Car frame front tube shaping device

A technology of frame front tube and shaping device, which is applied in the directions of feeding device, positioning device, storage device, etc., can solve the problems of low sensitivity of oil cylinder, error, and poor calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

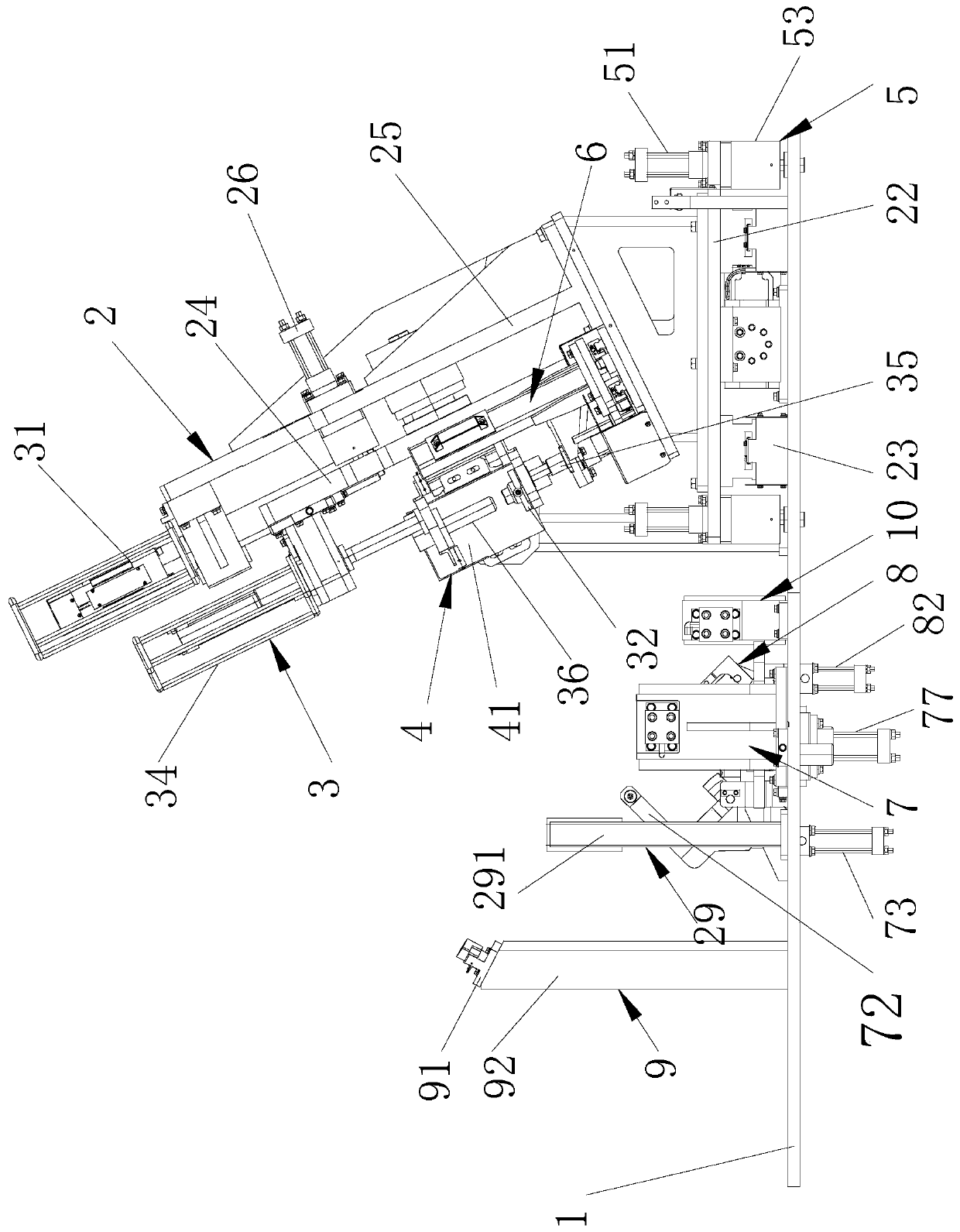

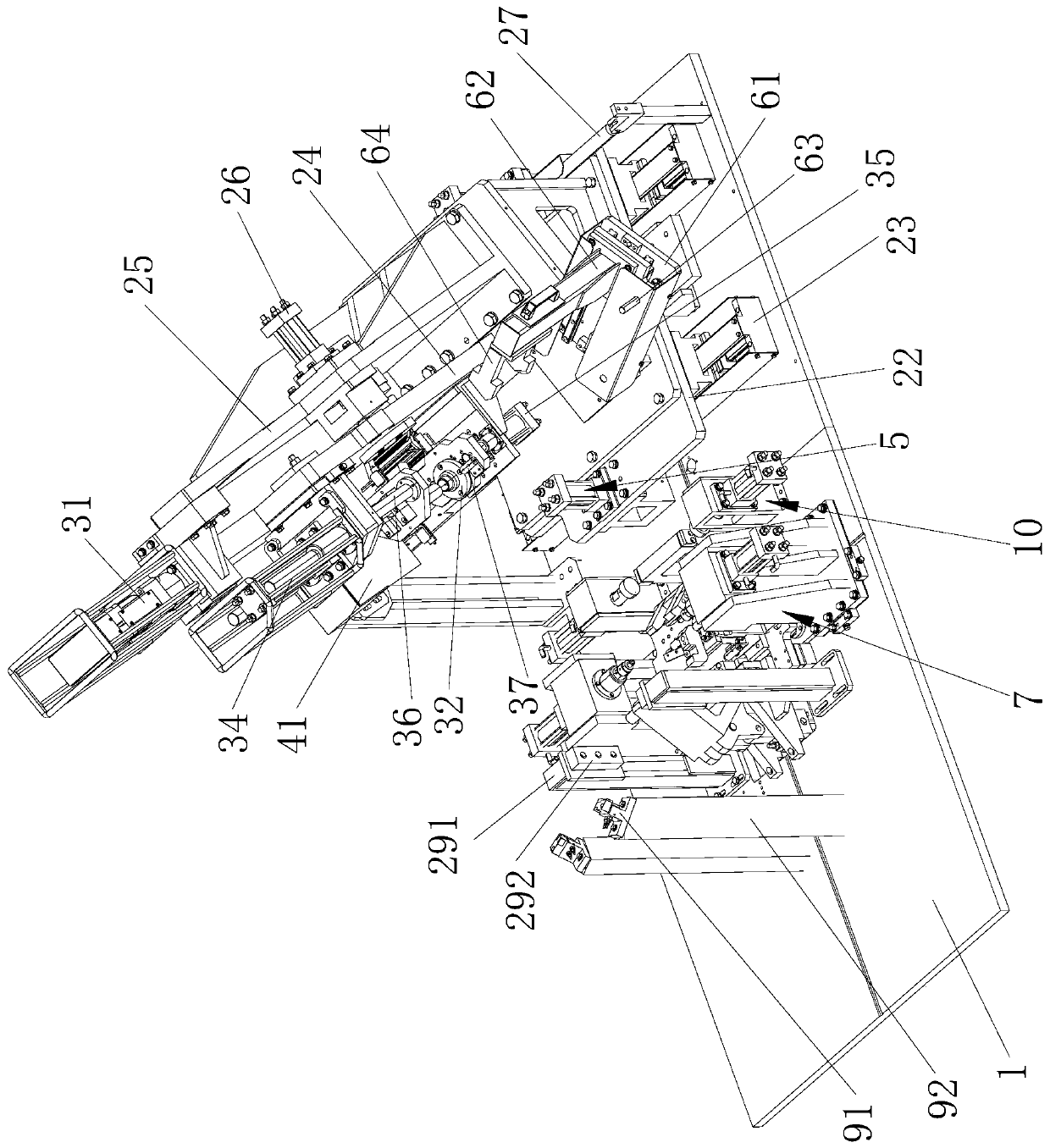

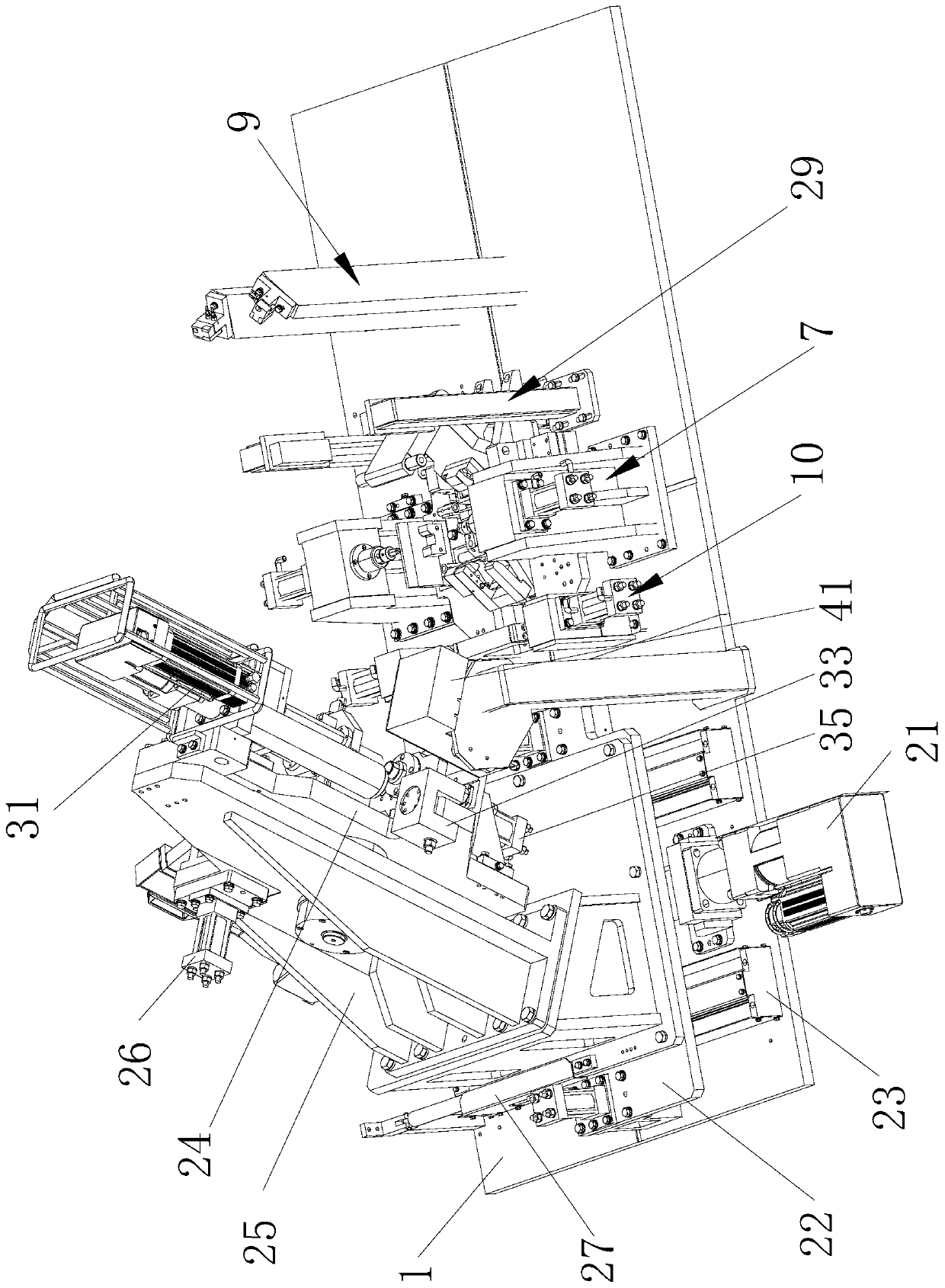

[0037] Such as figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, a frame front tube shaping device, including a base 1, and a frame positioning assembly and a frame front assembly located on the base 1 Tube shaping assembly, the frame positioning assembly is located on one side of the frame front tube shaping assembly, the frame front tube shaping assembly includes the overall deviation correction mechanism 2, the front tube twist correction mechanism 3 and the front tube Calibration detection mechanism 4,

[0038] The overall deflection correction mechanism 2 includes a first servo electric cylinder 21, a front pipe shaping pallet 22, a guide rail 23, a torsion plate 24, a torsion base 25 and a torsion plate locking cylinder 26, the guide rail 23 and the torsion plate The partial bases 25 are all arranged on the base 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com