Preparation method of apple enzyme functional beverage

An apple and enzyme technology, applied in the direction of bacteria used in food preparation, functions of food ingredients, food ingredients, etc., can solve the problem of low functional ingredients of enzymes, and achieve the effects of easy absorption, free radical scavenging, and mellow taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

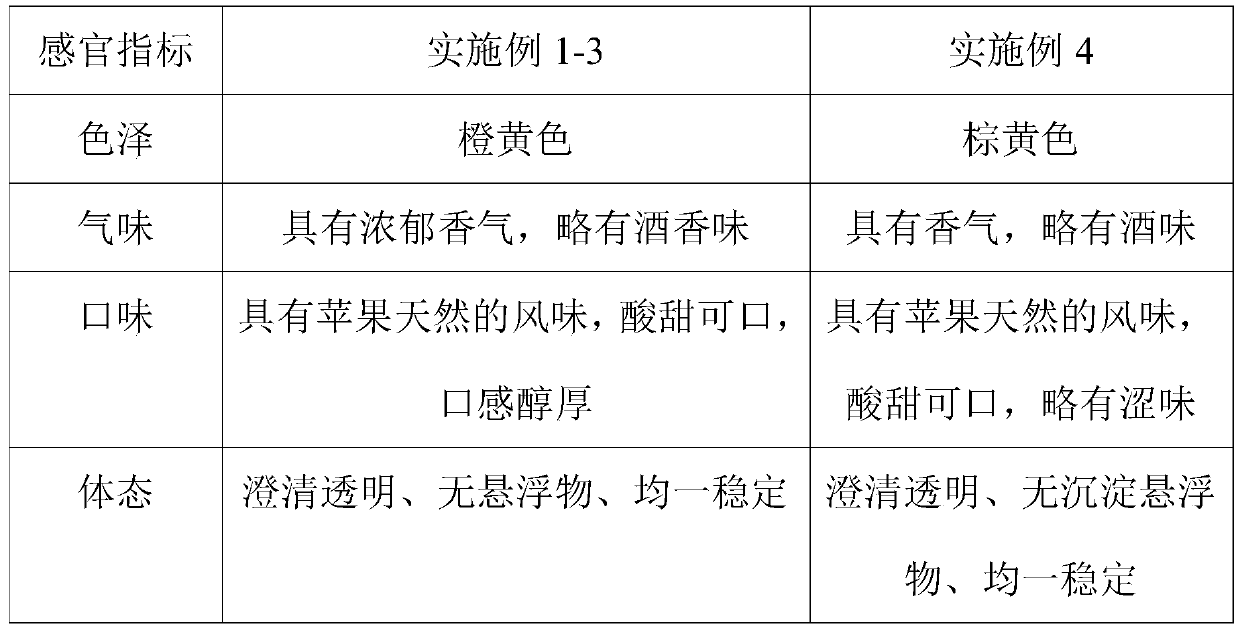

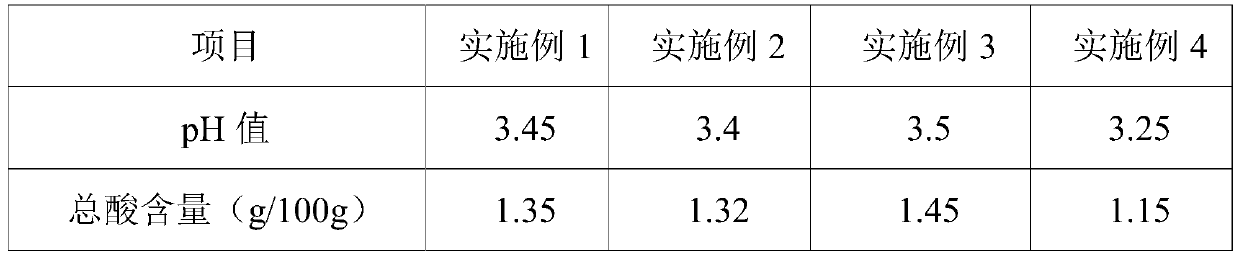

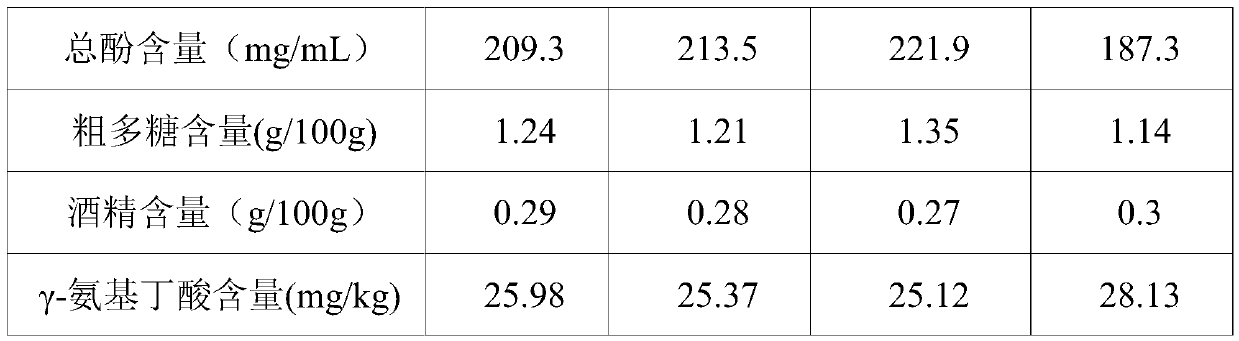

Examples

Embodiment 1

[0022] Prepare the apple enzyme functional drink according to the following steps:

[0023] S1: Prepare raw materials, including: apples, white sugar, purified water, and fermentation agents;

[0024] S2: remove the peel and core of the apple described in S1 with a high-temperature sterilized knife;

[0025] S3: Cut the apples into pieces, beat them, and put them into a sterilized fermentation glass tank; the ratio of material to water when the apples are beaten is 9:1.

[0026] S4: Add pectinase and cellulase for enzymolysis, add white sugar, mix thoroughly and then sterilize; The temperature is 30°C, and the enzymatic hydrolysis time is 75 minutes. Add white granulated sugar, adjust the sugar content of pulp to be 18°Brx.

[0027] S5: First inoculate Saccharomyces cerevisiae with an inoculation amount of 0.1%, ferment for 5 days, and sterilize; then inoculate Acetobacter pasteurian with an inoculum amount of 1.2%, ferment for 3 days, and sterilize; finally inoculate Lacto...

Embodiment 2

[0030] Prepare the apple enzyme functional drink according to the following steps:

[0031] S1: Prepare raw materials, including: apples, white sugar, purified water, and fermentation agents;

[0032] S2: remove the peel and core of the apple described in S1 with a high-temperature sterilized knife;

[0033] S3: Cut the apples into pieces, beat them, and put them into a sterilized fermentation glass tank; the ratio of material to water when the apples are beaten is 9:1.

[0034] S4: Add pectinase and cellulase for enzymolysis, add white sugar, mix thoroughly and then sterilize; The temperature is 30°C, and the enzymatic hydrolysis time is 75 minutes. Add white granulated sugar, adjust the sugar content of pulp to be 18°Brx.

[0035] S5: First inoculate Saccharomyces cerevisiae with an inoculation amount of 0.2%, ferment for 5 days, and then sterilize; then inoculate Acetobacter pasteurian with an inoculum amount of 1.8%, ferment for 3 days, and sterilize; finally inoculate ...

Embodiment 3

[0038] Prepare the apple enzyme functional drink according to the following steps:

[0039] S1: Prepare raw materials, including: apples, white sugar, purified water, and fermentation agents;

[0040] S2: remove the peel and core of the apple described in S1 with a high-temperature sterilized knife;

[0041] S3: Cut the apples into pieces, beat them, and put them into a sterilized fermentation glass tank; the ratio of material to water when the apples are beaten is 9:1.

[0042] S4: Add pectinase and cellulase for enzymolysis, add white sugar, mix well and then sterilize; The temperature is 30°C, and the enzymatic hydrolysis time is 75 minutes. Add white granulated sugar, adjust the sugar content of pulp to be 18°Brx.

[0043] S5: First inoculate Saccharomyces cerevisiae with an inoculation amount of 0.15%, ferment for 5 days, and sterilize; then inoculate Acetobacter pasteurian with an inoculum amount of 1.5%, ferment for 3 days, and sterilize; finally inoculate Lactobacil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com