High-throughput digital full-field metallographic in-situ statistic characterization analyzer and analysis method

A full field of view, high-throughput technology, applied in the direction of material analysis, analysis materials, instruments, etc. by optical means, can solve the problems of large workload, poor consistency, low reproducibility and accuracy, and achieve system gold. The effect of phase structure characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

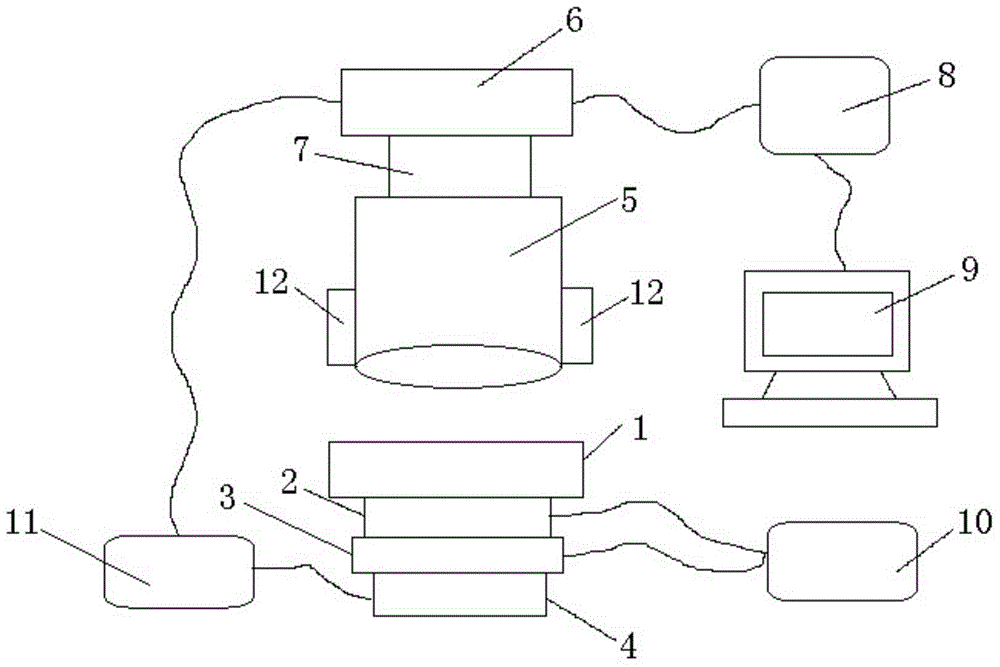

[0048] Such as figure 1 As shown, the high-throughput digital full-field metallographic in-situ statistical characterization analyzer of the present invention includes a high-throughput automatic sampling scanning system, a digital signal processing system, and an intelligent analysis system.

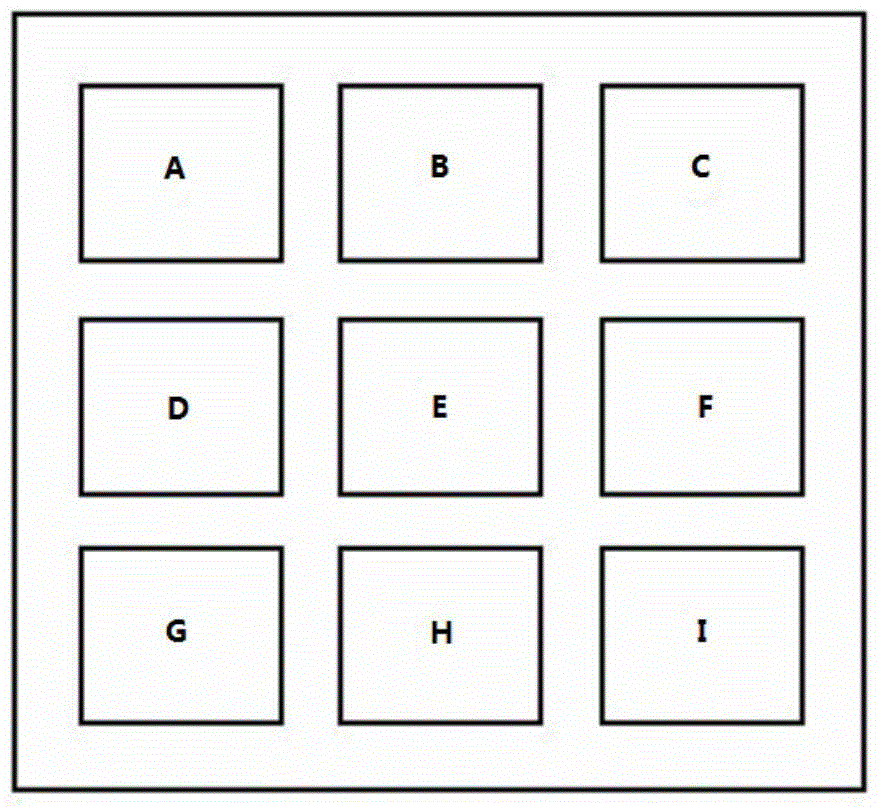

[0049] The high-throughput automatic sampling scanning system is used to continuously and automatically send multiple samples into the digital metallographic characterization system and complete the movement of the samples in three directions (x-y-z) during the analysis process, including sample stage 1 and X-axis guide rail 2 , Y-axis guide rail 3 and Z-axis guide rail 4, wherein, the sample table 1 includes sample placement places A~I for holding 1 to 9 samples, the sample table 1 is fixed on the upper part of the X-axis guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com