Ultra-high-vacuum ultra-low-temperature in-situ multi-probe transport measurement system

A technology of ultra-high vacuum and measurement system, which is applied in the direction of measurement device, scanning probe technology, scanning probe microscopy, etc., and can solve the problems that the in-situ transportation test of thin film device growth cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations. The basic principles of the present invention defined in the following description can be applied to other embodiments, variations, improvements, equivalents and other technical solutions without departing from the spirit and scope of the present invention.

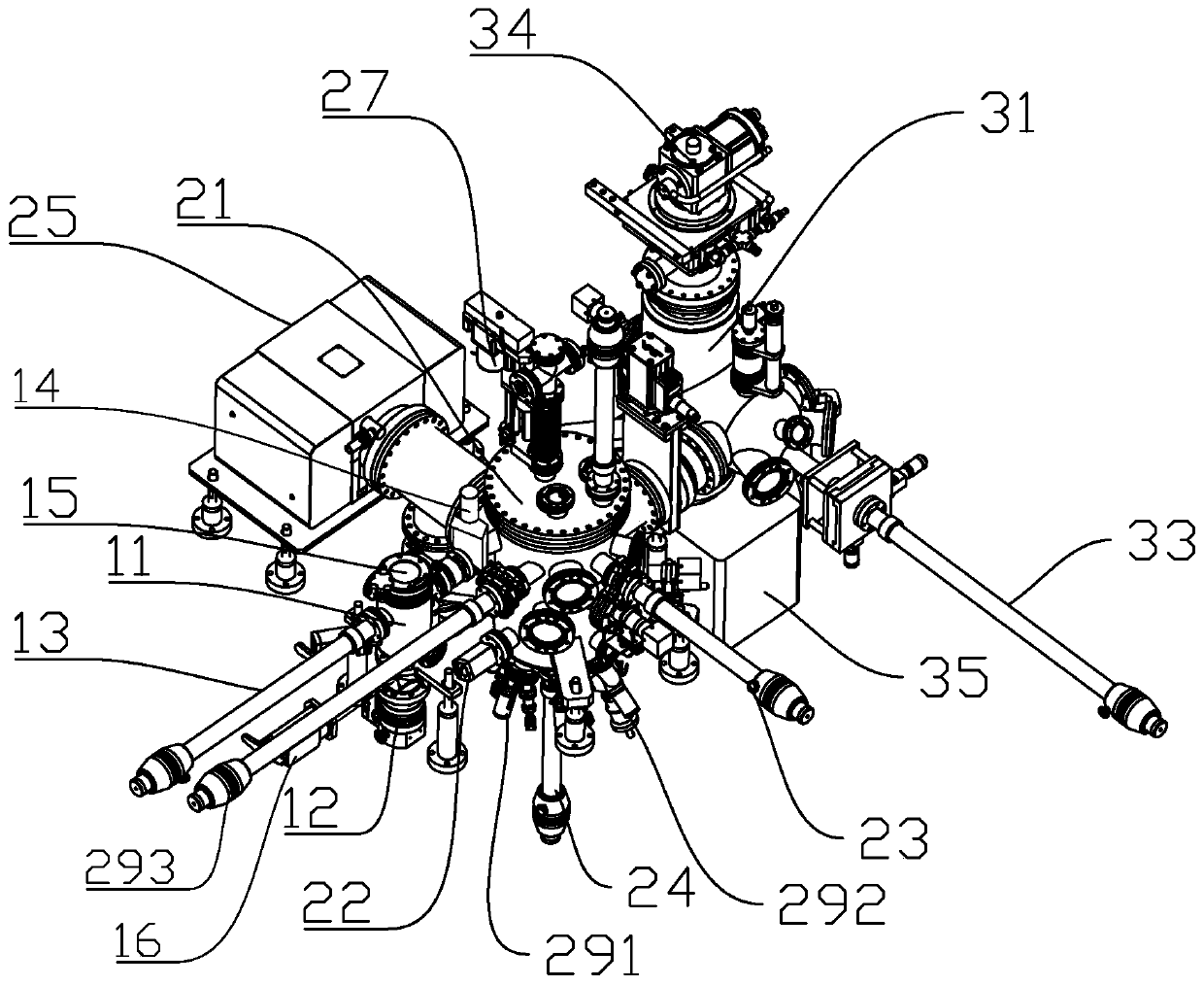

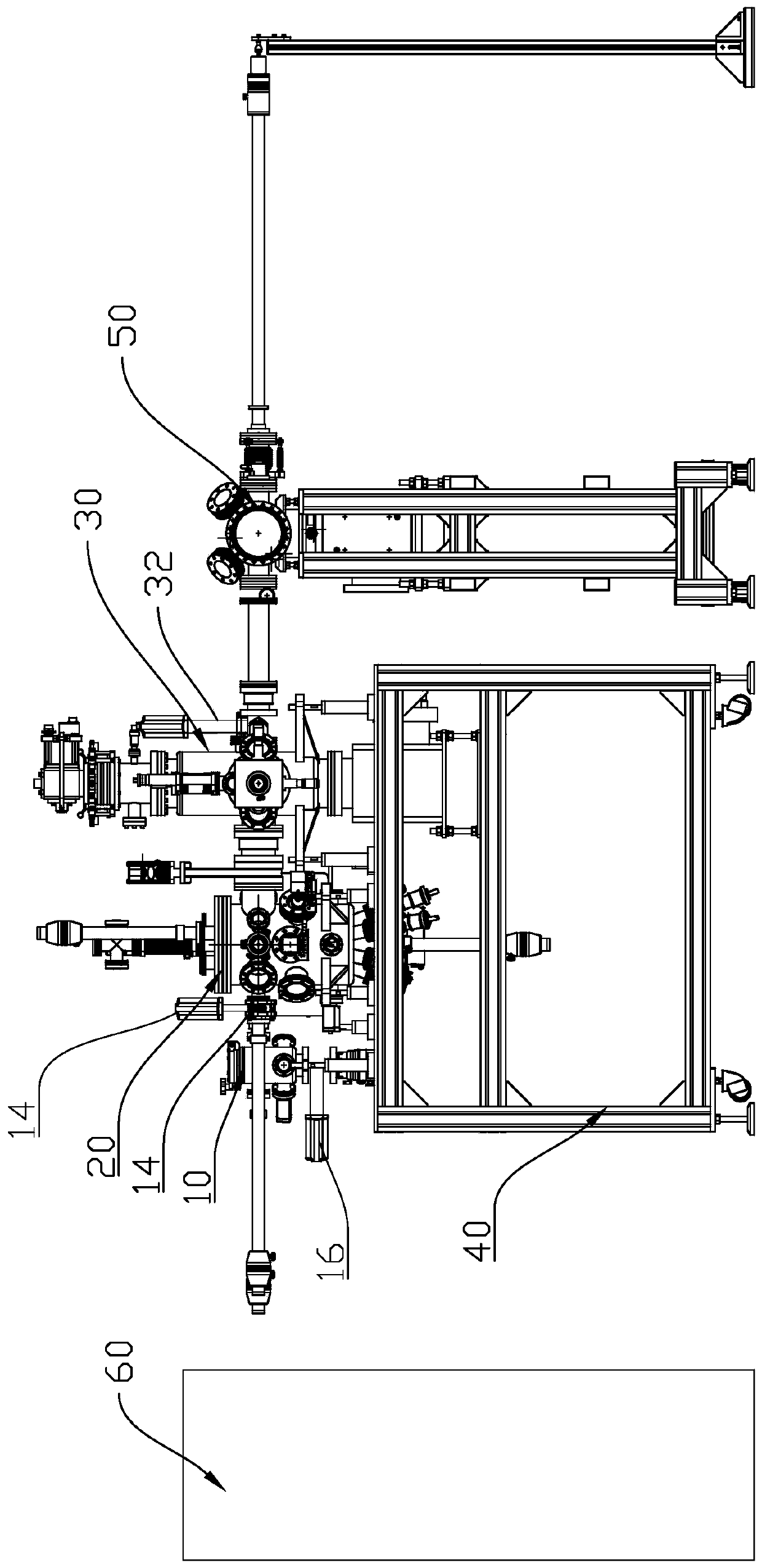

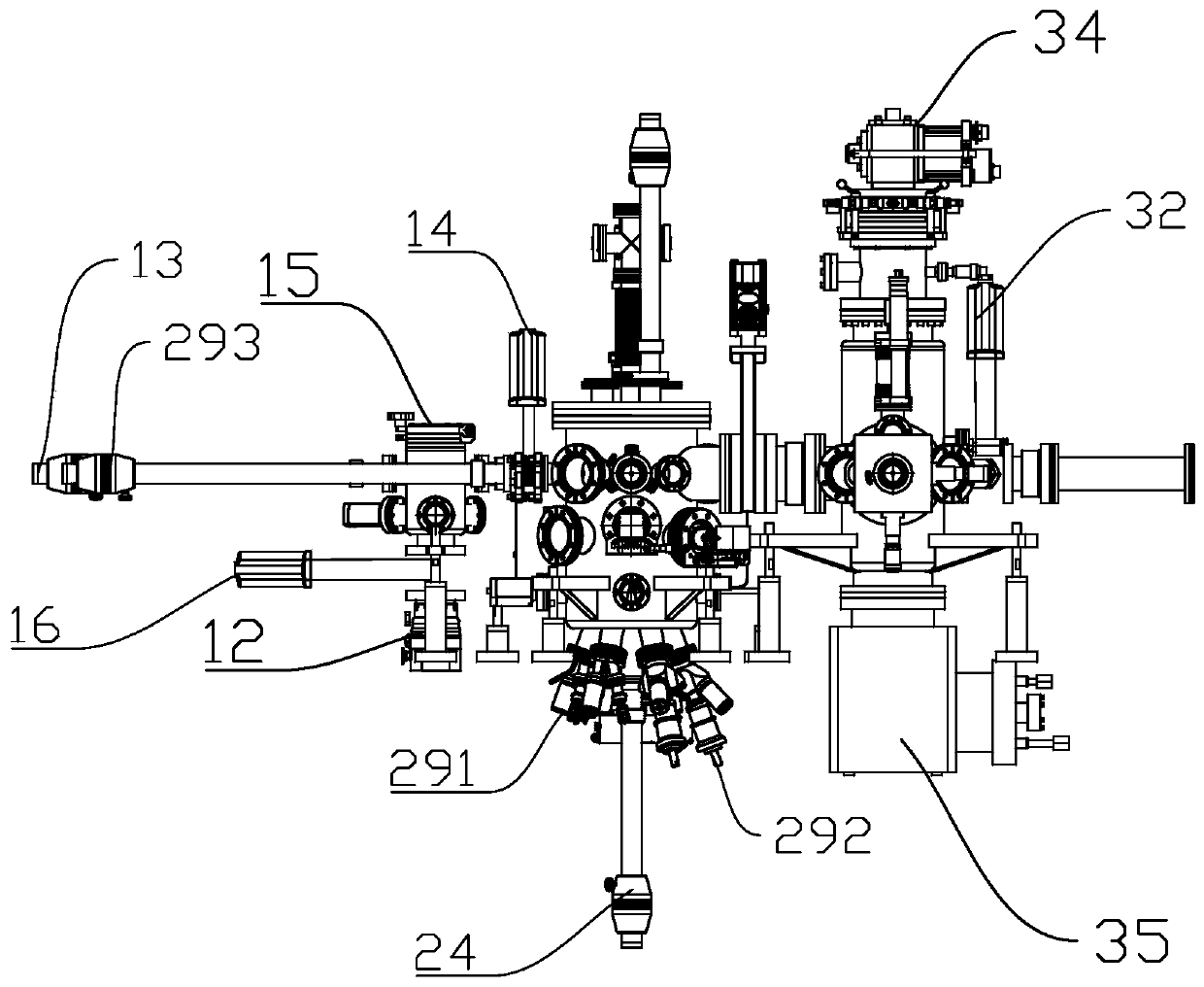

[0026] see attached figure 1 , figure 1 It is a structural schematic diagram of the ultra-high vacuum ultra-low temperature in-situ multi-probe transport measurement system of the present invention, figure 2 It is a structural schematic diagram of the ultra-high vacuum ultra-low temperature in-situ multi-probe transport measurement system of the present invention, image 3 It is a structural schematic diagram of the ultra-high vacuum ultra-low tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com