Online mounting method for bearing seats of wrapper roller frame of hot rolling coiler

A technology of bearing seat and roll-assisting roller, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of large matching clearance of sliding bearing, poor action sensitivity, difficult lubrication and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

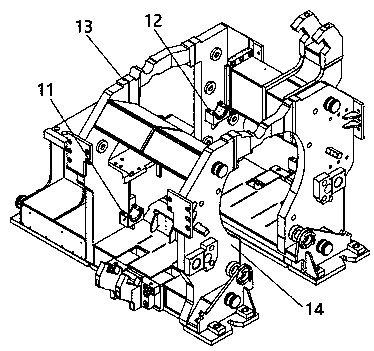

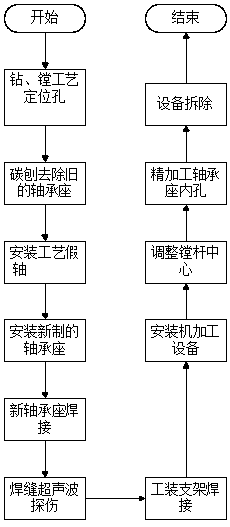

[0020] Example figure 2 As shown, the online installation method of the frame bearing housing of the auxiliary coiling roll of the hot rolling coiler of the present invention includes the following steps:

[0021] Step 1. Make a new bearing seat. In order to prevent the deformation of the weld seam stress when the bearing seat is welded on the frame archway, a 5mm machining allowance is reserved for the inner hole of the new bearing seat;

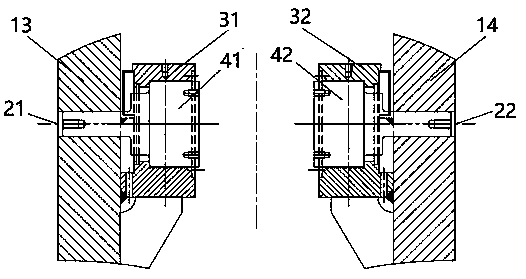

[0022] Step two, such as image 3 As shown, respectively drill and bore process positioning holes 22 and 21 at the centers of the original bearing housings of the archway 14 on the operation side and the archway 13 on the transmission side. Holes 22, 21 are used as positioning datums for the installation of new bearing seats 32, 31;

[0023] Step 3. Use carbon arc gouging to remove the weld seams around the old bearing seat and remove the old bearing seat;

[0024] Step 4: Make craft dummy shafts 42, 41 and install them in the craft pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com