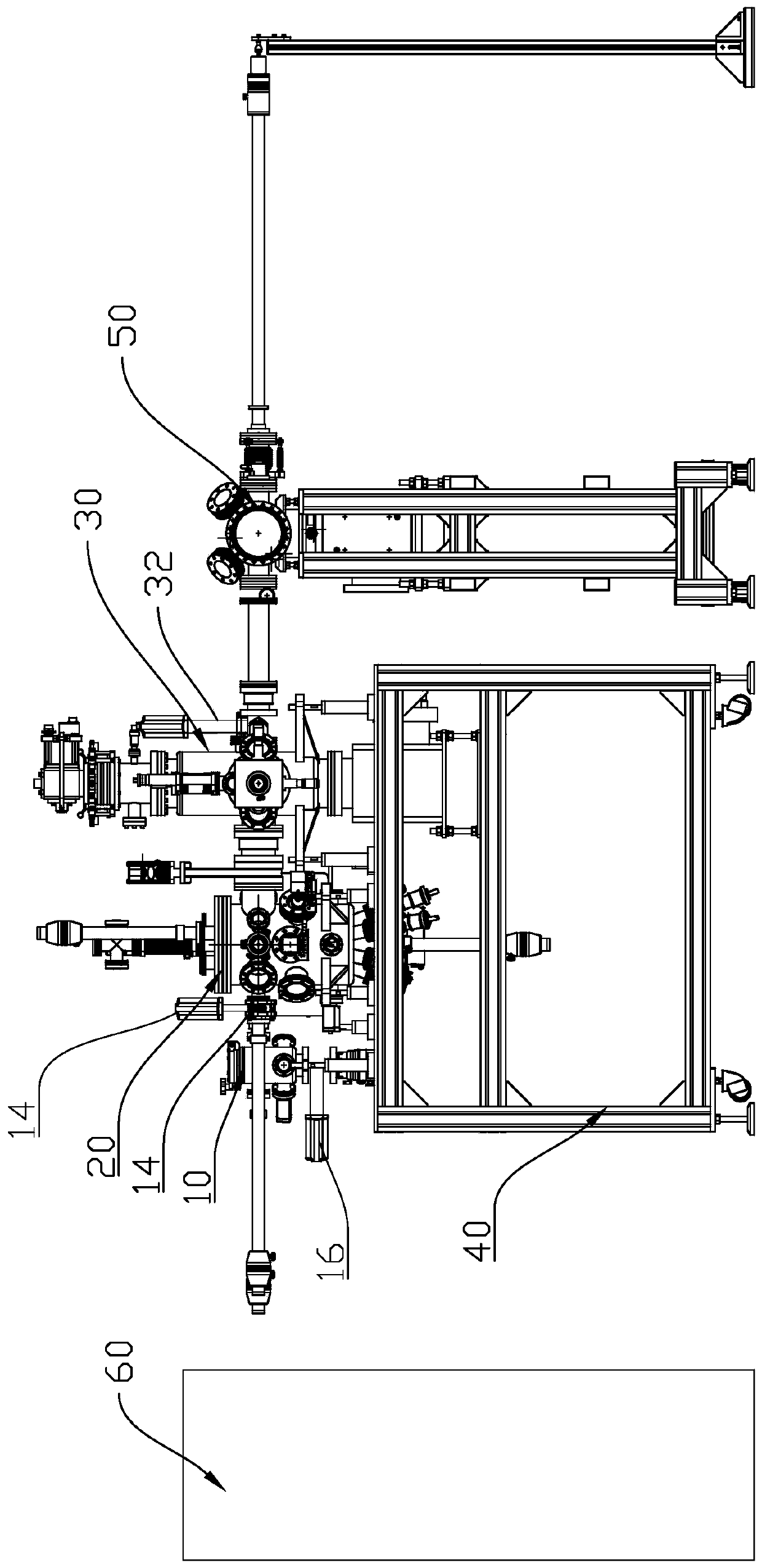

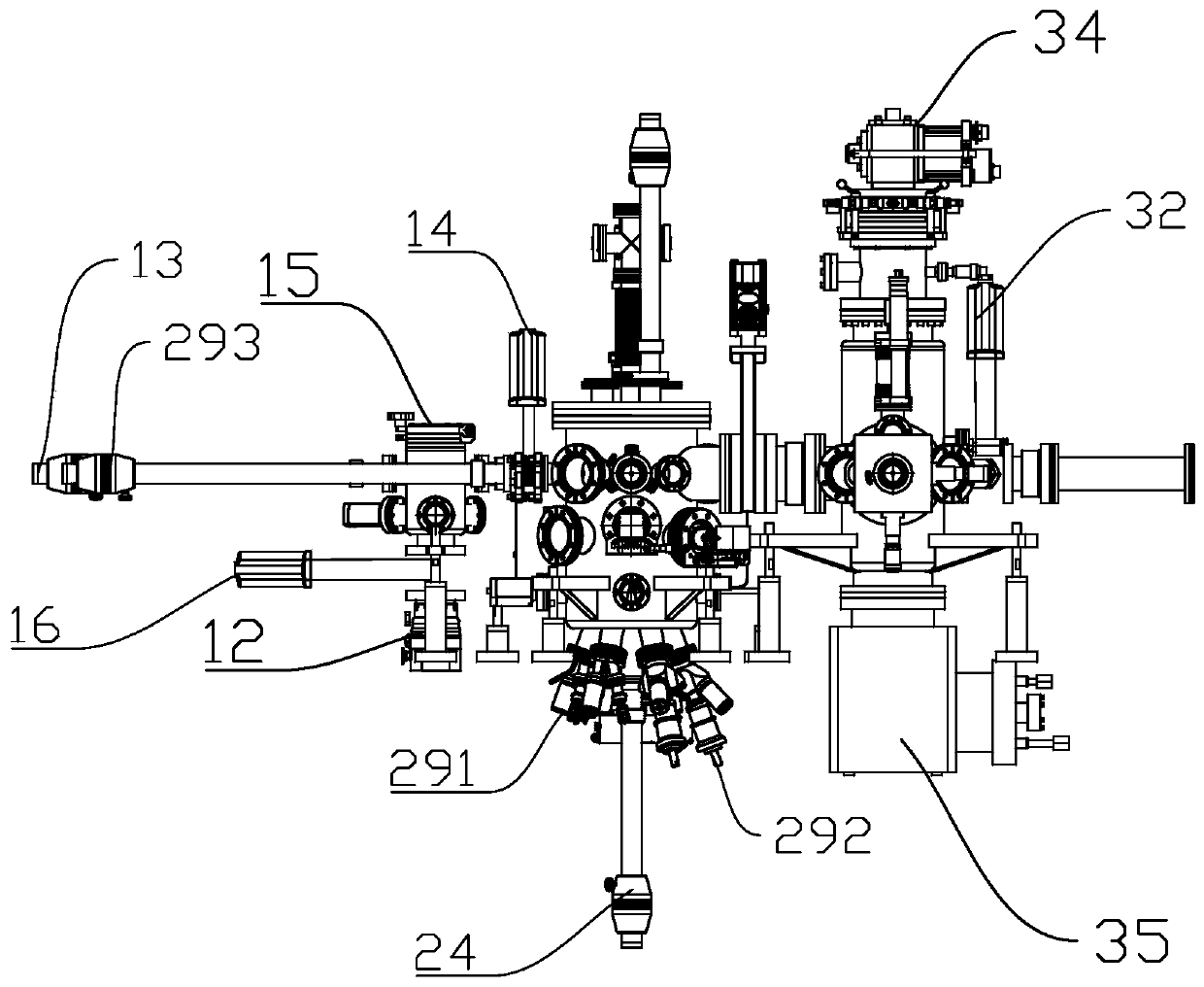

Scintillation crystal testing device

ActiveCN109541673ATest large batchesImprove efficiencyMaterial analysis using wave/particle radiationRadiation measurementScintillation crystalsEngineering

The invention provides a scintillation crystal testing device which comprises a mechanical module, a detecting module and a data module. The mechanical module comprises crystal loading units, a rotating unit and a coupling unit. A plurality of crystal loading units are separately arranged on the rotating unit. The coupling unit comprises a movable object carrying table. The detecting module is provided with a photoelectric converter and a data transmission unit. The photoelectric converter is arranged on the object carrying table. The photoelectric converter is successively coupled with the scintillation crystal which is mounted in the crystal loading unit. The photoelectric converter is in communication connection with the data transmission unit. The data module is in communication connection with the data transmission unit. The scintillation crystal testing device has automatic testing capability and can perform large-batch high-efficiency crystal testing. The scintillation crystal testing device can expand the performance parameter of the scintillation and can supply a testing result with higher stability.

Owner:RAYCAN TECH CO LTD SU ZHOU

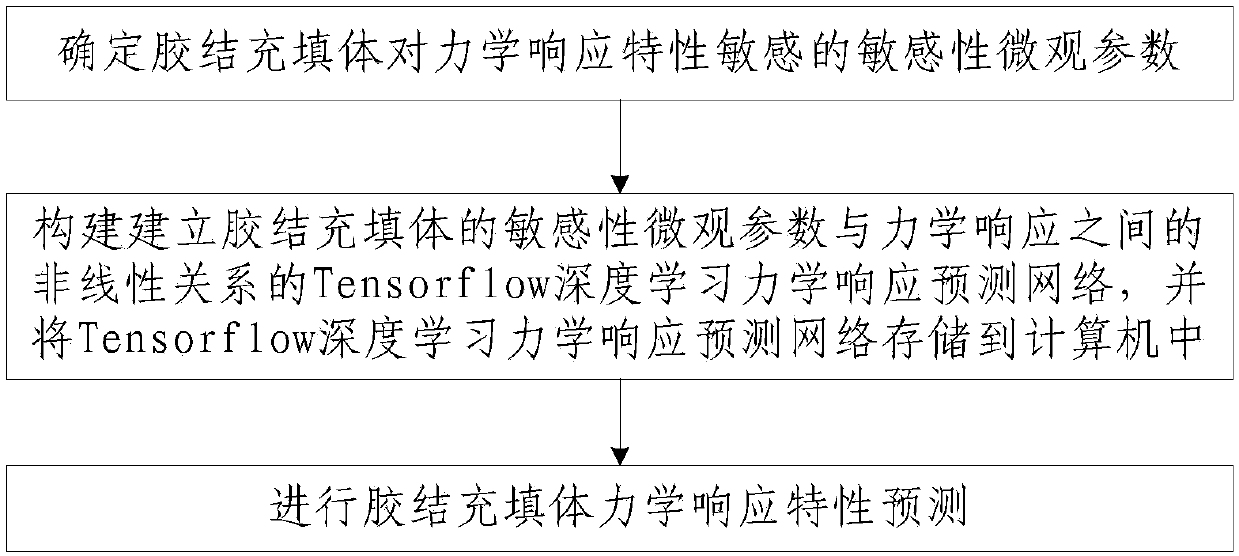

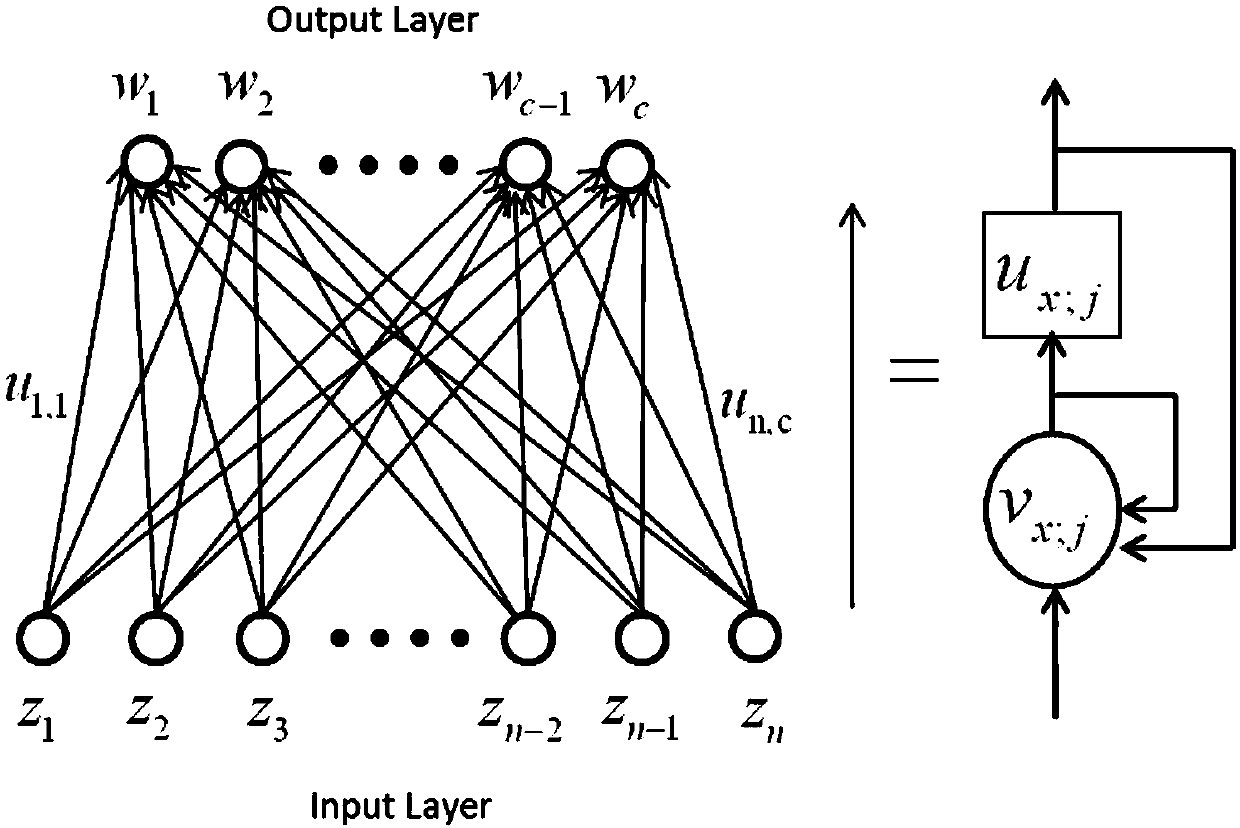

Method for predicting mechanical response characteristics of cemented filling mass on basis of sensitive microscopic parameters

ActiveCN108229062ANovel and reasonable designImprove efficiencyBiological neural network modelsCharacter and pattern recognitionMaterial resourcesEngineering

The invention discloses a method for predicting mechanical response characteristics of cemented filling mass on the basis of sensitive microscopic parameters. The method includes the steps of 1), determining the sensitive microscopic parameters of cemented filling mass on sensitivity of the mechanical response characteristics; 2), establishing non-linear Tensorflow deep-learning mechanical response prediction network between the sensitive microscopic parameters of the cemented filling mass and mechanical response and storing the Tensorflow deep-learning mechanical response prediction network into a computer; 3), predicting the mechanical response characteristics of the cemented filling mass. The method is novel and reasonable in design, convenient and rapid in implementation, capable of acquiring accurate prediction results of the mechanical response characteristics, high in prediction efficiency, low in consumption of labor force and material resources, capable of contributing to thestudy of new cemented filling mass, high in practicability, wide in application range and high in popularization value.

Owner:XIAN UNIV OF SCI & TECH

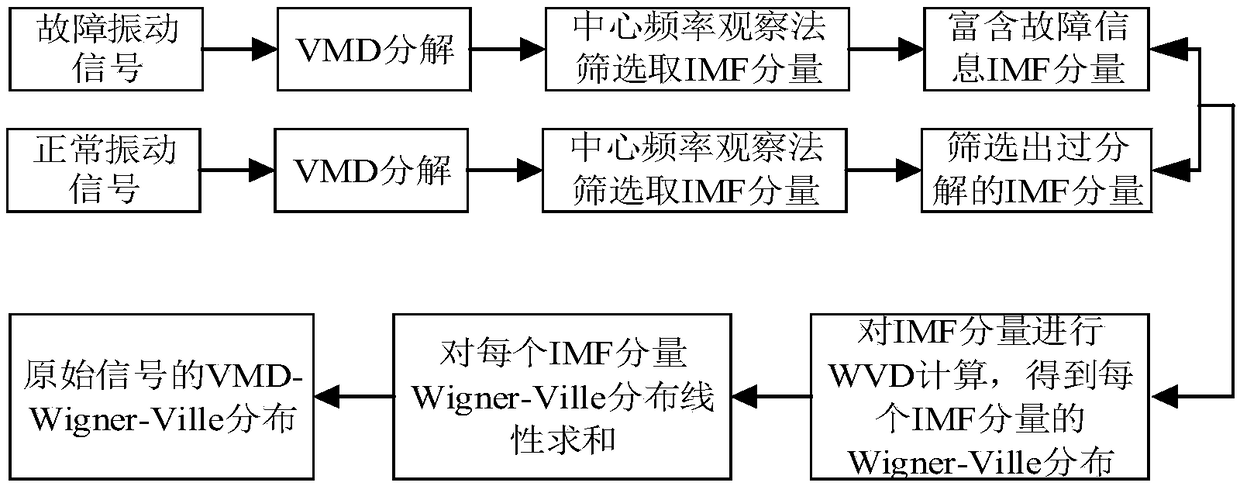

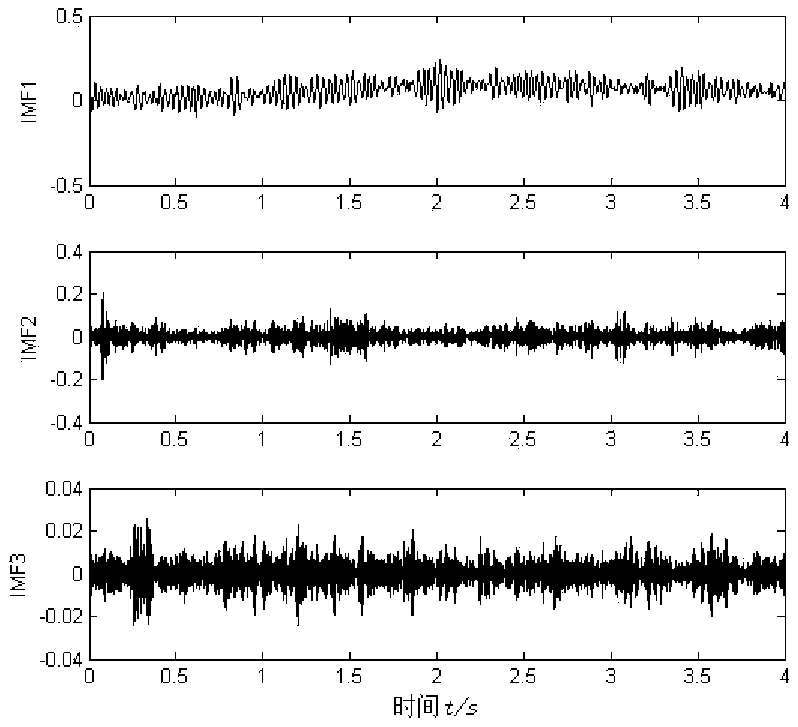

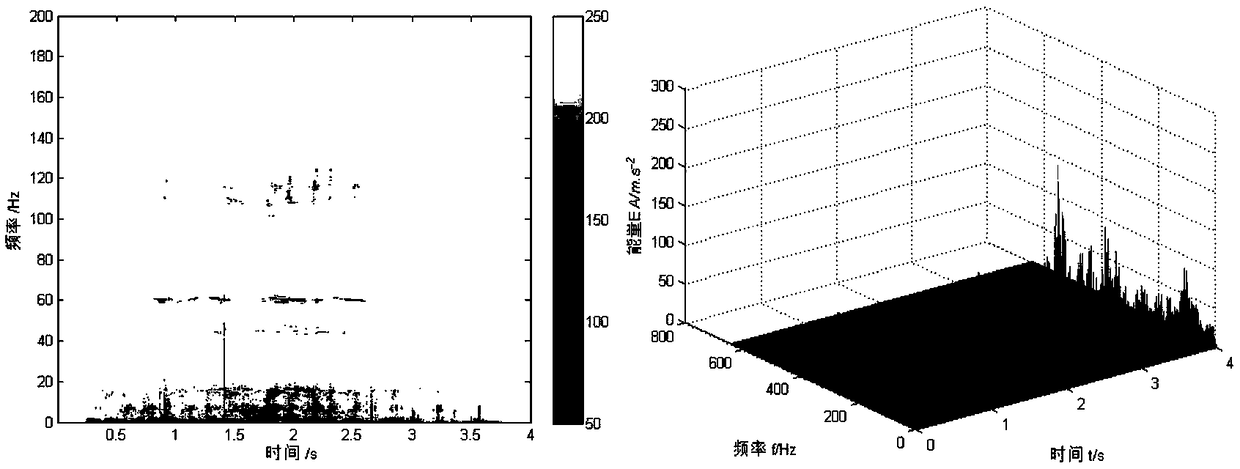

VMD and Wigner-Ville based high pressure diaphragm pump check valve fault diagnosis method

InactiveCN109282985AHigh precisionImproved time-frequency aggregation performanceMachine valve testingDiaphragm pumpDiagnosis methods

The invention discloses a VMD and Wigner-Ville based high pressure diaphragm pump check valve fault diagnosis method. The method includes: using an acceleration sensor to acquire vibration signals ofa high-pressure diaphragm pump check valve in a fault state and a normal state, and then adopting a VMD method to decompose the acquired signals in each state, and then selecting IMF components basedon a center frequency observation method for k-modal components of a fault vibration signal and a normal vibration signal; calculating the Wigner-Ville distribution of each selected IMF component; linearly superimposing the Wigner-Ville distribution results of each modal component to obtain the Wigner-Ville distribution of the fault and normal vibration signals; acquiring the vibration signals ofthe high pressure diaphragm pump check valve, comparing the vibration signals with the Wigner-Ville distribution of the fault vibration signal and the normal vibration signal, and extracting fault features; and diagnosing the fault. The method realizes the comprehensive and effective characterization of the state information of the check valve, and effectively achieves fault diagnosis of the high-pressure diaphragm pump check valve.

Owner:KUNMING UNIV OF SCI & TECH

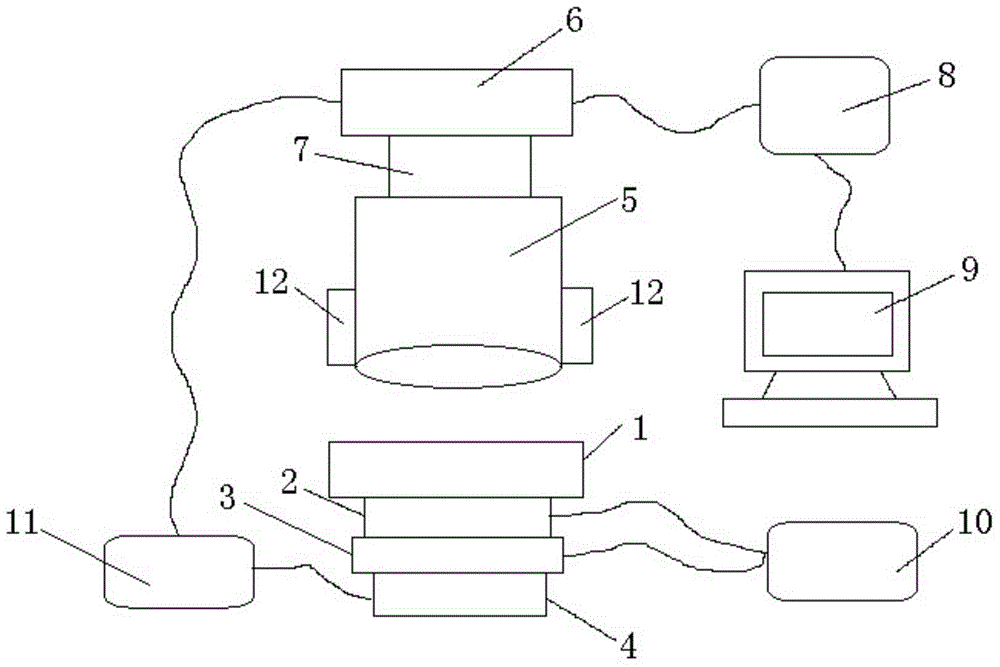

High-throughput digital full-field metallographic in-situ statistic characterization analyzer and analysis method

InactiveCN104483317ASystem metallographic structure characterizationRealize in-situ statistical distribution analysis and characterizationMaterial analysis by optical meansDigital signal processingMicroscope

The invention belongs to the technical field of material properties characterization, and particularly relates to a high-throughput digital full-field metallographic in-situ statistic characterization analyzer and analysis method. The analyzer comprises a high-throughput automatic sampling scanning system, a digital signal processing system and an intelligent analysis system, wherein the high-throughput automatic sampling scanning system comprises a sample table (1), an X-axis guiderail (2), a Y-axis guiderail (3) and a Z-axis guiderail (4); the digital signal processing system comprises a metallographic microscope (5), a CCD digital camera (6), an interface (7), an image processing device (8) and a lighting source (12). The analyzer is capable of realizing high-throughput data acquisition through obtaining a large amount of original digital signals of metallographic structures of samples in a large scale range (cm2 level), realizing the automatic identification, rating and evaluation of various metallographic structures through statistically analyzing a large amount of original digital signals and realizing the positioning of the metallographic structures on original positions through precise point-to-point corresponding of original digital signals and the surface of the samples.

Owner:NCS TESTING TECH

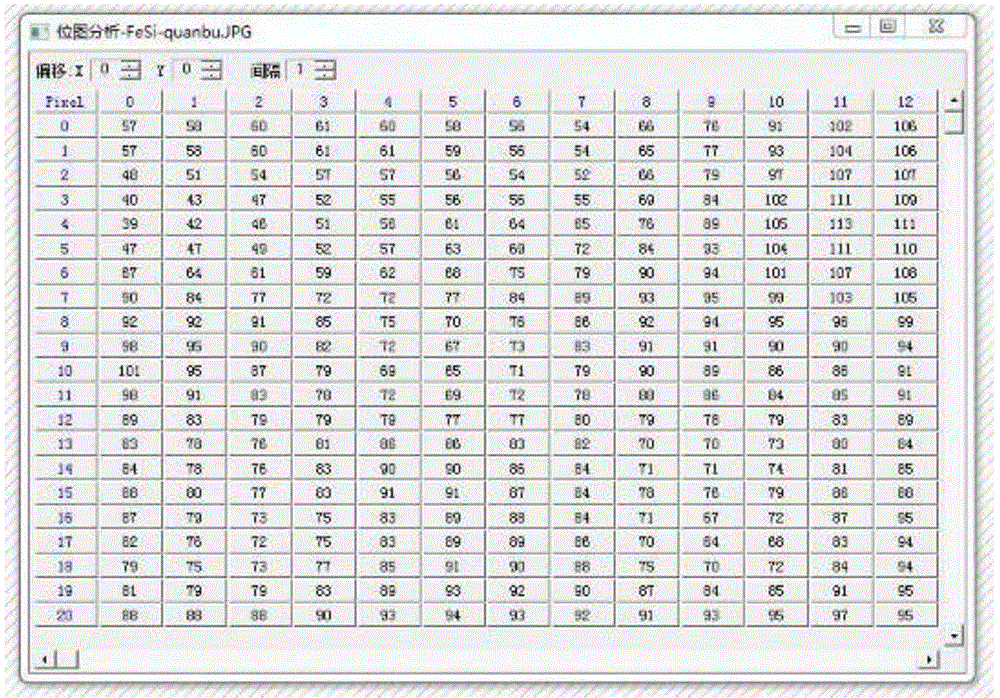

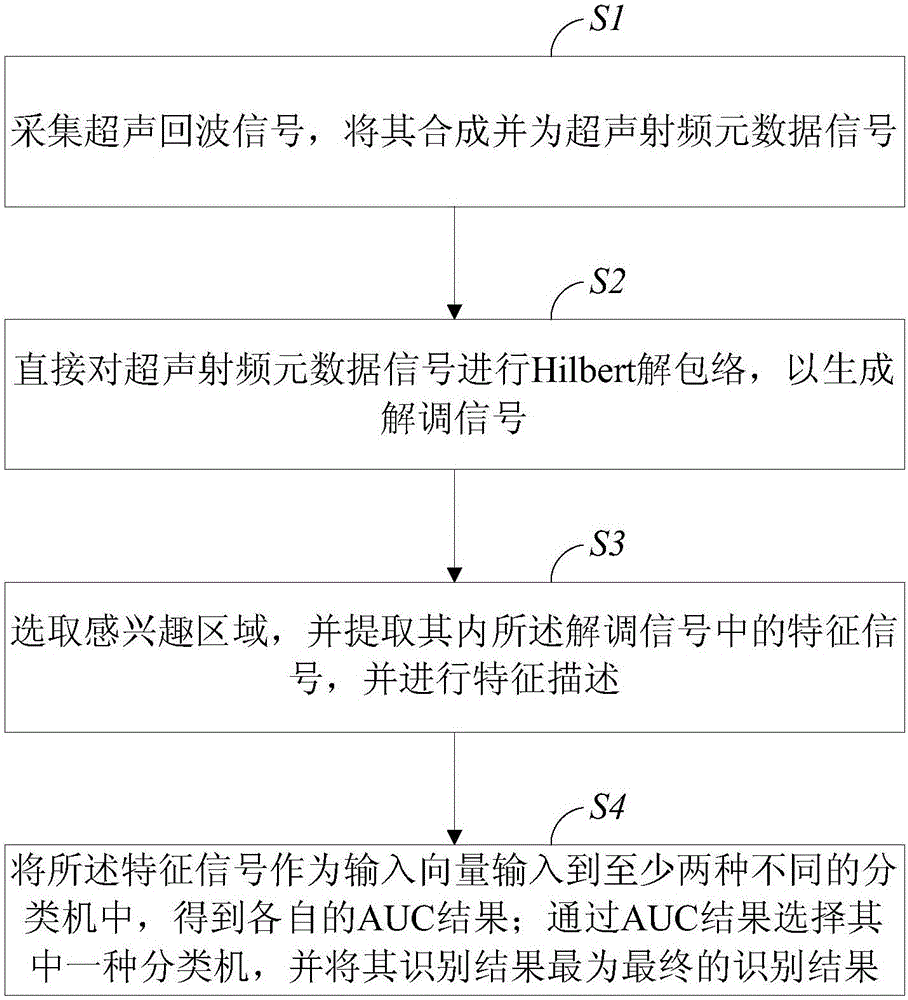

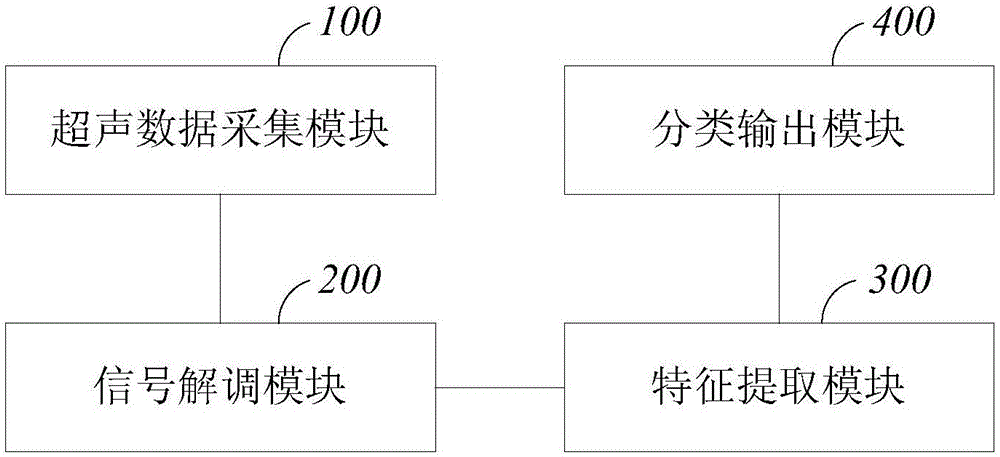

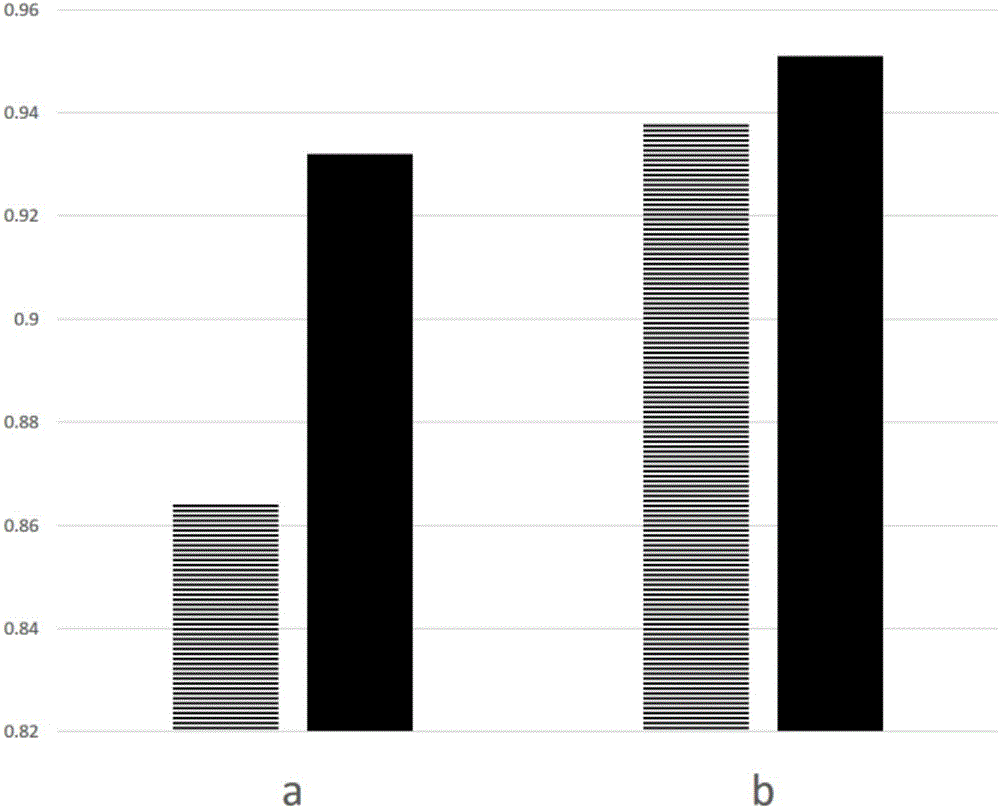

Automatic recognizing method and system for ultrasonic radiofrequency metadata

InactiveCN106725592AGood data consistencyComprehensive representationUltrasonic/sonic/infrasonic diagnosticsCharacter and pattern recognitionPattern recognitionSonification

The invention provides an automatic recognizing method and system for ultrasonic radiofrequency metadata. The method comprises the following steps: acquiring ultrasonic echo signals, and synthesizing the ultrasonic echo signals into ultrasonic radiofrequency metadata signals; directly carrying out Hilbert unwrapping on the ultrasonic radiofrequency metadata signals to generate demodulated signals; selecting an area-of-interest, extracting feature signals of the demodulated signals in the area-of-interest, and carrying out feature description; inputting the feature signals as input vectors to at least two different classifiers to obtain respective AUC results; selecting one of the classifiers through the AUC result; and setting the recognition result as the final recognition result. Extracted features cover strength, texture and fractal, and features of characterization images can be represented comprehensively; and furthermore, a plurality of classifiers are adopted, the optimal classifier is used, and therefore, the boundedness of the classifiers is overcome.

Owner:VINNO TECH (SUZHOU) CO LTD +2

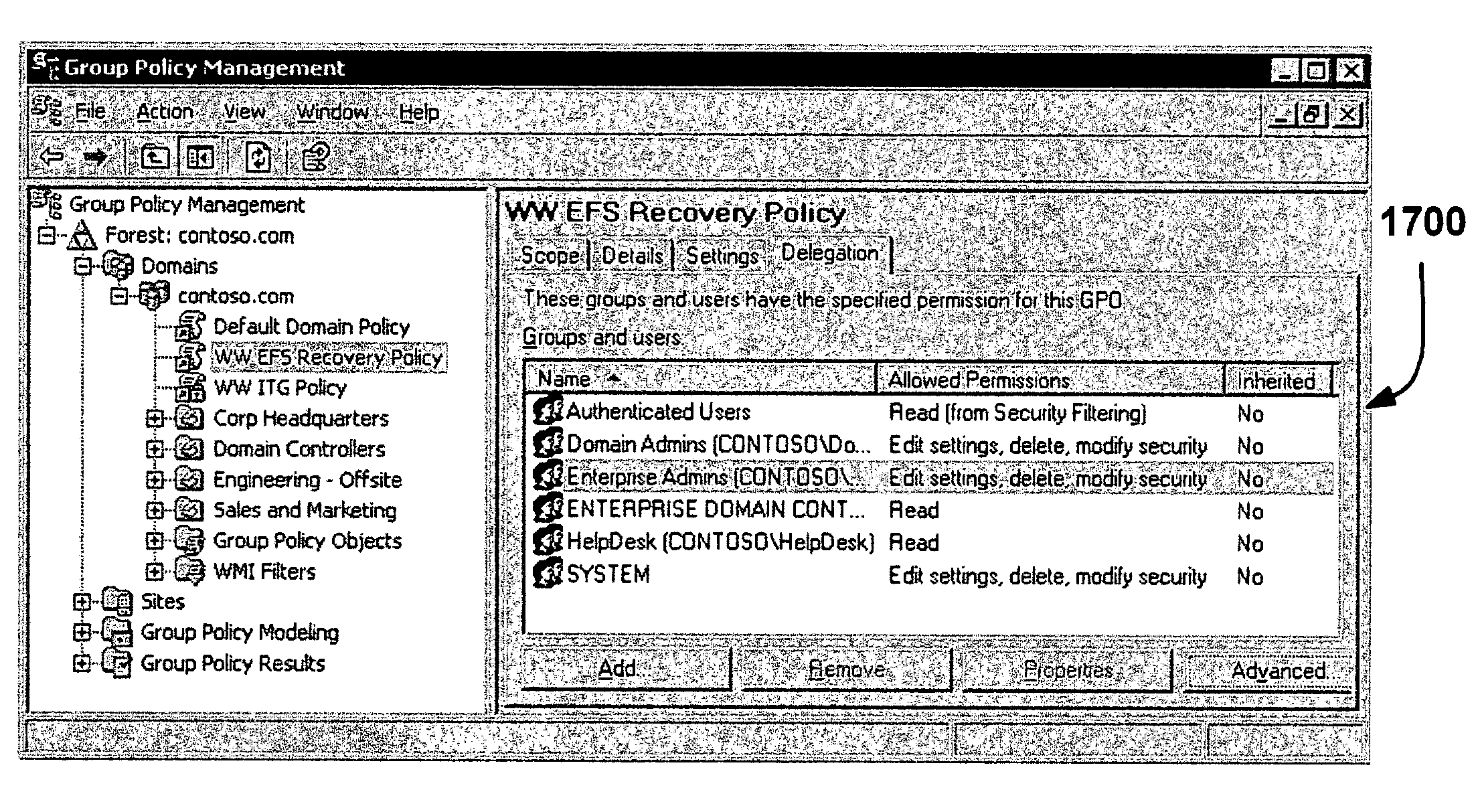

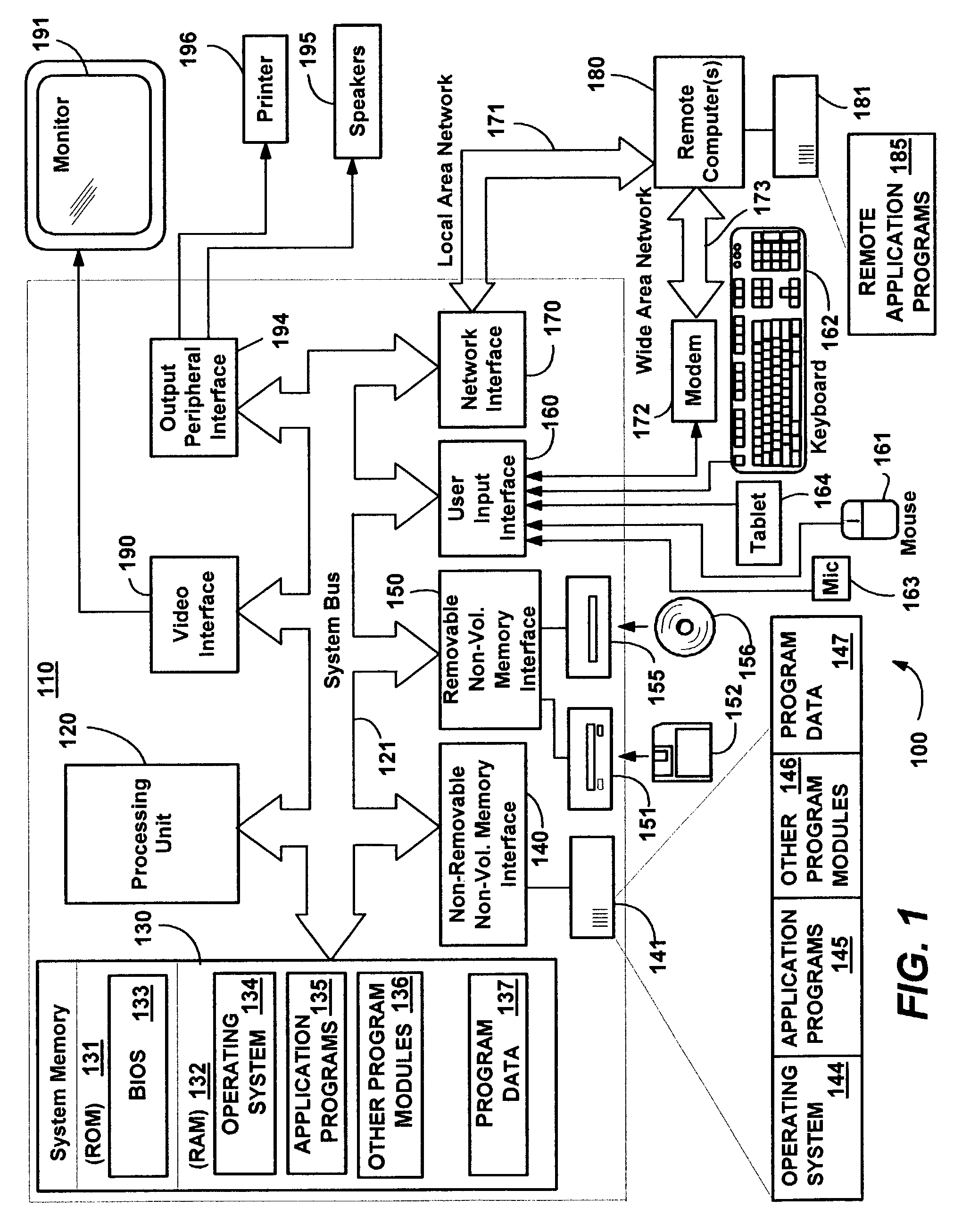

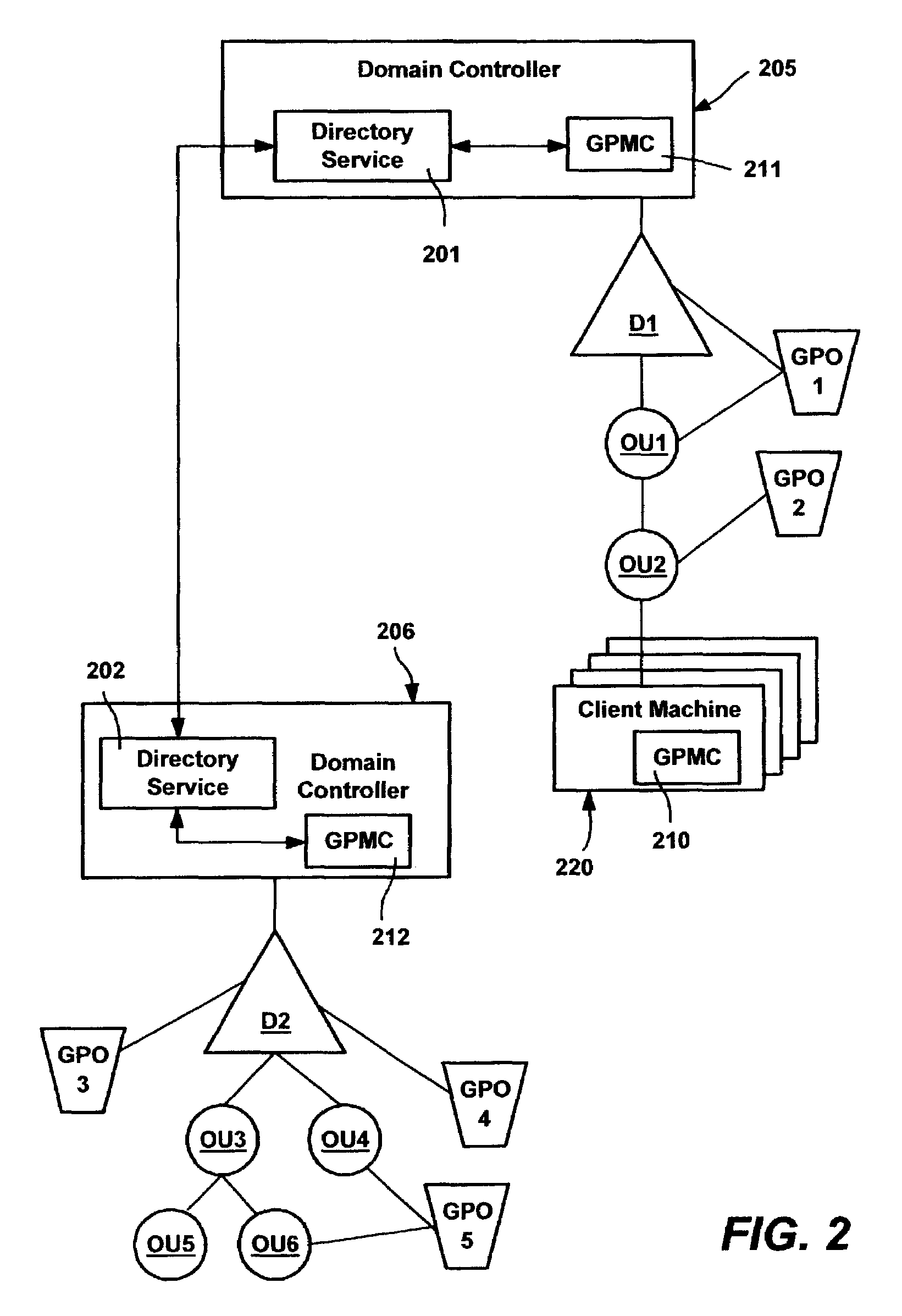

Method and system for representing group policy object topology and relationships

ActiveUS7614015B2Easy to manageComprehensive representationDigital data processing detailsMultiple digital computer combinationsTrust relationshipGroup Policy

A user interface is disclosed for representing group policy object topology and relationships, while allowing interaction to facilitate group policy management. Forests, sites and domains are hierarchically displayed in a treeview that reflects the network topology. The treeview also represents group policy objects, links, filters and other nodes. Administrators perform operations across forests, domains and sites, and perform operations on other nodes in the treeview. Administrators control which forests, sites and domains are viewable in the treeview, and the treeview state is persisted. Logic automatically reduces the topology's complexity by limiting the presentation of forests and / or domains to only those with which the administrator's forest and domain have a proper trust relationship. Also provided is a tabbed view in a result pane area that provides a rich display of complex data, and intelligent refresh logic to update changes in one user interface area to other user interface areas.

Owner:MICROSOFT TECH LICENSING LLC

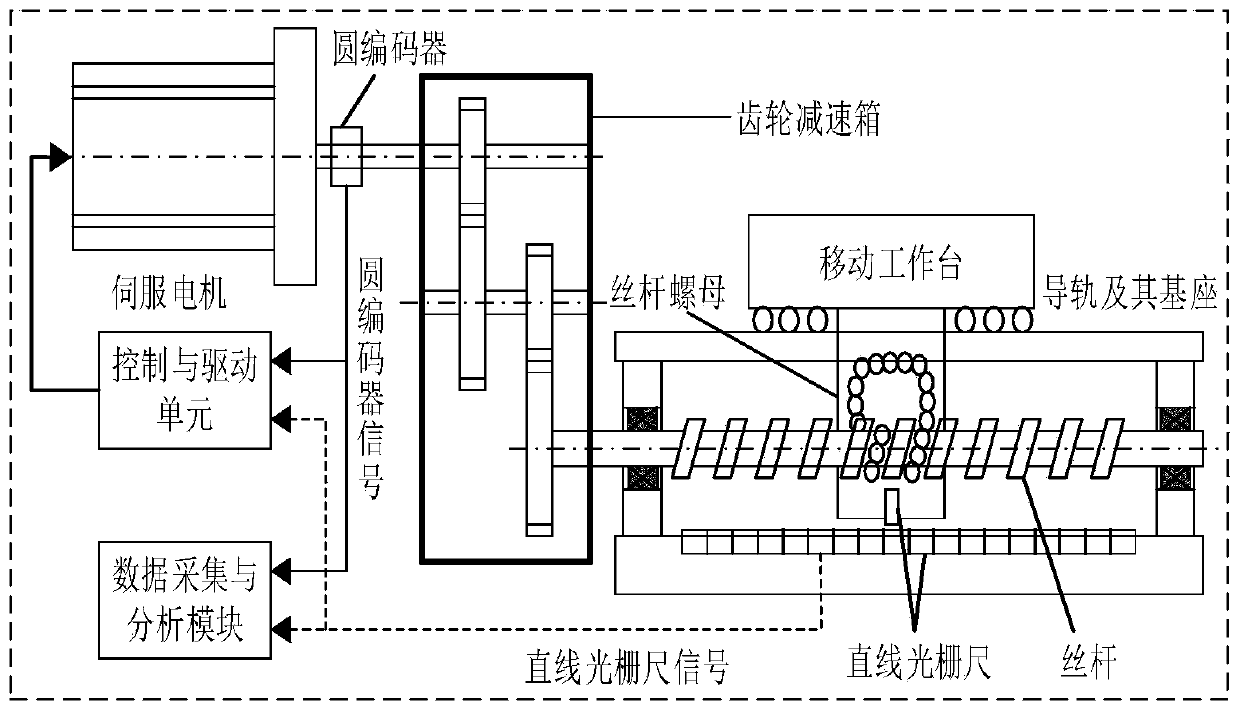

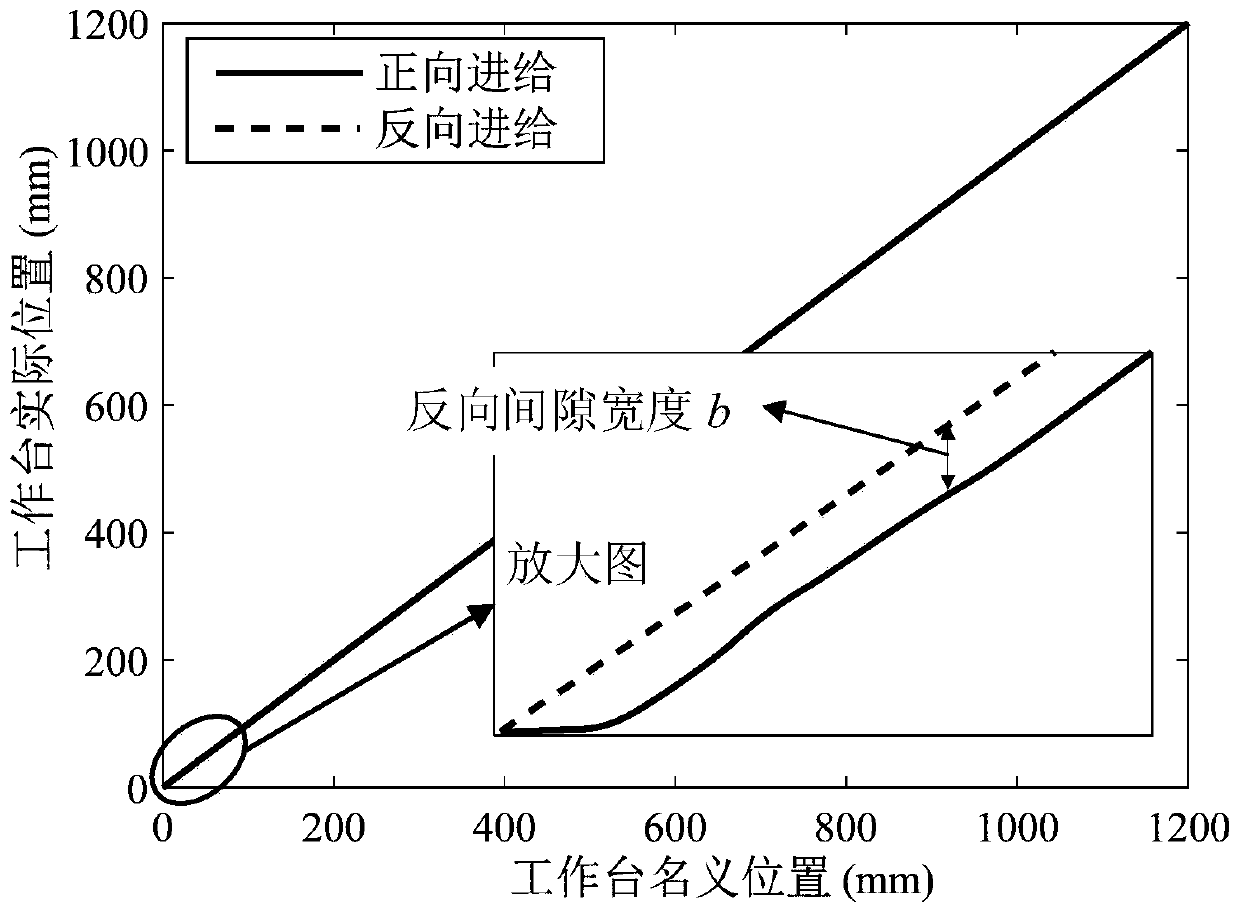

Method and device for dynamically detecting comprehensive error of mechanical transmission chain

PendingCN110398359ASimplify the calibration processEasy to operateMachine part testingStable stateGrating

The invention discloses a method for dynamically detecting the comprehensive error of a mechanical transmission chain. The method comprises the steps of: (1), controlling the workshop temperature to the constant temperature, and running a servo shaft system to feed for a period in a reciprocating manner in an effective stroke, so that the mechanical transmission chain reaches a thermal stable state; (2), controlling a servo shaft to feed for one time in a reciprocating manner in an effective stroke, simultaneously, measuring the motor rotation angle theta and the actual position of a workbenchby utilizing a built-in round coder, a linear grating ruler and a data acquisition system, and converting the motor rotation angle theta into the nominal position of the workbench; (3), calculating the reverse gap of a servo shaft transmission chain; (4), calculating the lead error of the transmission chain while positive feeding and the evaluation parameter of the lead error of the transmissionchain while positive feeding; and (5), calculating the evaluation parameter of the reverse lead error. A comprehensive, convenient and precise transmission chain comprehensive error detection method is established in the invention.

Owner:SOUTH CHINA UNIV OF TECH

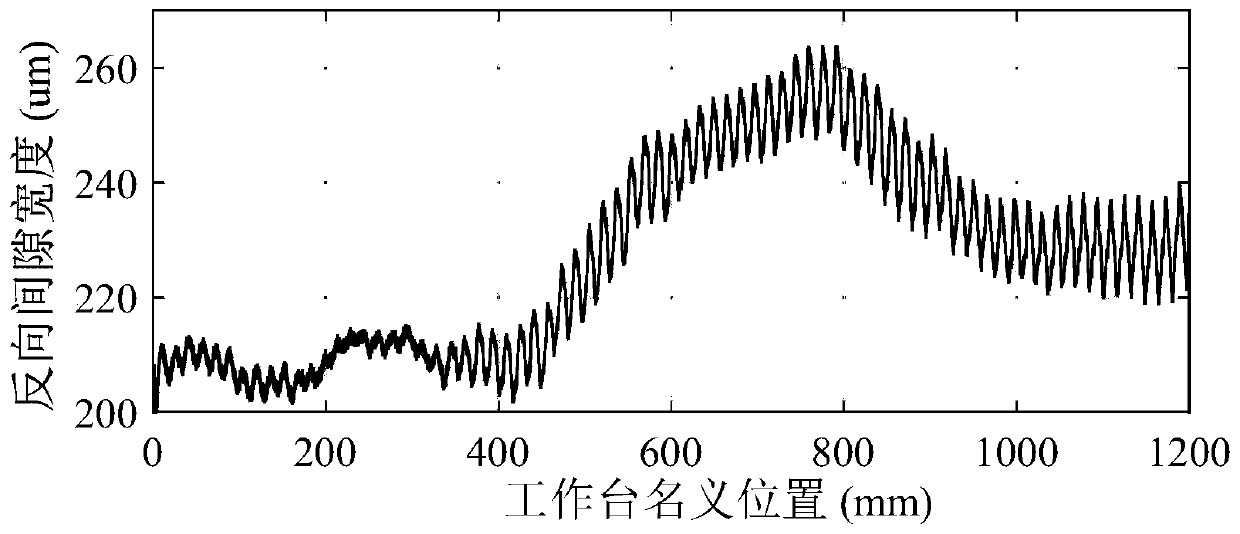

Thermal optical property representation and optimization method of optical window under low-temperature vacuum environment

The invention discloses a thermal optical property representation and optimization method of an optical window under a low-temperature vacuum environment, wherein a fused quartz window in a large-diameter parallel optical tube system under the low-temperature vacuum environment is simulated through a finite element method. The method is based on a customized surface type of an optical design software, wherein the surface type is combined with an even order aspheric surface type and the surface type of a gradient refractive index surface and used for representing optical window surface shape variation and material refractive index variation caused by temperature difference and pressure difference. A biasing afocal lens group is used for optimizing off-axis field of view wave aberration of the large-diameter parallel optical tube system, after surface shape variation caused by temperature variation is added, a zoom design is used for compensating system wave aberration and focal length variation caused by temperature, the wave aberration is optimized to be less than diffraction limit, thus, requirements of use are satisfied. The method has the advantages of comprehensively representing the optical window thermal optical property, using a small-diameter element for optimizing aberration of the large-diameter element, being adaptive to various temperature variations, being simple in structure, and so on.

Owner:NANJING UNIV OF SCI & TECH

Friction-stir-welding temperature field measurement special-purpose backing plate with grooves at bottom and method thereof

InactiveCN103644977AMeet the temperature field measurementComprehensive measurementThermometer detailsWork holdersEngineeringThermal cycle

The invention discloses a friction-stir-welding temperature field measurement special-purpose backing plate with grooves at the bottom and a method thereof. The special-purpose backing plate includes a backing-plate main body and set screws. The backing-plate main body includes an upper bottom face and a lower bottom face. The length direction of the backing-plate main body is identical with the welding direction of the friction stir welding. A plurality of grooves and bosses are arranged in the lower bottom face in a direction vertical to the welding direction of the friction stir welding. The grooves and the bosses are arranged alternatively. The middle position of each groove is provided with a through hole. Threads are arranged in a group of through holes on a center line in the length direction of the backing plate. The set screws are screwed into the through holes which are provided with the threads. The special-purpose backing plate and the measurement method thereof are capable of measuring welding thermal-cycle curves of different test points in a three-dimension direction within a shaft shoulder range of a welding piece precisely and reliably in a friction-stir-welding process so that the welding temperature field is understood and grasped comprehensively. Therefore, the special-purpose backing plate and the measurement method are of great significance both to comprehensive and systematical realizing of testing of the friction-stir-welding temperature field and promotion of scientific researches and engineering application of the friction stir welding.

Owner:JIANGSU UNIV OF SCI & TECH

Ultra-high-vacuum ultra-low-temperature in-situ multi-probe transport measurement system

PendingCN110501528AAchieve temperature controlRealize measurementScanning probe microscopyUltra-high vacuumAtmospheric air

The invention discloses an ultra-high-vacuum ultra-low-temperature in-situ multi-probe transport measurement system, which comprises a rapid sample injection chamber, a growth chamber, a transport test chamber, a vacuum interconnection system, a system support and a power system, wherein the rapid sample injection chamber is mainly used for realizing rapid transfer of samples and probe tips between the atmosphere and an ultra-high vacuum environment; the growth chamber mainly realizes growth of specified-pattern thin film devices and electrodes at high temperature; the transport test chamber mainly realizes in-situ multi-probe transport measurement of the grown thin film devices at extremely-low temperature; and the vacuum interconnection system mainly realizes vacuum connection between the system and other systems. The ultra-high-vacuum ultra-low-temperature in-situ multi-probe transport measurement system can control the sample temperature from low temperature to room temperature through the vacuum environment and refrigeration technology.

Owner:YISHENG SCI INSTR (JIAXING) CO LTD

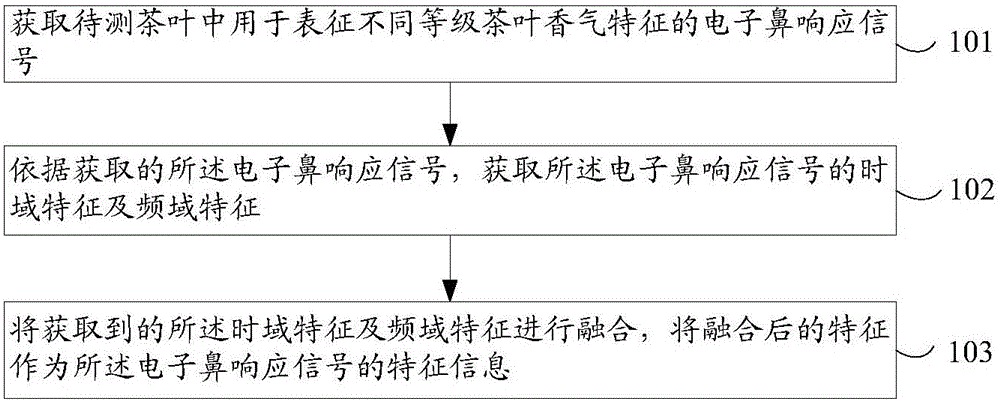

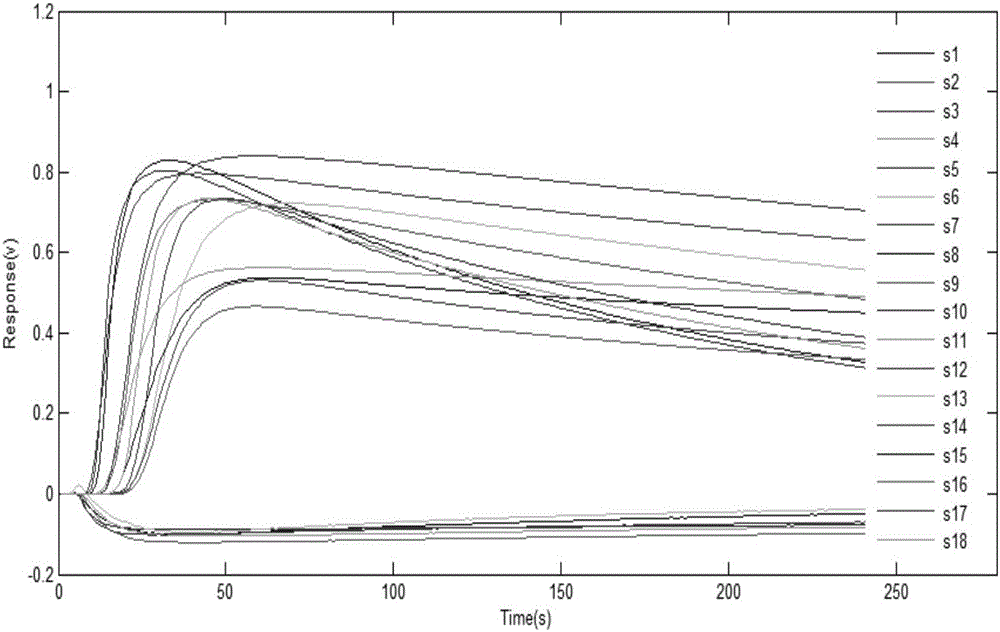

Method for fusing characteristic parameters of electron nose response signals in tea leaf grade identification

InactiveCN106093120AImprove recognition rateComprehensive representationMaterial analysis by electric/magnetic meansTime domainSensory analysis

The invention provides a method for fusing characteristic parameters of electron nose response signals in tea leaf grade identification. The method allows characteristic information of the electron nose response signals to be comprehensively characterized in order to improve the tea leaf grade recognition rate. The method comprises the following steps: acquiring electron nose response signals of tea leaves to be measured and used for characterizing the fragrance characteristics of tea leaves with different grades; acquiring the time domain characteristics and the frequency domain characteristics of the electron nose response signals according to the acquired electron nose response signals; and fusing the acquired time domain characteristics and the frequency domain characteristics, and using the fused characteristics as the characteristic information of the electron nose response signals. The method is suitable for the technical field of intelligent sensory analysis of foods.

Owner:UNIV OF SCI & TECH BEIJING

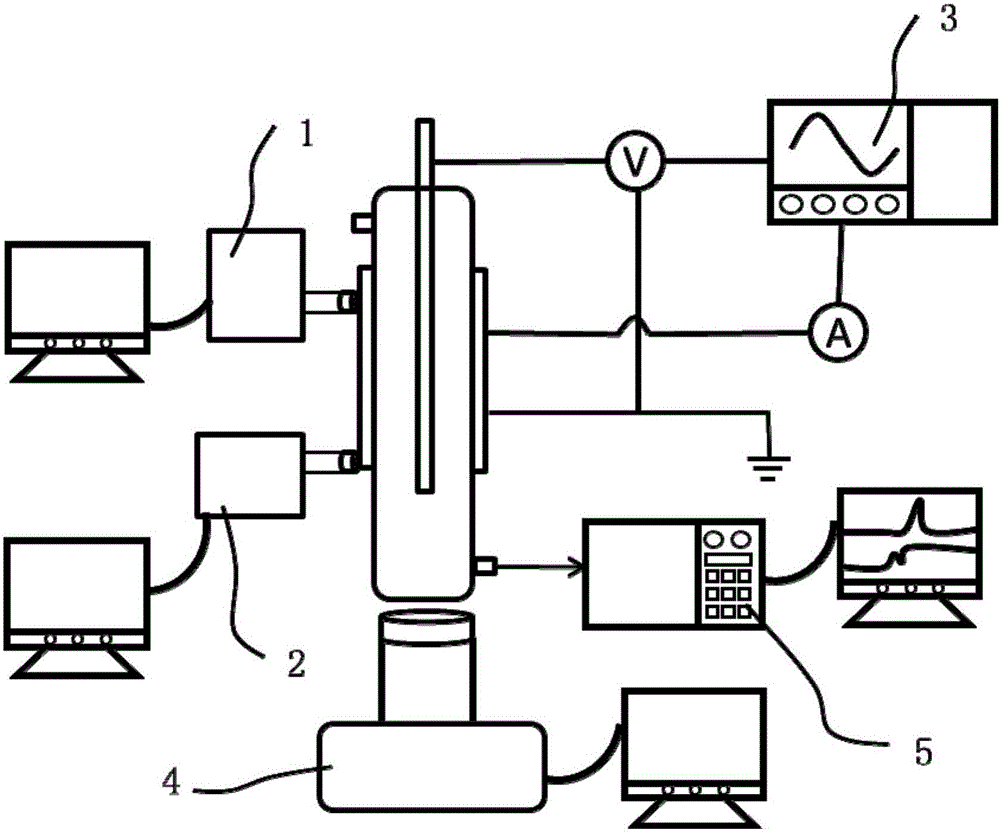

Plasma in-situ characterization system

InactiveCN106248654AReal-time monitoring of temperature distributionRecord the discharge status in real timeDigital variable displayMaterial analysis by electric/magnetic meansPlasma electronHigh pressure

The invention relates to a plasma in-situ characterization system, which comprises an emission spectrometer, a high speed image capturing system, a digital oscilloscope, an infrared imager and an online mass spectrometer, wherein an optical fiber probe and a first image collector are arranged in the discharge core region of a plasma discharge reactor, the voltage probe attachment high voltage electrode of the digital oscilloscope is connected to the high voltage electrode of the plasma discharge reactor, the voltage probe attachment grounding electrode is connected to a ground wire, the current probe is connected to the plasma discharge reactor, the second image collector of the infrared imager is towards the plasma discharge core region, and the sample injection tube of the online mass spectrometer is connected to the outlet of a plasma discharge reaction zone. According to the present invention, various parts of the plasma in-situ characterization system are synergistically matched, such that the types and the number of the plasma active species, the plasma discharge state, the current voltage waveform, the plasma electron density, the plasma zone temperature distribution, the plasma zone product composition and the like can be real-timely monitored in the full-direction, and the in-situ characterization can be performed on the plasma discharge process.

Owner:CHINA PETROLEUM & CHEM CORP +1

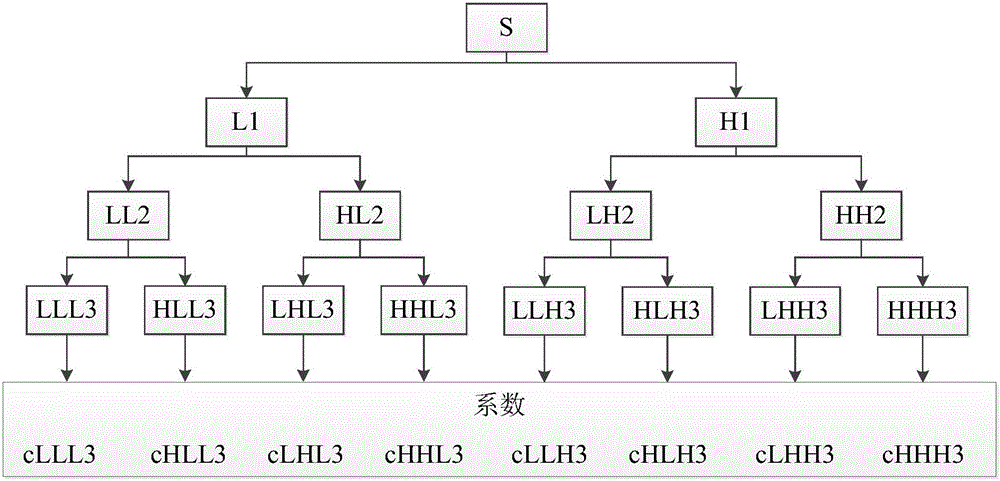

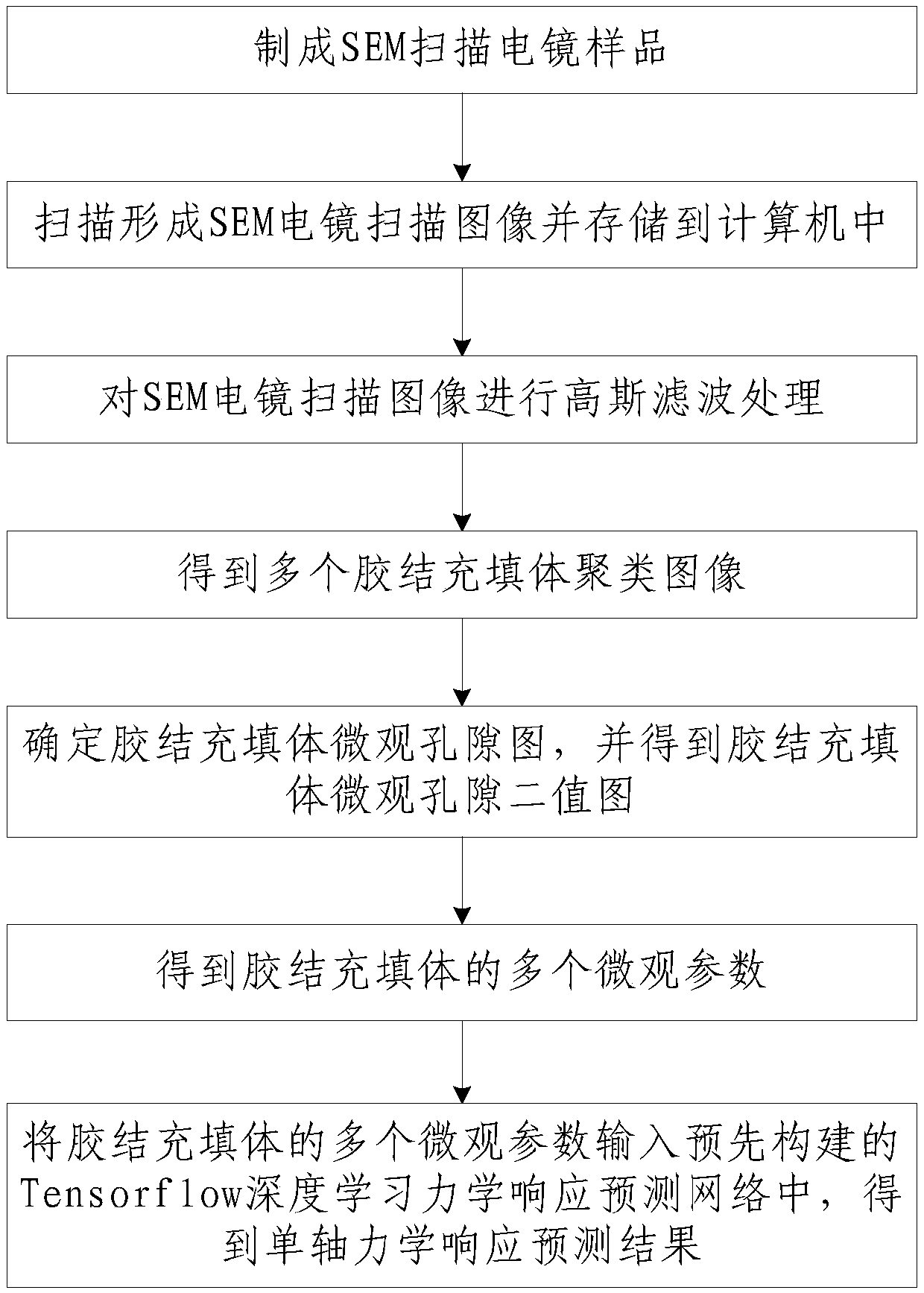

Method for predicating mechanical response characteristic of cemented backfill based on images and microscopic parameters

ActiveCN108445030APredicting Mechanical Response PropertiesThe method steps are simpleImage enhancementImage analysisScanning electron microscopeMaterial resources

The invention discloses a method for predicating the mechanical response characteristic of a cemented backfill based on images and microscopic parameters. The method comprises the following steps: 1,preparing an SEM (scanning electron microscope) sample; 2, performing scanning to form an SEM scanning image, and storing the SEM scanning image in a computer; 3, performing Gaussian filtering processing on the SEM scanning image; 4, obtaining multiple cluster images of the cemented backfill; 5, determining the microscopic pore map of the cemented backfill to obtain a microscopic pore binary imageof the cemented backfill; 6, analyzing and processing the microscopic pore binary image of the cemented backfill to obtain multiple microscopic parameters of the cemented backfill; and 7, inputting the multiple microscopic parameters of the cemented backfill into a pre-built Tensorflow deep learning mechanical response prediction network, and obtaining a uniaxial mechanical response prediction result. The method has the advantages of high prediction efficiency, high prediction precision, low consumption of manpower and material resources, great values in studying the strength and the stability of the cemented backfill, strong practicability and high promotion and application values.

Owner:XIAN UNIV OF SCI & TECH

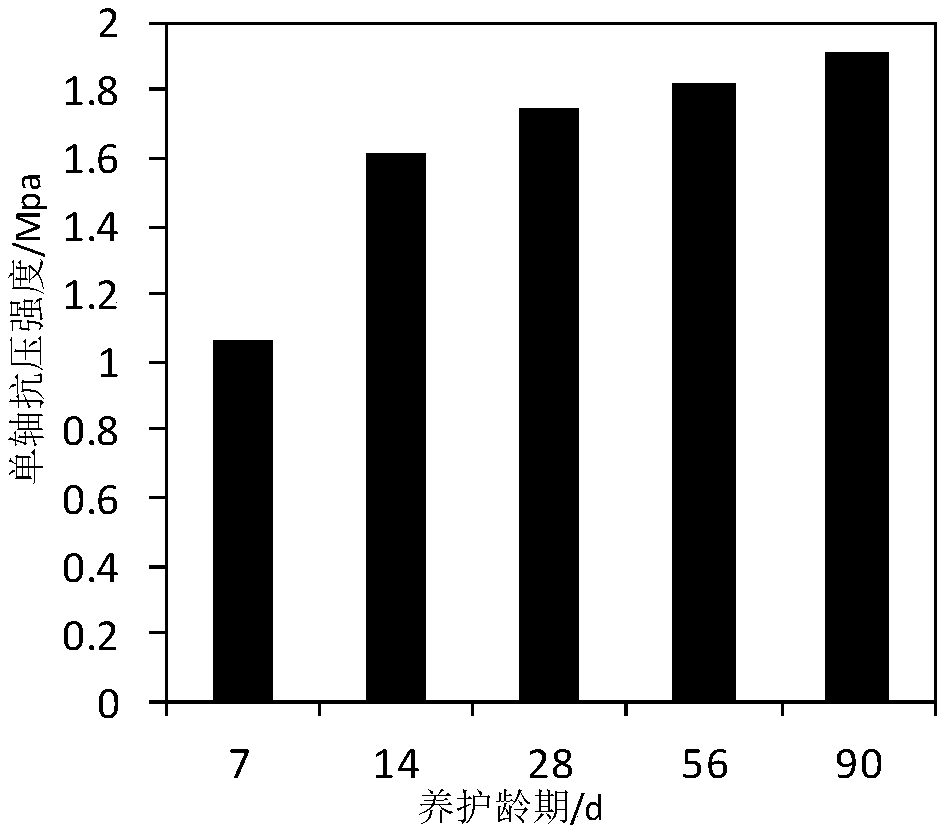

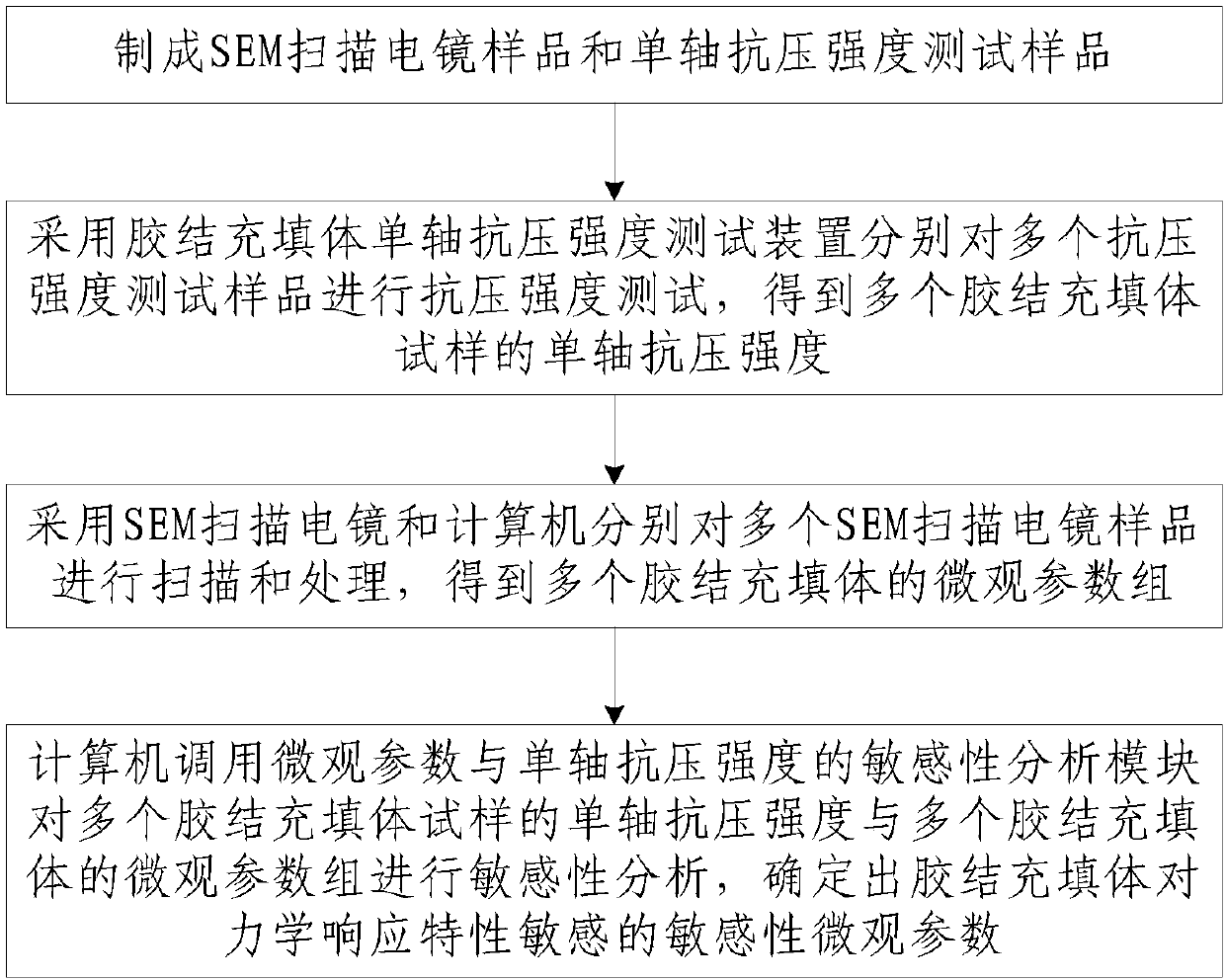

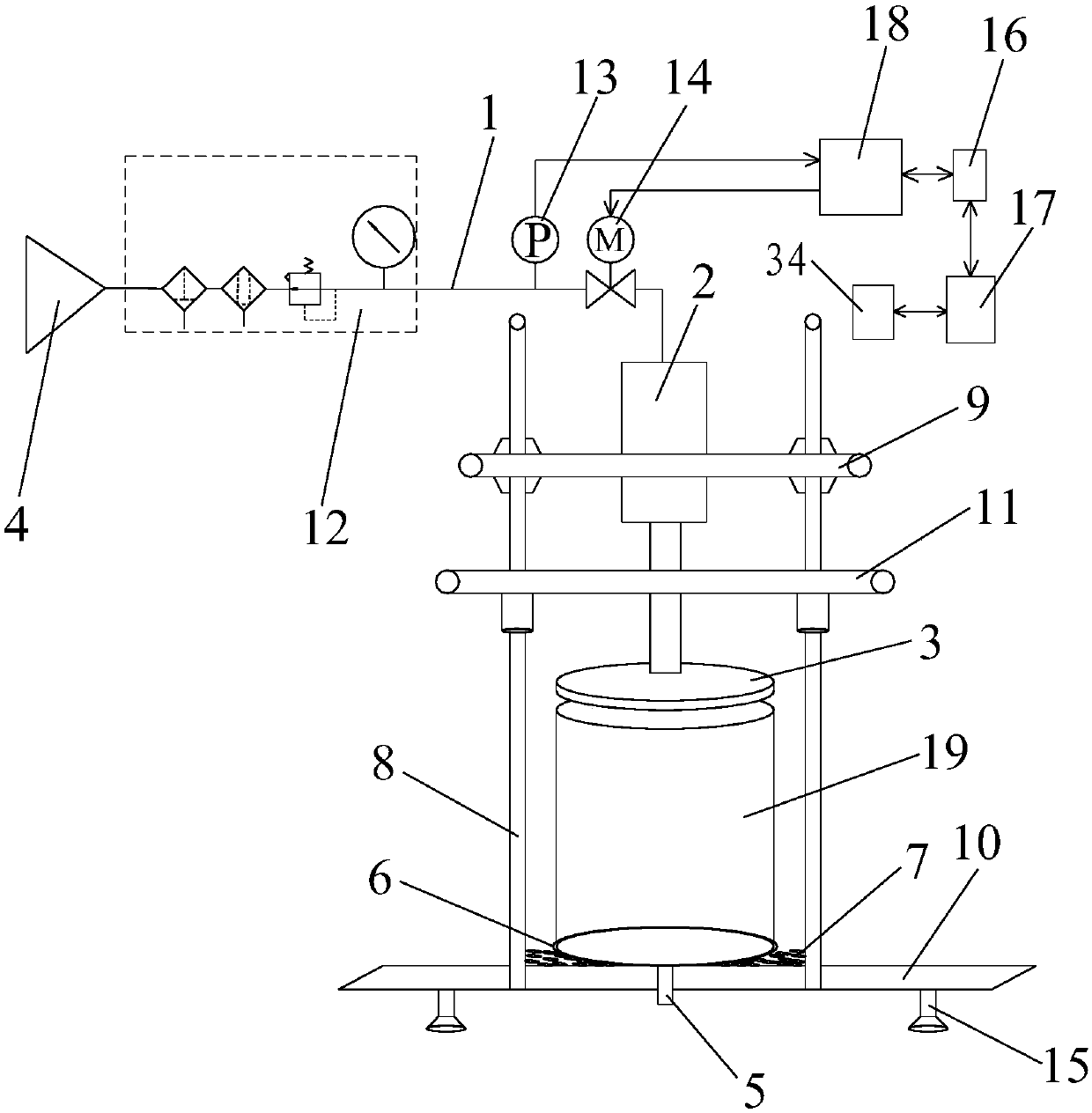

Cemented backfill microscopic parameter sensitivity analysis method based on image processing

ActiveCN108287254AThe method steps are simpleNovel and reasonable designMaterial strength using tensile/compressive forcesScanning probe techniquesImaging processingSensitive analysis

The invention discloses a cemented backfill microscopic parameter sensitivity analysis method based on image processing. The method comprises the steps of 1, preparing an SEM scanning electron microscope sample and a single-axis compressive strength testing sample; 2, performing single-axis compressive strength testing on a plurality of compressive strength testing samples by means of a cemented backfill single-axis compressive strength testing device, and obtaining the single-axis compressive strength of a plurality of cemented backfill samples; 3, obtaining a microscopic parameter set of theplurality of cemented backfills; and 4, calling the microscopic parameter and a sensitivity analysis module for the single-axis compressive strength for performing sensitivity analysis on the single-axis compressive strength of the plurality of cemented backfill samples and the microscopic parameter set of the plurality of cemented backfills, and determining the sensitivity microscopic parameterof the cemented backfill to mechanical response characteristic sensitivity. The method can well determine a primary and secondary relation of the microscopic parameters and can help in researching a new cemented backfill.

Owner:XIAN UNIV OF SCI & TECH

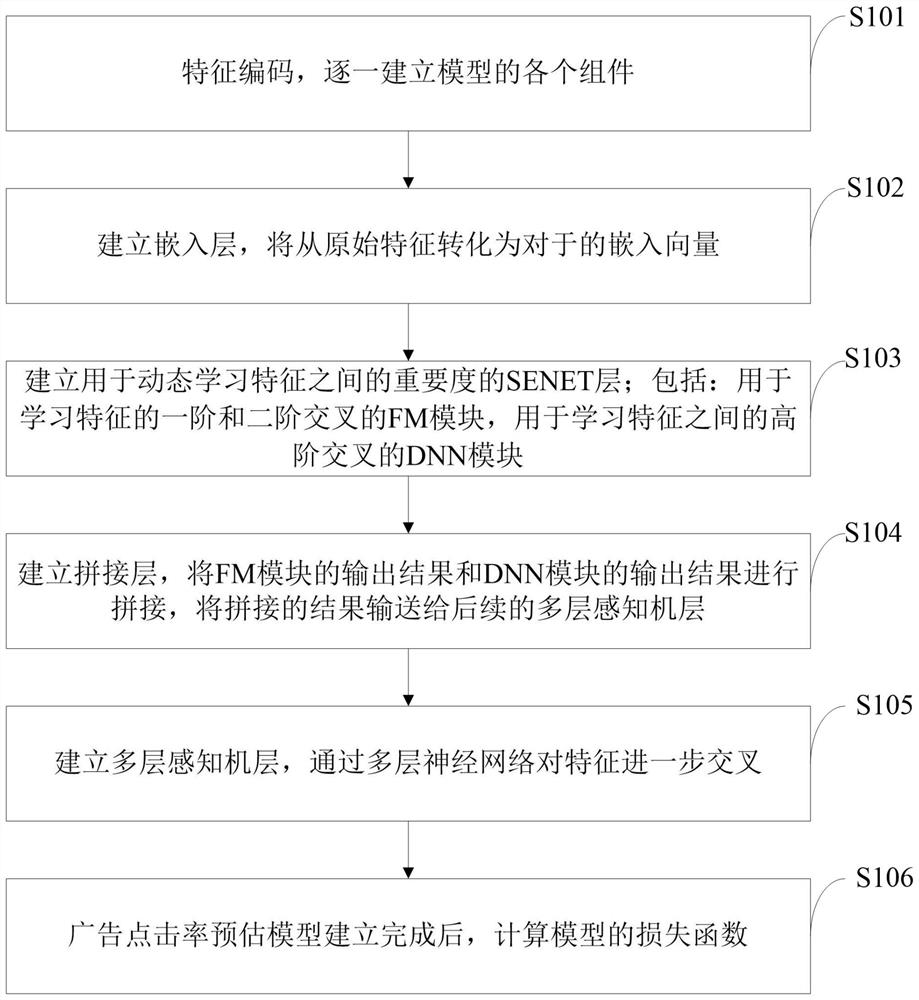

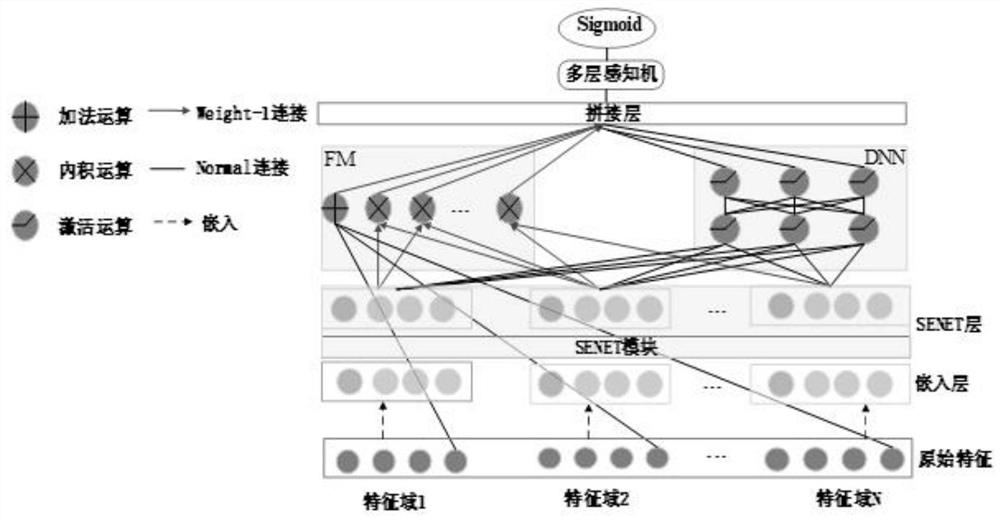

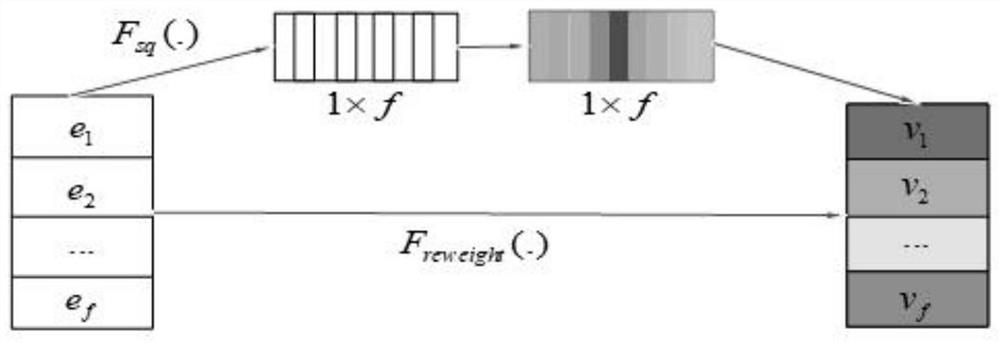

Advertisement click rate estimation method

ActiveCN112365297AComprehensive representationImprove accuracyNeural architecturesMarketingPattern recognitionActivation function

The invention belongs to the technical field of advertisement click rate estimation, and discloses an advertisement click rate estimation method, which comprises the steps of dividing original features into different feature domains to obtain corresponding onehot vectors; obtaining a corresponding embedded vector; carrying out compression and excitation processing on the embedded vector of each feature domain through an SENET layer, learning the importance degree of the features, carrying out re-calibration, and weighting the importance degree of the features to the original embedded vector toobtain a new embedded vector; learning second-order feature interaction information through FM, and learning high-order feature interaction information through DNN to obtain a corresponding output vector; splicing the output vectors of the FM and the DNN; and inputting a spliced result into a multi-layer perceptron, obtaining an estimated advertisement click probability through a softmax activation function, and evaluating the quality of the model. Compared with other models, the advertisement click rate prediction model is better in performance, and the accuracy is improved.

Owner:EAST CHINA UNIV OF TECH

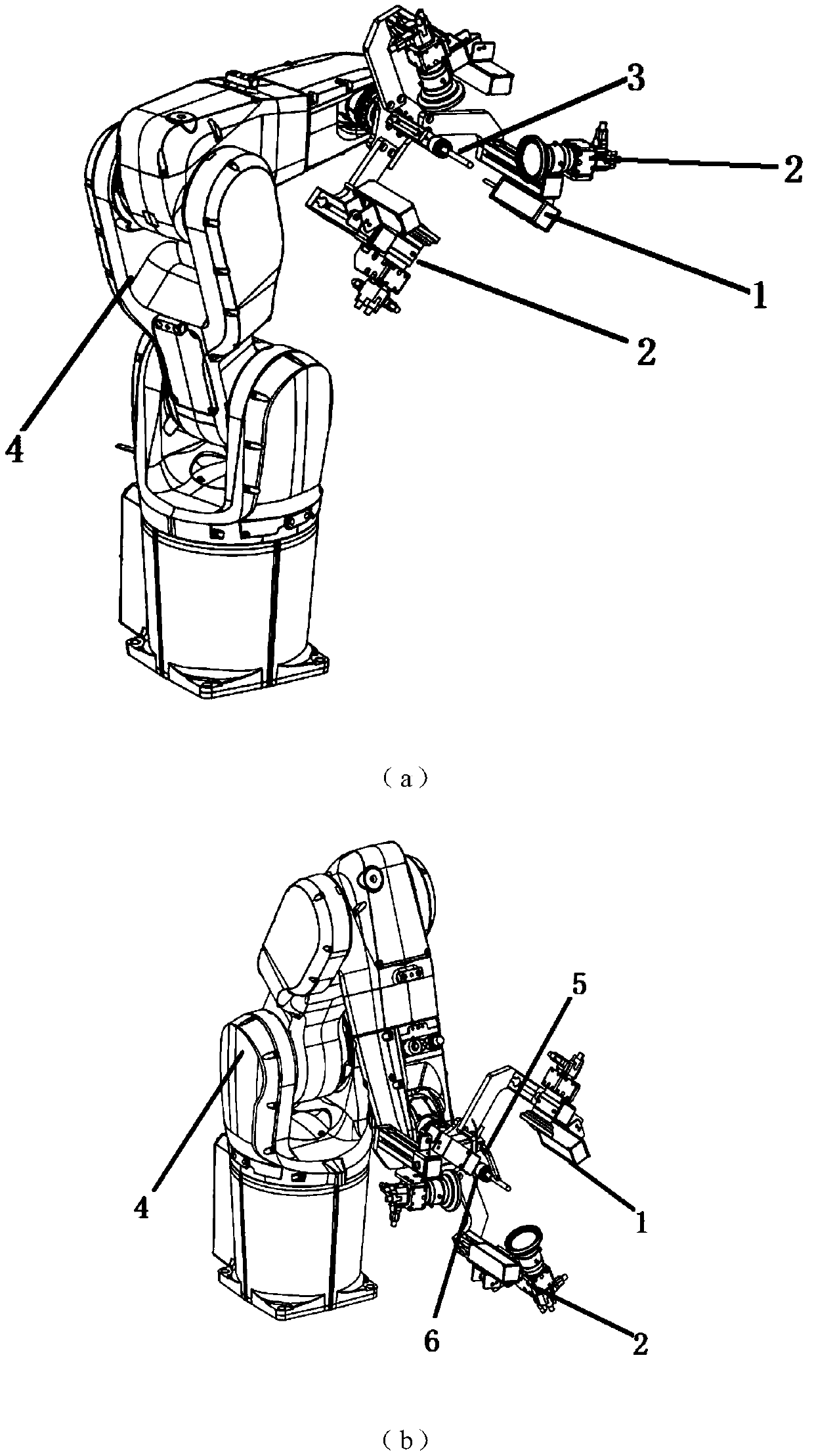

Method for characterizing cigarette combustion carbon line quality by simulating whole cigarette smoking process of human body and full-vision measurement based on manipulator

ActiveCN111426794AGuaranteed collectionLight evenlyProgramme-controlled manipulatorChemical analysis using combustionTest sampleEngineering

The invention relates to a method for characterizing cigarette combustion carbon line quality by simulating a human body cigarette smoking whole process and full vision measurement based on a manipulator. The method is as follows: a cigarette to be detected is clamped by the manipulator, and the axial direction of a cigarette placed at a clamping position is vertical to a camera of a camera systemand a light source of a lighting system; after the cigarette to be detected is ignited, the manipulator starts to move or statically burn according to a cigarette smoking path of a simulated human body, and the camera system collects an image of the cigarette before combustion and collects an image of a cigarette combustion ash column in real time; and when the cigarette is burnt to a set test length, the acquisition of the cigarette burning ash column image is stopped, an acquired image is processed, and the cigarette burning carbon line quality is judged according to obtained cigarette burning carbon line width and cigarette burning carbon line uniformity. According to the invention, through the real-time acquisition and datamation of cigarette combustion images, a test sample is accurately and objectively judged and compared, and the influence of test data distortion caused by single-side acquisition on the accuracy of a test result is avoided.

Owner:CHINA TOBACCO YUNNAN IND

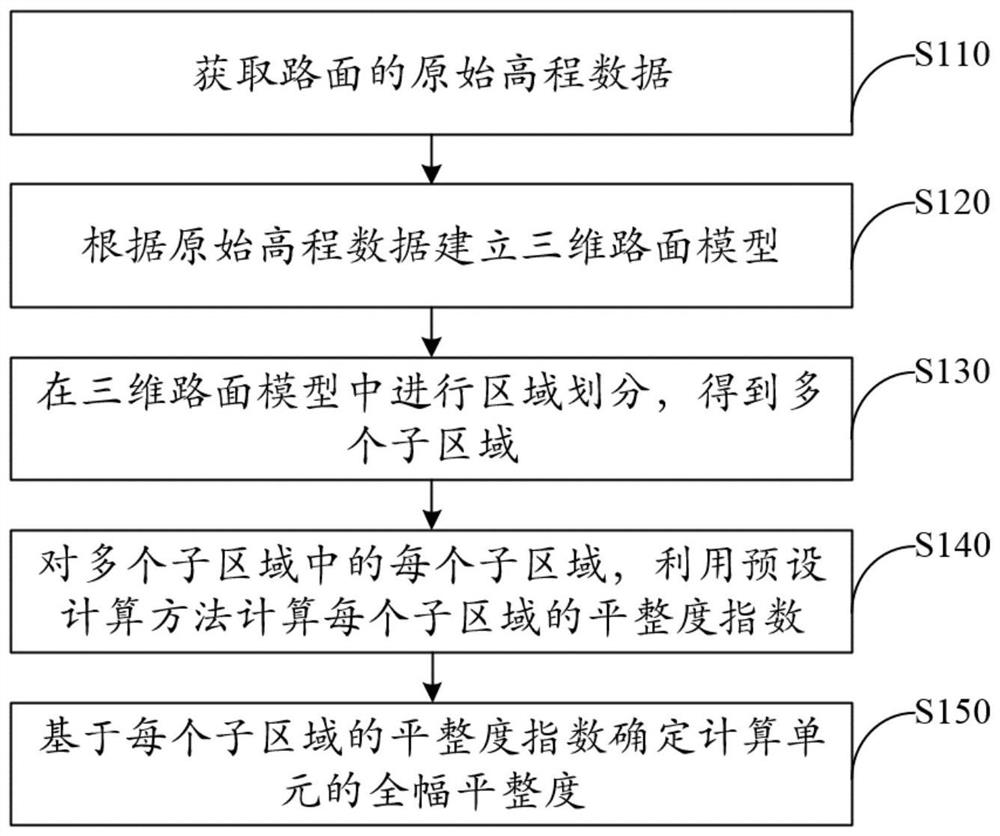

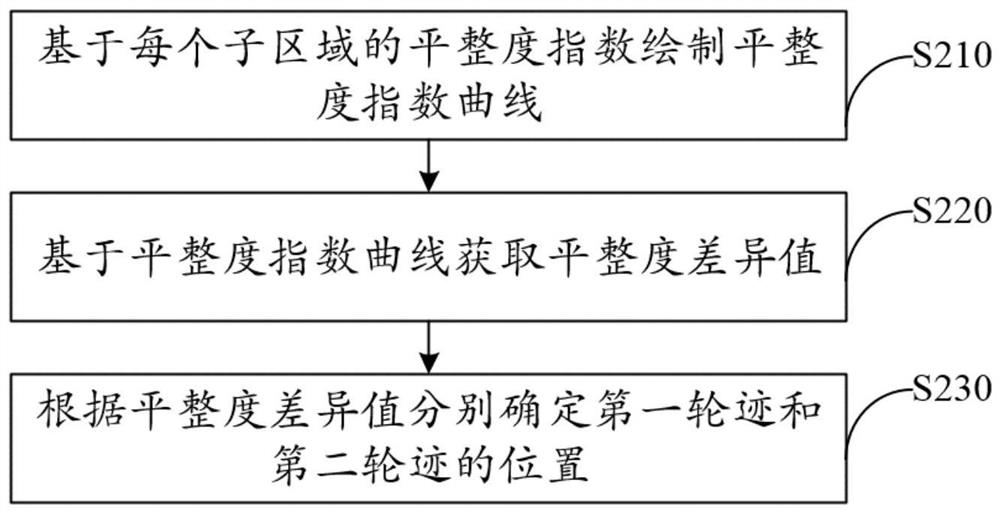

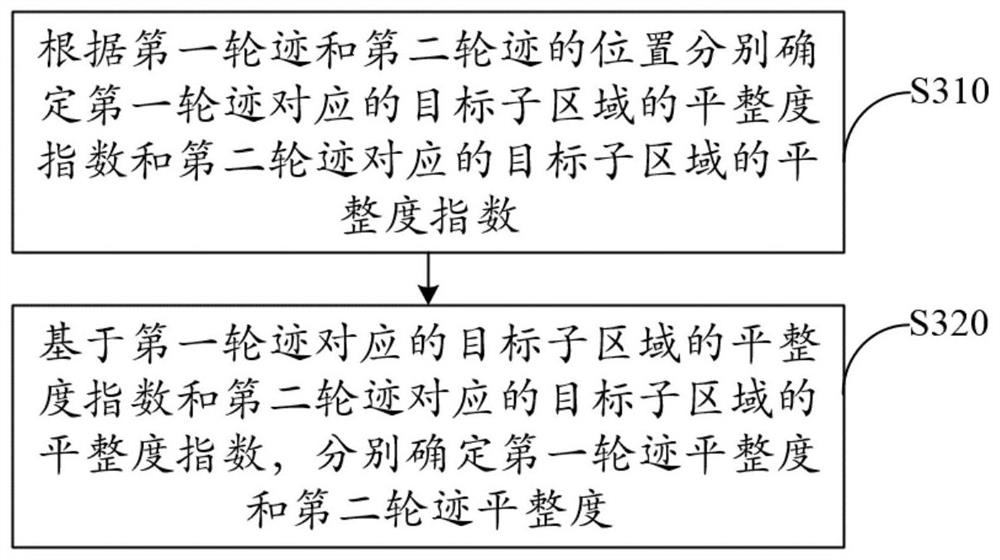

Full-width flatness detection method based on three-dimensional road surface

ActiveCN113638295AComprehensive representationAccurate representationRoads maintainence3D modellingRoad surfaceControl theory

The invention provides a full-width flatness detection method based on a three-dimensional road surface, and belongs to the technical field of road detection. The method comprises the following steps: acquiring original elevation data of a road surface; establishing a three-dimensional pavement model according to the original elevation data, wherein the three-dimensional pavement model is used for representing the elevation of each position point in the pavement; performing region division in the three-dimensional pavement model to obtain a plurality of sub-regions, wherein the width and length of each sub-region are within a preset numerical interval, and the combination of the plurality of sub-regions covers the measured breadth of the pavement; for each sub-region in the plurality of sub-regions, calculating the flatness index of each sub-region by using a preset calculation method; and determining the full-width flatness of the calculation unit based on the flatness index of each sub-region, wherein the full-width flatness comprises the maximum flatness, the flatness mean value, the first wheel track flatness, the second wheel track flatness and the weighted flatness. According to the invention, the flatness condition of the road under the whole measurement breadth can be represented.

Owner:WUHAN WUDA ZOYON SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com