VMD and Wigner-Ville based high pressure diaphragm pump check valve fault diagnosis method

A pump check valve and high-pressure diaphragm technology, which is used in mechanical valve testing, mechanical component testing, and machine/structural component testing. Obfuscation problem, improved time-frequency aggregation performance, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: The No. 3 high-pressure diaphragm pump of the Yunnan Dahongshan Tiejing pipeline is used for verification. It is a three-cylinder crankshaft-driven piston piston pump of the TZPM series. The maximum working pressure is 24.44Mpa. The feed check valve and the feed check valve are arranged with vibration acceleration sensors whose model is PCB-ICP, the adopted frequency is 2560Hz, and the adopted data length is 10240. The data used are the vibration signals of the normal operation of the check valve, the wear and breakdown of the check valve, and the vibration signals of the coarse particle stuck in the check valve.

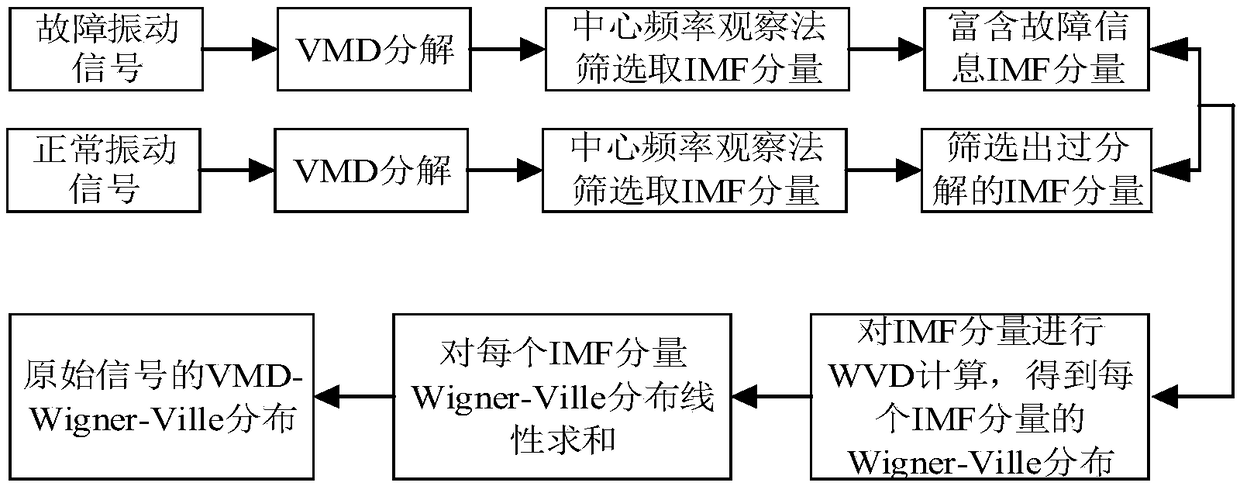

[0058] A kind of high-pressure diaphragm pump check valve fault diagnosis method based on VMD and Wigner-Ville of the present invention, such as figure 1 As shown, the specific steps are as follows:

[0059] (1) Three kinds of vibration signals, namely check valve wear and breakdown fault, coarse particle sticking fault and normal state, are selec...

example 2

[0098] Example 2: In order to analyze the effectiveness of this method, a multi-point AM and FM simulation signal is established, and its analytical expression is:

[0099]

[0100] In the simulation signal (0≤t≤3), the frequency of x(t) is 2560Hz, and the data length is 10240. The process of the method is as follows figure 1 Shown:

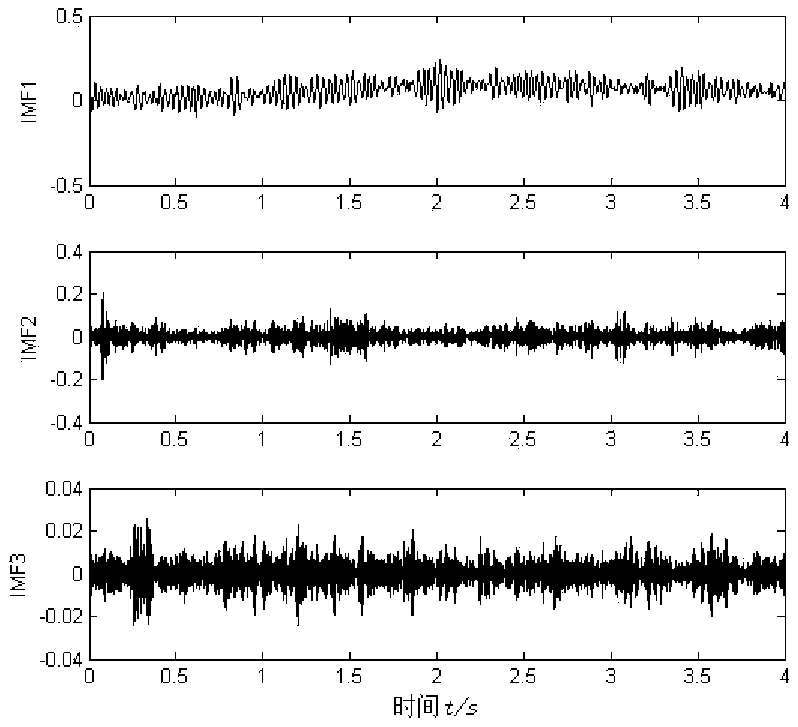

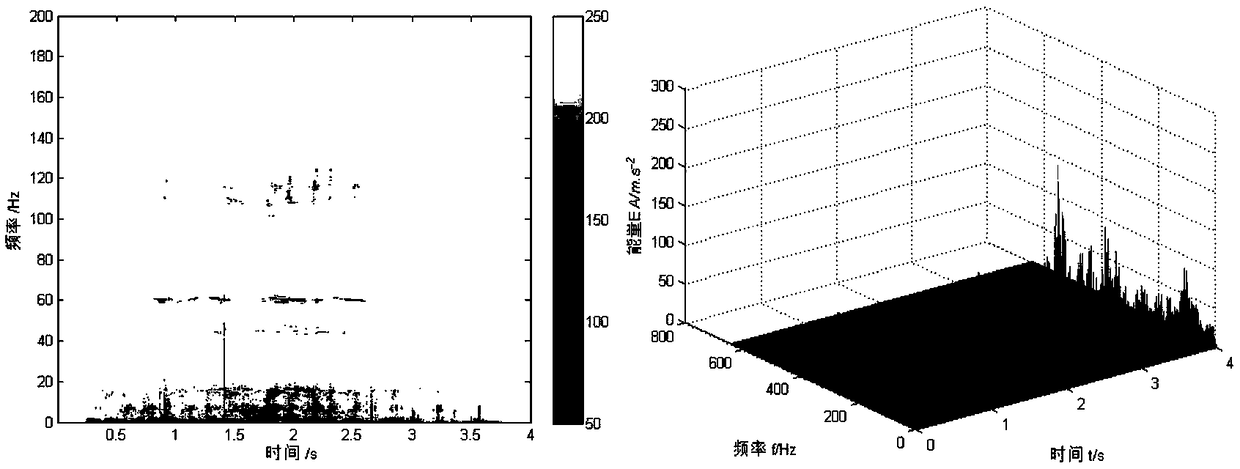

[0101] (1) Use VMD to decompose the simulation signal, such as Image 6 shown;

[0102] (2) Based on the center frequency observation method, the IMF component rich in fault information is screened. When m=4, it is decomposed into four modal functions, and the center frequency 0.012 corresponding to the fourth modal function is the same as the third mode The center frequency 0.0046 corresponding to the function has a different series, the ratio of the two is 2.61, and when m=5, five modal functions are decomposed, the center frequency of the fifth modal function is 0.019 and the fourth modal function The series of center frequency 0.012 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com