Thermal optical property representation and optimization method of optical window under low-temperature vacuum environment

An optical window and low-temperature vacuum technology, applied in the field of optical thermal analysis, can solve the problems of difficult operation, high cost, and insufficient characterization, and achieve the effect of difficult operation, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A thermo-optical characteristic characterization and optimization method of an optical window in a low-temperature vacuum environment, the method steps are as follows:

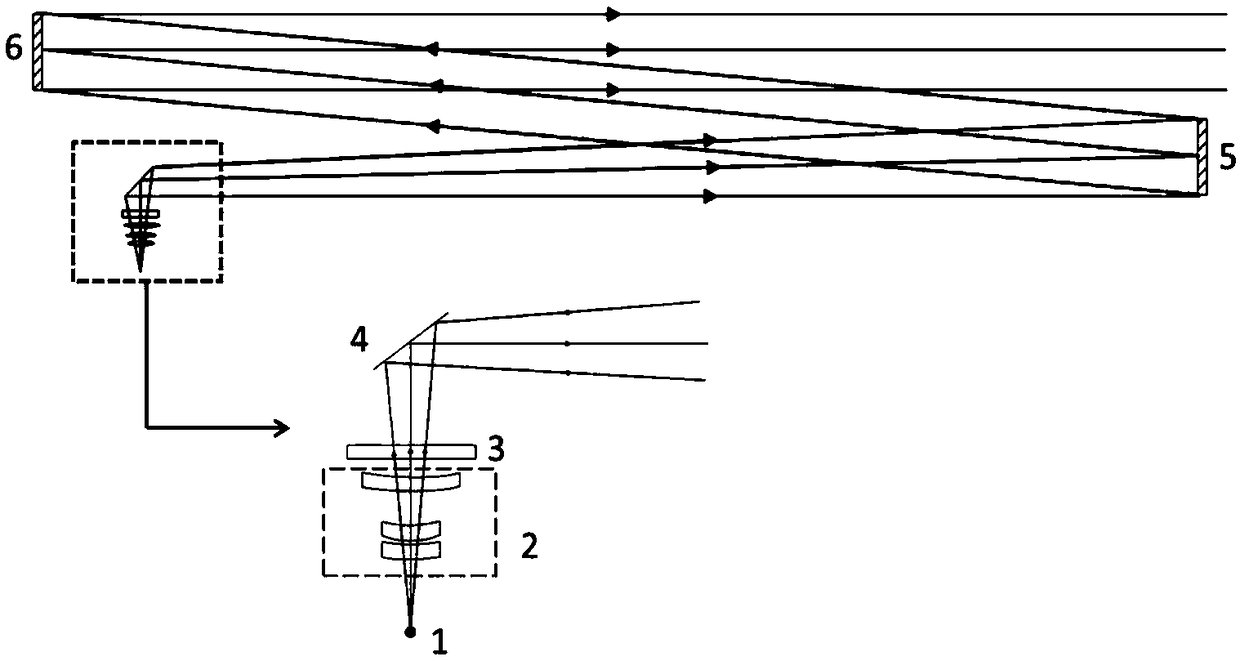

[0063] Step 1, establish the optical design model of the large-aperture collimator (in ZEMAX software), and form the large-aperture collimator system;

[0064] combine figure 1 , to establish the initial structure, which only contains the optical window 3, the first plane mirror 4, the second plane mirror 5 and the off-axis paraboloid 6, such as Figure 4 As shown in (a1) and (a2), the wave aberration in most of the field of view of the system is above the diffraction limit.

[0065] Step 2, using an afocal offset lens group to optimize the off-axis field of view aberration of the large aperture collimator system;

[0066] In the optical design software ZEMAX, the light path of the large-aperture collimator is established. The light source 1 emits a bunch of spherical waves that enter the offset lens ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com