System and method for compensation of track precision of industrial robot based on kinematics analysis

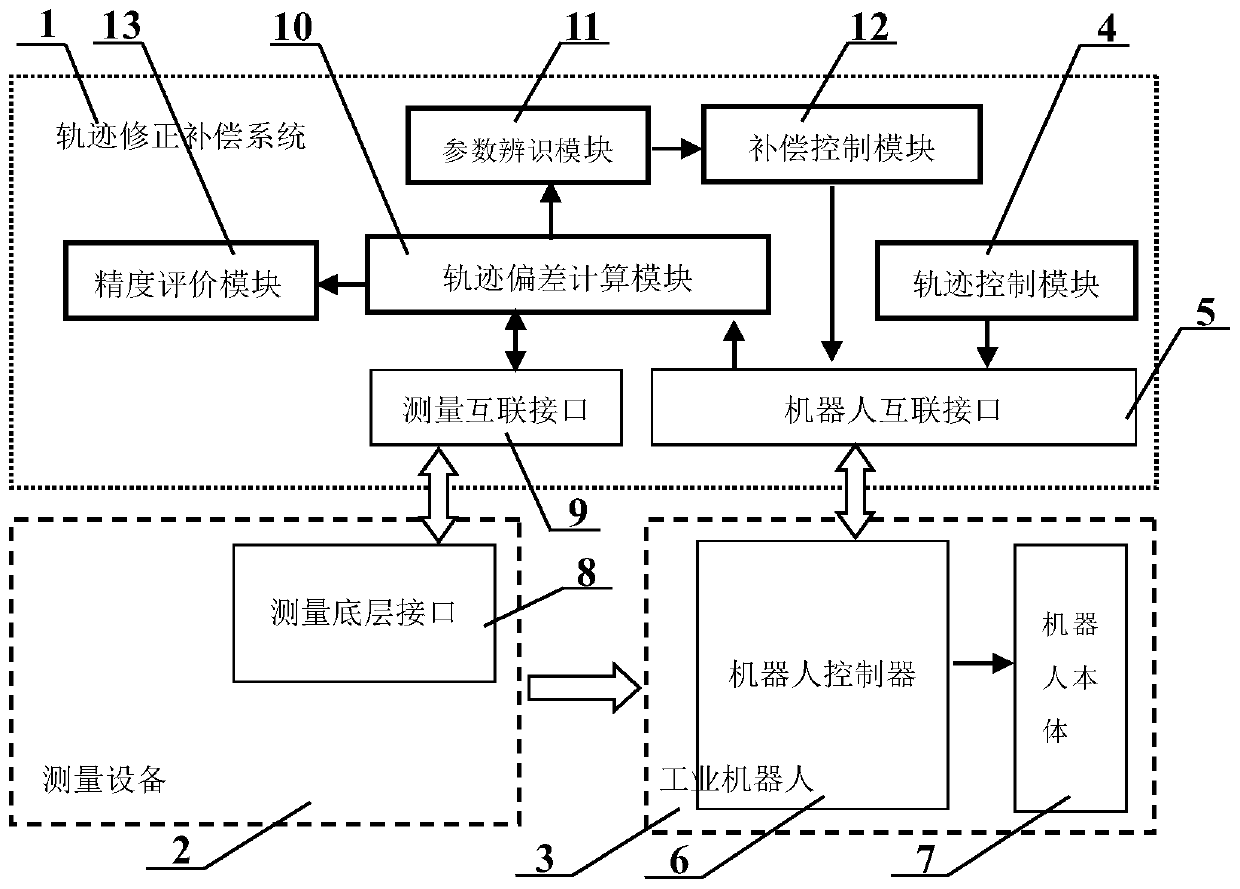

An industrial robot and kinematics analysis technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as few systems and methods, difficulty in meeting the demand for high motion trajectory accuracy, etc., to achieve improved accuracy, fast and effective trajectory deviation Correction of compensation solutions and technical references, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0049] The embodiment implemented according to the complete method of the content of the present invention is as follows:

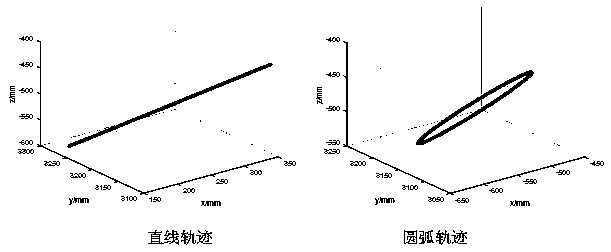

[0050] In this embodiment, the measurement device 2 is a laser tracker, specifically the RADIAN-API tracker of Precision Engineering Company, which uses laser interferometry to measure track data. Its linear measurement range is 40m, and its angular resolution is 0.018as. The resolution is 1μm, and the maximum tracking speed is 6m / s. The industrial robot 6 used in the trajectory correction and compensation experiment is the SR4C six-degree-of-freedom robot of Hangzhou Xinsong, with a load of 4kg and a repeat positioning accuracy of ±0.03mm. The robot has a robot controller 6 with an open interface, and the controller uses It is designed and implemented based on open-source RT-Linux, and the trajectory data from the trajectory co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com