Method for preparing super hydrophobic polymeric coating using non-crystalline polymer

A polymer coating, non-crystalline technology, applied in coatings, devices for coating liquid on the surface, polycarbonate coatings, etc., can solve problems that are difficult to have practical value and harsh conditions, and achieve excellent anti-coagulation The effect of blood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

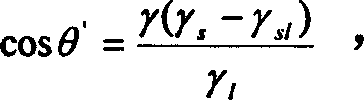

Method used

Image

Examples

Embodiment 1

[0016] Set the molecular weight to 1×10 5 ~1×10 8 Amorphous polystyrene mixed with N,N-dimethylformamide (DMF) at a concentration of 1×10 -3 ~1×10g / ml, coated on the surface of the glass plate, and the solvent is naturally evaporated at 10-40 degrees Celsius to form a film. The obtained polymer coating has a contact angle with water of 155-165 degrees.

Embodiment 2

[0018] Set the molecular weight to 1×10 5 ~1×10 6 Polycarbonate, mixed with N,N-dimethylformamide (DMF) solvent, the concentration is 1×10 -3 ~1×10g / ml, coated on the surface of the glass plate, and the solvent is naturally evaporated at 10-40 degrees Celsius to form a film. The obtained polymer coating has a contact angle with water of 160-170 degrees.

Embodiment 3

[0020] Set the molecular weight to 1×10 5 ~1×10 6 Styrene-methyl methacrylate diblock, multi-block copolymer or random copolymer, mixed with N,N-dimethylformamide (DMF) solvent respectively, the concentration is 1×10 -3 ~1×10g / ml, coated on the solid surface, and the solvent is naturally evaporated at 10-40 degrees Celsius to form a film. The obtained polymer coating has a contact angle with water of 150-160 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com