Production mold for micro-fluidic chip and preparation method and application thereof

A microfluidic chip and preparation process technology, applied in laboratory utensils, laboratory containers, chemical instruments and methods, etc., can solve the problems of difficult mold processing, low precision, and rising costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The application of the above-mentioned preparation mold of the microfluidic chip in the preparation of the microfluidic chip.

[0036] A preparation process for a microfluidic chip, comprising the following steps:

[0037] A conformal mold with the same size as the microfluidic channel of the microfluidic chip is prepared;

[0038] Molding the heated and softened intermediate mold preform with the same-shaped mold to prepare the intermediate mold;

[0039] Plating a composite coating on the surface of the intermediate mold to obtain a coated intermediate mold;

[0040] The microfluidic chip is prepared by molding the heated and softened chip preform by using the coating intermediate mold.

[0041] By preparing a conformal mold with the same shape and size as the microfluidic chip, and then preparing an intermediate mold with the conformal mold, and coating the intermediate mold with a composite coating. The microfluidic chip is prepared through the intermediate mold,...

Embodiment 2

[0059] This embodiment provides a preparation process for preparing a microfluidic chip using the preparation mold 100 of the embodiment, including the following steps:

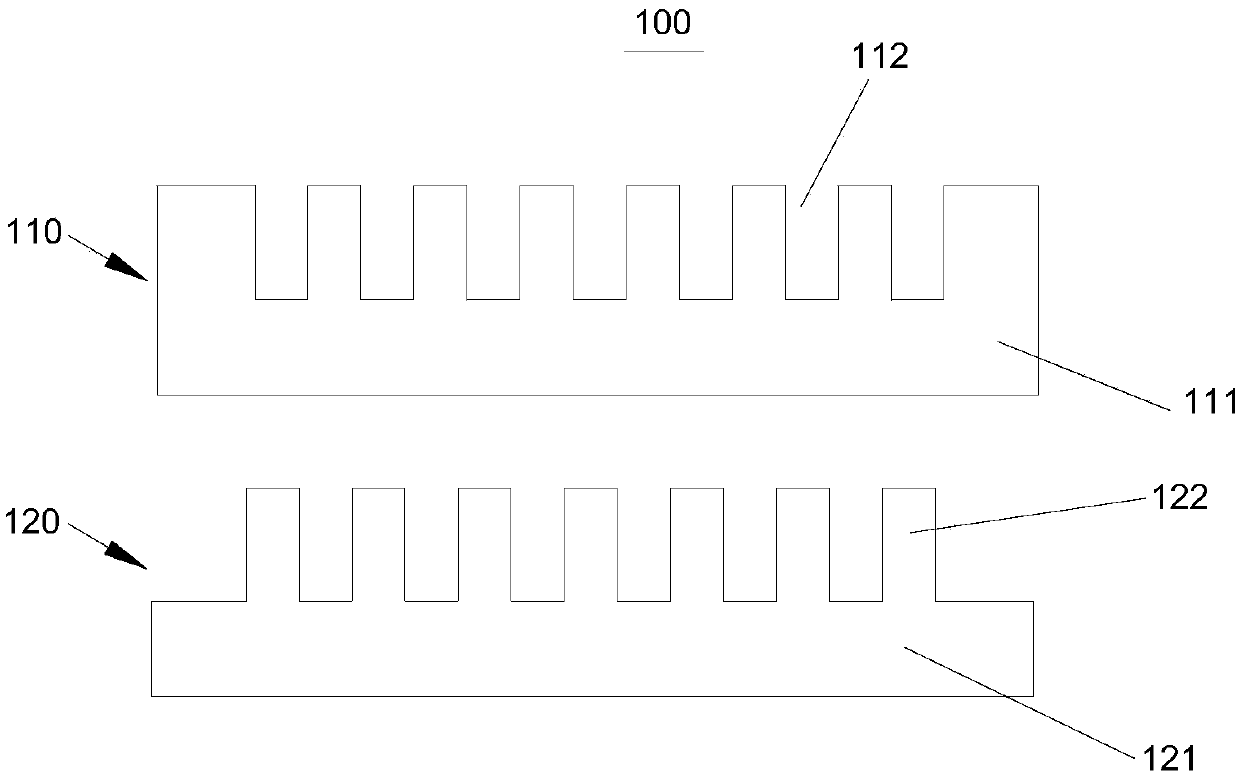

[0060] 1.1 Prepare tungsten carbide as a raw material into a mold 110 of the same shape as the size of the microfluidic chip, especially the microfluidic channel of the microfluidic chip;

[0061] 1.2 Select the intermediate mold raw material to be heated and softened, and after obtaining the softened raw material, use the same-shaped mold 110 to reverse the mold, and prepare the softened raw material into an intermediate mold 120;

[0062] 1.3 Coating an inert metal rhenium coating on the surface of the intermediate mold 120 to obtain a coated intermediate mold 120;

[0063] 1.4 Select glass raw material as the raw material of the microfluidic chip, heat and soften it, and then mold it to obtain the microfluidic chip.

[0064] Wherein, the strain point temperature of the coating intermediate mold 120 is hig...

Embodiment 3

[0066] This embodiment provides a preparation process for preparing a microfluidic chip using the preparation mold 100 of the embodiment, including the following steps:

[0067] 1.1 Using nickel phosphide as a raw material to prepare a conformal mold 110 that is consistent with the size of the microfluidic chip, especially the microfluidic channel of the microfluidic chip;

[0068] 1.2 Select the intermediate mold raw material to be heated and softened, and after obtaining the softened raw material, use the same-shaped mold 110 to reverse the mold, and prepare the softened raw material into an intermediate mold 120;

[0069] 1.3 Coating an inert metal rhenium coating on the surface of the intermediate mold 120 to obtain a coated intermediate mold 120;

[0070] 1.4 Select the resin raw material as the raw material of the microfluidic chip, heat and soften it, and then mold it to obtain the microfluidic chip.

[0071] Wherein, the strain point temperature of the coating interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com