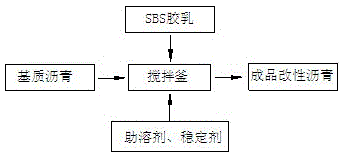

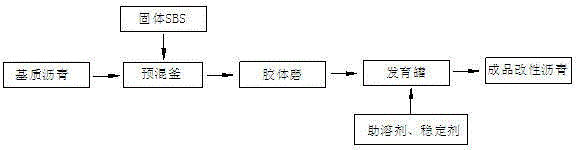

Production process of SBS modified asphalt

A modified asphalt and production process technology, applied in building components, building insulation materials, construction and other directions, can solve the problems of consuming more energy, affecting performance, prolonging production time, etc., achieving simple equipment technology, long production cycle, The effect of high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The base asphalt adopts Zhonghai 70#, which reaches the I-D index. Heat 100 parts of Zhonghai 70# to 130°C, slowly add 6 parts of SBS latex under stirring, wait until the bubbles disappear, indicating that the water has evaporated, heat up to 165°C, and then add 1 part of rubber oil and 0.2 parts of stabilizer (Sulfur or sulfide) stirring and developing for 1 hour to obtain SBS modified asphalt. The indicators of the obtained modified asphalt are: softening point 62°C, penetration 53dmm, ductility 23cm at 5°C.

Embodiment 2

[0026] The base asphalt adopts Qilu 70#, which reaches the I-D index. Heat 100 parts of Qilu 70# to 140°C, slowly add 8 parts of SBS latex under stirring, wait until the bubbles disappear, indicating that the water has evaporated, heat up to 170°C, and then add 2 parts of rubber oil and 0.2 parts of stabilizer (Sulphur) stirring and developing for 1 hour to obtain SBS modified asphalt. The indicators of the obtained modified asphalt are: softening point 66°C, penetration 55dmm, ductility 27cm at 5°C.

Embodiment 3

[0028] The base asphalt adopts Zhonghai 90#, which reaches the I-C index. Heat 100 parts of Zhonghai 90# to 140°C, slowly add 8 parts of SBS latex under stirring, wait until the bubbles disappear, indicating that the water has evaporated, heat up to 165°C, and then add 1 part of furfural oil and 0.2 parts of stabilizer (sulfide) stirring and developing for 1 hour to obtain SBS modified asphalt. The indicators of the obtained modified asphalt are: softening point 63°C, penetration 65dmm, ductility 35cm at 5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com