Double hollow glass lighting window with an organic glass fiber reinforced plastic frame

A double-layer insulating glass and plexiglass technology, applied in the field of lighting windows, can solve the problems of easy aging, short service life, large thermal expansion and cold contraction deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

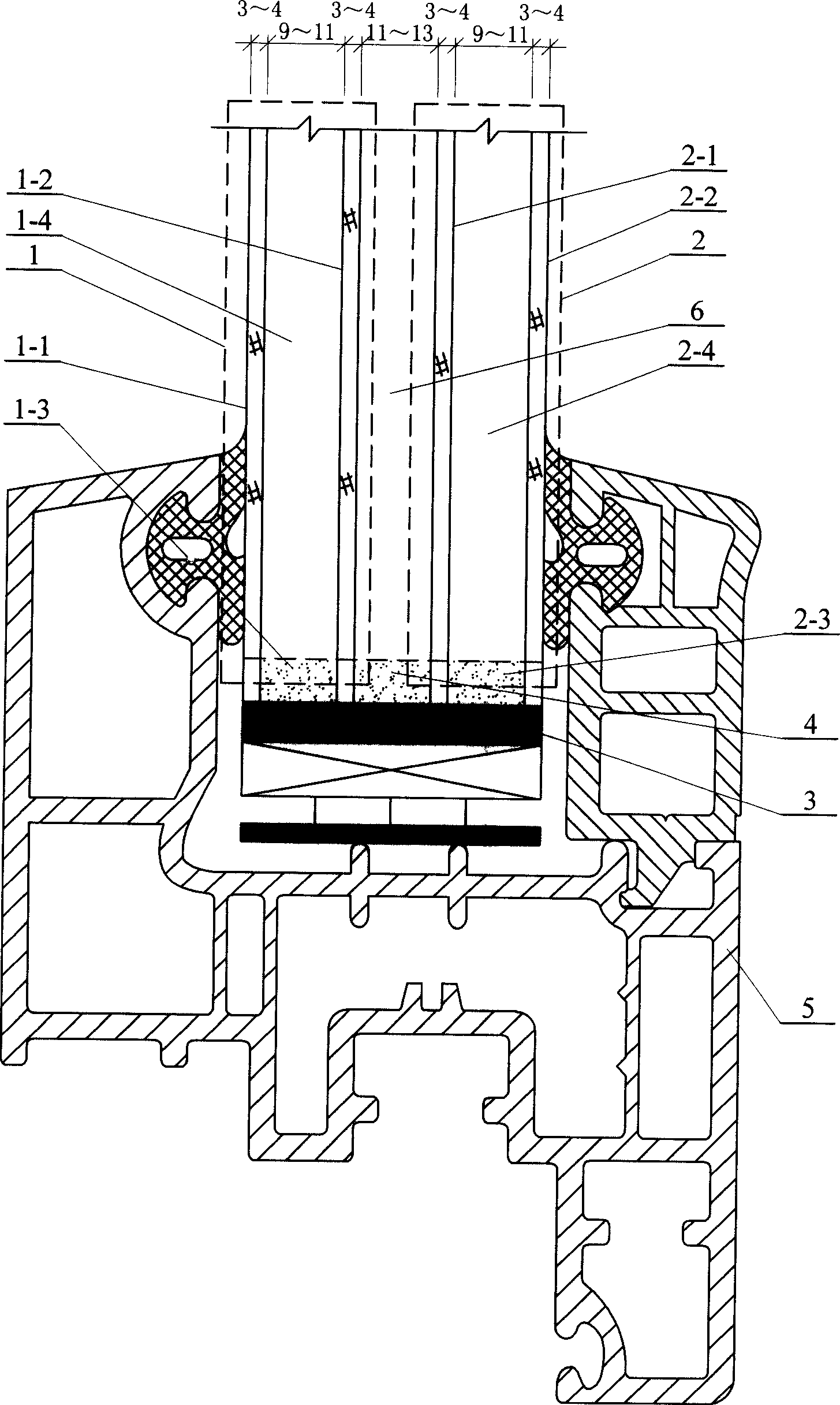

[0005] Specific implementation mode one: (see figure 1 ) This embodiment is composed of the first hollow glass layer 1, the second hollow glass layer 2, the sealing ring 3, the intermediate molecular sieve 4 and the plexiglass steel window frame 5, the first hollow glass layer 1 and the second hollow glass layer 2 are front and rear Relatively, the sides are fixed in the organic glass steel window frame 5 parallel to each other, a sealing ring 3 is fixed between the first hollow glass layer 1 and the second hollow glass layer 2 and the organic glass steel window frame 5, the first hollow glass layer 1 and the second hollow glass layer An intermediate molecular sieve 4 is fixed at the bottom between the two insulating glass layers 2 , and an intermediate cavity 6 is formed between the first insulating glass layer 1 , the second insulating glass layer 2 and the intermediate molecular sieve 4 . The distance between the first hollow glass layer 1 and the second hollow glass layer ...

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 1 ) The first insulating glass layer 1 of this embodiment is made up of the first glass 1-1, the second glass 1-2 and the first molecular sieve 1-3, and the front and back of the first glass 1-1 and the second glass 1-2 Opposite, the sides are arranged parallel to each other, the bottom between the first glass 1-1 and the second glass 1-2 is fixed with the first molecular sieve 1-3 which is both moisture-absorbing and airtight, and the first glass 1-1 and the second glass 1-1 A first cavity 1-4 is formed between the glass 1-2 and the first molecular sieve 1-3. The thicknesses of the first glass 1-1 and the second glass 1-2 of the first hollow glass layer 1 are respectively 3-4 mm, and the distance between the first glass 1-1 and the second glass 1-2 is 9-11 mm. The first cavity 1-4 between the first glass 1-1, the second glass 1-2 and the first molecular sieve 1-3 is filled with an inert gas. The inert gas is argon or heli...

specific Embodiment approach 3

[0007] Specific implementation mode three: (see figure 1 ) The second hollow glass layer 2 of this embodiment is made up of the third glass 2-1, the fourth glass 2-2 and the second molecular sieve 2-3, and the third glass 2-1 and the fourth glass 2-2 have a lighting front and back Opposite, the sides are arranged parallel to each other, and the bottom between the third glass 2-1 and the fourth glass 2-2 is fixed with a second molecular sieve 2-3 that absorbs moisture and seals, and the third glass 2-1 and the fourth glass 2-1 A second cavity 2-4 is formed between the glass 2-2 and the second molecular sieve 2-3. The thicknesses of the third glass 2-1 and the fourth glass 2-2 of the second hollow glass layer 2 are respectively 3-4 mm, and the distance between the third glass 2-1 and the fourth glass 2-2 is 9-11 mm. The second cavity 2-4 between the third glass 2-1, the fourth glass 2-2 and the second molecular sieve 2-3 is filled with an inert gas. The inert gas is argon or h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com