Patents

Literature

43results about How to "Addressing the drop in accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

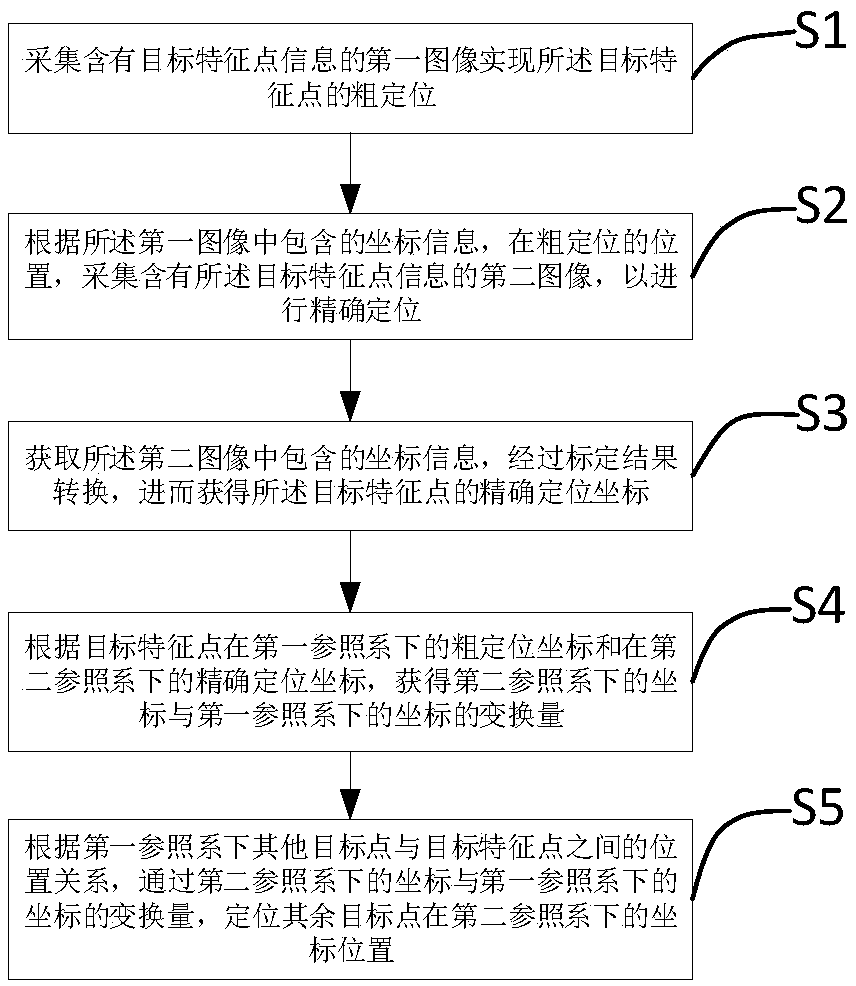

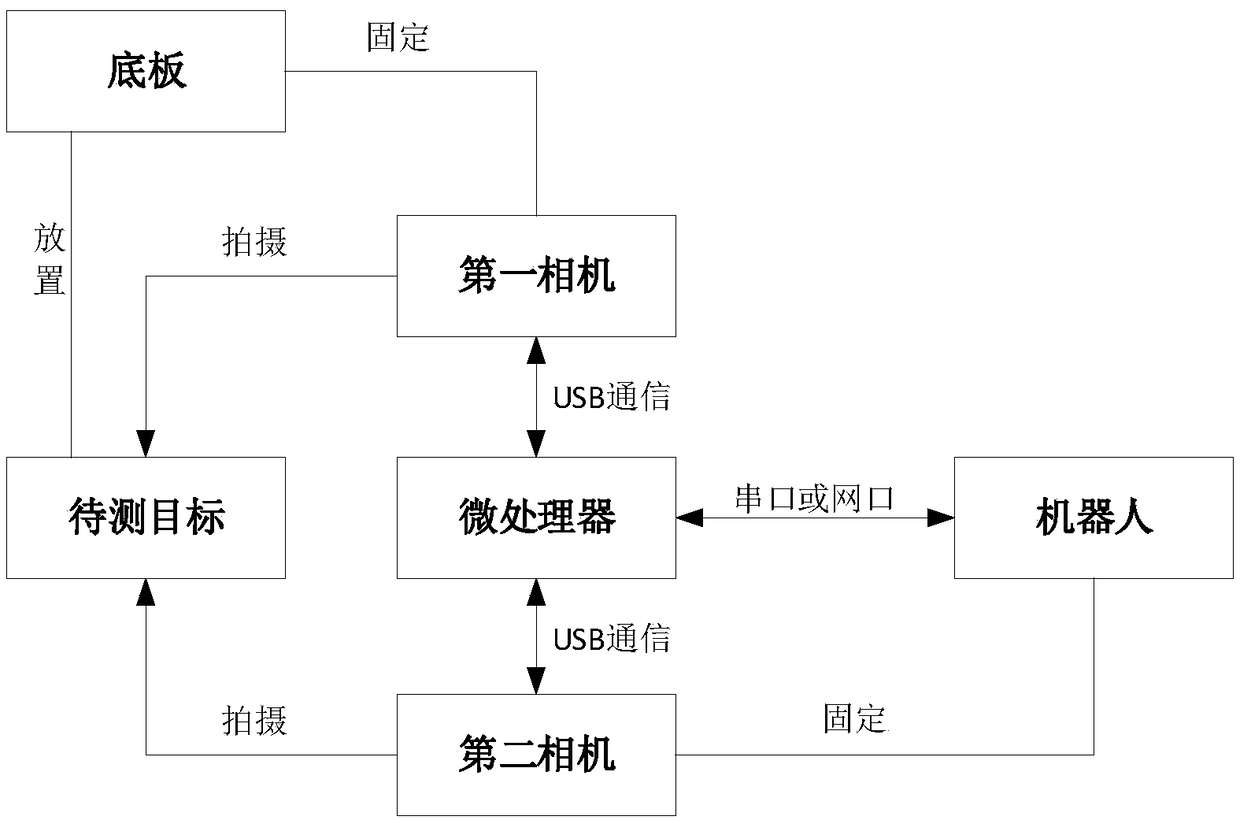

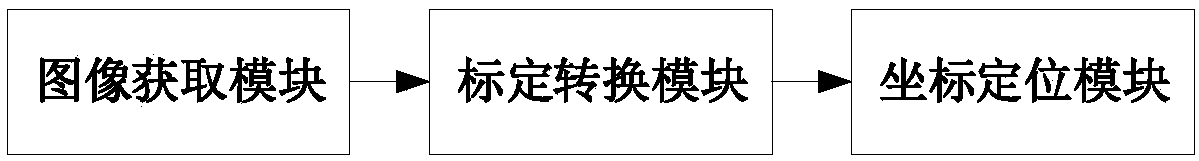

Method, application, device and system for positioning object step by step based on vision fusion

InactiveCN109448054AAddressing the drop in accuracySmall distortionImage enhancementImage analysisComputer graphics (images)Vision based

The invention discloses a method for positioning object step by step based on vision fusion, comprising collecting a first image containing target feature points to realize the coarse positioning of the target feature points, according to the coordinate information contained in the first image, collecting the second image containing the target feature point information, carrying out the precise positioning, obtaining the coordinate information contained in the second image, and obtaining the target feature point based on the coordinate transformation amount under the same coordinate system according to the conversion relationship between different coordinate systems, and locating the target feature point. At the same time, the invention also discloses an application, device and system forpositioning object step by step based on vision fusion. The scheme separates the positioning accuracy from the condition of large field of view, two different types of cameras are used to realize step-by-step positioning, which solves the problem that the positioning accuracy is insufficient when the workpiece moves in a large range; and when there are many screw holes, there is no need to take photographs repeatedly, which can reduce the number of photographs, improve the production efficiency, and has the advantages of high precision and high positioning efficiency.

Owner:SHENZHEN UNIV

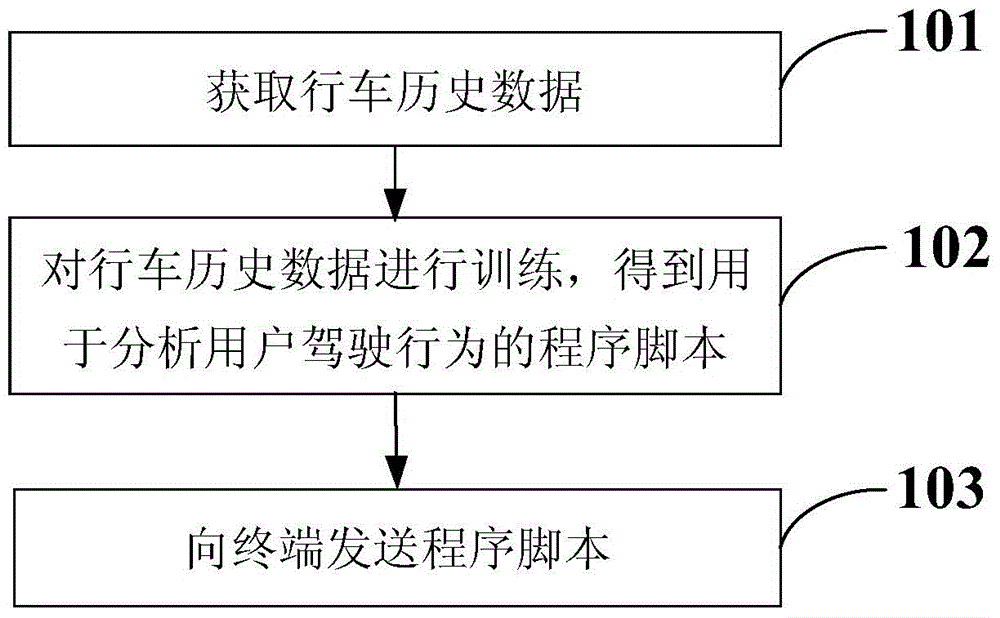

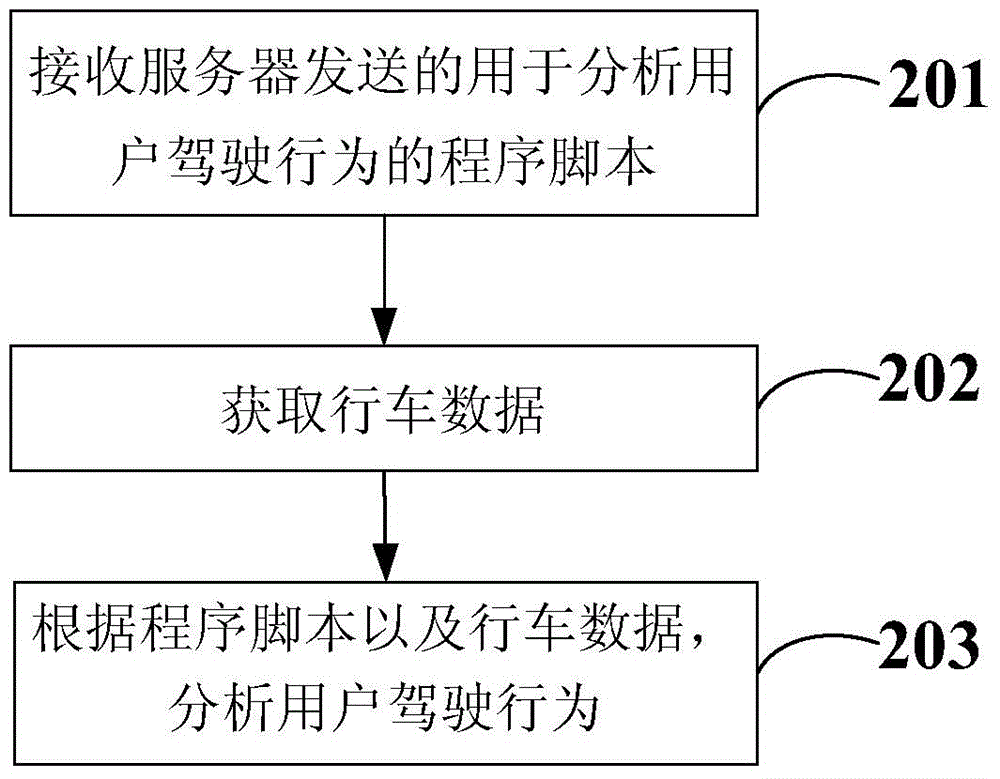

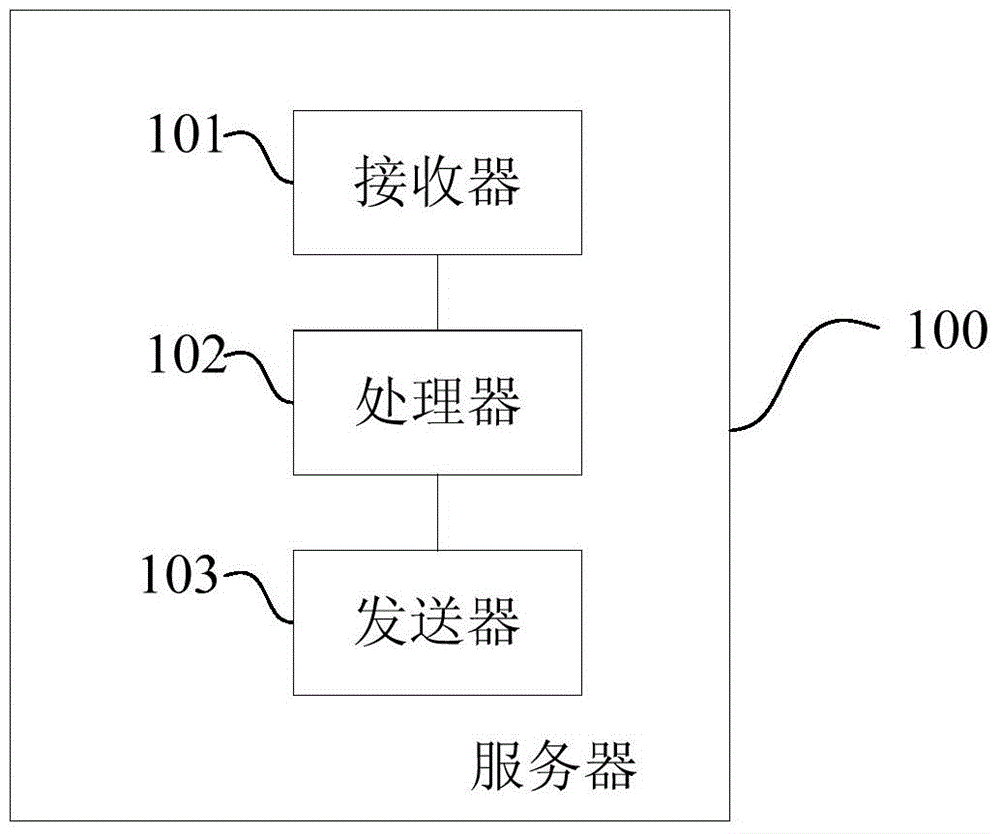

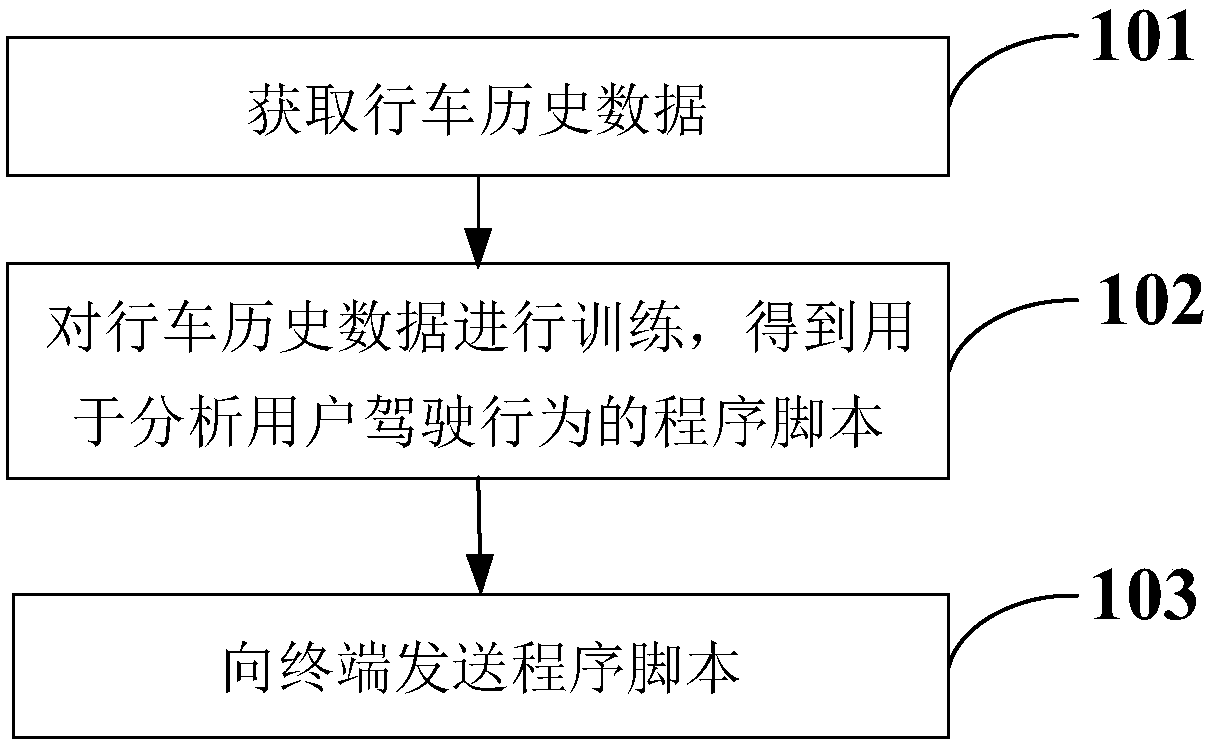

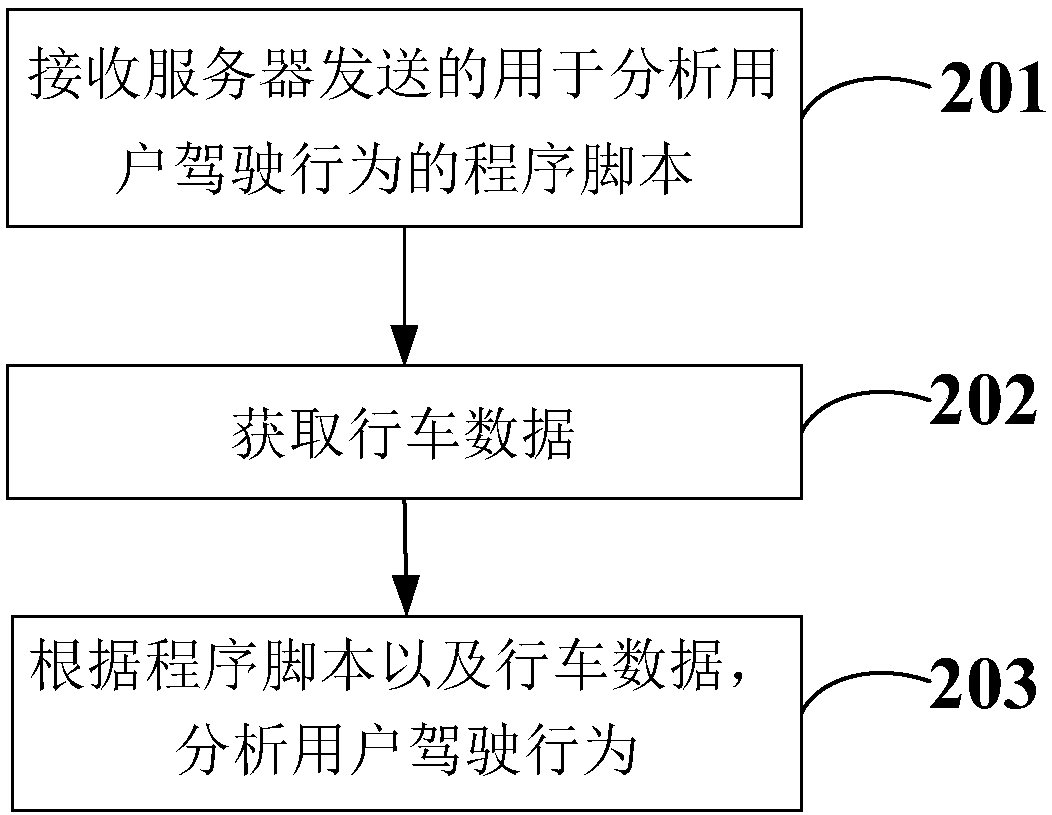

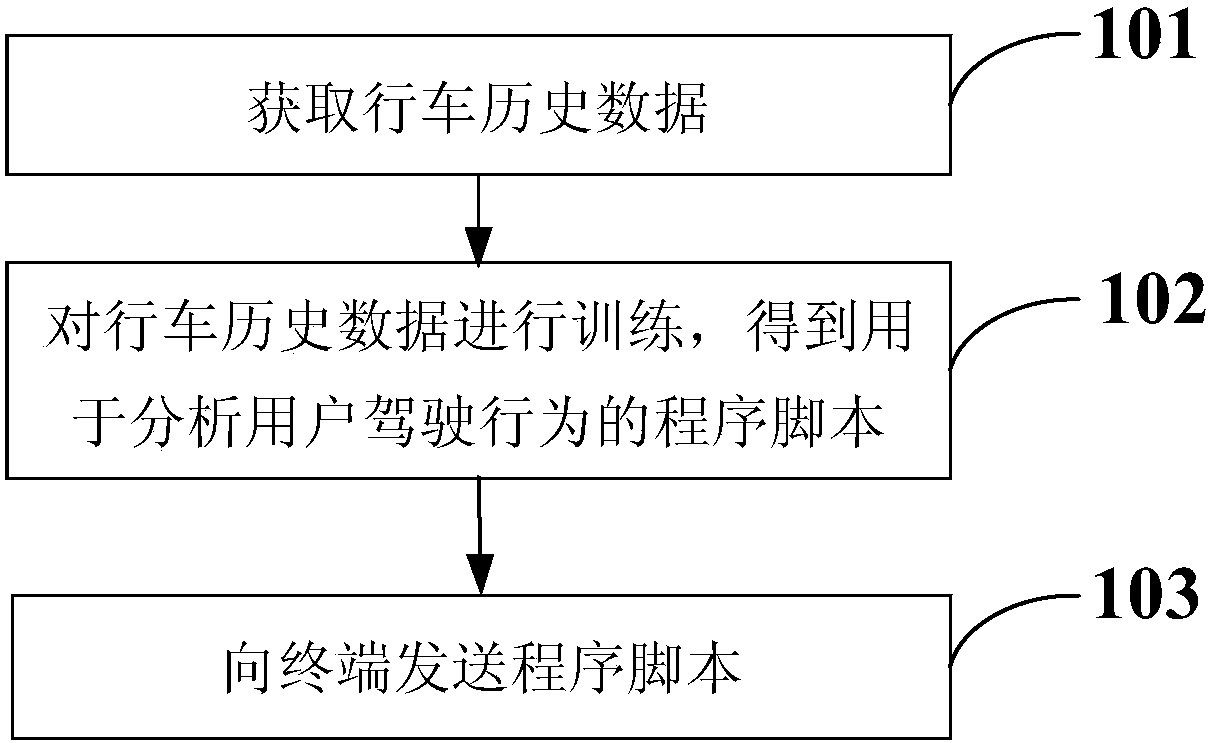

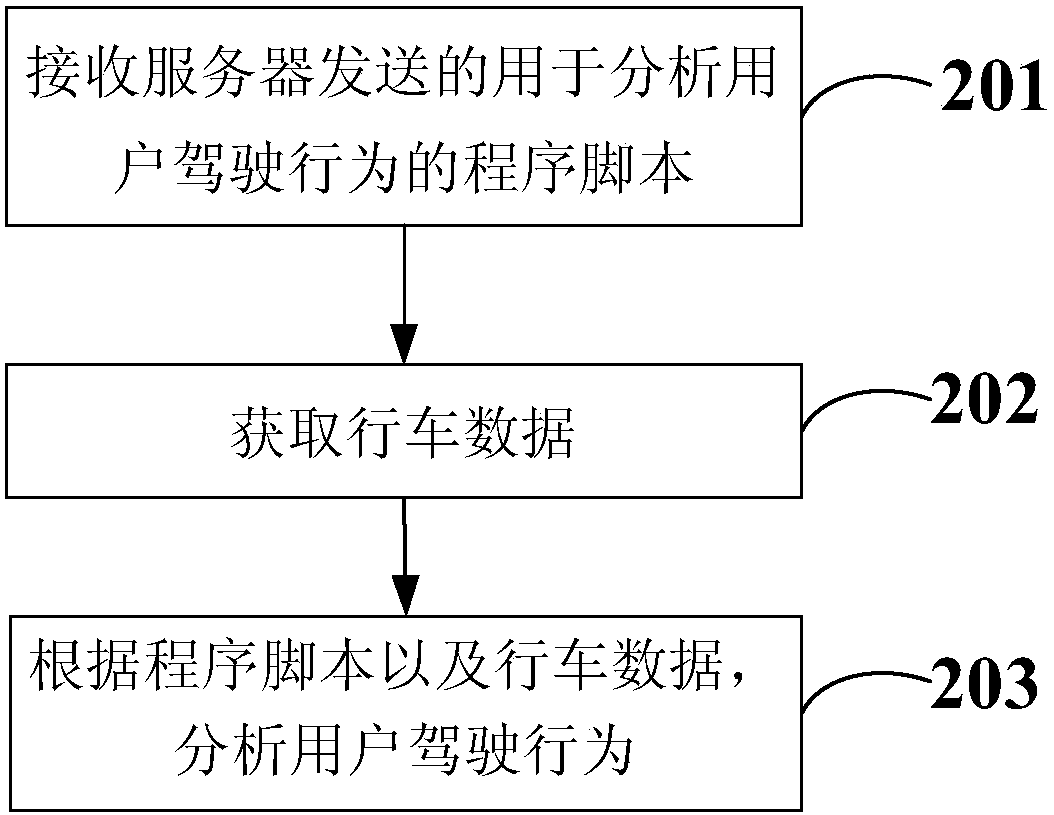

Internet of Vehicles data processing method, server and terminal

ActiveCN104429047AAddressing the drop in accuracyGuaranteed accuracyFinanceRegistering/indicating working of vehiclesThe InternetComputer terminal

The invention provides an Internet of Vehicles data processing method, a server and a terminal. The method comprises obtaining historical traffic data through the server; performing training of the historical traffic data, and obtaining program scripts for analyzing user's driving behaviors; and sending the program scripts to the terminal. According to the technical scheme, the historical traffic data is obtained firstly through the server, the training is performed on the historical traffic data then, the program scripts for analyzing the user's driving behaviors are obtained, and the program scripts are finally sent to the terminal. The user' driving behaviors are dynamically analyzed according to the program scripts and the driving data, the problem that algorithm precision is reduced because the algorithm is not updated in time is solved, accuracy of analysis of the user's driving behaviors is guaranteed, and, further, extra cost brought by updating of a terminal firmware is reduced.

Owner:HUAWEI DEVICE CO LTD

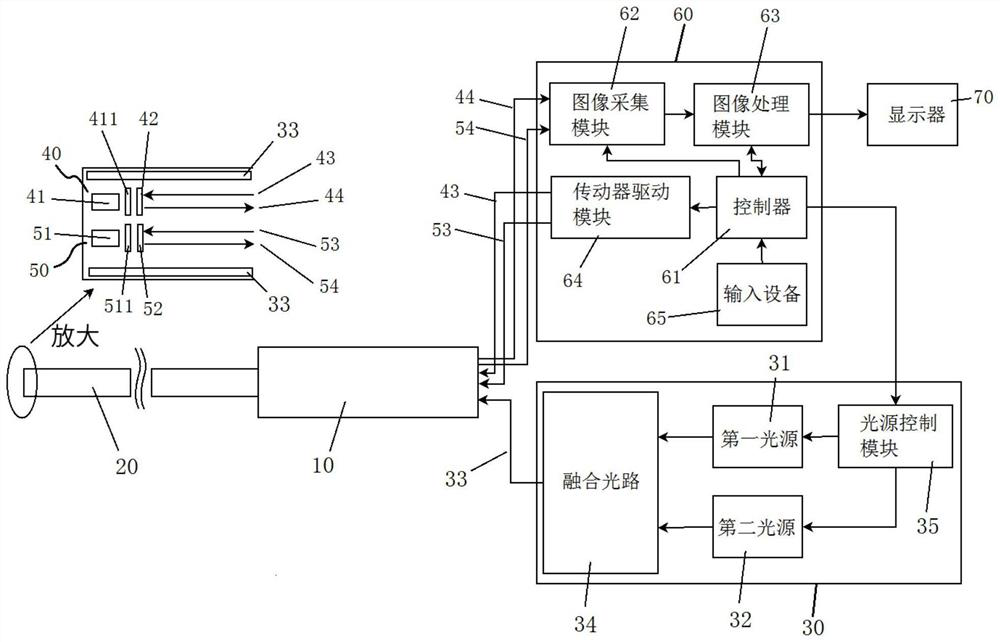

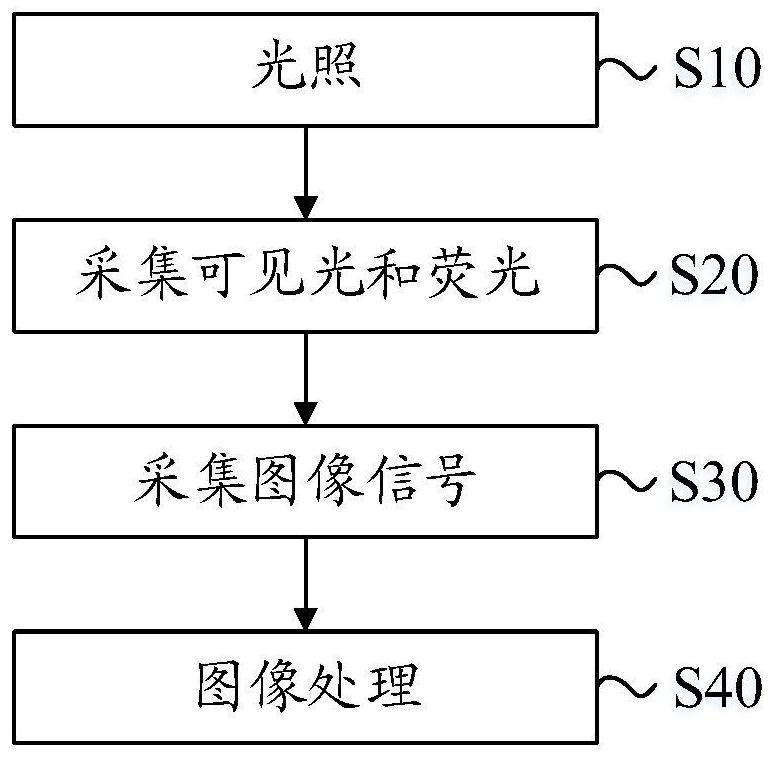

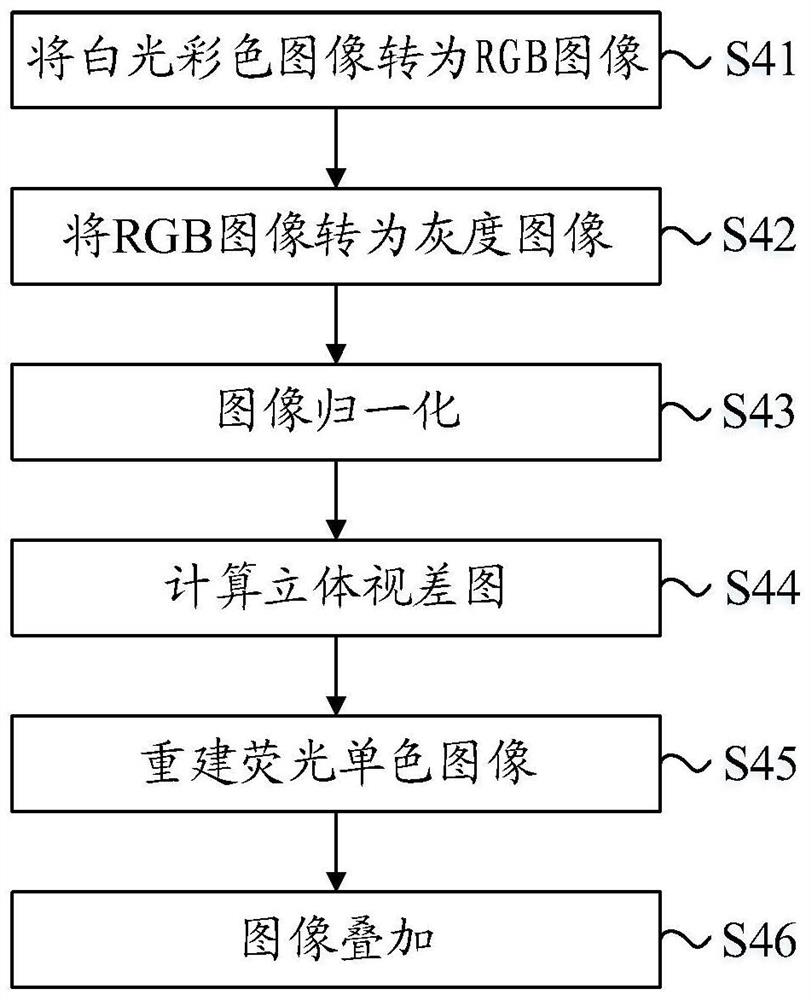

Endoscope imaging method and endoscope imaging system

The invention discloses an endoscope imaging method and an endoscope imaging system. The endoscope imaging method comprises the following steps of illumination, visible light and fluorescence collection, image signal collection and image processing. Visible light reflected by a human subject and excited fluorescence are collected through two sensors located at the front end of an endoscope tube, corresponding image signals are generated, and then the image signals are transmitted to the rear end to be processed to obtain a final endoscope image. Compared with the prior art that visible light and fluorescence are transmitted to the rear end through a light path and then collected and processed, the endoscope of the invention solves the problem that the precision is reduced due to light pathpropagation, the imaging precision is improved, and the light path cost and the light path occupied space are also saved; in addition, the visible light and the fluorescence can be focused and collected respectively due to the design of independent light paths of the visible light and the fluorescence, so that the visible light image and the fluorescence image are consistent in definition; and the endoscope imaging system is binocular stereoscopic vision, and can obtain three-dimensional information to compensate fluorescence brightness of different depth areas.

Owner:SHENZHEN PROXINSE MEDICAL LTD

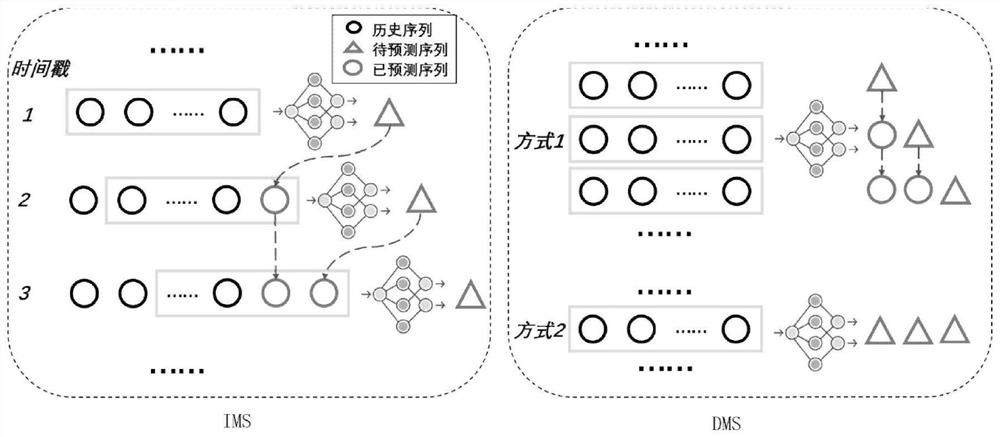

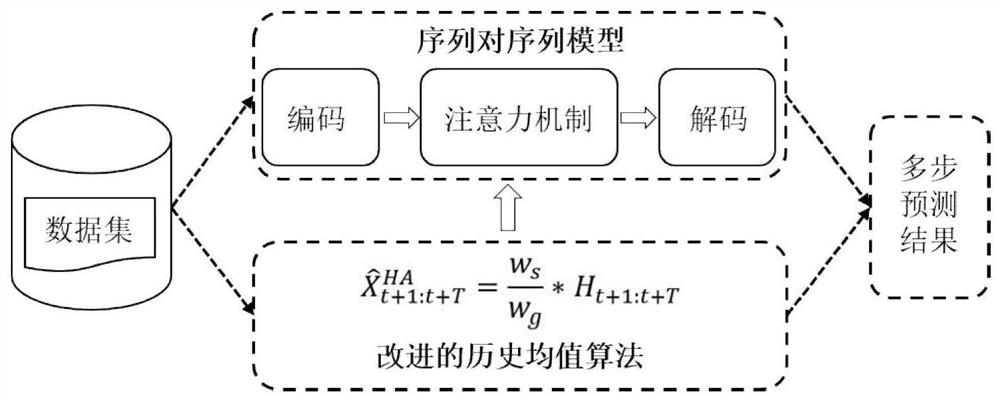

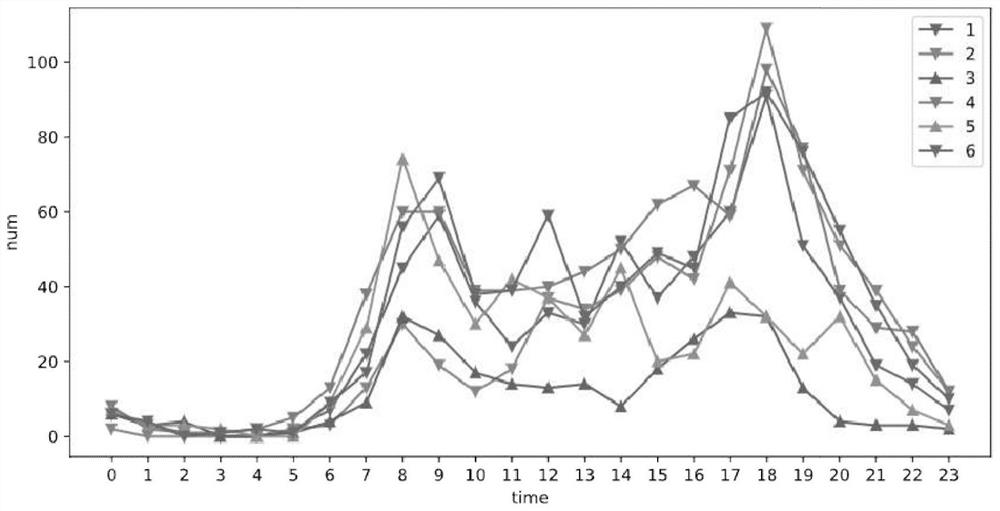

Traffic space-time sequence multi-step prediction method and system and storage medium

PendingCN112508173AIncrease flexibilityAddressing the drop in accuracyDigital data information retrievalForecastingAlgorithmSequence model

The invention discloses a traffic space-time sequence multi-step prediction method and system, and a storage medium, and the method comprises the steps: 1, calculating an improved historical mean value based on historical data X1:T; 2, carrying out the downsampling of the historical data X1:T and the improved historical mean value through a 3D-CNN module; 3, performing multi-step prediction from asequence to a sequence model to obtain an encoder and a decoder of a model, wherein the encoder and the decoder respectively consist of ConvLSTM, fusing an attention mechanism into the decoder, and further performing up-sampling by using transposed 3D convolution; 4, performing multi-model fusion to obtain a final prediction result. The prediction method provided by the invention is higher in precision.

Owner:CENT SOUTH UNIV

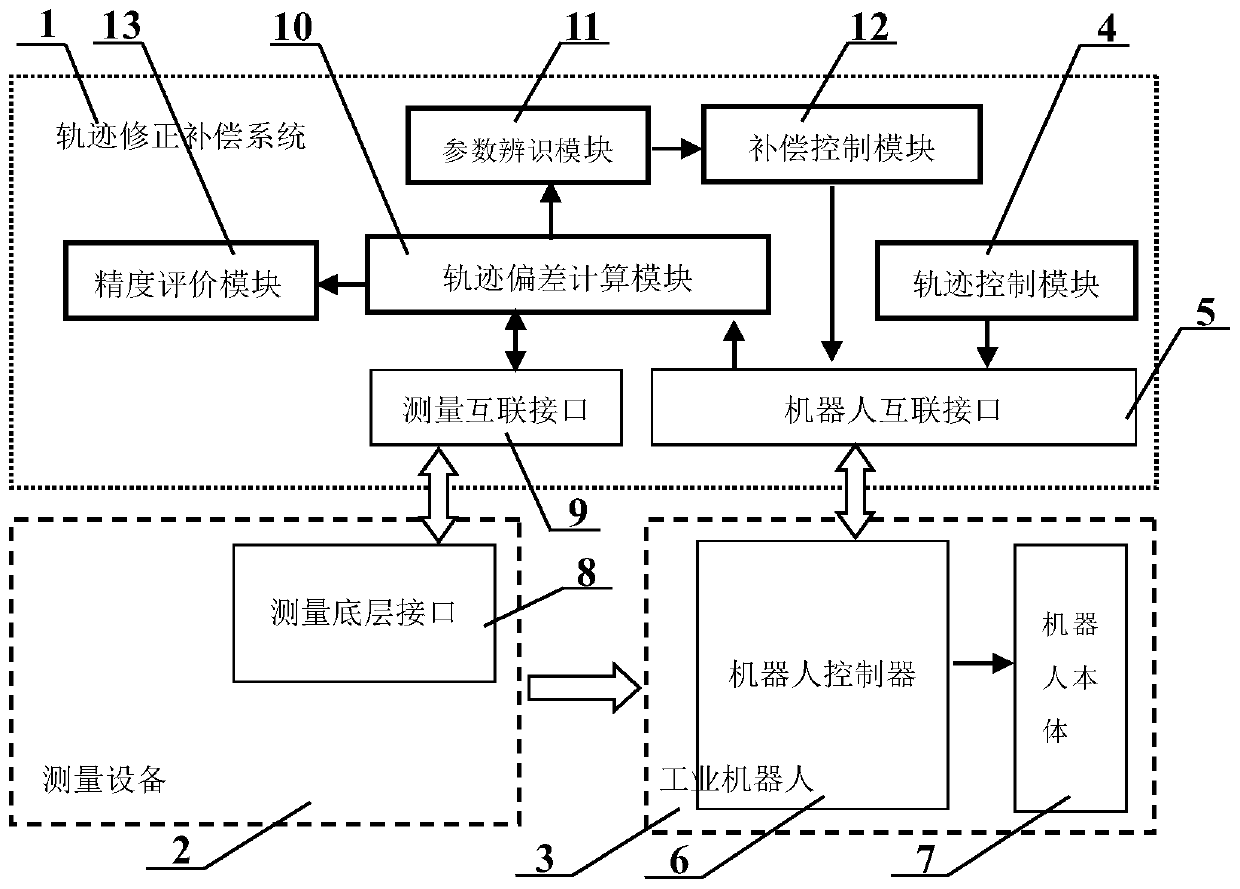

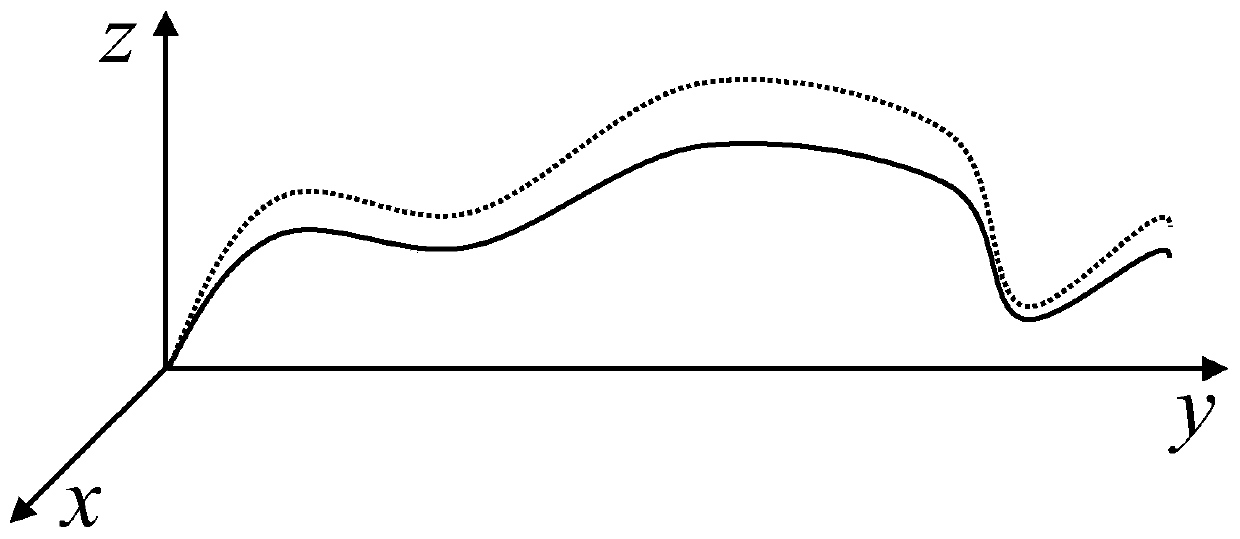

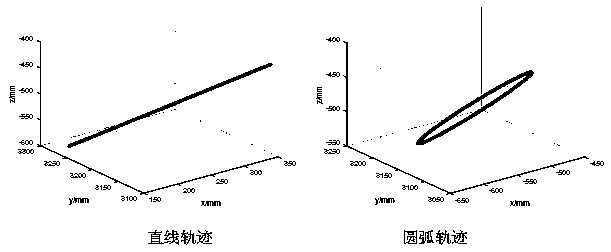

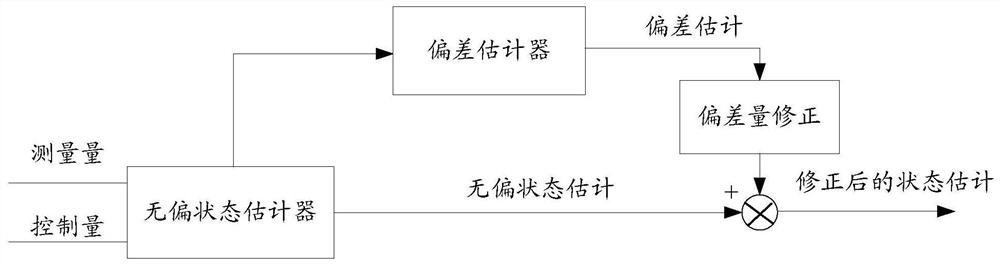

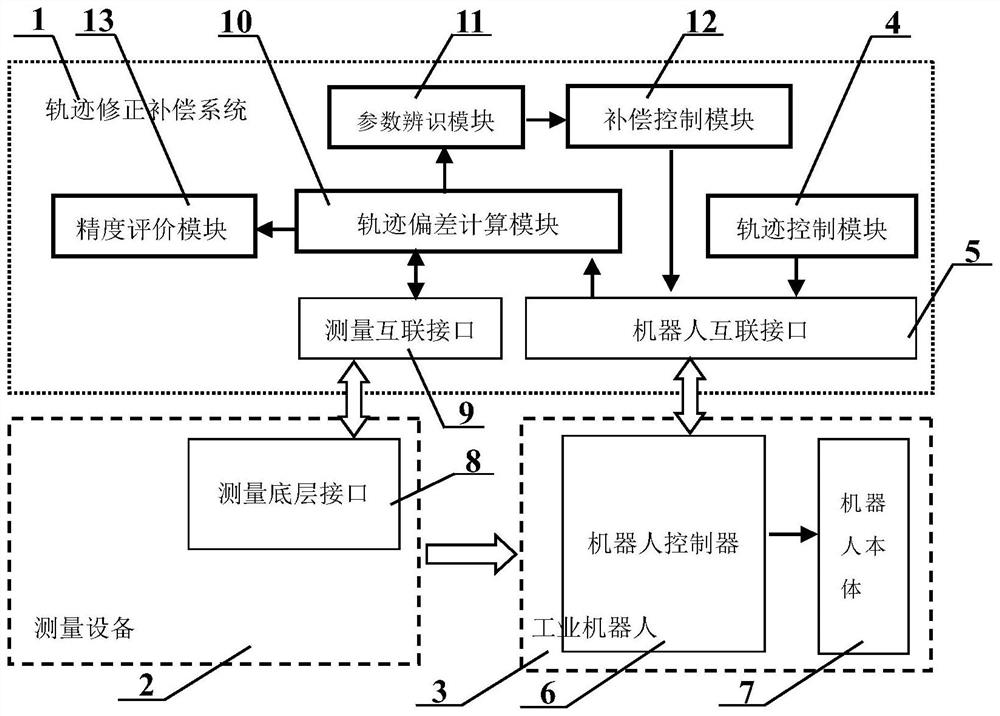

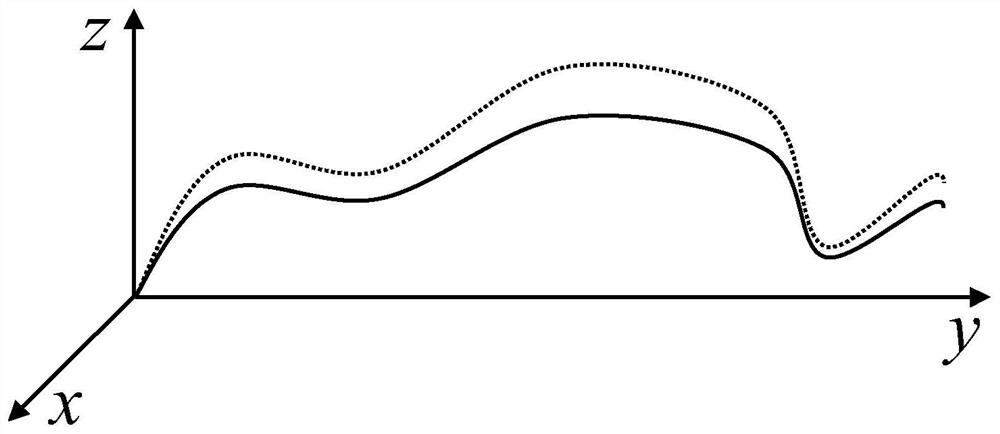

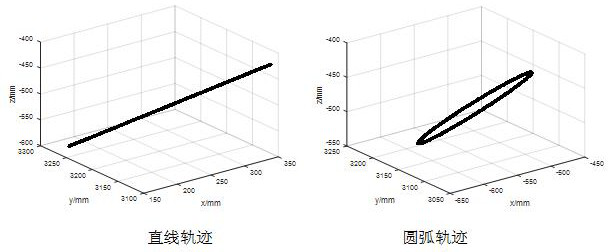

System and method for compensation of track precision of industrial robot based on kinematics analysis

ActiveCN111300406AImprove motion trajectory accuracyImplement fixesProgramme-controlled manipulatorControl engineeringRobot kinematics

The invention discloses a system and method for compensation of track precision of an industrial robot based on kinematics analysis. A robot interconnection interface and a measurement interconnectioninterface are in communication connection with a robot controller and a measurement lower-layer interface respectively; the robot interconnection interface and the measurement interconnection interface are connected to an input end of a track bias computation module; output ends of the track bias computation module are connected to a parameter identification module and a precision evaluation module respectively; an output end of the parameter identification module is connected to the robot interconnection interface via a compensation control module; and a track control module is connected tothe robot interconnection interface. According to the method, a motion track bias model of the industrial robot is established; then, model parameter identification is carried out according to robot track data measured by measurement equipment; and finally, error data identified is used in a robot kinematic model for parameter compensation. The system and method disclosed by the invention have thebeneficial effects that a motion track bias of the industrial robot is compensated from the perspective of kinematics analysis; the motion track precision of the robot is increased; cost is low; andimplementation is easy.

Owner:ZHEJIANG SCI-TECH UNIV

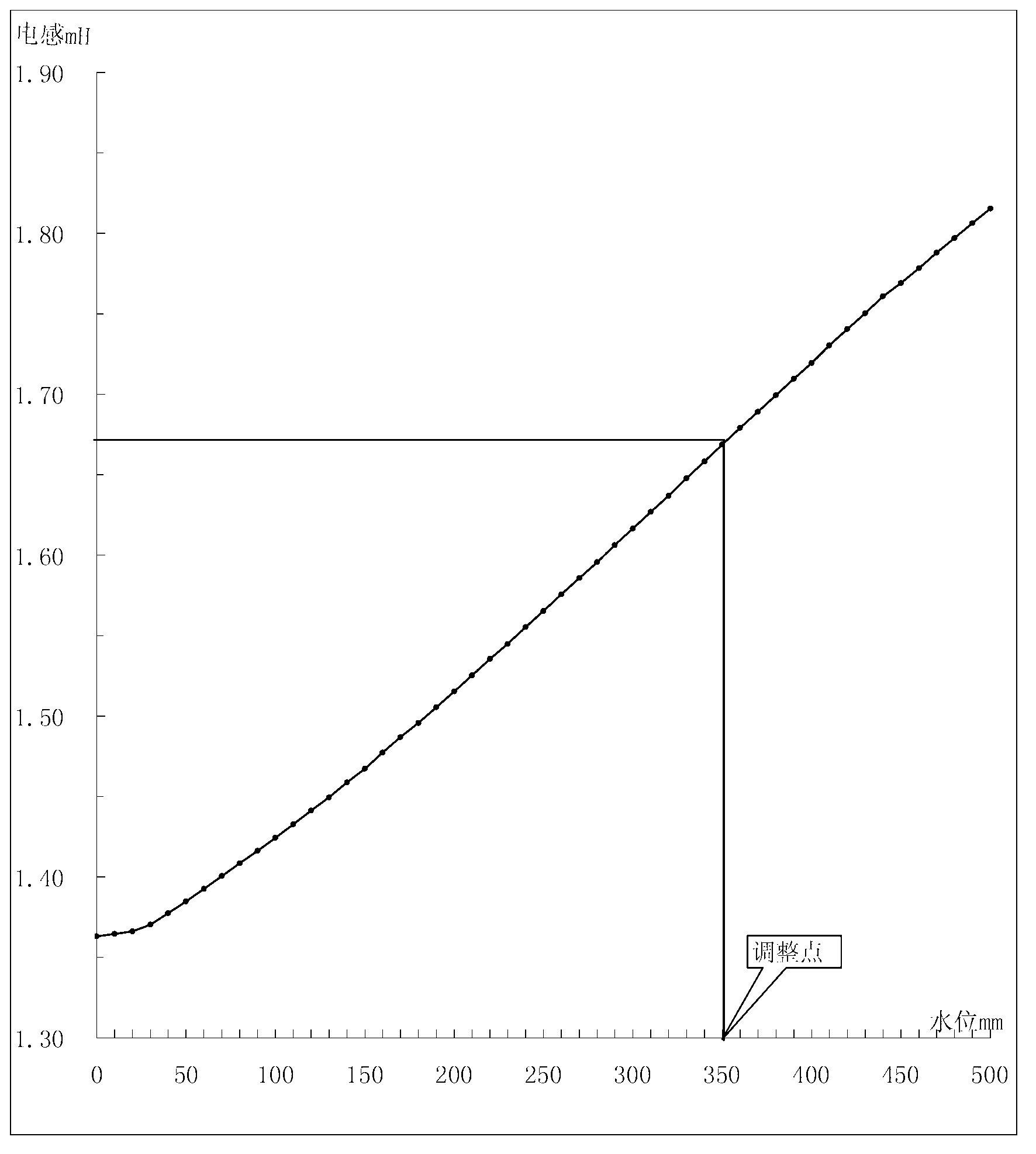

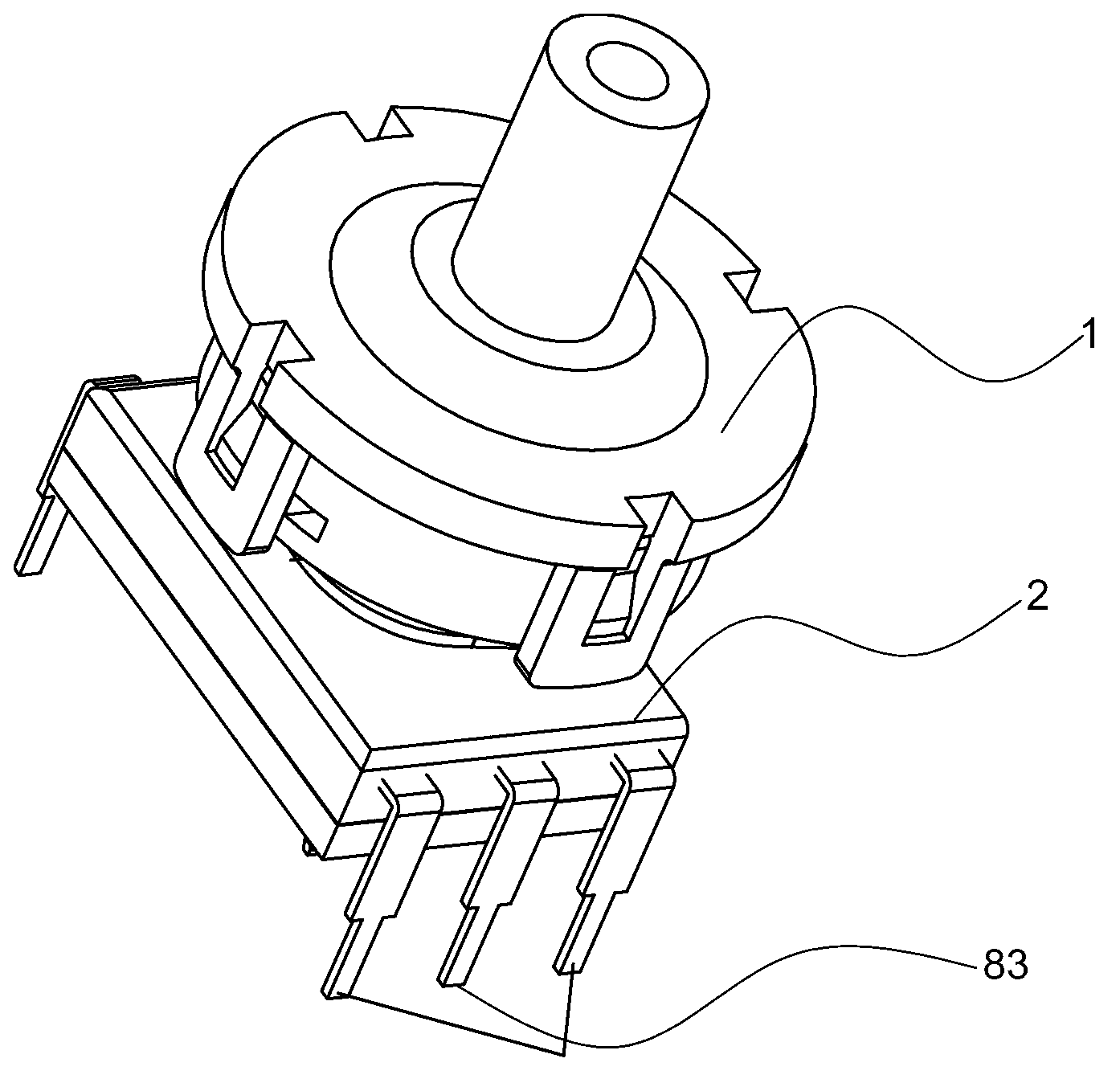

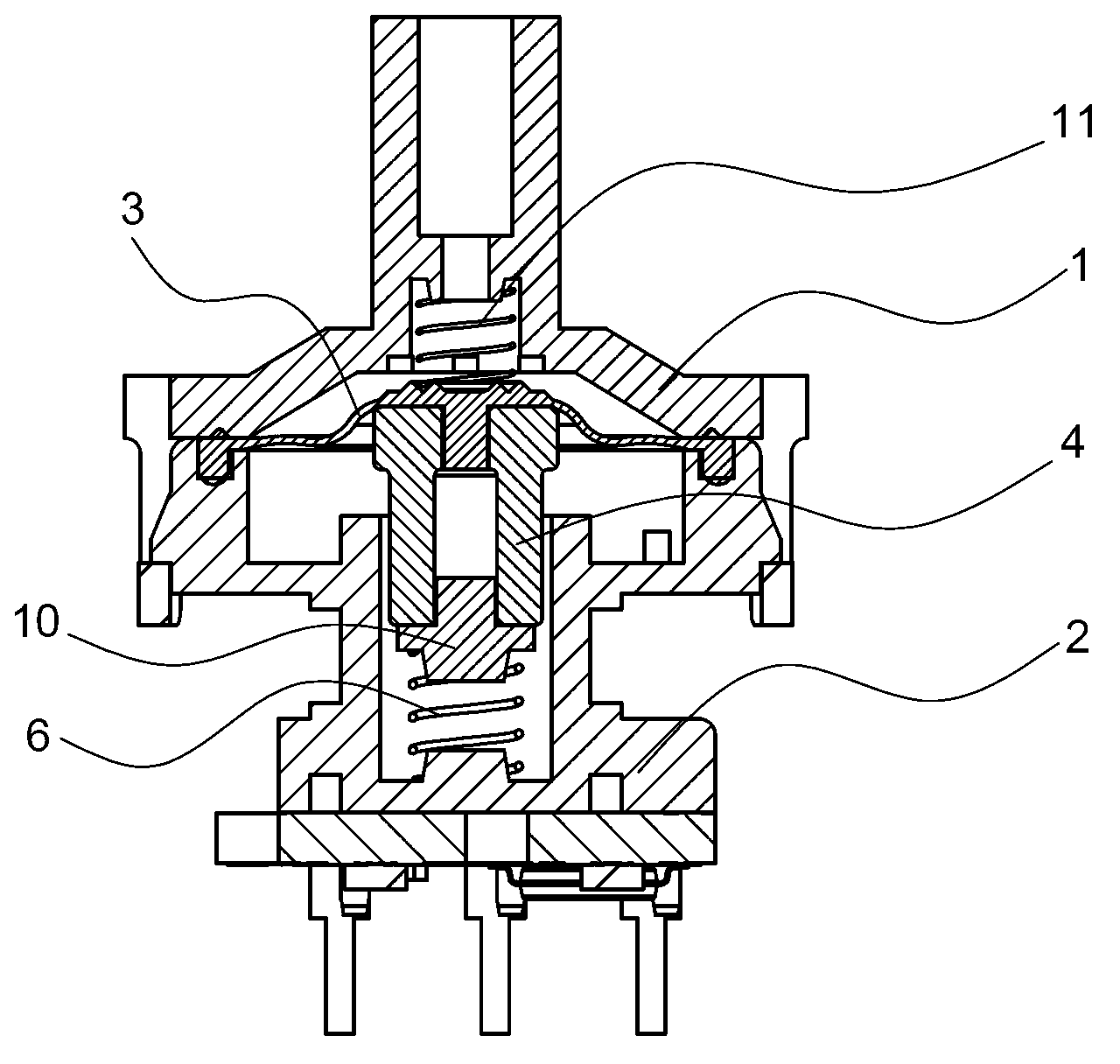

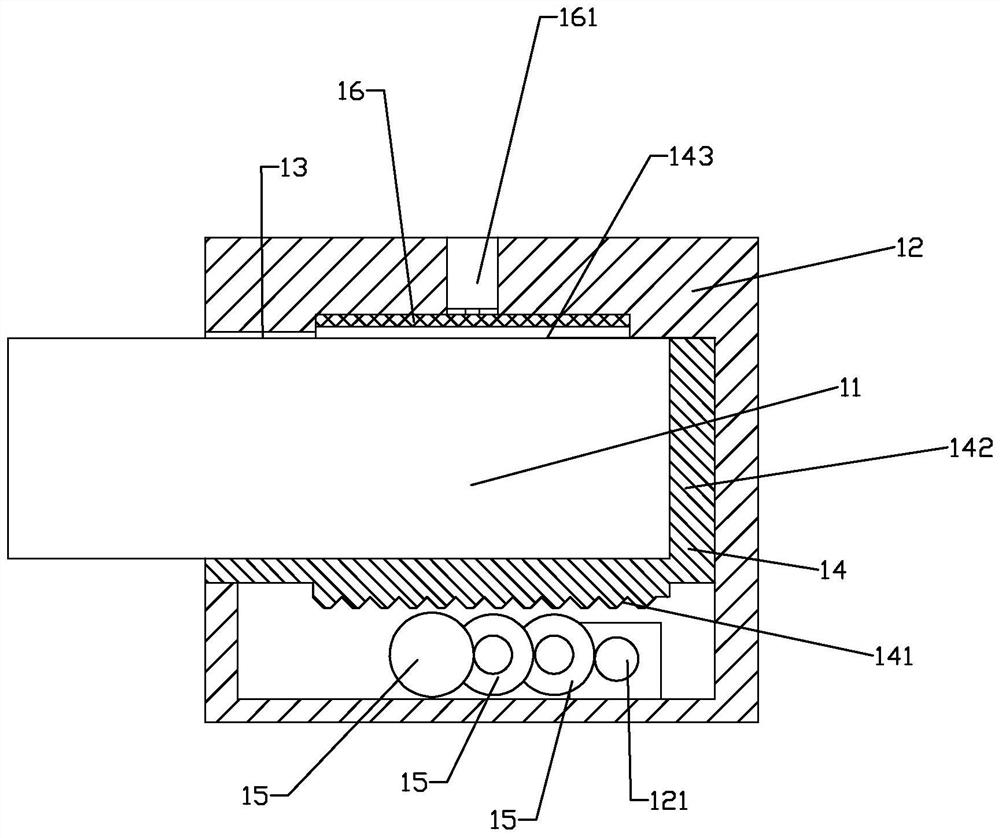

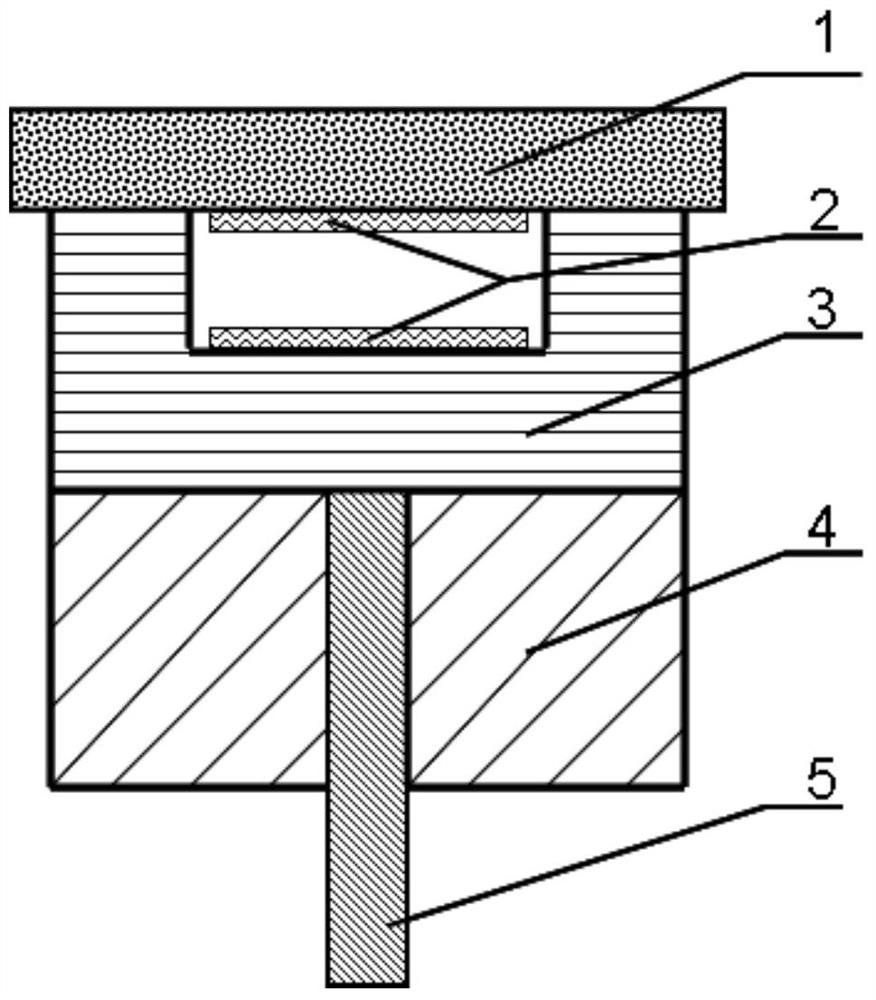

Pressure sensor

InactiveCN102937498AAddressing the drop in accuracyHigh measurement accuracyFluid pressure measurement by electric/magnetic elementsLevel indicators by pressure measurementEngineeringWater level

The invention provides a pressure sensor with a small measurement error. An elastic membrane (3) is fixedly arranged at a combined part of an air cover and a shell; an iron core (4) is arranged at the center of the elastic membrane; an inductance coil (5) is wound on a framework of the shell; a circuit board (7) is arranged below the shell; the circuit board is provided with a memory device (71); the shell is fixedly provided with a frequency signal output terminal (8) and a memory signal input / output terminal (9); one end (81) of the frequency signal output terminal and one end (91) of the memory signal input / output terminal outward output signals; a middle part (82) of the frequency signal output terminal and a middle part (92) of the memory signal input / output terminal are fixed with the shell; the other end (83) of the frequency signal output terminal and the other end (93) of the memory signal input / output terminal are connected with the circuit board; and the memory device stores a frequency value obtained by outputting through the frequency signal output terminal under different pressures. The pressure sensor disclosed by the invention is applicable to being used as a water level pressure sensor.

Owner:HANGZHOU KAMBAYASHI ELECTRONICS

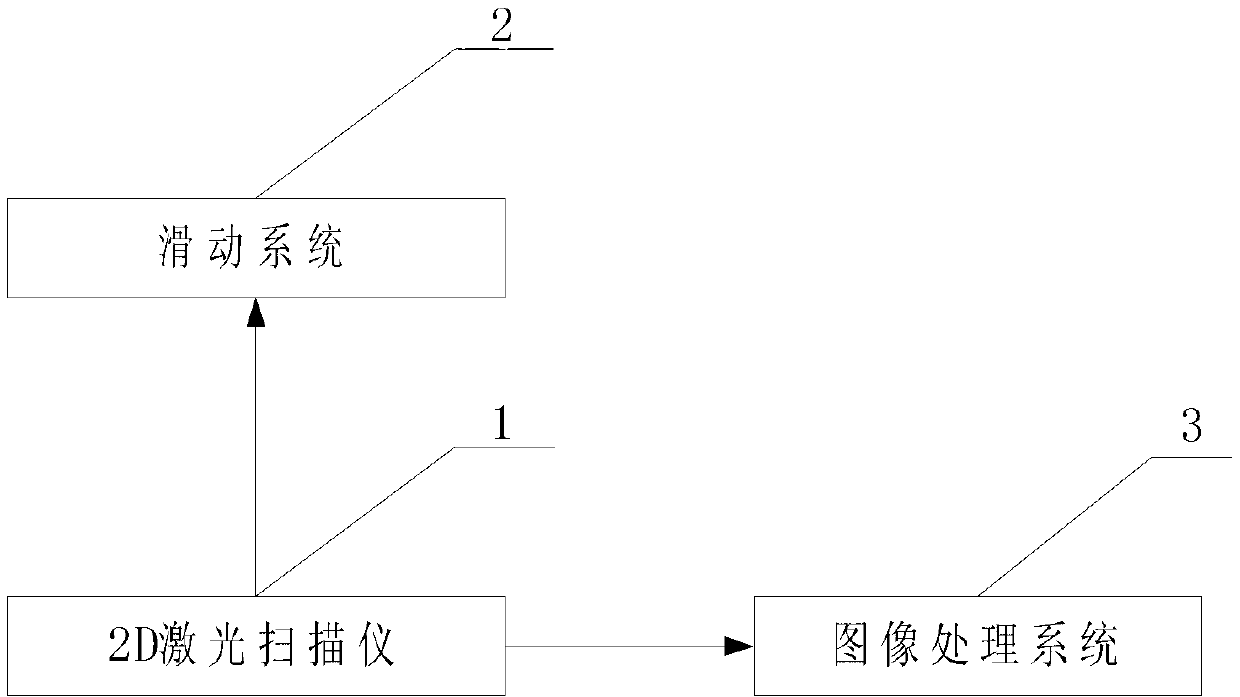

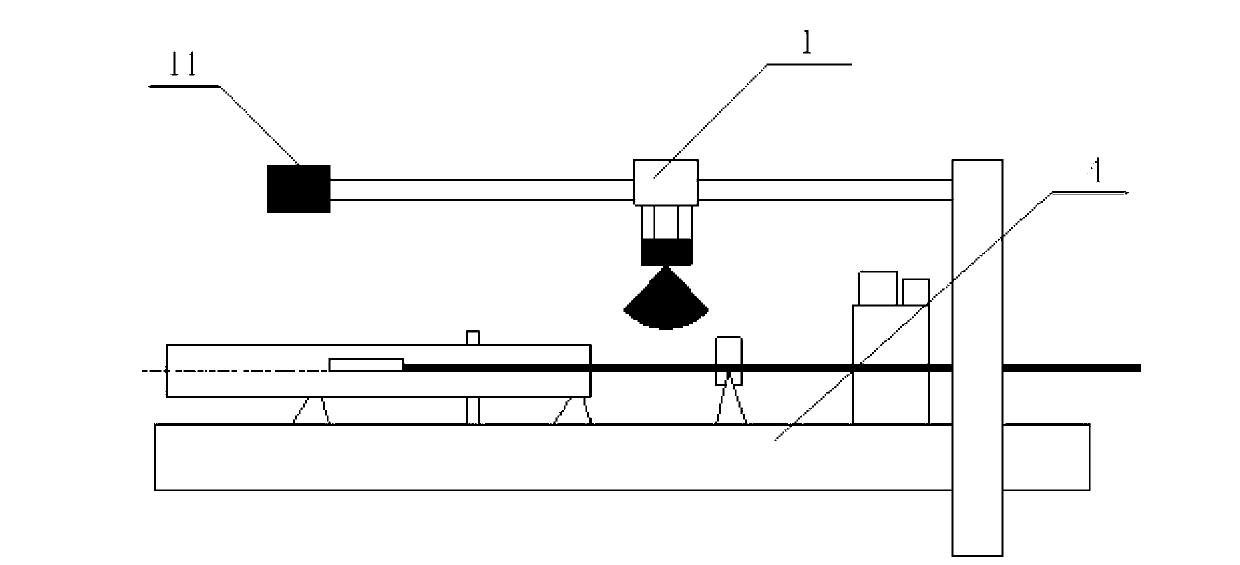

Honing machine detecting system

The invention discloses a honing machine detecting system which comprises a two-dimension (2D) laser scanner, a sliding system and an image processing system. The 2D laser scanner is used for transmitting laser to a guide rail and obtaining an appearance light section curve of the guide rail. The sliding system is connected with the 2D laser scanner and used for fixing and moving the 2D laser scanner. The image processing system is connected with the 2D laser scanner and used for analyzing the light section curve. The 2D laser scanner is utilized to quickly detect a large-scale horizontal type honing machine in a high-efficiency mode, a light section line image is transmitted to a digital signal processor (DSP) processing circuit by a charge-coupled device (CCD) camera, so that all parameters to be measures of each section of guide rail are obtained and compared with specified parameters of the guide rail of the honing machine to confirm whether the honing machine meets machining requirement or not, well solve the problem that accuracy of the honing machine is reduced, and conform to the requirements for being high in machining manufacturing accuracy and high in speed of modern industry. In addition, the honing machine detecting system is simple in structure, low in manufacturing cost, and obvious in practical effect, and has good application value.

Owner:NANJING UNIV OF TECH

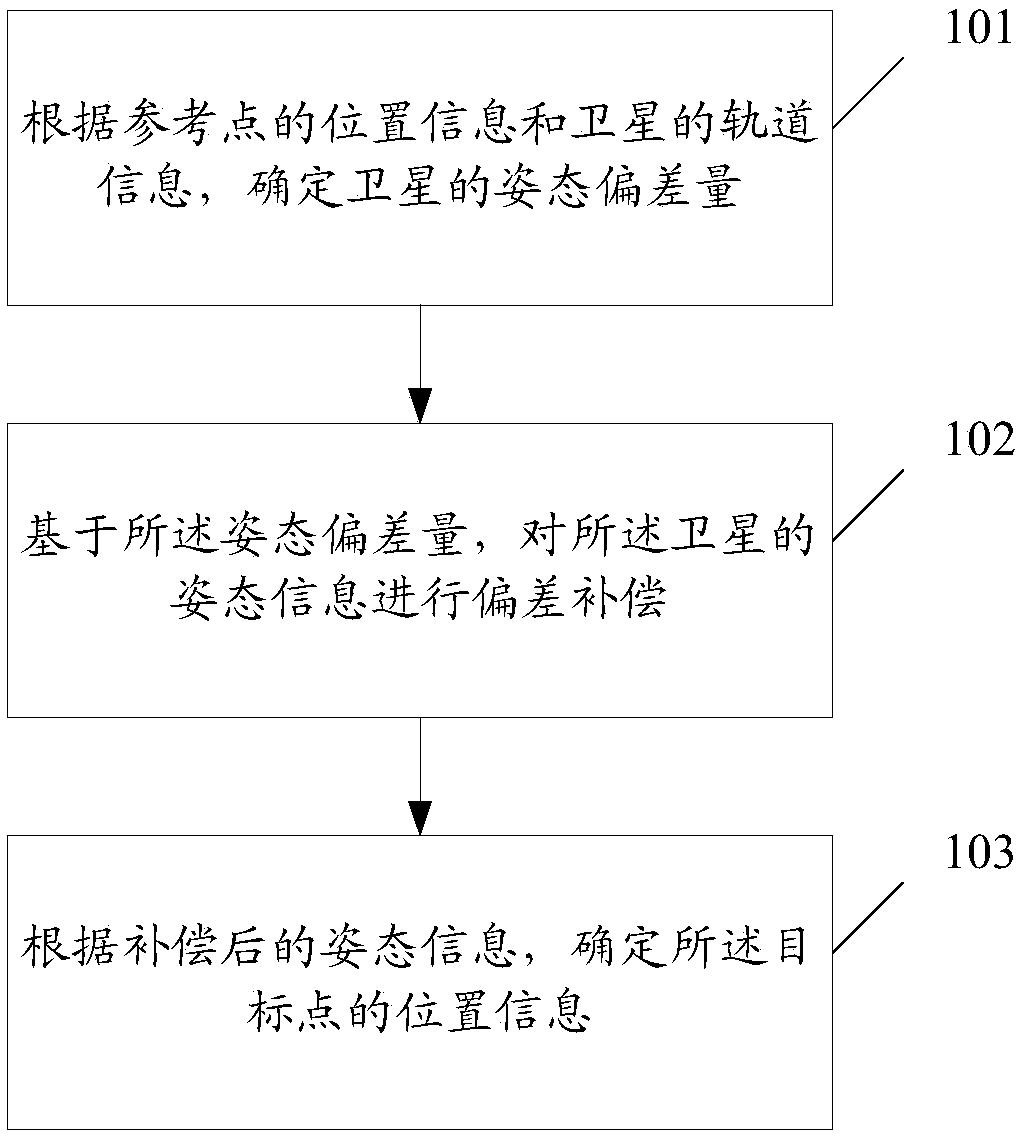

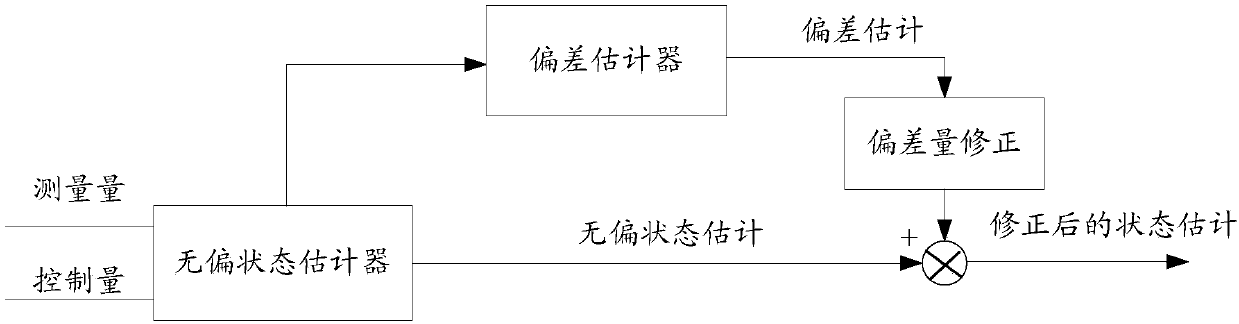

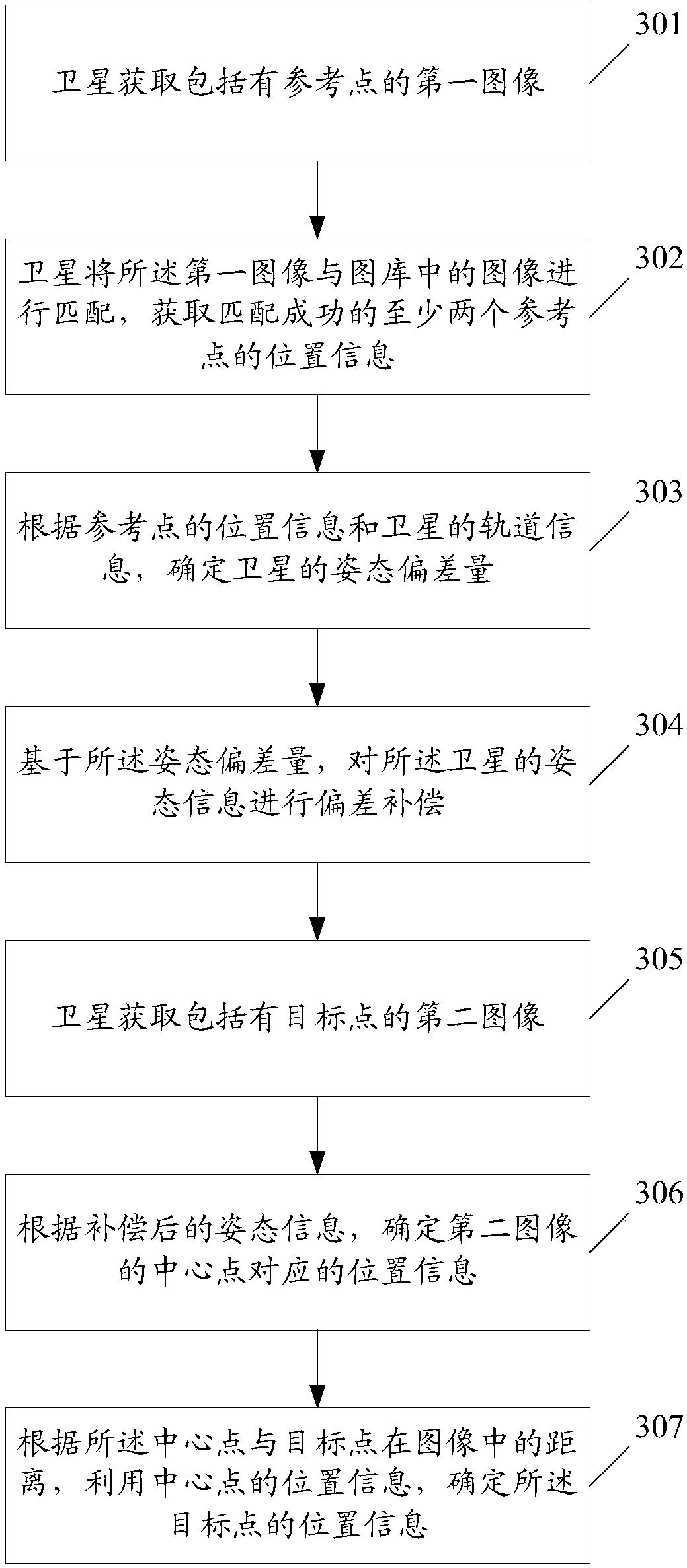

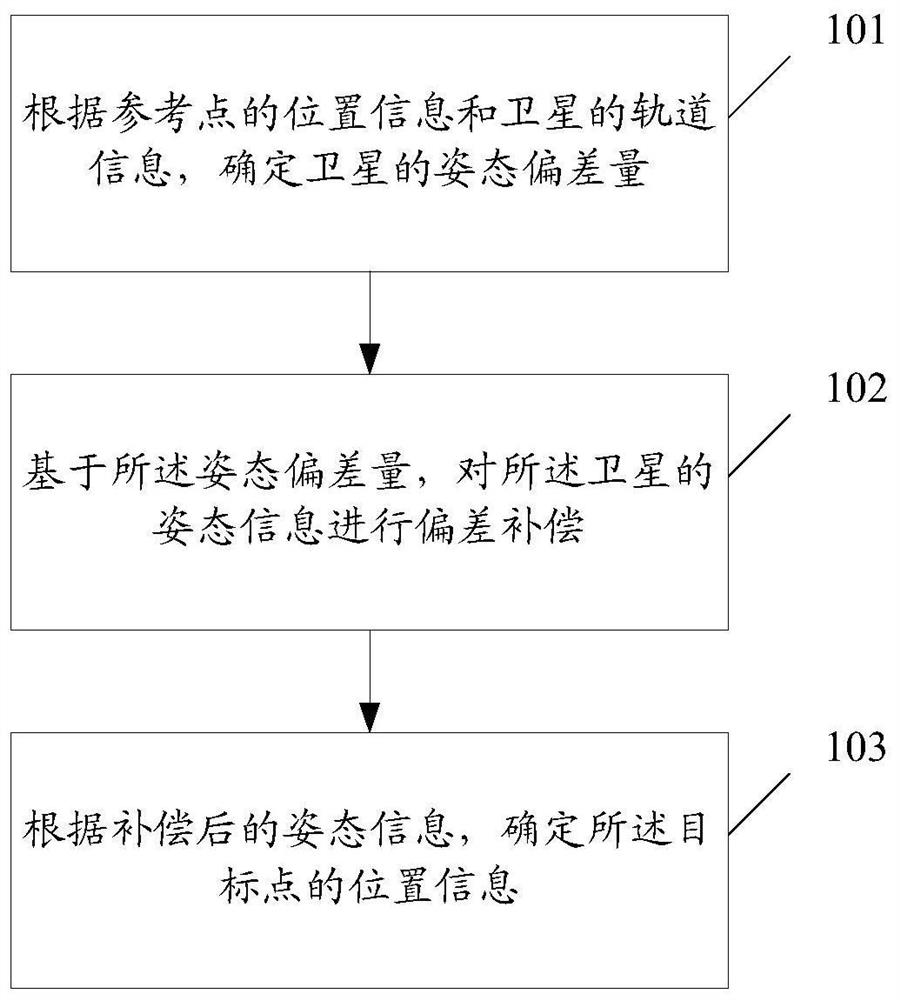

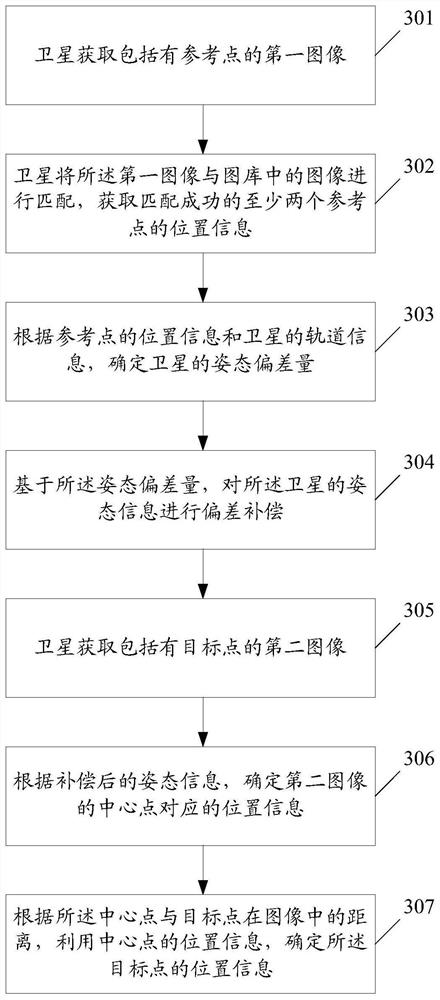

Ground object coordinate information-based rapid target positioning method, device, satellite-mounted device and storage medium

ActiveCN108051831AHigh precisionAddressing the drop in accuracySatellite radio beaconingSatelliteOrbit

The invention discloses a ground object coordinate information-based rapid target positioning method. The method includes the following steps that: the attitude deviation quantity of a satellite is determined according to the position information of a reference point and the orbit information of the satellite; deviation compensation is performed on the attitude information of the satellite based on the attitude deviation quantity; and the position information of a target point is determined according to the compensated attitude information. The present invention also discloses a ground objectcoordinate information-based rapid target positioning device, a satellite-mounted device and a storage medium.

Owner:HARBIN INST OF TECH

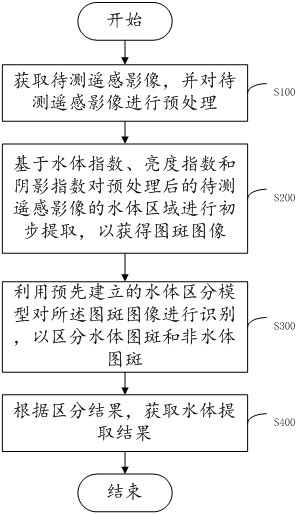

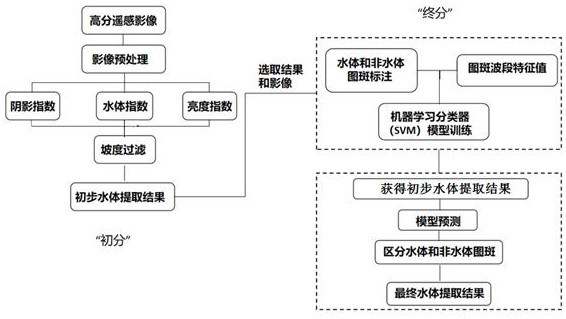

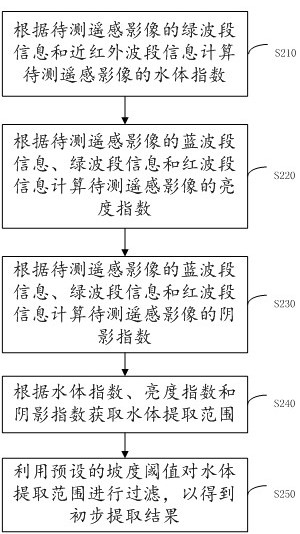

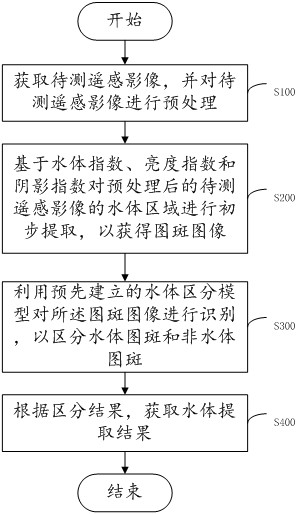

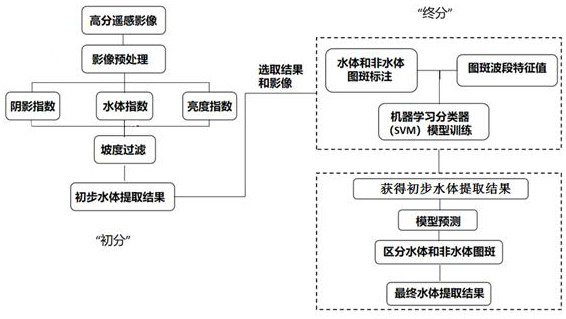

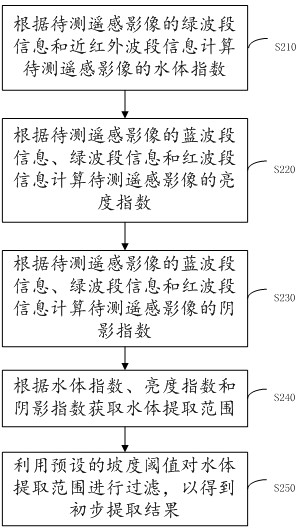

Remote sensing image water body extraction method and device, electronic equipment and storage medium

ActiveCN111931709AHigh precisionAddressing the drop in accuracyImage enhancementImage analysisEngineeringComputer science

The embodiment of the invention provides a remote sensing image water body extraction method and device, electronic equipment and a storage medium, and relates to the technical field of remote sensingimages. The method comprises the following steps: acquiring a to-be-measured remote sensing image, and preprocessing the to-be-measured remote sensing image; based on the water body index, the brightness index and the shadow index, carrying out preliminary extraction on the preprocessed water body area of the remote sensing image to be measured so as to acquire a pattern spot image; identifying the pattern spot image by using a pre-established water body distinguishing model so as to distinguish a water body pattern spot from a non-water body pattern spot; and obtaining a water body extraction result according to the distinguishing result, and removing interference by adopting a brightness index and a shadow index, thereby improving the precision of the water body extraction result, and solving the problem of precision reduction caused by interference in the existing method.

Owner:BEIJING AEROSPACE HONGTU INFORMATION TECH

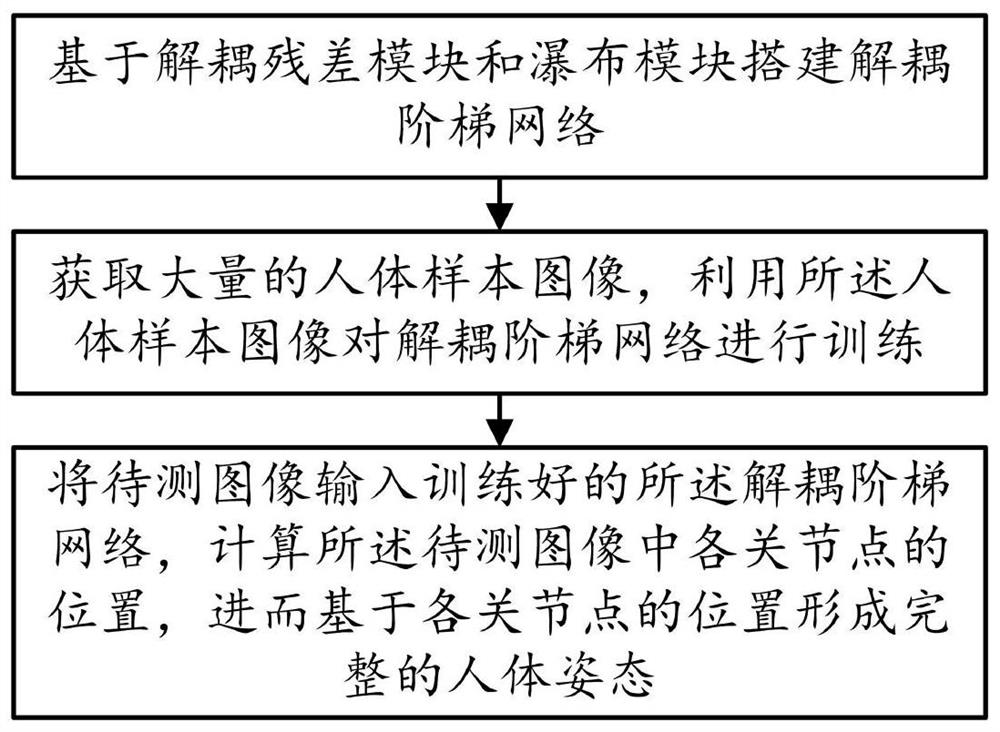

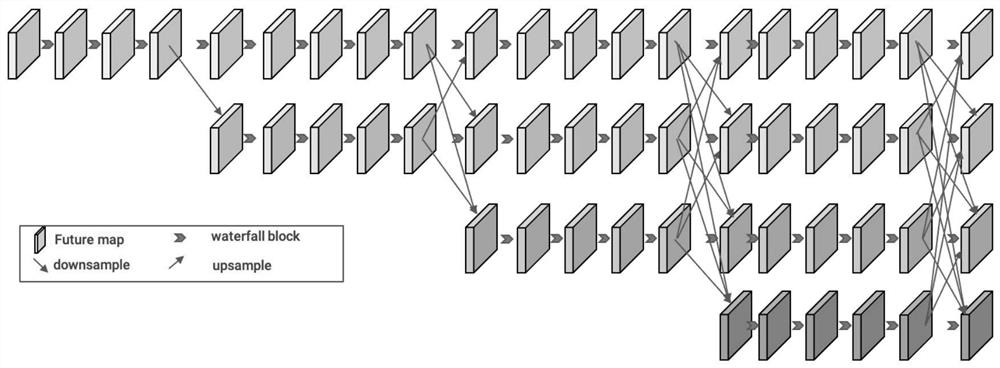

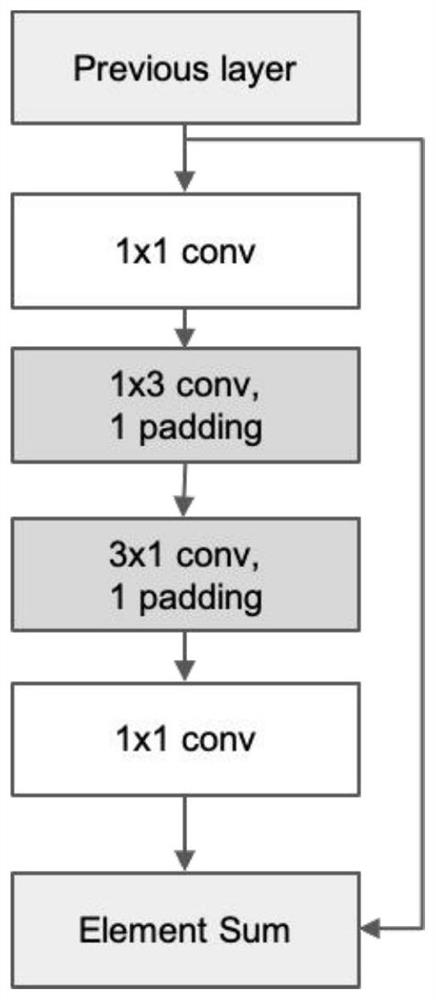

Attitude estimation method based on decoupling step network

ActiveCN112418070AReduce the amount of parametersIncrease training speedImage enhancementImage analysisHuman bodyEngineering

The invention provides an attitude estimation method based on a decoupling step network in the technical field of human body attitude estimation. The attitude estimation method comprises the followingsteps of S10, building the decoupling step network based on a decoupling residual module and a waterfall module; S20, acquiring a large number of human body sample images, and training a decoupling step network by using the human body sample images; and S30, inputting a to-be-tested image into the trained decoupling step network, calculating the position of each joint point in the to-be-tested image, and forming a complete human body posture based on the position of each joint point. The method has the advantage that the speed and precision of human body posture estimation are greatly improved.

Owner:HUAQIAO UNIVERSITY +1

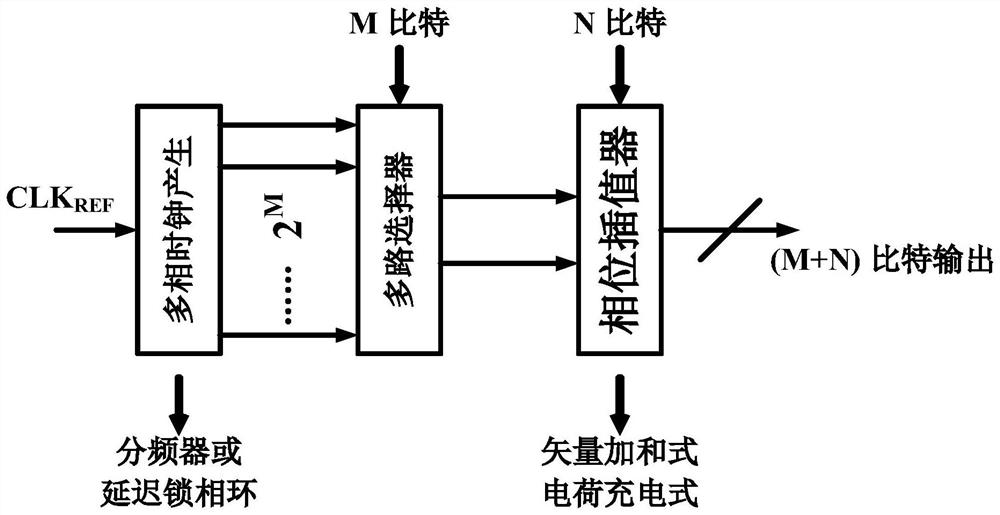

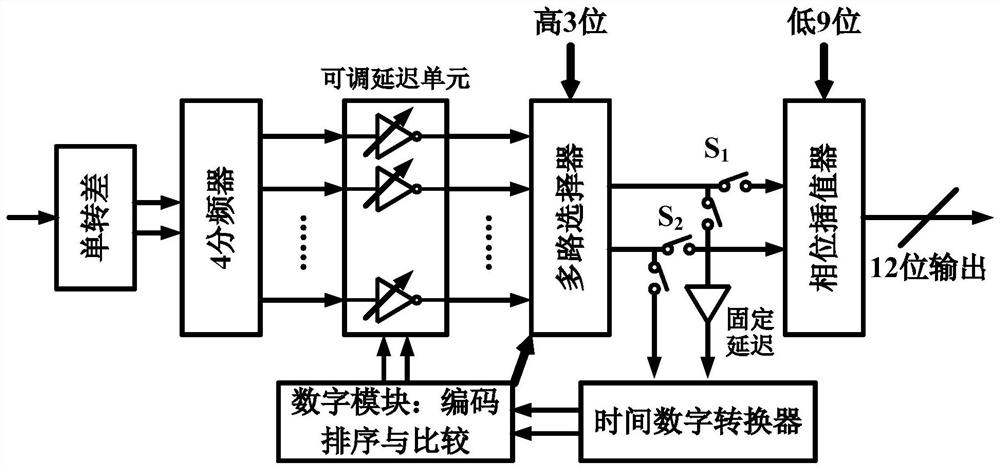

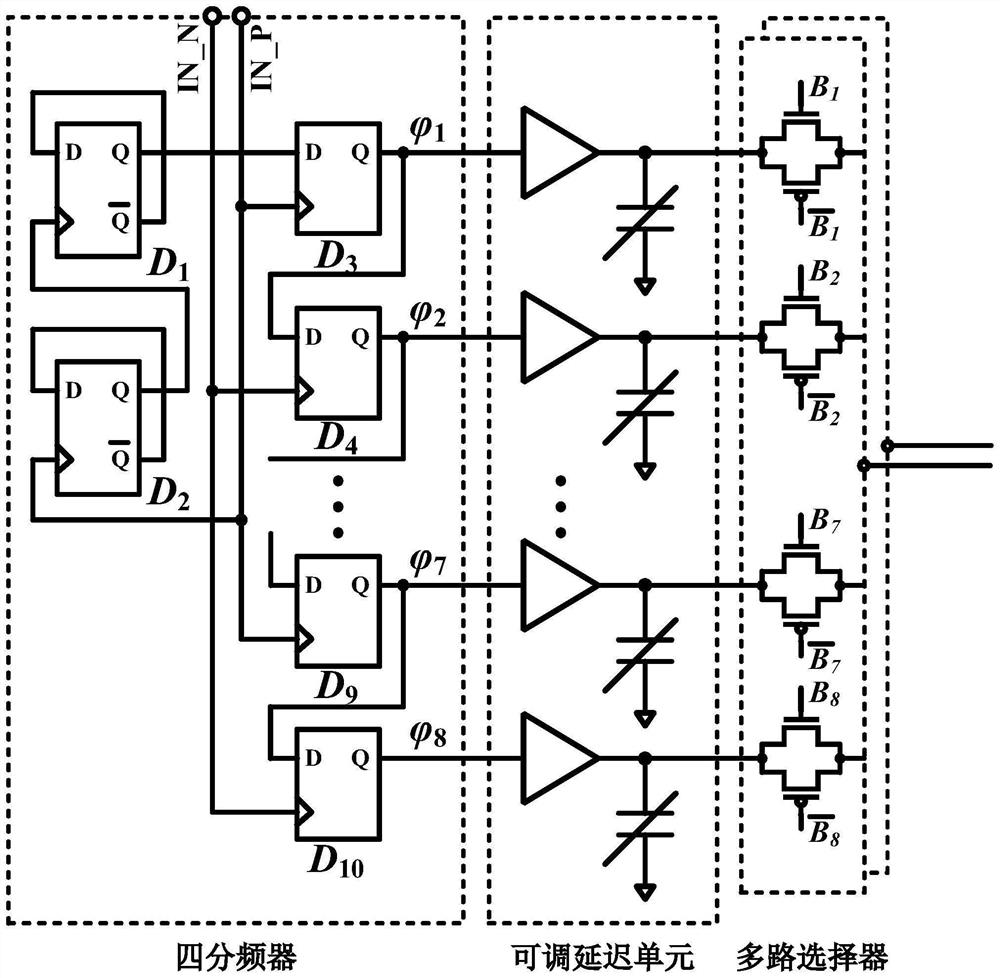

Full-period digital time converter based on clock calibration technology

ActiveCN114153136AHigh precisionGood linearityTime-to-digital convertersEmbedded systemDifferential circuits

The invention discloses a full-period digital time converter based on a clock calibration technology, which is characterized by comprising a single-to-differential circuit used for converting an input single-ended signal into a differential signal and inputting the differential signal into a multi-phase clock signal generation unit; the multi-phase clock signal generation unit is used for generating a multi-phase clock signal according to an input differential signal and inputting the multi-phase clock signal into the adjustable delay module; the adjustable delay module is used for delaying the multi-phase clock signal according to the output signal of the digital module and then inputting the delayed multi-phase clock signal into the multiplexer; the multiplexer is used for selecting a group of adjacent two-phase signals to output according to the switch control signal generated by the digital module; the phase interpolator is used for generating numerical control time signals according to two adjacent phase signals; the time-to-digital converter is used for calculating the time difference of rising edges of two adjacent phase signals and inputting the time difference to the digital module; and the digital module is used for generating a delay control signal of the adjustable delay module on the multiphase clock signal and a switch control signal according to the time difference of the rising edges of each group of adjacent two-phase signals.

Owner:PEKING UNIV

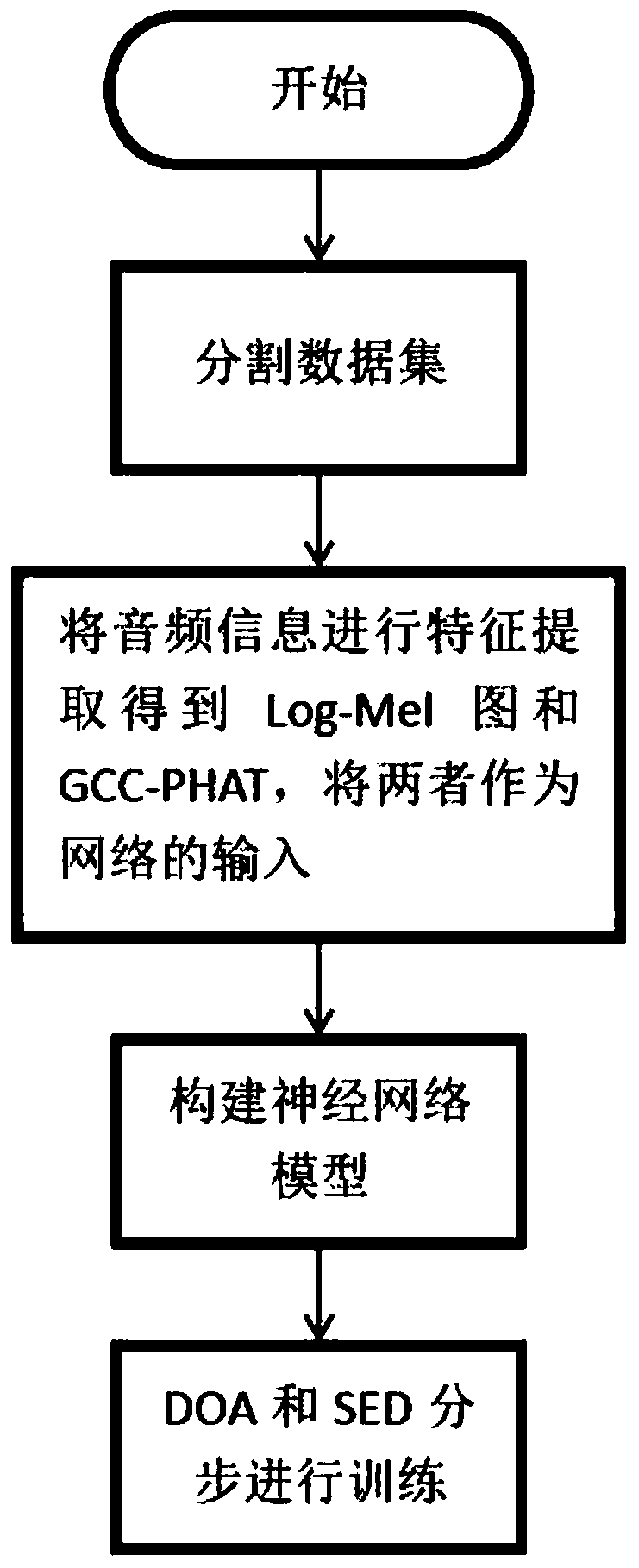

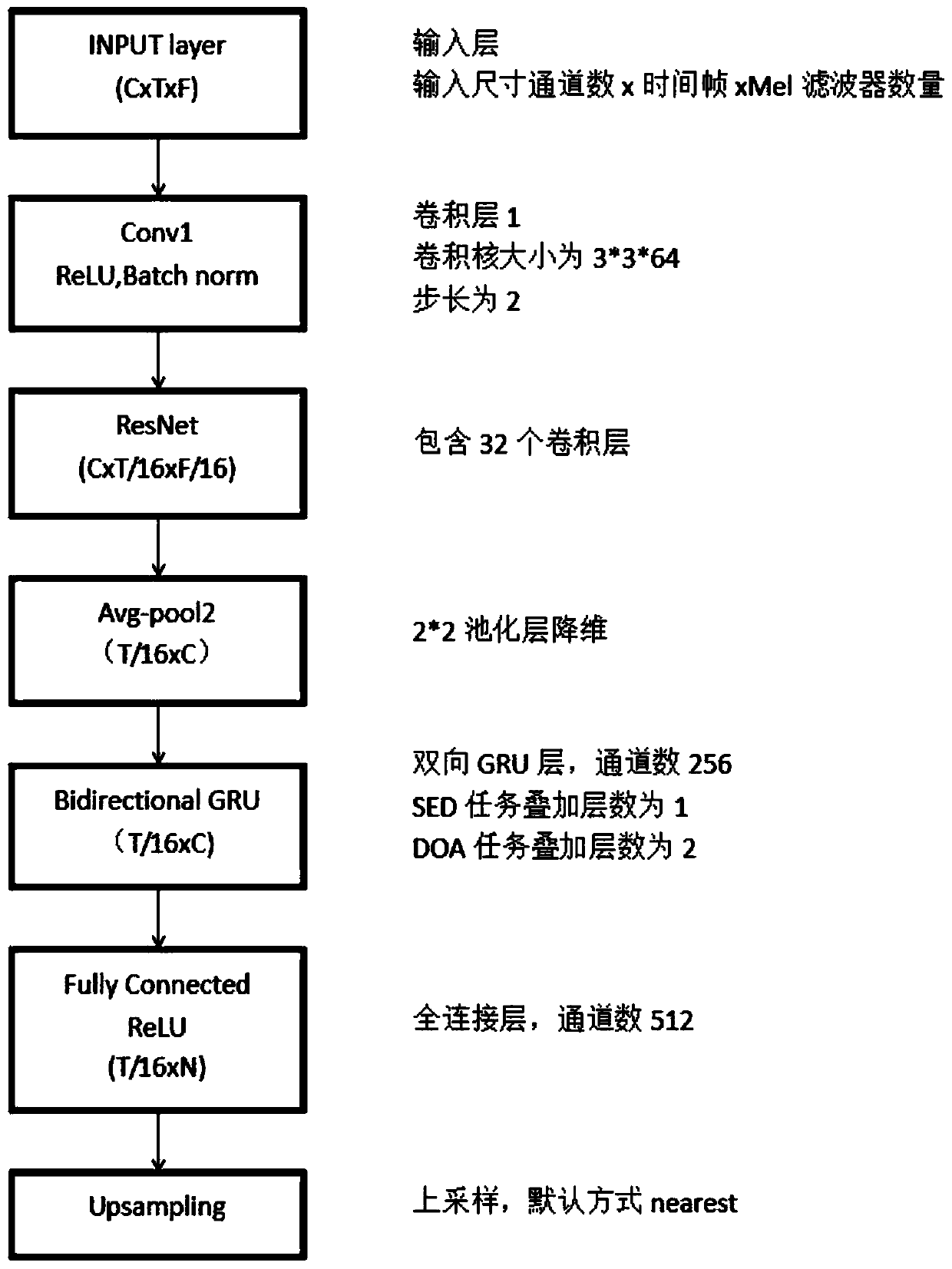

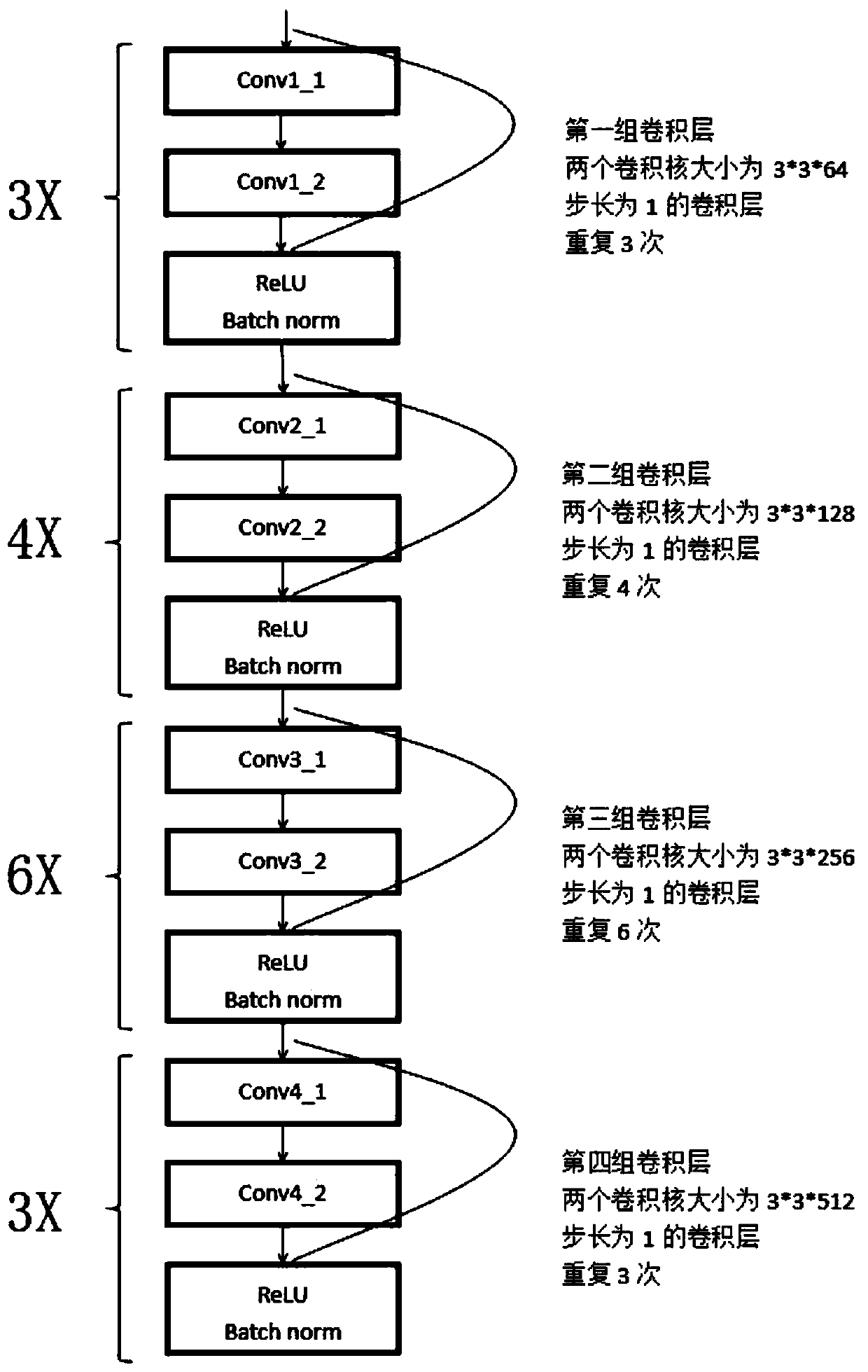

Sound event detection and positioning method based on deep learning

PendingCN111443328AOutstanding advantagesOutstanding FeaturesPosition fixationNeural architecturesNetwork architectureEngineering

The invention relates to a sound event detection and positioning method based on deep learning. The method comprises the following steps of: step 1, segmenting a data set; step 2, preprocessing, namely performing feature extraction on the data set containing the sound signal to obtain a Log-Mel spectrogram and GCC-PHAT; step 3, constructing a deep learning model, namely constructing a network architecture combining a ResNet framework and RNN by referring to the ResNet framework, and compounding a pooling module, a regularization module and a normalization module between layers for optimizing feature extraction and improving nonlinearity; and step 4, two-step training, namely firstly training the SED task to obtain an optimal model and inputting the training result into DOA task training asa feature; and then training the DOA task to finally obtain an optimal training model. According to the method, the characteristics suitable for task training are extracted firstly, so that the reverberation resistance is improved, a new frame structure is provided to solve the problem that the precision is reduced due to network deepening, and finally the prediction precision is improved.

Owner:SHANGHAI UNIV

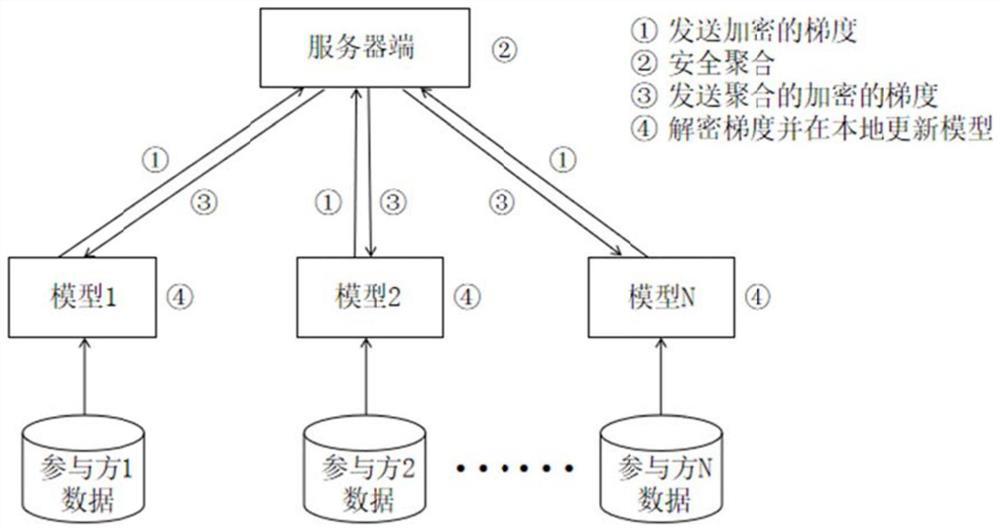

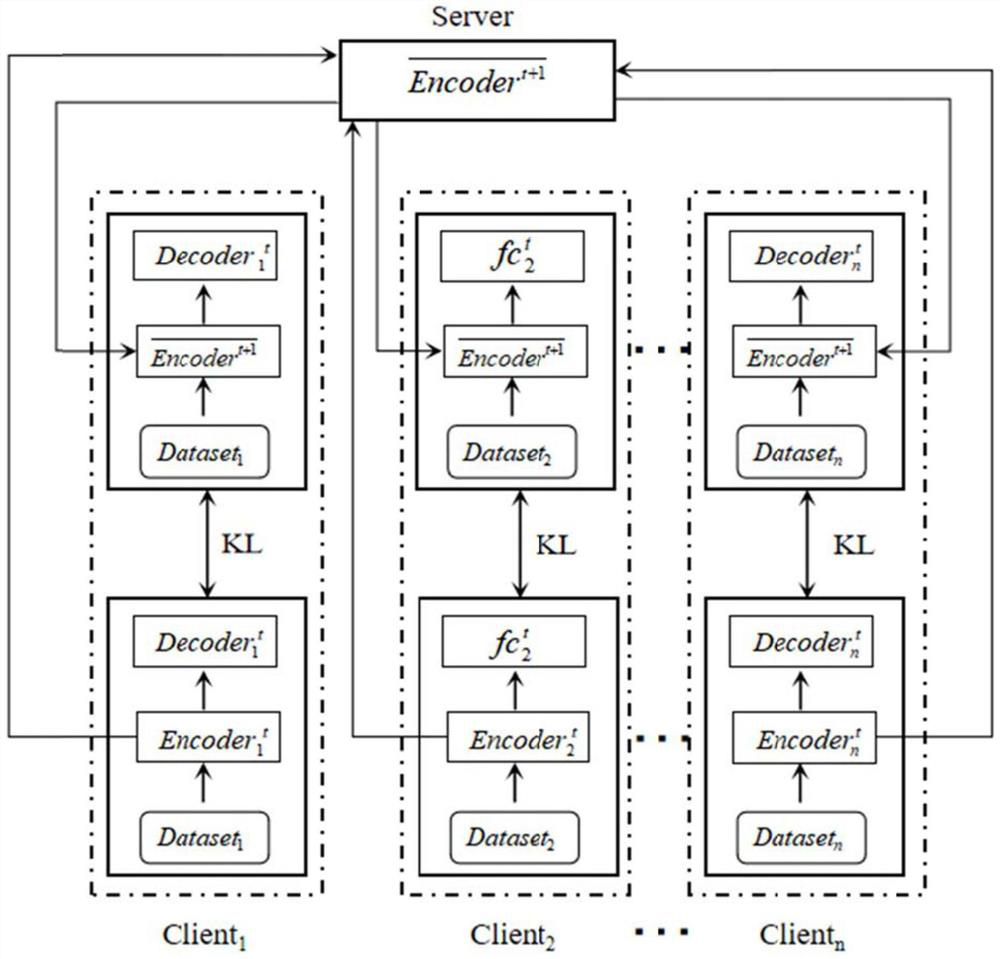

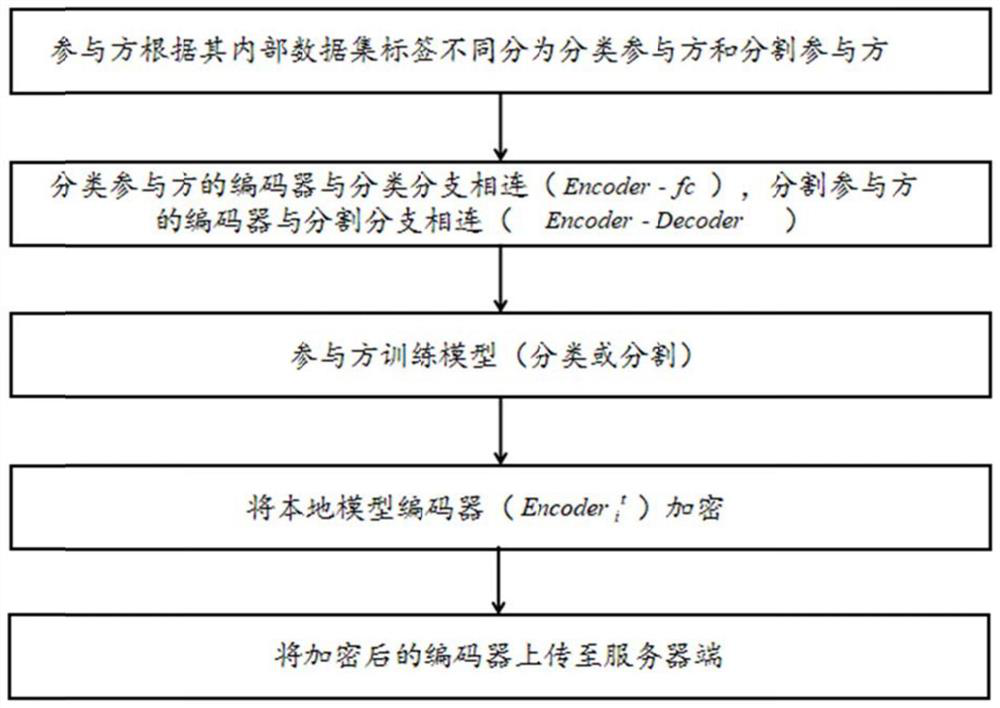

Federal learning system for multi-type task image analysis

PendingCN113240129AImprove accuracyImprove personalizationEnsemble learningCharacter and pattern recognitionImage analysisFederated learning

The invention belongs to the technical field of images, and discloses a federated learning system for multi-type task image analysis, the federated learning system comprises a Server and a Client, the Client comprises a Decoder, an Encoder, an Encoder average value and fc, and the Server comprises the Encoder average value. According to the method, data islands among all parties are broken through by using a federated learning framework, so that modeling can be carried out by combining data of all parties on the premise of protecting image data privacy, the accuracy is higher than that of independent modeling, and image analysis of multiple types of tasks can be carried out at the same time.

Owner:DALIAN UNIV OF TECH +1

Vehicle networking data processing method, server and terminal

ActiveCN108200121AAddressing the drop in accuracyGuaranteed accuracyFinanceRegistering/indicating working of vehiclesComputer terminalUser driven

The invention provides a vehicle networking data processing method, a server and a terminal. The method comprises the following steps of acquiring vehicle-running historical data by the server; training the vehicle-running historical data and acquiring a program script used for analyzing a user driving behavior; and sending the program script to the terminal. In the technical scheme of the invention, through the server, the vehicle-running historical data is firstly acquired, then, the vehicle-running historical data is trained and the program script used for analyzing the user driving behavior is acquired, and finally, the program script is sent to the terminal. According to the program script and the vehicle-running data, the user driving behavior is dynamically analyzed. A problem thatalgorithm precision is reduced because algorithm updating is not timely is solved. Accuracy of user driving behavior analysis is guaranteed, and further, extra cost brought by terminal firmware updating is reduced.

Owner:HUAWEI DEVICE CO LTD

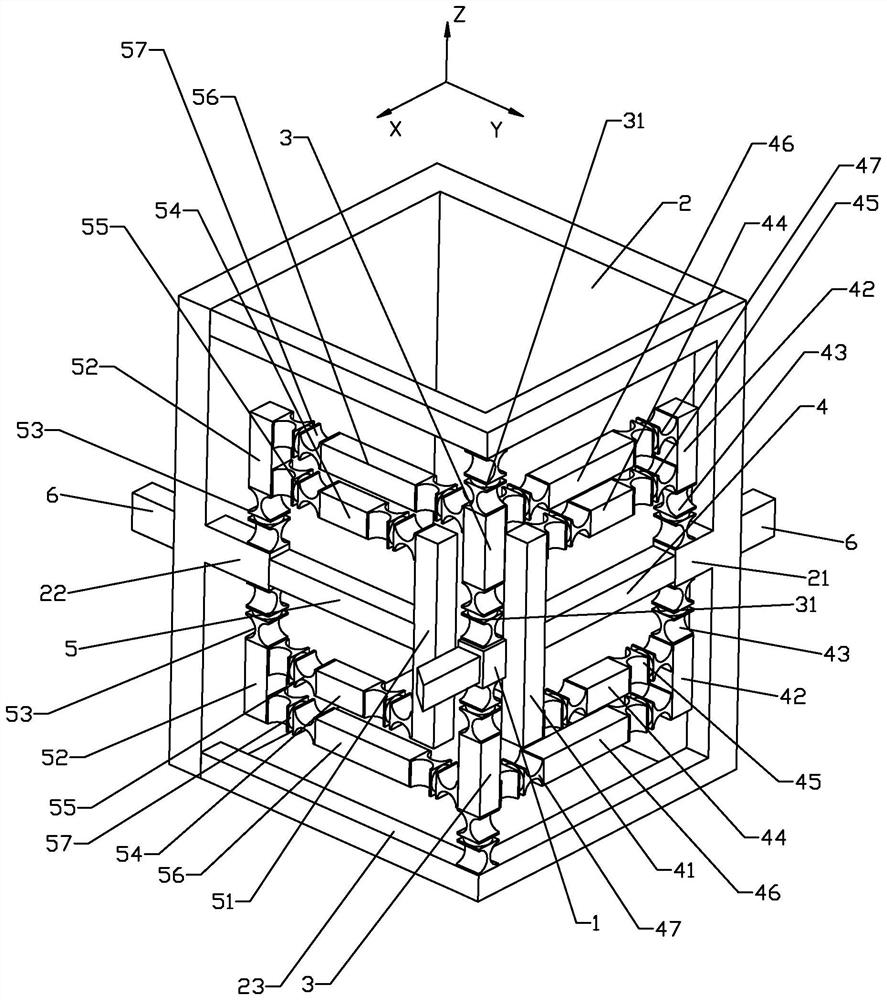

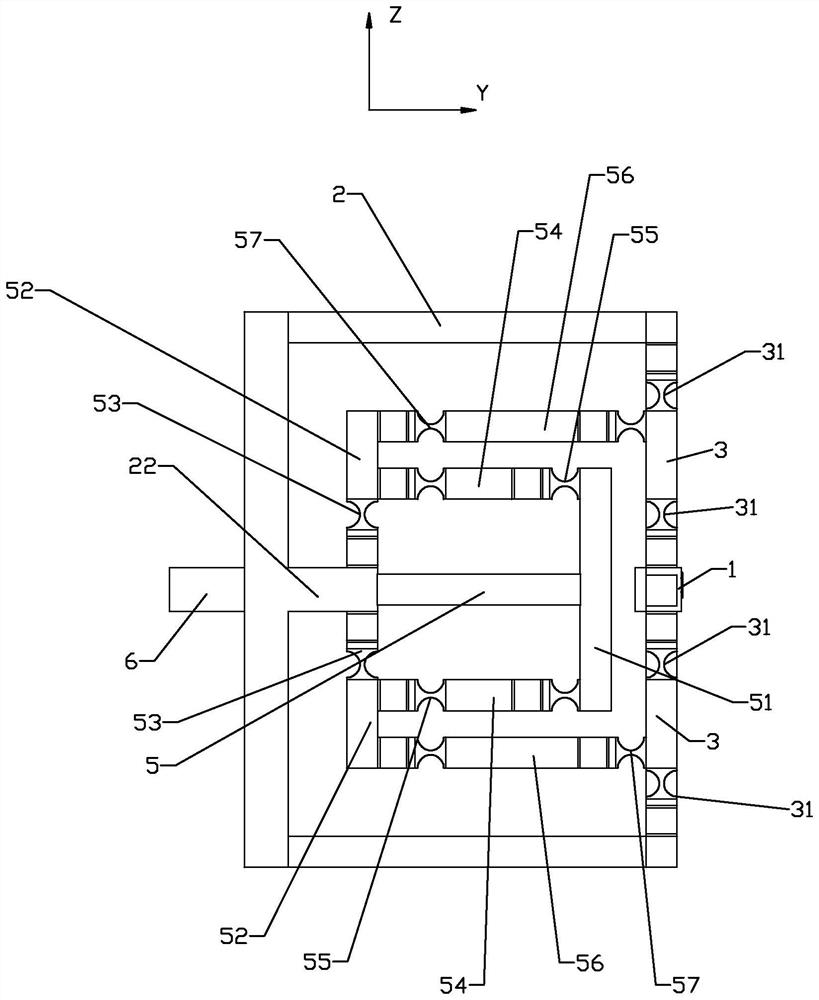

Two-degree-of-freedom self-decoupling large-rigidity large-stroke piezoelectric quick servo tool rest

PendingCN114123849AOvercoming physical characteristicsMeet processing needsPiezoelectric/electrostriction/magnetostriction machinesWorking accessoriesEngineeringServo

The invention relates to a two-degree-of-freedom self-decoupling large-rigidity large-stroke piezoelectric rapid servo tool rest which comprises a tool, a base and a piezoelectric ceramic driver. An installation hinge set composed of a transverse deformation flexible hinge and a longitudinal deformation flexible hinge is arranged between the other end, opposite to the cutter, of the cutter adjusting and controlling vertical rod and the base, and the two piezoelectric ceramic drivers are located on the two sides of the cutter correspondingly. The piezoelectric ceramic drivers comprise a first piezoelectric ceramic driver for outputting longitudinal driving force and a second piezoelectric ceramic driver for outputting transverse driving force, and the two piezoelectric ceramic drivers are respectively provided with a two-stage lever amplification mechanism with a decoupling function. By the adoption of the scheme, the two-degree-of-freedom self-decoupling large-rigidity large-stroke piezoelectric rapid servo tool rest is high in precision, the stroke is enlarged, and the machining stability is improved.

Owner:WENZHOU UNIVERSITY

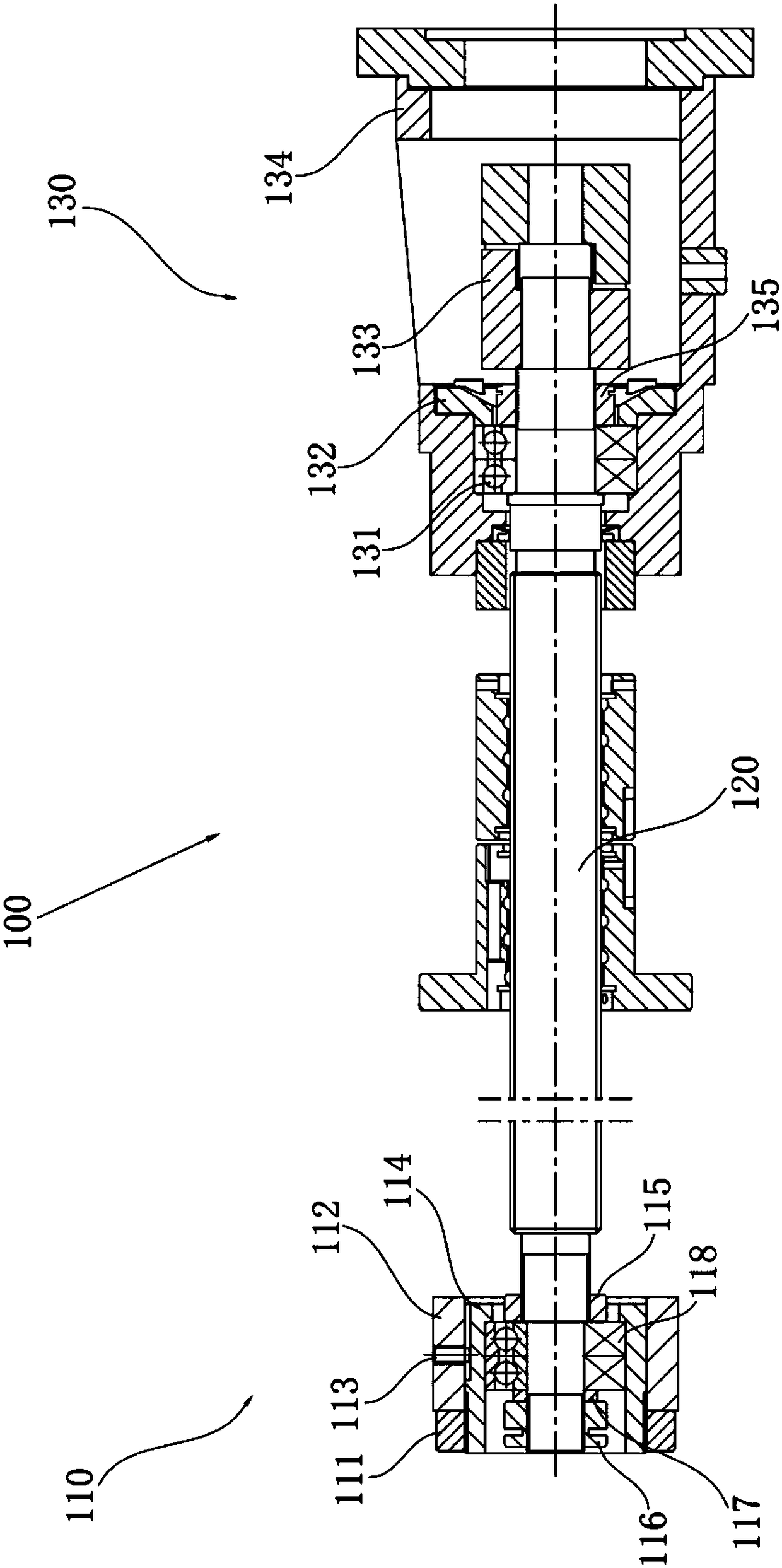

Ball screw pre-stretching mechanism and pre-stretching method

ActiveCN105922049BAvoid the phenomenon of "locking to death"Addressing the drop in accuracyMetal working apparatusMaintainance and safety accessoriesBall screwMechanical engineering

The invention discloses a ball screw prestretching mechanism and a prestretching method thereof. The ball screw prestretching mechanism comprises a ball screw pair, a front locking module and a back locking module, wherein the front end and the back end of the ball screw pair are respectively fixed by the front locking module and the back locking module; the back locking module includes a back end bearing, a back end bearing sleeve and a back end bearing base coating the ball screw pair in sequence from inside to outside; the back end bearing sleeve is coated with a stretching unit; the stretching nut is near the outer side of the back end bearing base; and a rotation preventing pin is inserted in the back end bearing base, and is butted against the outer surface of the back end bearing sleeve after penetrating through the back end bearing base. The ball screw prestretching mechanism can obtain the beneficial effect of preventing the blockage phenomenon of a ball screw by a bearing inner ring due to a bearing locking nut stretching the ball screw when locking a ball screw bearing.

Owner:JIANGSU YUANLI AVIA PRECISION MACHINE TOOL

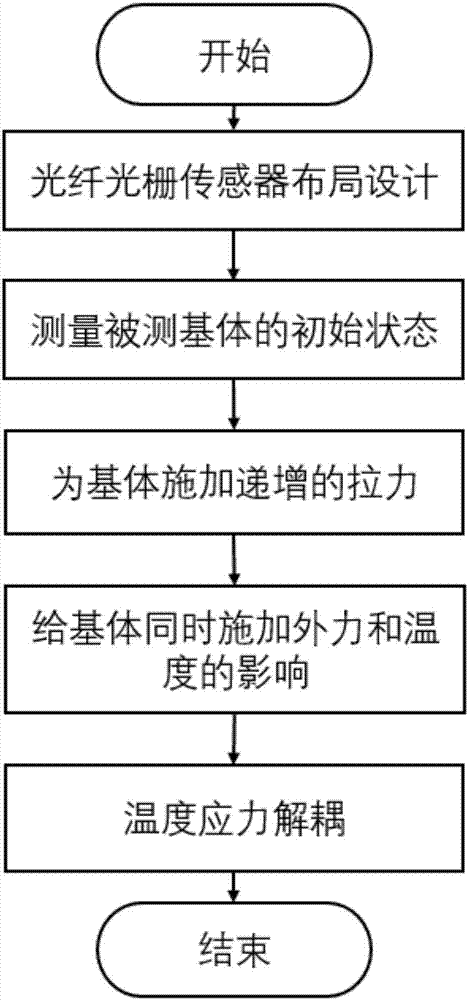

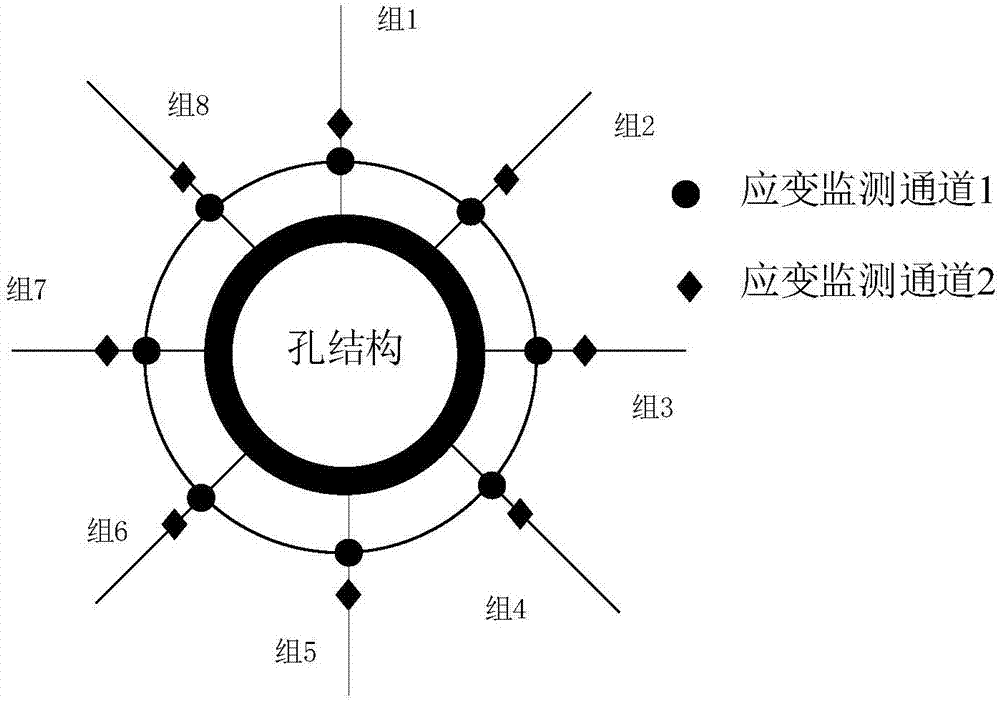

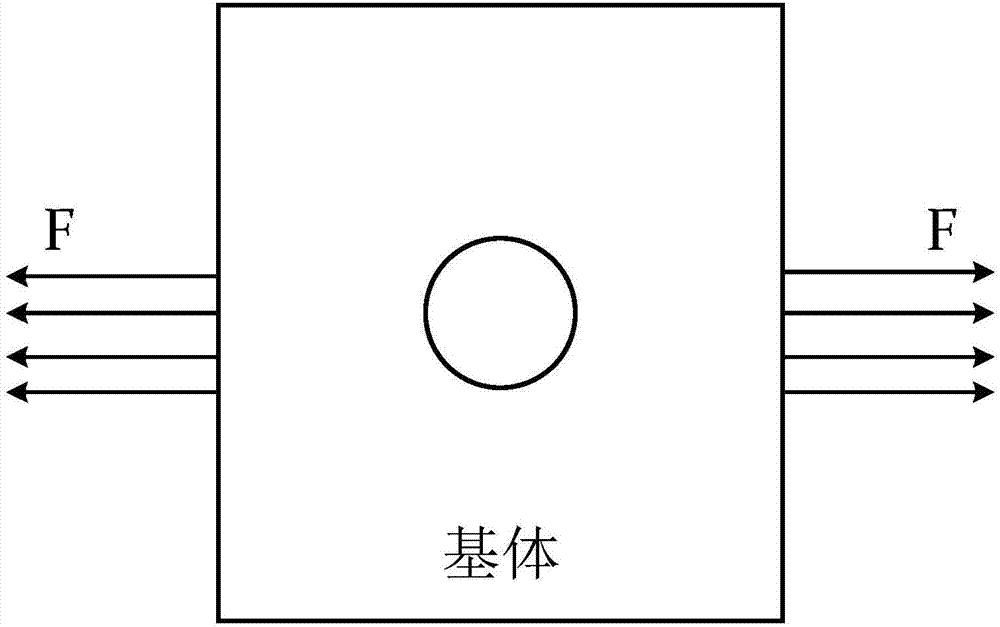

Fiber grating sensor temperature stress decoupling method in metal hole structure

InactiveCN107255540AHigh precisionAddressing the drop in accuracyForce measurement by measuring optical property variationUsing optical meansPhysicsFiber bragg grating sensor

The invention provides a fiber grating sensor temperature stress decoupling method in a metal hole structure. The fiber grating sensor temperature stress decoupling method in the metal hole structure comprises steps of designing a layout of the fiber grating sensor, measuring an original state of a detected basal body, applying an increasing pulling force to the detected basal body, measuring central wavelength changing conditions of two grid points in a first group, applying external force and temperature influences to the detected basal body at the same time, measuring a changing quantity of the central wavelength of each grid point, and further calculating stress strains of all other points around a hole. The fiber grating sensor temperature stress decoupling method in the metal hole structure realizes fiber grating sensor temperature and stress decoupling in the metal hole structure, respectively solves magnitudes of temperature and the stress of the fiber grating sensor, improves accuracy of a fiber grating stress sensor monitoring a structure stress, solves a problem that the accuracy of the fiber grating stress sensor is reduced due to temperature interference and benefits popularization and application of a fiber Bragg grating sensor.

Owner:BEIHANG UNIV

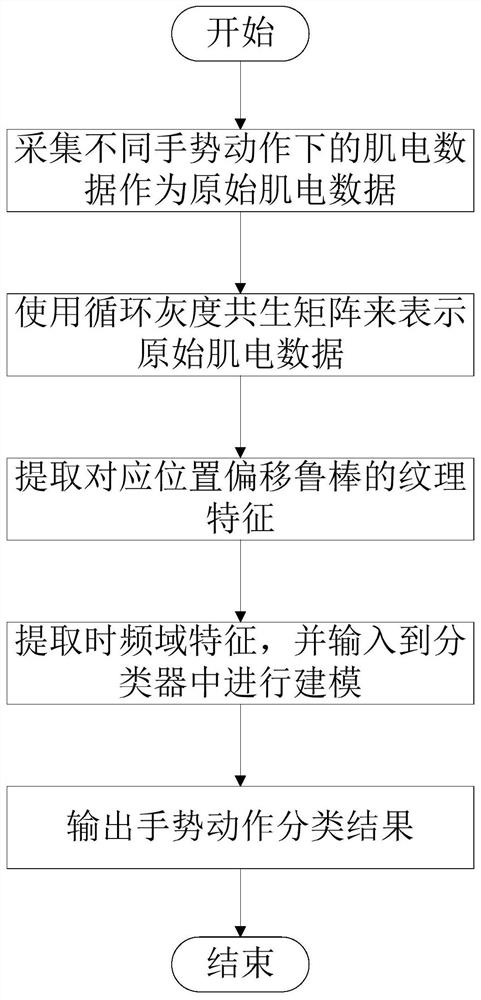

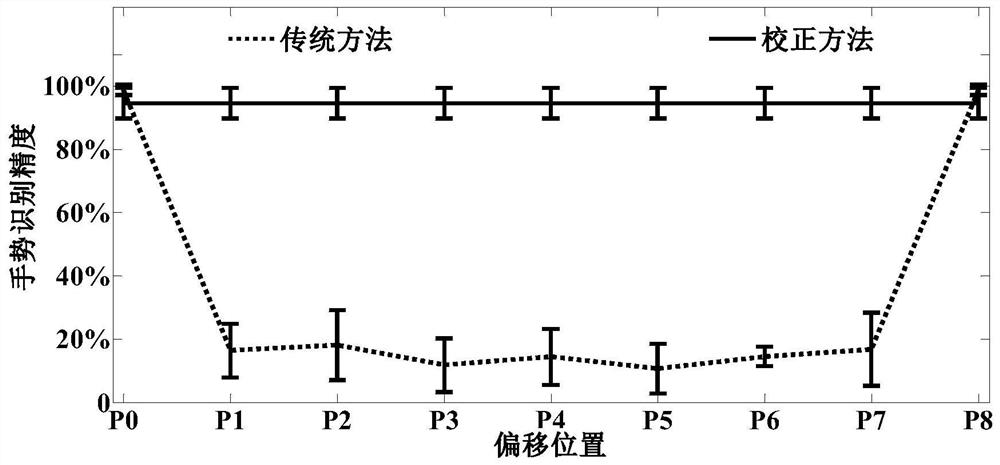

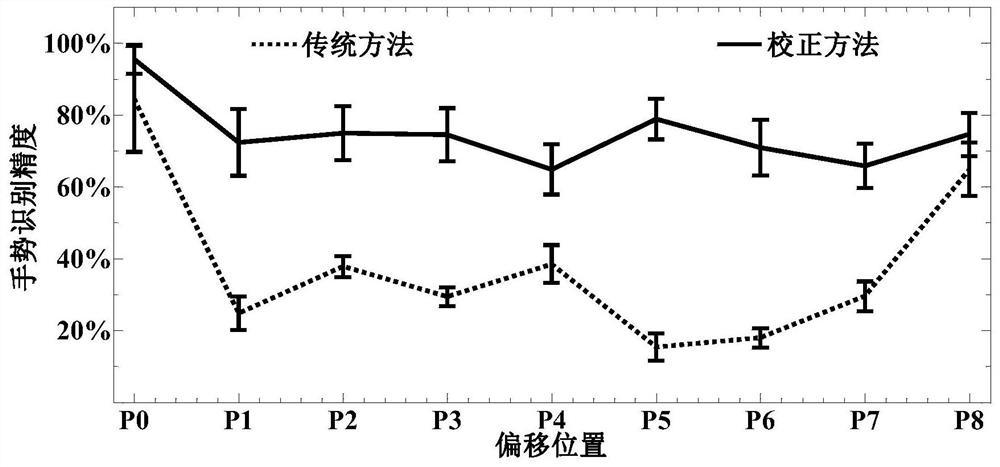

Electromyographic signal gesture action recognition method based on texture features

PendingCN112764524AReduce complexityHigh Action Recognition ResultsInput/output for user-computer interactionDiagnostic recording/measuringTime domainEngineering

The invention relates to the technical field of biological signal recognition, in particular to an electromyographic signal gesture action recognition method based on texture features. The method comprises the steps of firstly collecting myoelectricity data under different gesture actions, secondly representing original myoelectricity data by using a cyclic gray-level co-occurrence matrix, then extracting texture features of corresponding position offset robustness according to the obtained cyclic gray-level co-occurrence matrix, finally extracting time domain features on the basis of the texture features; and inputting the obtained time domain features into a classifier for model training, and finally outputting a gesture action classification result. The method provided by the invention has great flexibility, can well solve the problem that the model precision is reduced due to the position offset of the sensor in practical application, and effectively improves the robustness of the myoelectricity man-machine interaction system.

Owner:沈阳智能机器人国家研究院有限公司 +2

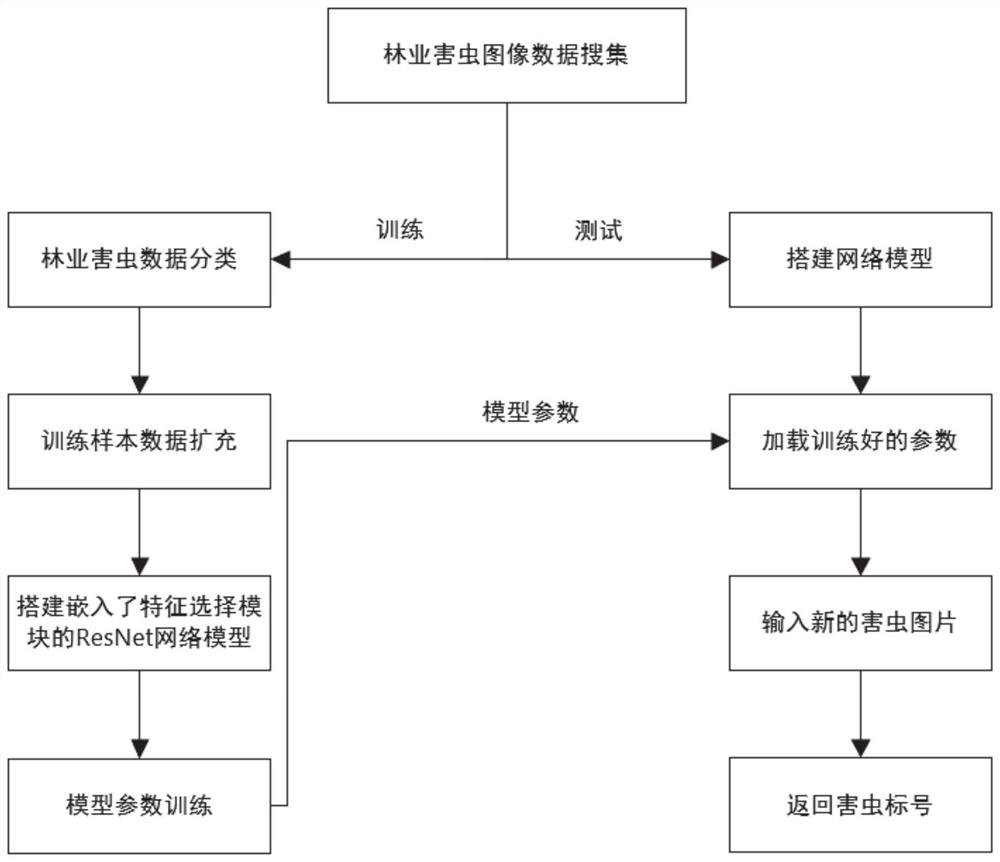

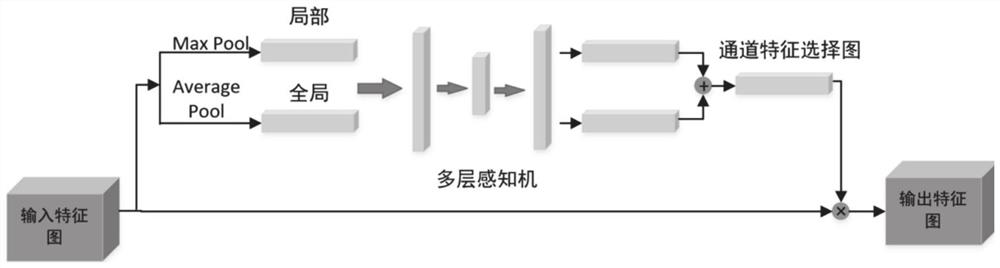

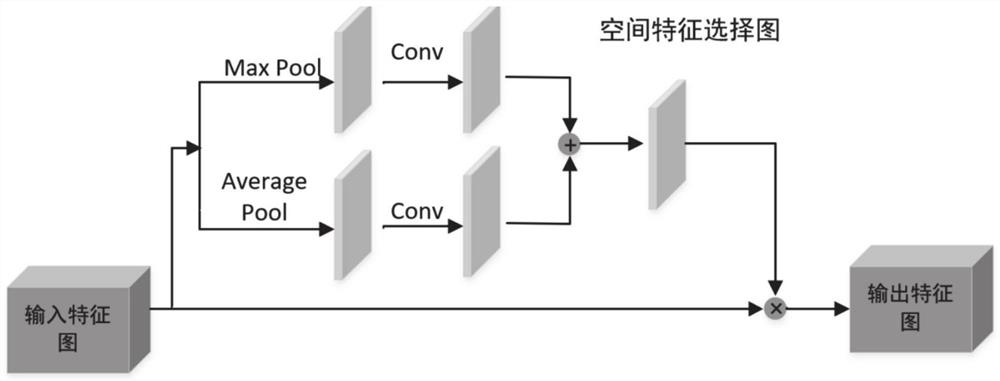

Forestry pest identification method and system based on feature selection module

PendingCN113591794AAccurate and effective identificationImprove the level of intelligent managementCharacter and pattern recognitionNeural architecturesForest industrySoil science

The invention provides a forestry pest identification method and system based on a feature selection module. The method comprises the steps of obtaining a forestry pest image; according to the obtained forestry pest image and a preset forestry pest recognition network model, obtaining a forestry pest classification result, and performing forestry pest recognition; wherein the forestry pest recognition network model is obtained by training a ResNet network embedded with a feature selection module through an expanded forestry pest image training set; obtaining the feature selection module by combining a feature selection unit and residual mapping. According to the invention, a classic ResNet feature extraction network is combined with a designed feature selection module, so that the network can perform feature extraction on purpose, select pest feature information in input data and enhance the pest feature information, the problems of high complexity of a pest picture background and high similarity of part of pests can be effectively solved, and the identification precision is effectively improved.

Owner:QILU UNIV OF TECH

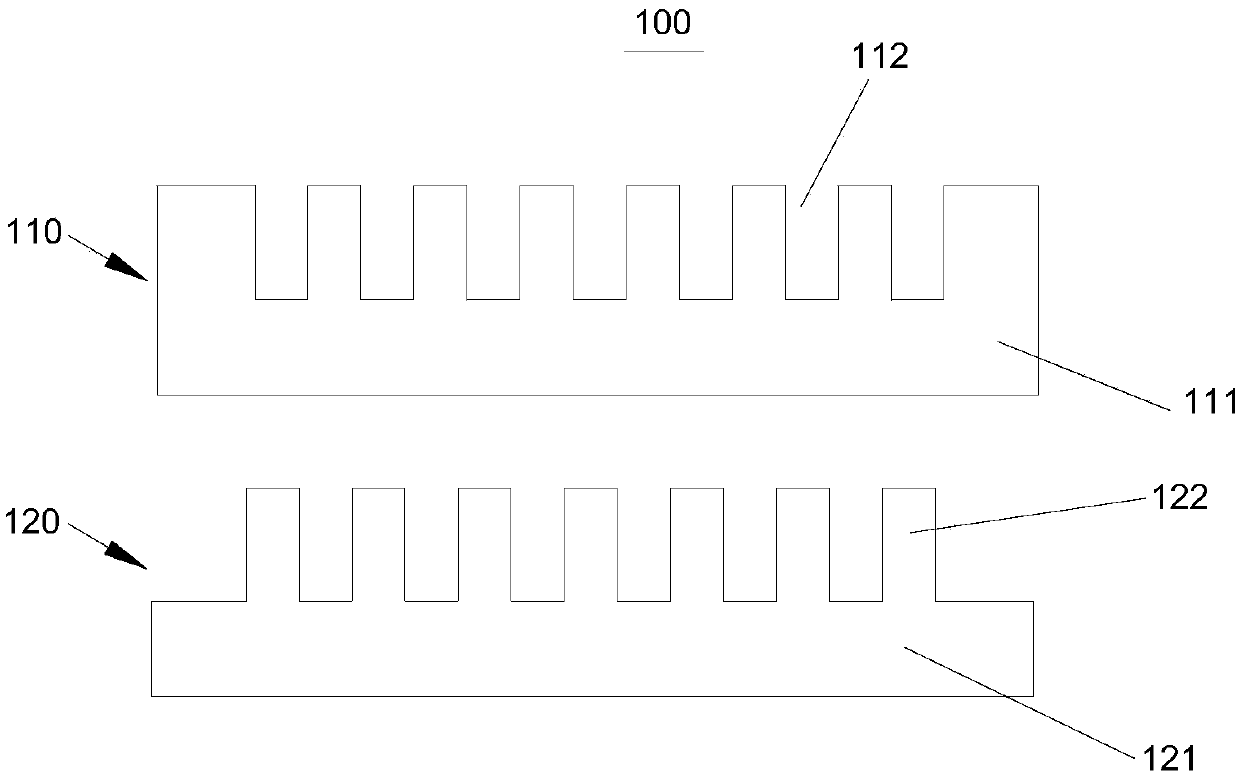

Production mold for micro-fluidic chip and preparation method and application thereof

InactiveCN109550526AAddressing the drop in accuracyAvoid rising costsLaboratory glasswaresMaterials scienceMicro fluidic

The invention provides a production mold for a micro-fluidic chip and a preparation method and an application thereof and belongs to the technical field of biochemical instrument and equipment production. In embodiments, during the preparation of the micro-fluidic chip, the production mold can greatly prolong the service life of a mold in the same shape, so that production cost of a glass micro-fluidic chip is greatly reduced.

Owner:NORTHWEST A & F UNIV

Method, device, satellite carrying equipment and storage medium for rapid target positioning based on ground object coordinate information

ActiveCN108051831BHigh precisionReduce the burden onSatellite radio beaconingEngineeringComputer vision

The invention discloses a fast target positioning method based on ground object coordinate information, which determines the attitude deviation of the satellite according to the position information of the reference point and the orbit information of the satellite; and determines the attitude information of the satellite based on the attitude deviation Perform deviation compensation; determine the position information of the target point according to the compensated attitude information. The invention also discloses a device for quickly locating a target based on ground object coordinate information, a satellite carrying device and a storage medium.

Owner:HARBIN INST OF TECH

Vehicle networking data processing method, server and terminal

ActiveCN104429047BAddressing the drop in accuracyGuaranteed accuracyFinanceRegistering/indicating working of vehiclesThe InternetComputer terminal

The present invention provides a data processing method for the Internet of Vehicles, a server and a terminal, comprising: the server acquires driving history data; trains the driving history data to obtain a program script for analyzing user driving behavior; sends the program script to the terminal . In the technical solution of the present invention, the server first obtains the driving history data, then trains the driving history data to obtain a program script for analyzing the user's driving behavior, and finally sends the program script to the terminal. By dynamically analyzing the user's driving behavior according to the program script and driving data, the problem of algorithm accuracy decline due to untimely algorithm update is solved, the accuracy of the analysis of user driving behavior is ensured, and further, the update terminal firmware is reduced. additional costs.

Owner:HUAWEI DEVICE CO LTD

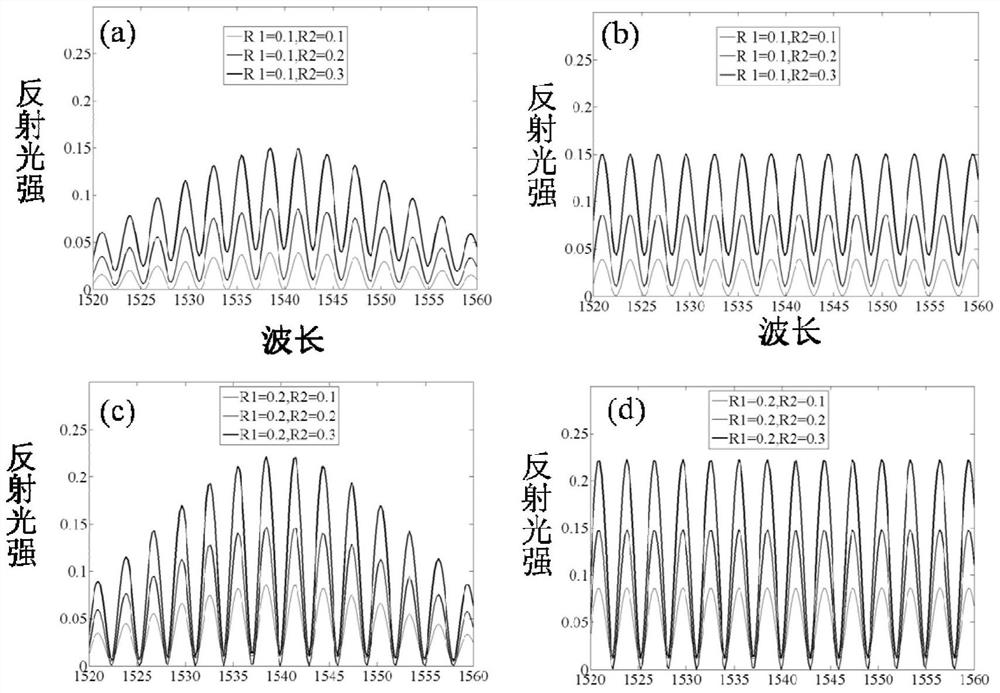

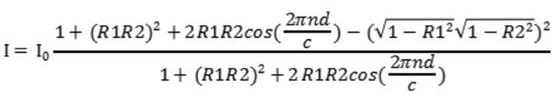

f-p pressure sensor with composite dielectric film

ActiveCN106323516BHigh hardnessImprove thermal stabilityForce measurement by measuring optical property variationFluid pressure measurement by optical meansFiberResonant cavity

Owner:CHENGDU KAITIAN ELECTRONICS

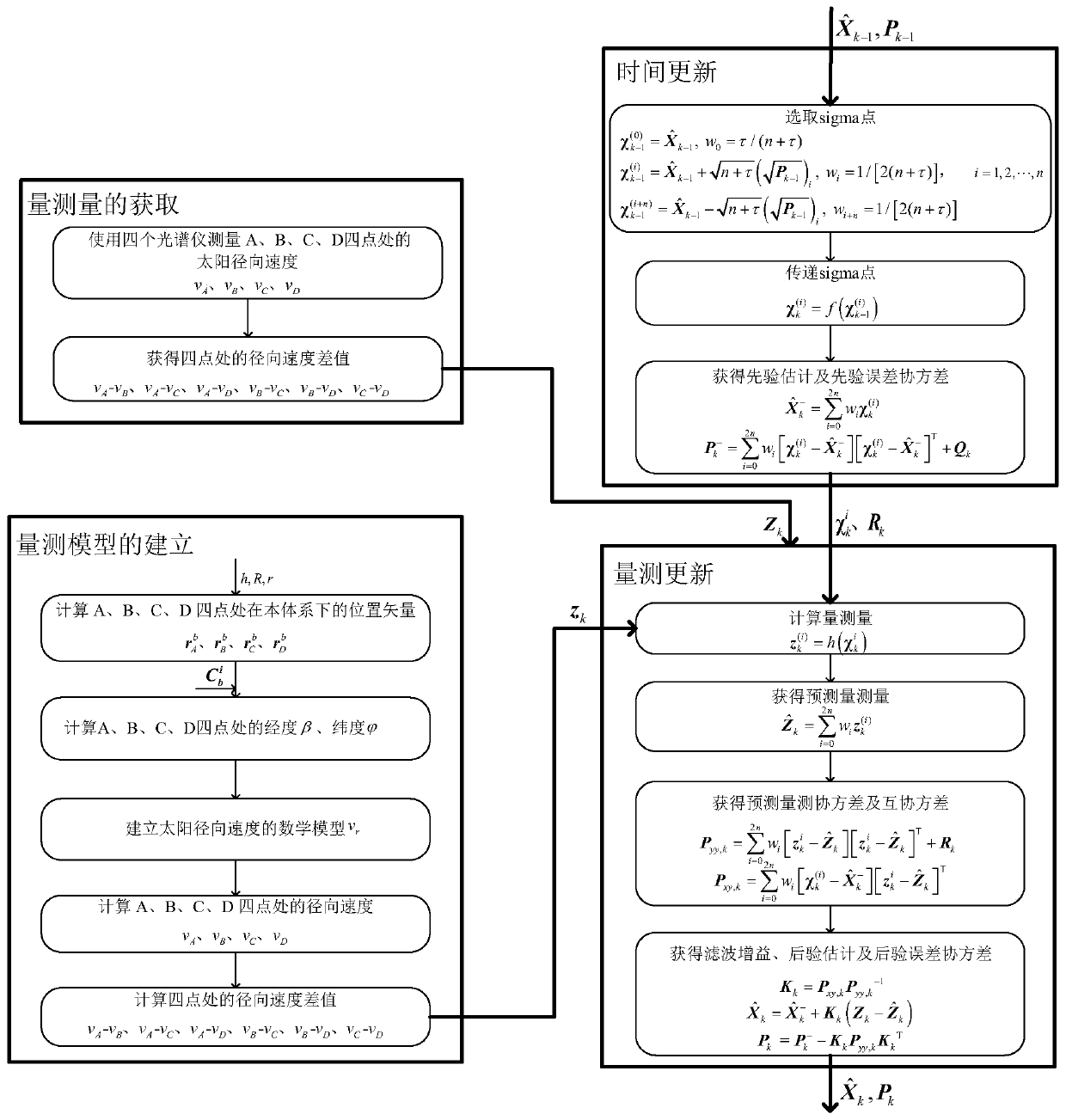

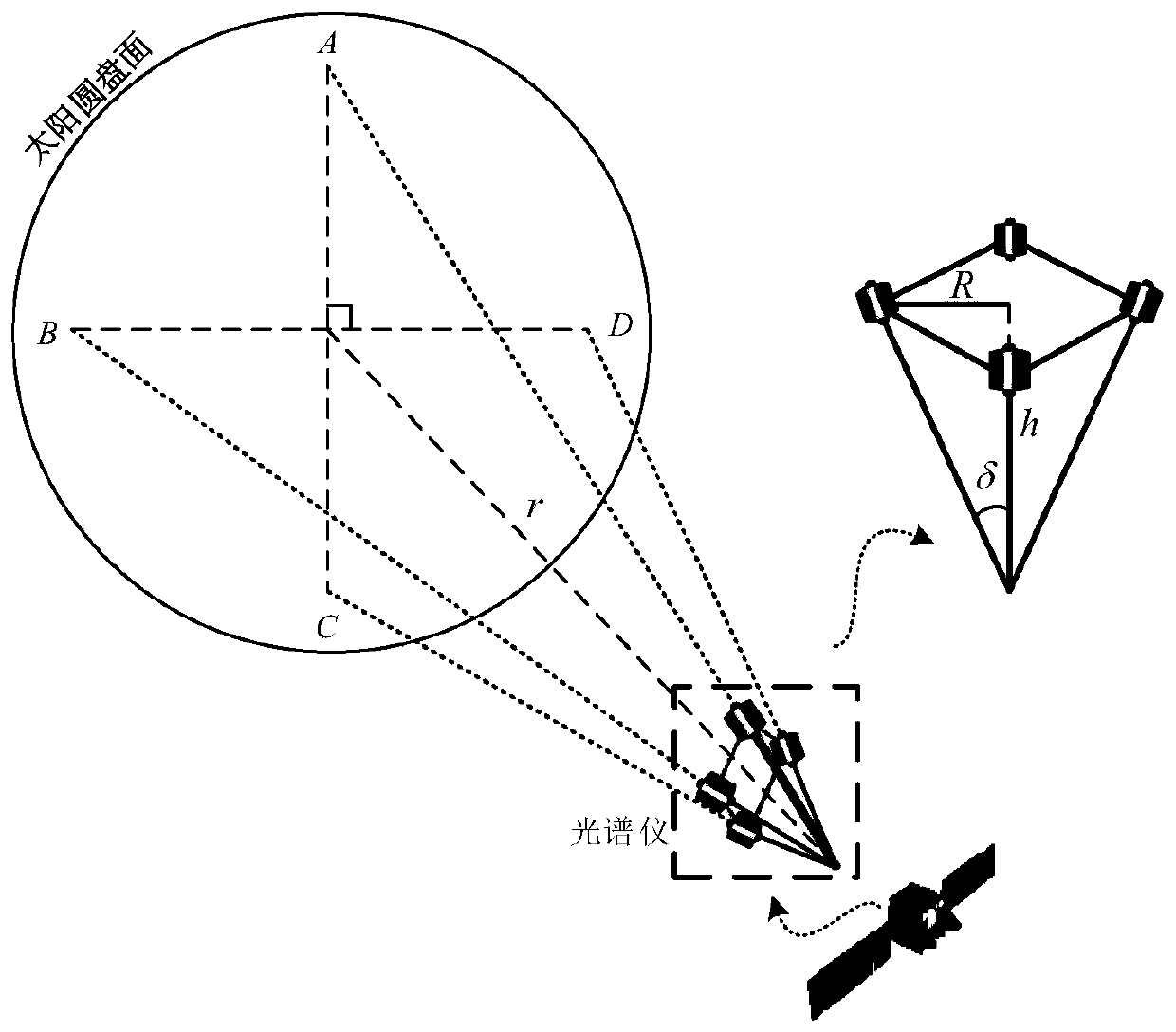

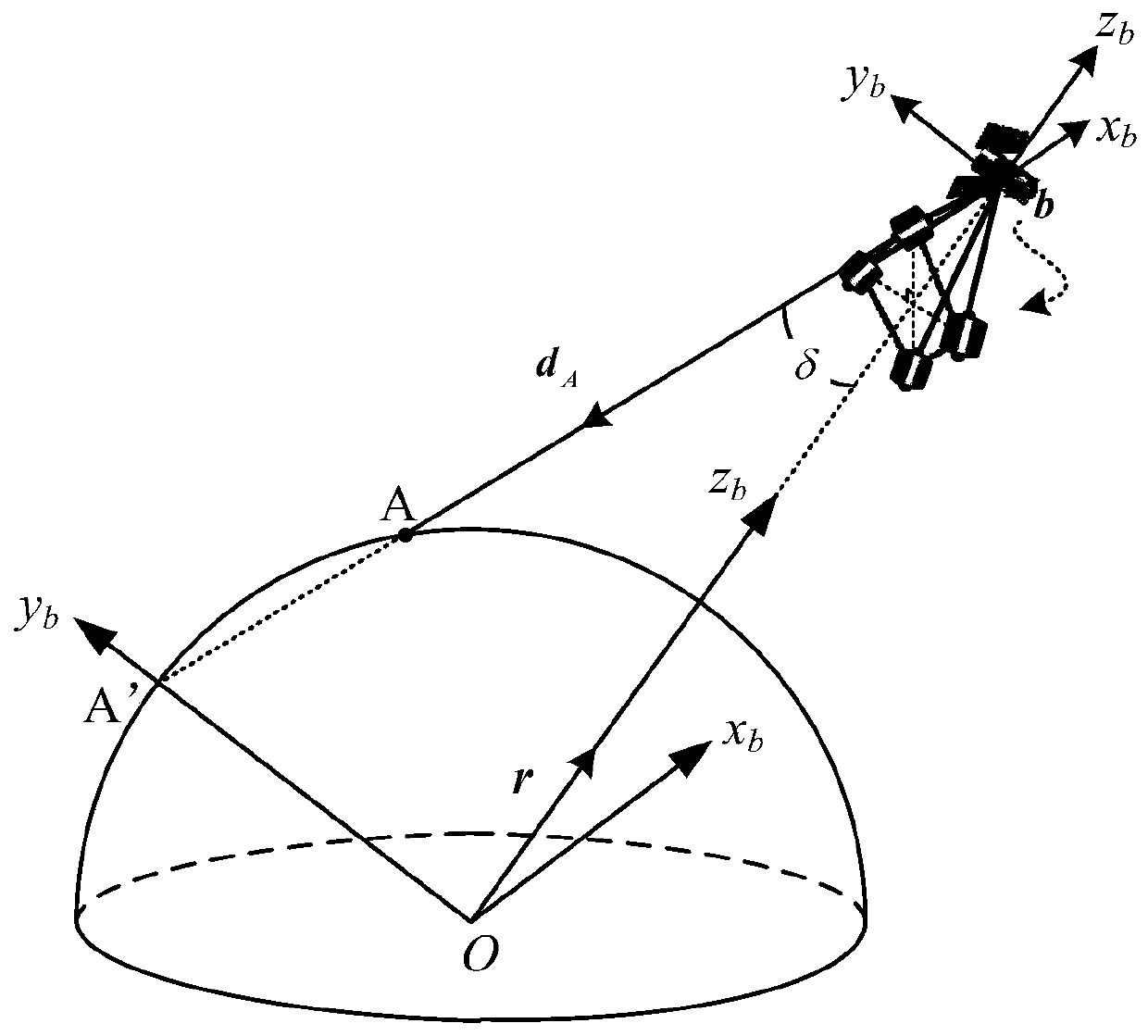

Sun disc surface speed difference-based autonomous celestial navigation method

ActiveCN110617820AEliminate the effects ofImprove navigation accuracyNavigational calculation instrumentsInstruments for comonautical navigationPhysicsKalman filter

Owner:BEIHANG UNIV

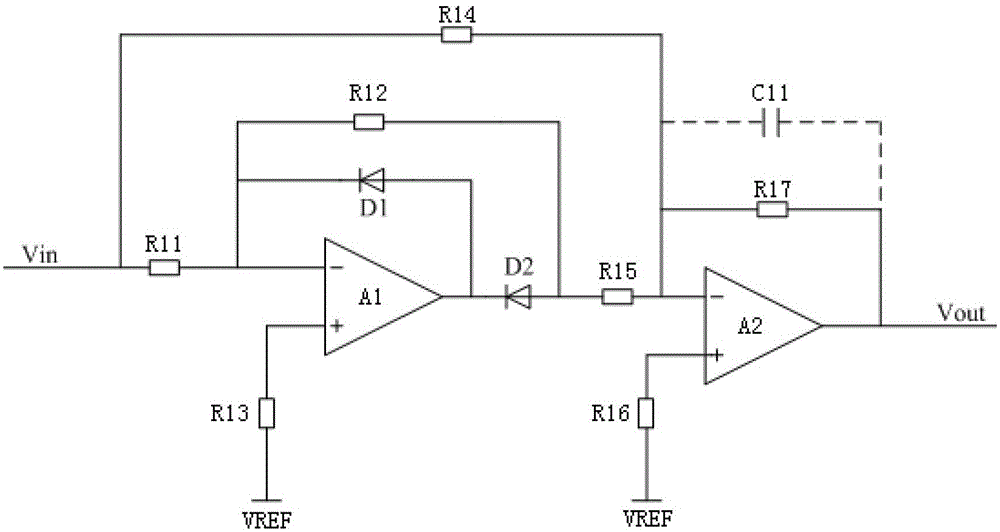

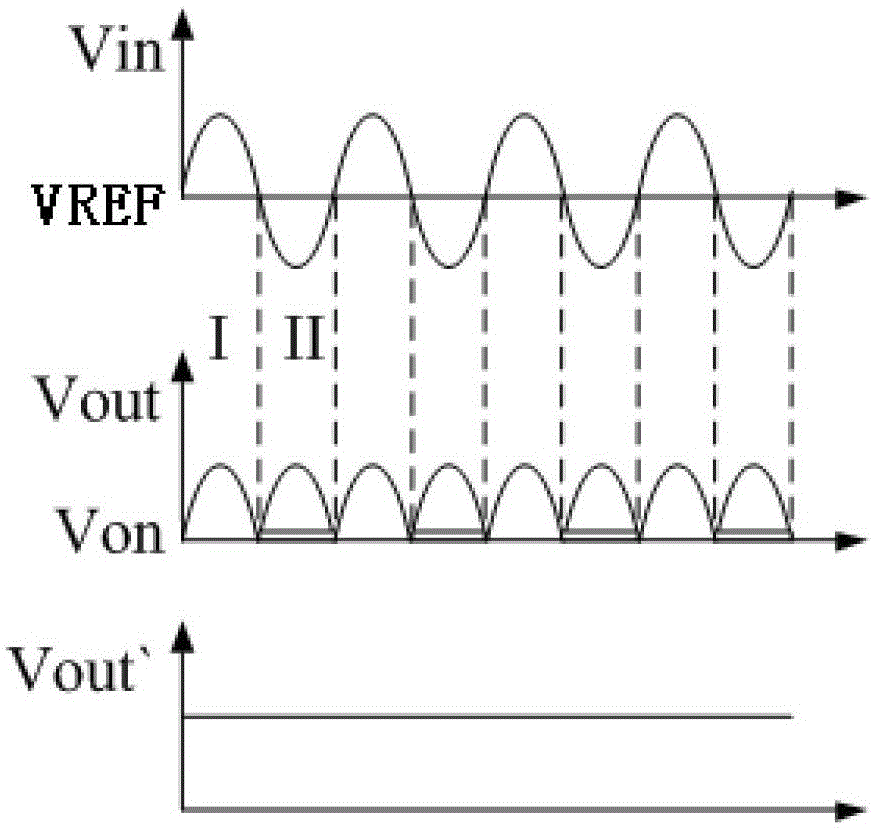

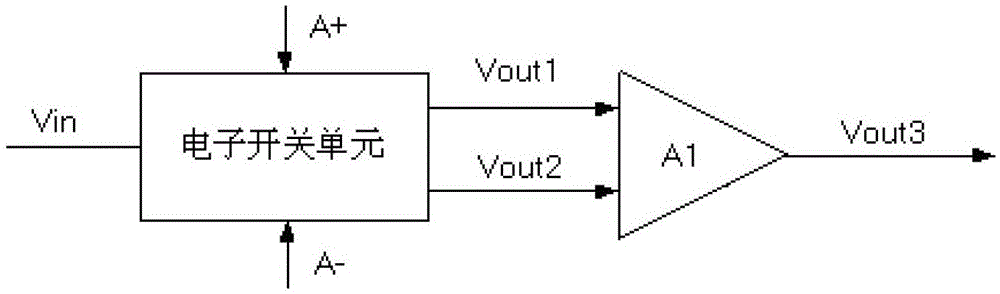

A signal waveform conversion circuit

ActiveCN102857200BAddressing the drop in accuracySolve the problem of long delayMultiple input and output pulse circuitsCapacitanceElectronic switch

The invention provides a signal waveform converting circuit. The signal waveform converting circuit comprises an electronic switch unit and a differential motion output unit, wherein the electronic switch unit converts an input signal into two in-phase output signals, and the signal waveform converting circuit outputs a difference value between two in-phase output signals and converts the input signal into a direct current signal; as the input signal is not required to be converted into a steamed bread wave and then converted into the direct current signal, the problem of precision decrease caused by introducing of a diode when the input signal is converted into the steamed bread wave is solved, and the problem of long delay caused by introducing of a capacitor when the steamed bread wave is converted into a direct wave signal is solved.

Owner:BEIJING JINGWEI HIRAIN TECH CO INC

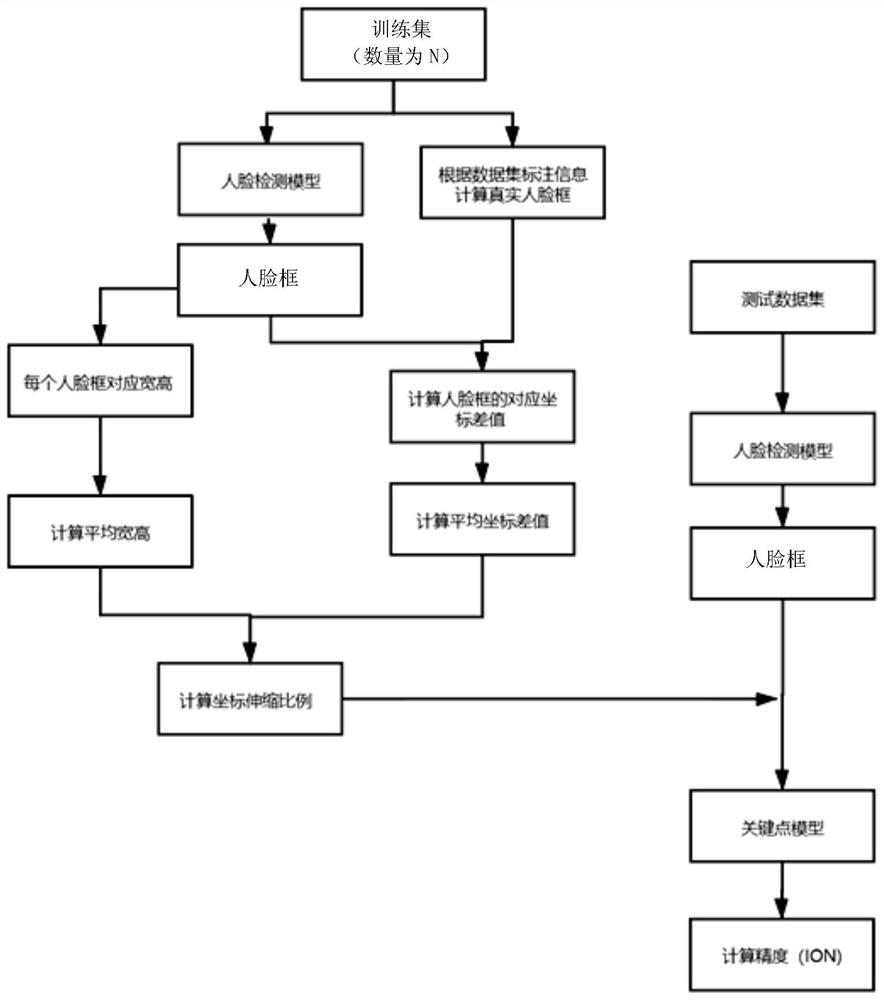

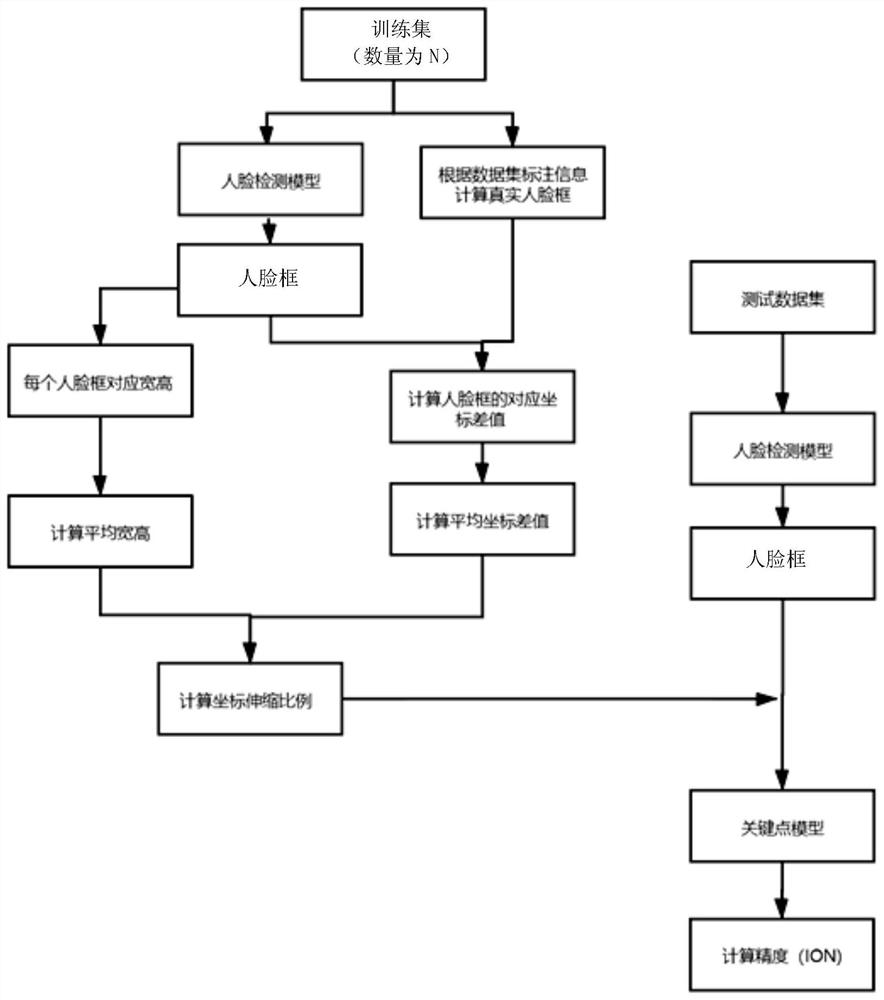

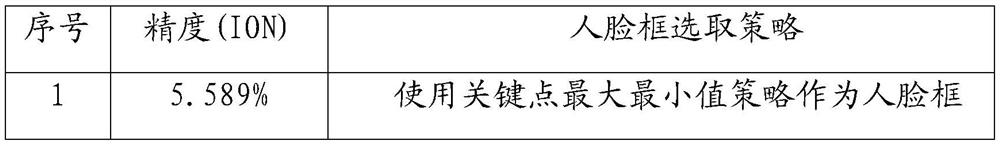

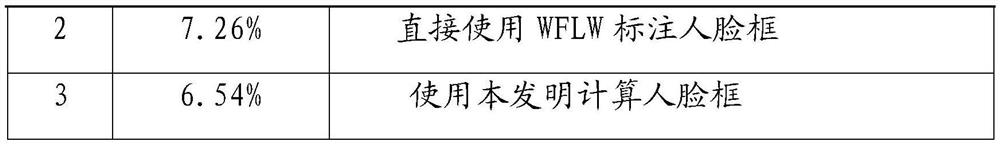

Face box selection method in face key point detection module

ActiveCN112084992ASolve the drop in accuracy of key pointsAddressing the drop in accuracyCharacter and pattern recognitionComputer visionEngineering

The invention relates to the field of face key point detection, and discloses a face box selection method in a face key point detection module, which comprises the steps of obtaining a face detectionmodel and a key point model; obtaining a face box coordinate scaling ratio according to the face box coordinates of N pictures and the real face box coordinates of N pictures obtained by the face detection model; optimizing the face box coordinates of each picture in a test data set output by the trained face detection model by using the face box coordinate scaling ratio to obtain the optimized face box coordinates of each picture in the test data set; and performing coordinate conversion on the optimized face box coordinates to obtain new face box coordinates, cutting out a face box from theoriginal picture according to the new face box coordinates, and inputting the cut-out face box into the trained key point model to obtain key point coordinates. According to the method, the problem ofkey point precision reduction caused by inconsistent face box selection standards in the face detection module and the key point detection module can be effectively solved.

Owner:BEIJING ICHINAE SCI & TECH CO LTD

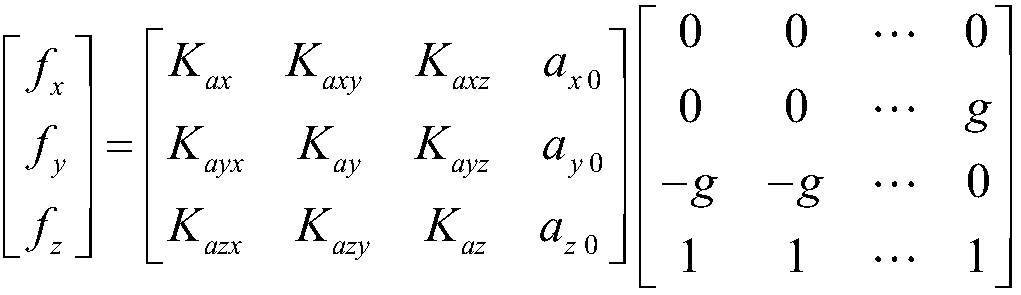

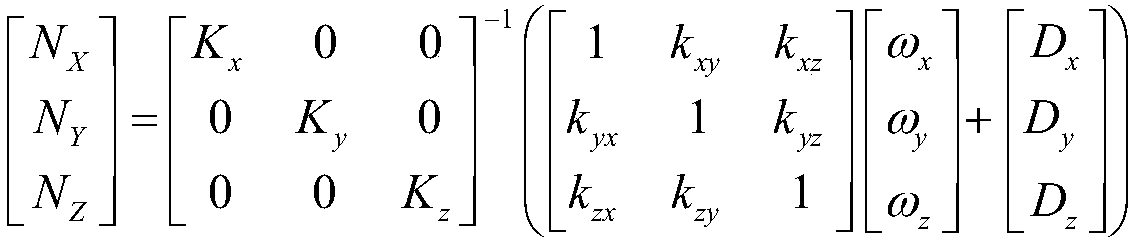

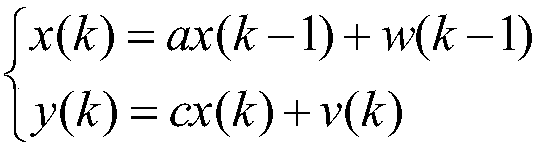

Method for reducing precision of continuous gyroscope clinometer under influence of irregular vibration

The invention discloses a method for reducing the precision of a continuous gyroscope clinometer under the influence of irregular vibration. The method adopts the three-axis acceleration information and combines the z-axis angular velocity information of a fiber-optic gyroscope. Meanwhile, the interference, except the instrument attitude measurement, is removed. Therefore, the measurement precision of the continuous gyroscope clinometer is comprehensively improved. According to the method, the problem that the precision of the continuous gyroscope clinometer is reduced due to the irregular collision of the continuous gyroscope clinometers with an oil sleeve during the downhole upward and downward process can be solved.

Owner:贵州航天凯山石油仪器有限公司

A face frame selection method in face key point detection module

ActiveCN112084992BAddressing the drop in accuracyCharacter and pattern recognitionPattern recognitionFace detection

The invention relates to the field of human face key point detection, and discloses a method for selecting a human face frame in a human face key point detection module, including obtaining a human face detection model and a key point model; Face frame coordinates and the real face frame coordinates of N pictures to obtain the face frame coordinate scaling ratio; use the face frame coordinate scaling ratio to the face frame coordinates of each picture in the test data set output by the trained face detection model Perform optimization to obtain the optimized face frame coordinates of each picture in the test data set; perform coordinate transformation on the optimized face frame coordinates to obtain new face frame coordinates, and cut out from the original image according to the new face frame coordinates Face frame, input the cropped face frame into the trained key point model to obtain key point coordinates. The present invention can effectively solve the problem that the accuracy of key points decreases due to inconsistent selection standards of human face frames in human face detection and key point detection modules.

Owner:BEIJING ICHINAE SCI & TECH CO LTD

System and method for trajectory accuracy compensation of industrial robots based on kinematics analysis

ActiveCN111300406BImprove motion trajectory accuracyImplement fixesProgramme-controlled manipulatorSimulationRobot kinematics

Owner:ZHEJIANG SCI-TECH UNIV

Water body extraction method, device, electronic equipment and storage medium for remote sensing images

ActiveCN111931709BHigh precisionAddressing the drop in accuracyImage enhancementImage analysisEngineeringComputer science

Embodiments of the present application provide a water body extraction method, device, electronic device, and storage medium for remote sensing images, which relate to the technical field of remote sensing images. The method includes acquiring a remote sensing image to be tested, and preprocessing the remote sensing image to be tested; and preliminarily extracting the water body region of the preprocessed remote sensing image to be tested based on a water body index, a brightness index and a shadow index, to obtain Spot image; use the pre-established water body discrimination model to identify the spot image to distinguish the water body spot and the non-water body spot; according to the discrimination result, obtain the water body extraction result, and use the brightness index and the shadow index to remove the interference, so as to The accuracy of the water body extraction result is improved, and the problem that the accuracy of the existing method is reduced due to interference is solved.

Owner:BEIJING AEROSPACE HONGTU INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com