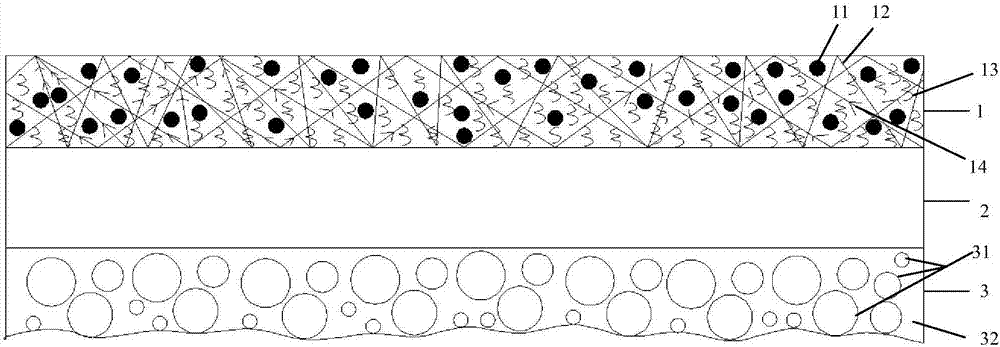

Perovskite quantum dot membrane, quantum dot diffusion composite membrane and preparation method of quantum dot diffusion composite membrane

A quantum dot film, diffusion composite technology, applied in chemical instruments and methods, luminescent coatings, polycarbonate coatings, etc., can solve problems such as poor adhesion, and achieve the effect of improving adhesion and firm chemical bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the quantum dot diffusion composite film of the present invention comprises the following steps:

[0039](1) The polymer is dissolved in an organic solvent, and the mass ratio is controlled to be: polymer: organic solvent=1:5~1:50. After the polymer is completely dissolved, a uniform and viscous polymer solution is obtained. Add additive in the polymer solution, control mass ratio is: polymer: additive=1:0~1:0.5, add adhesion promoter after mixing, control mass ratio is: polymer: adhesion promoter=1: 0.01~1:0.15, mix well, and the obtained solution is used as the first solution.

[0040] The polymer described in this step is polyvinylidene fluoride (PVDF), polyvinyl acetate (PVAc), cellulose acetate (CA), polysulfone (PSF), aromatic polyamide (PA), polyimide (PI ), polycarbonate (PC), polystyrene (PS); said additive is a kind of in polyvinylpyrrolidone (PVP), polyethylene glycol (PEG), and the effect of additive is to regulate polymer The vis...

Embodiment 1

[0047] (1) The polymer is dissolved in an organic solvent, and the mass ratio is controlled to be: polymer: organic solvent=1:5. After the polymer is completely dissolved, a uniform and viscous polymer solution is obtained. In the above-mentioned prepared polymer solution Add additives in the mixture, the control mass ratio is: polymer: additive=1:0, add adhesion promoter after mixing uniformly, control mass ratio is: polymer: adhesion promoter=1:0.08, mix uniformly, the solution obtained As the first solution; the polymer is polyvinyl acetate (PVAc); the organic solvent is N,N-dimethylformamide (DMF); the adhesion promoter is carboxyl-containing resin adhesion Accelerator (Teco LTW).

[0048] (2) the organic amine halide CH 3 NH 3 Br and inorganic halide PbBr 2 Dissolve in the organic solvent according to the stoichiometric ratio of 1:1, the control mass ratio is: organic solvent: inorganic halide=1:0.01, mix well, and the solution obtained is used as the second solution; ...

Embodiment 2

[0053] (1) The polymer is dissolved in an organic solvent, and the mass ratio is controlled to be: polymer: organic solvent=1:10. After the polymer is completely dissolved, a uniform and viscous polymer solution is obtained. In the polymer solution prepared above Add additives in the mixture, control mass ratio is: polymer: additive=1:0.1, add adhesion promoter after mixing uniformly, control mass ratio is: polymer: adhesion promoter=1:0.1, mix uniformly, the solution obtained As the first solution; the polymer is cellulose acetate (CA); the organic solvent is dimethylsulfoxide (DMSO); the additive is polyvinylpyrrolidone (PVP); the adhesion promoter is containing Carboxyl-based resin adhesion promoter (Teco LTW).

[0054] (2) the organic amine halide CH 3 NH 3 Cl, CH 3 NH 3 Br and inorganic halide PbBr 2 According to the stoichiometric ratio of 0.5:0.5:1 dissolved in the organic solvent, the control mass ratio is: organic solvent: inorganic halide = 1:0.02, mixed uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Shine | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com