f-p pressure sensor with composite dielectric film

A technology of pressure sensor and composite dielectric film, which is applied in the measurement of fluid pressure using optical methods, and the measurement of force by measuring the change of optical properties of materials when they are stressed, and can solve the problems of thermal stability and reflectivity accuracy decline. , to solve the effect of reducing precision, high hardness and high mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

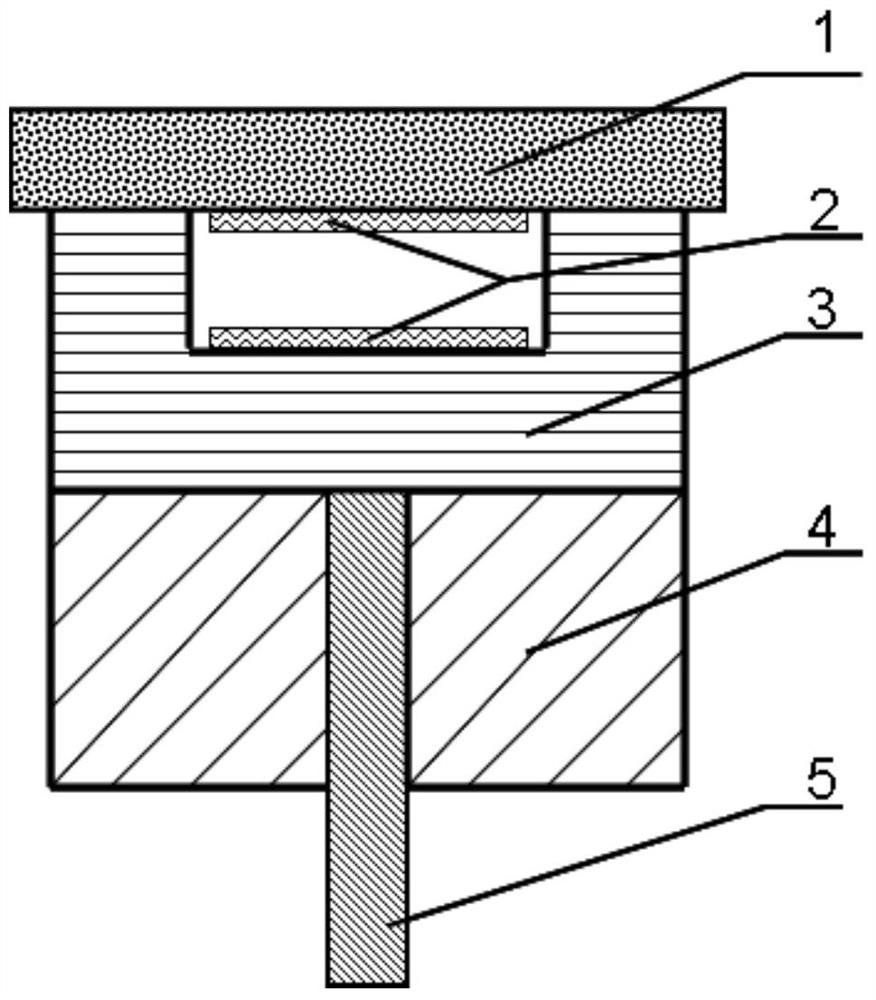

[0019] exist figure 1 In the shown embodiment, the F-P pressure sensor with composite dielectric film is composed of pressure diaphragm 1, composite dielectric film 2, upper ferrule 3, lower ferrule 4 and optical fiber 5, wherein, upper ferrule 3 and lower ferrule The cores are interconnected as a whole, a part of the optical fiber 5 is inserted into the lower ferrule 4, and the other part is located outside the lower ferrule, and is used as a conductive optical fiber to connect with the demodulation equipment. A composite dielectric film (2) grows on the back of the pressure diaphragm 1, and a composite dielectric film 2 grows on the bottom surface of the groove with an upper ferrule (3). The pressure diaphragm 1 is connected with the upper ferrule 3 to form an F-P resonant cavity. The upper ferrule 3 and the lower ferrule 4 are interconnected to form a whole. At least one layer of composite dielectric film grown on the back of the pressure diaphragm and the bottom of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com