Cold rolled thin steel strip for battery shell and production method thereof

A production method and battery shell technology, applied in the field of cold-rolled thin steel strips for battery shells and its production, can solve problems such as high carbon content and reduced deep drawing performance, and achieve the effect of improving formability and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The mass percentage of continuous casting slab obtained by RH refining and casting includes: C0.0065%; Mn0.31%; Si0.01%; P0.012%; S0.0035%; Als0.035%; .033%; the balance is Fe and unavoidable impurities. The continuous casting slab is heated to 1180°C in a walking heating furnace, the holding time is 165min, the final rolling temperature is 880°C, the front cooling is adopted, and the coiling temperature is 685°C to obtain a 2.5mm thick hot-rolled steel coil; hot-rolled coil Pickling after uncoiling, continuous rolling by 5-stand rolling mill to obtain 0.5mm thick rolled hard steel coil, the cold rolling reduction is 80%, after the hard rolled steel coil is uncoiled, the steel plate enters the continuous annealing furnace after surface cleaning, The soaking temperature for annealing is 790°C, the soaking time is 120s, and the leveling elongation in leveling and tension leveling is 1.1%.

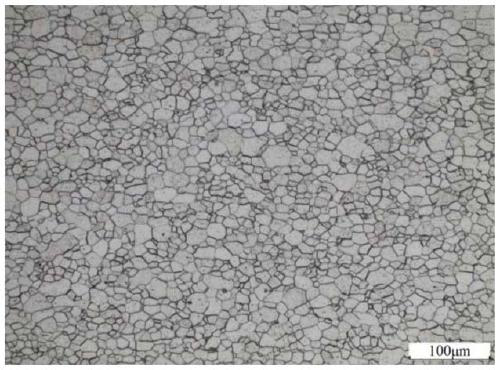

[0026] Such as figure 1 The photo of the typical metallographic microstructure o...

Embodiment 2

[0028] The mass percentage of continuous casting slab obtained by RH refining and casting includes: C0.0073%; Mn0.35%; Si0.01%; P0.010%; S0.0033%; Als0.033%; .036%; the balance is Fe and unavoidable impurities. The continuous casting slab is heated to 1250°C in a walking heating furnace, the holding time is 170min, the final rolling temperature is 890°C, the front cooling is adopted, and the coiling temperature is 695°C to obtain a 2.5mm thick hot-rolled steel coil; hot-rolled coil Pickling after uncoiling, continuous rolling by 5-stand rolling mill to obtain 0.5mm thick rolled hard steel coil, the cold rolling reduction is 80%, after the hard rolled steel coil is uncoiled, the steel plate enters the continuous annealing furnace after surface cleaning, The soaking temperature for annealing is 780°C, the soaking time is 120s, and the leveling elongation rate in leveling and tension leveling is 1.15%.

[0029] Through performance testing, the mechanical properties of the produc...

Embodiment 3

[0031] The mass percentage of continuous casting slab obtained by RH refining and casting includes: C0.0080%; Mn0.38%; Si0.01%; P0.010%; S0.0033%; Als0.038%; .040%; the balance is Fe and unavoidable impurities. The continuous casting slab is heated to 1180°C in a walking heating furnace, the holding time is 165min, the final rolling temperature is 878°C, the front cooling is adopted, and the coiling temperature is 685°C to obtain a 2.5mm thick hot-rolled steel coil; hot-rolled coil Pickling after uncoiling, continuous rolling by 5-stand rolling mill to obtain 0.5mm thick rolled hard steel coil, the cold rolling reduction is 80%, after the hard rolled steel coil is uncoiled, the steel plate enters the continuous annealing furnace after surface cleaning, The soaking temperature for annealing is 785°C, the soaking time is 120s, and the leveling elongation in leveling and tension leveling is 1.18%.

[0032] Through the performance test, the mechanical properties of the product in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com