Gearbox simulation test bench

A test bench, gearbox technology, used in vehicle testing, machine/structural component testing, machine gear/transmission testing, etc., to solve problems such as lack of accuracy, performance sensitivity, and dynamic range limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

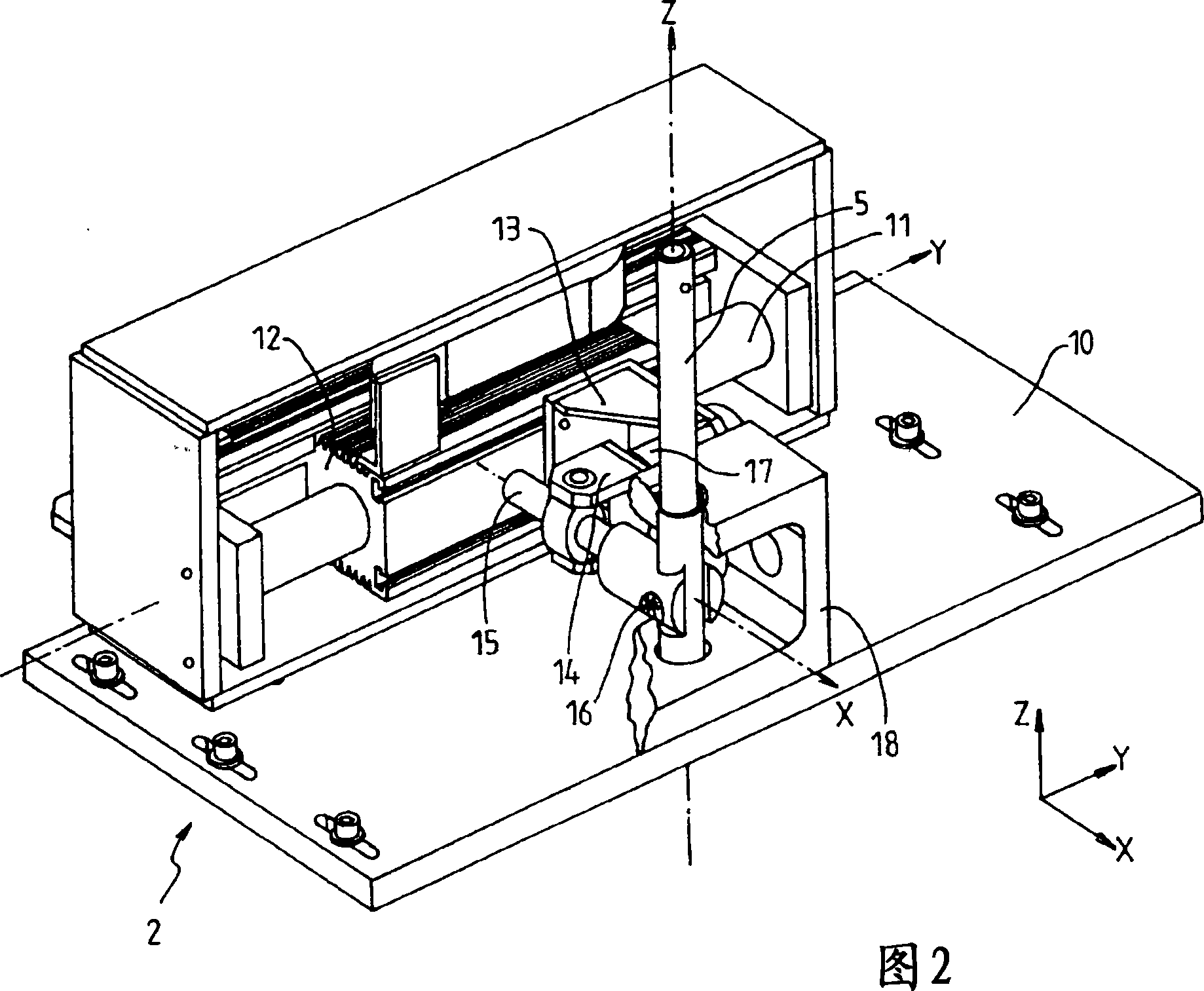

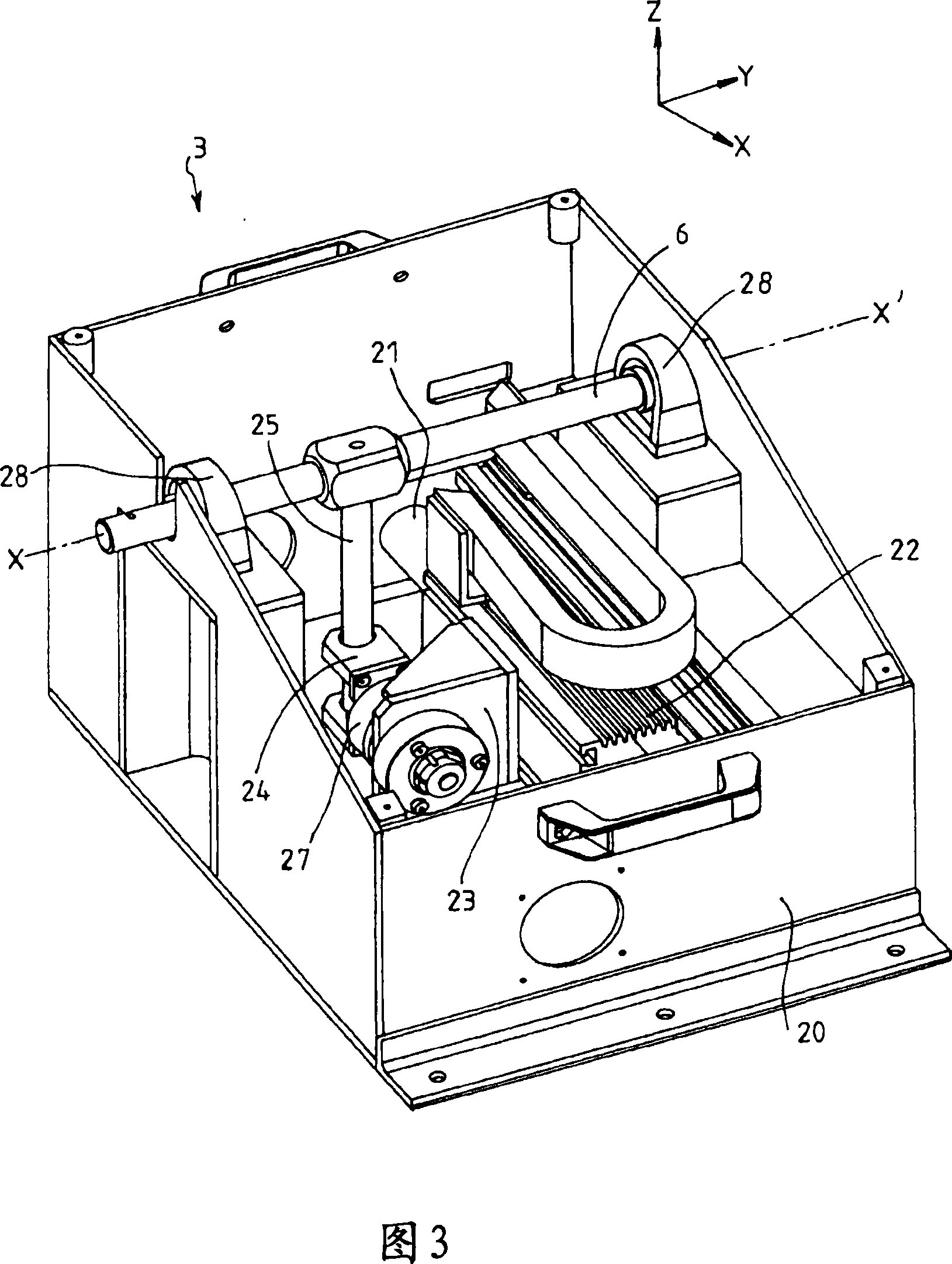

[0020] [20] The test bench that the present invention proposes to manufacture is a test bench that simulates a gearbox. More specifically, the test bench needs to reproduce aspects of performance corresponding to different types of gearboxes. This test bench is used in particular for the external control of gearboxes.

[0021] [21] The transmissions commonly used are in the form of automatic or manual transmissions.

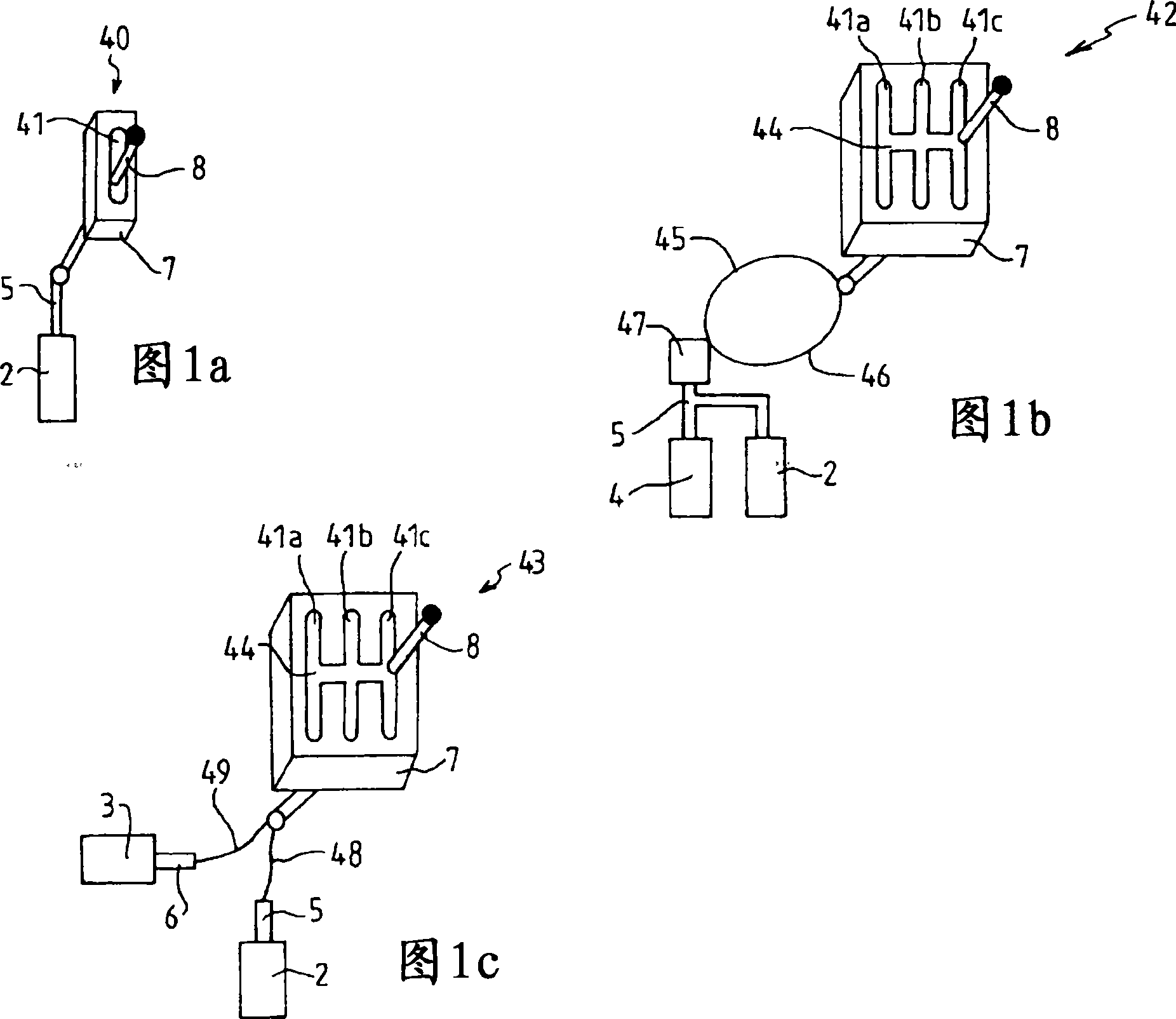

[0022] [22] Figure 1a shows the first type of gearbox simulated by the present invention. Such a transmission is an automatic transmission type 40. The mechanically controlled automatic transmission 40 is generally actuated by an external control device 7 comprising a joystick 8 movable along a longitudinal section 41 . The joystick 8 thus allows selection of P, R, N or D modes, and allows manual change of gear (M+ or M-). In this case, only the shift file module is used. For this type of gearbox, it is only necessary to simulate the shift pattern correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com