Accuracy calibration of birefringence measurement systems

A measurement system, birefringence technology, applied in the field of systems of birefringence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

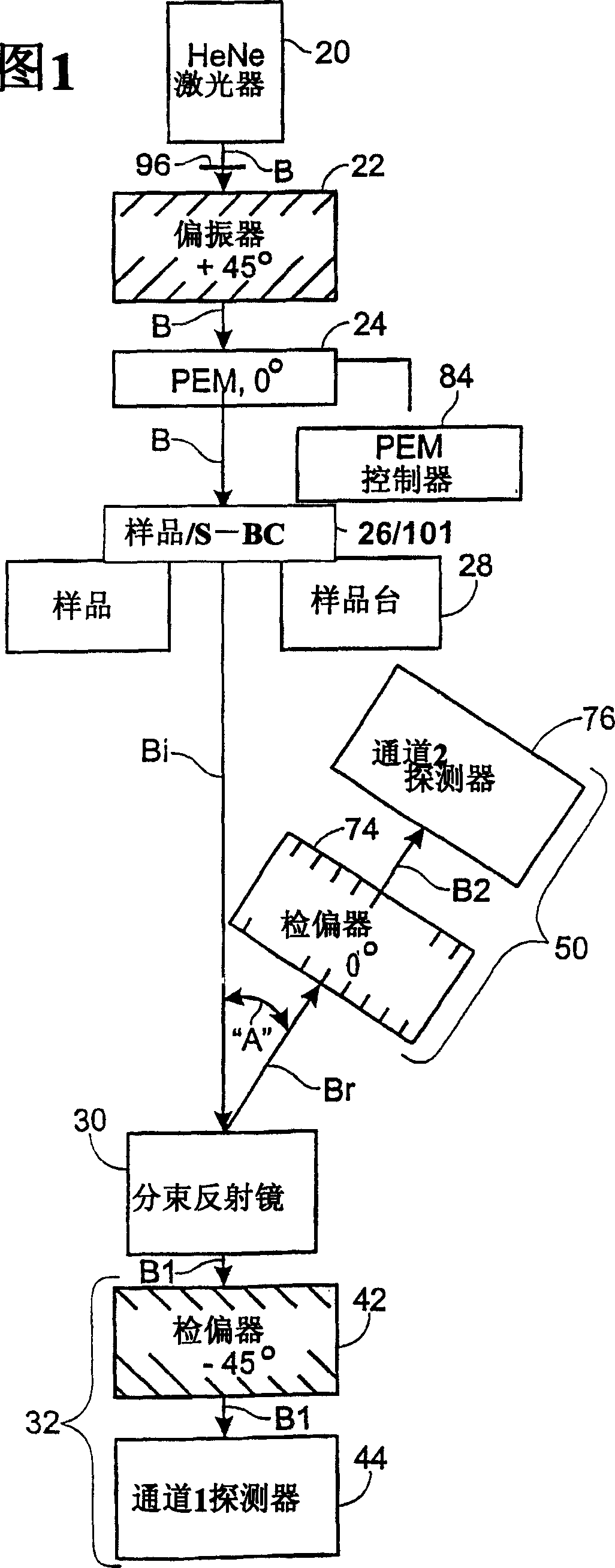

[0027] Figure 1 depicts the main optical elements of a system that can be calibrated according to the invention. These elements include as light source 20 a HeNe laser at a wavelength of 632.8 nanometers (nm). Beam "B" emanating along the optical path from the light source has a cross-sectional area or "spot size" of approximately 1 millimeter (mm).

[0028] Source beam "B" is directly incident on polarizer 22 whose polarization direction is oriented at +45° with respect to the baseline axis. High extinction polarizers are preferred, such as Glan-Thomson calcite polarizers. Polarizers 22 with stable precision and indexed rotators are also preferred.

[0029] Polarized light from polarizer 22 is incident on optical element 25 of photoelastic modulator 24 (FIGS. 1 and 5). In a preferred embodiment, the photoelastic modulator (hereinafter "PEM") is a low birefringence version of Model PEM-90 I / FS50 manufactured by Hinds Instruments, Inc., of Hillsboro, Oregon. While a PEM is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com