Method and device for dynamically detecting comprehensive error of mechanical transmission chain

A mechanical transmission and comprehensive error technology, which is applied in the testing of mechanical components, measuring devices, and testing of machine/structural components, can solve the problems of complex transmission mechanism of precision transmission chains and the inability to comprehensively evaluate the transmission performance of transmission chains, etc., to achieve The effect of easy calibration, economical price and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

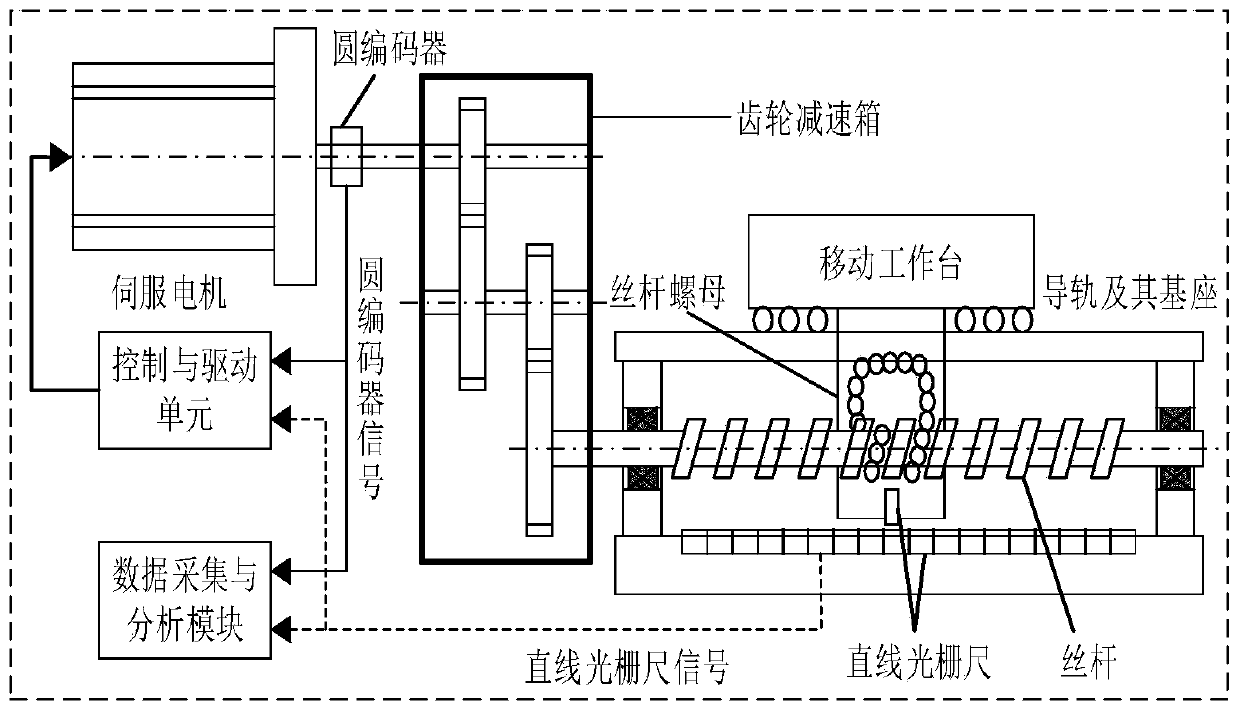

[0051] Such as figure 1 Shown is a structural diagram of a dynamic detection device for the comprehensive error of a mechanical transmission chain, including a motor module, a guide rail slide module, a data acquisition and analysis module, and a transmission chain module to be tested;

[0052] The transmission chain module under test includes a screw nut pair and a gear reduction box; the screw nut pair includes a screw rod and a screw nut, which are used to convert the rotary motion of the screw rod into the linear motion of the nut, and drive the mobile work The table moves; one end of the gear reduction box is connected to the servo motor, and the other end is connected to the screw rod, which is used to transmit the rotation motion of the motor to the screw rod;

[0053] The motor module includes a servo motor and a control and drive unit. The servo motor adopts a closed-loop servo control mode, and a circular encoder is arranged on the output shaft; the servo motor drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com