Method for multi-scale representing of dense reservoir pore throat characteristics based on high-pressure mercury intrusion

A compact reservoir, multi-scale technology, applied in the direction of suspension and porous material analysis, permeability/surface area analysis, measurement devices, etc., can solve the problems of errors, inability to directly obtain the real existence of fluid seepage characteristics, etc., to achieve accurate characterization, Improve the authenticity and reliability, reduce the effect of experimental error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

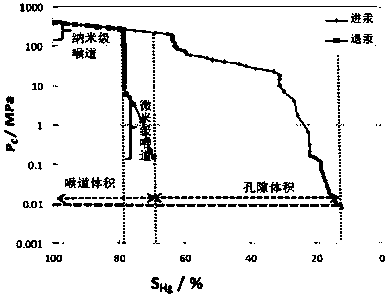

[0060] Taking a tight sandstone reservoir sample with a depth of more than 3,000 meters in a certain area of Shengli Oilfield as an example, relevant experiments such as high-pressure mercury intrusion, pressure-covered pore-permeability, and scanning electron microscopy are carried out to illustrate the specific technical solutions of the present invention:

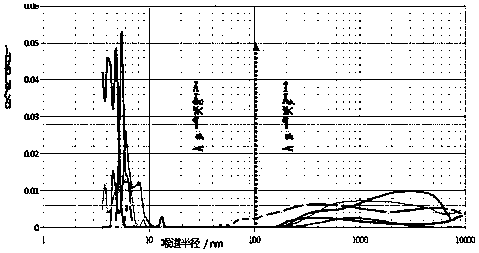

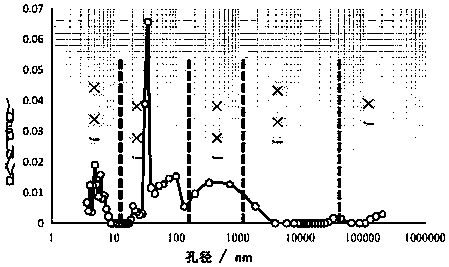

[0061] A multi-scale method for characterizing the pore-throat characteristics of tight reservoirs based on high-pressure mercury injection, specifically as follows: figure 1 shown, including the following steps:

[0062] Step 1: Measure the permeability K and porosity Φ of the core under the original formation overburden pressure by using the standard test method of the automatic overburden porosimeter—PoroPDP-200;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com