A method for preparing thread wear-resistant, corrosion-resistant and anti-locking coatings by multi-arc ion plating

A multi-arc ion plating and anti-locking technology, which is applied in the direction of ion implantation plating, coating, superimposed layer plating, etc., to achieve good bonding ability, avoid corrosion damage, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

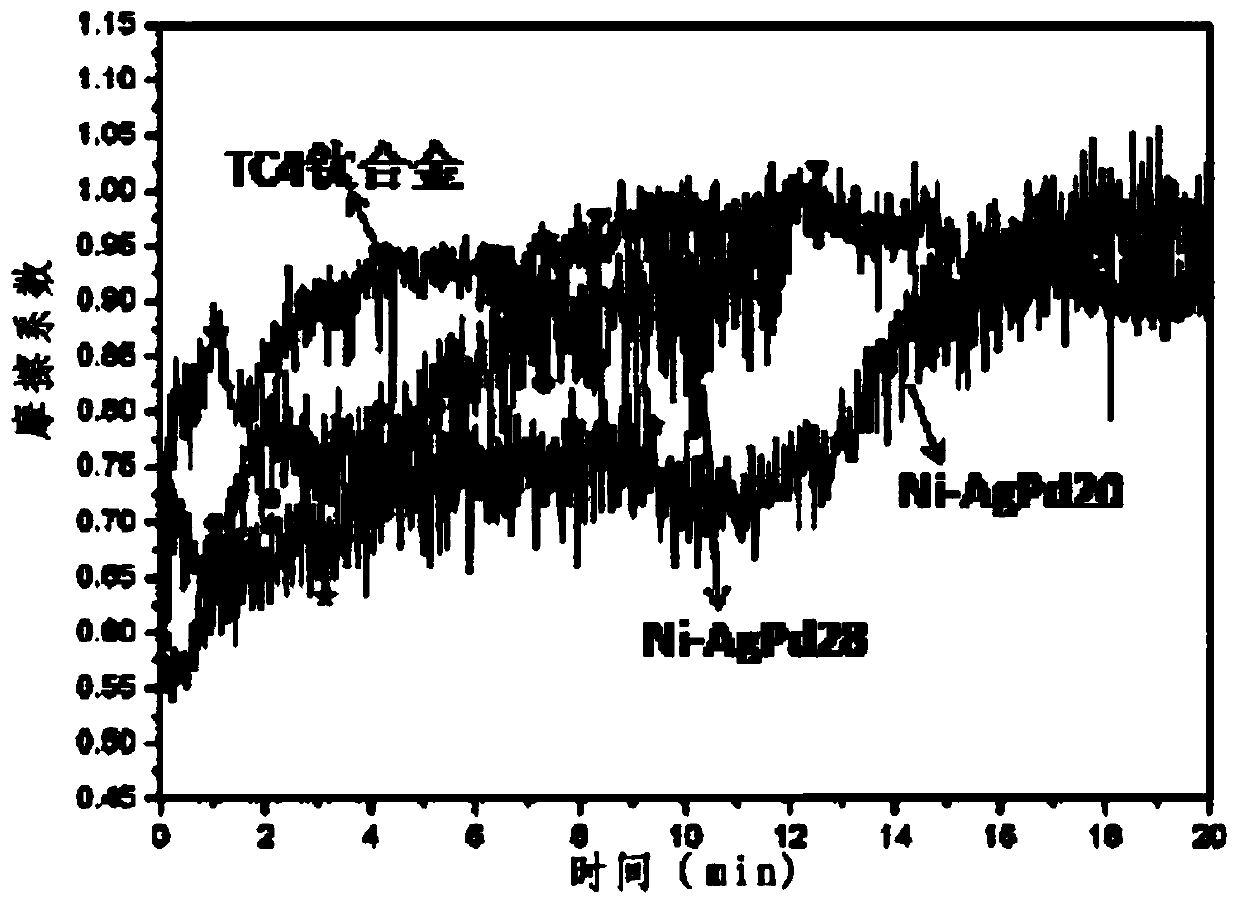

[0025] This embodiment includes the following steps:

[0026] Step 1. Put the 316 stainless steel threads into a vibration polishing machine for polishing for 15 minutes, then use acetone, distilled water, and ethanol to ultrasonically clean the polished metal threads for 8 minutes, 2 minutes, and 2 minutes respectively, and then dry them; the polishing process Add white corundum balls with a diameter of 1mm to 5mm and diamond polishing fluid;

[0027] Step 2, the 316 stainless steel threads dried in step 1 are subjected to sandblasting roughening treatment; the sand grains of the sandblasting roughening treatment are 200 mesh quartz sand, the sandblasting pressure is 0.15MPa, and the sandblasting time is 600s;

[0028] Step 3. Place the 316 stainless steel threads that have been roughened by sandblasting in step 2 in the coating chamber of the multi-arc ion plating equipment, and then vacuumize the coating chamber to a vacuum degree of 0.004Pa, and put it into the vacuumized ...

Embodiment 2

[0033] This embodiment includes the following steps:

[0034] Step 1. Put the TC4 titanium alloy thread into a vibration polishing machine for polishing for 25 minutes, then use acetone, distilled water, and ethanol to ultrasonically clean the polished metal thread for 10 minutes, 5 minutes, and 5 minutes respectively, and then dry; Add white corundum balls with a diameter of 1mm to 5mm and diamond polishing fluid during the process;

[0035] Step 2, performing sandblasting roughening treatment on the dried TC4 titanium alloy thread in step 1; the sand grains of the sandblasting roughening treatment are 250 mesh quartz sand, the sandblasting pressure is 0.3MPa, and the sandblasting time is 200s;

[0036] Step 3. Place the TC4 titanium alloy thread after sandblasting and roughening treatment in step 2 in the coating chamber of the multi-arc ion plating equipment, and then vacuumize the coating chamber to a vacuum degree of 0.003Pa, and put it into the vacuumized reaction chambe...

Embodiment 3

[0040] This embodiment includes the following steps:

[0041] Step 1. Put the TC4 titanium alloy thread into a vibration polishing machine for polishing treatment for 40 minutes, then use acetone, distilled water and ethanol to ultrasonically clean the polished metal thread for 9 minutes, 3 minutes and 3 minutes respectively, and then dry; Add white corundum balls with a diameter of 1mm to 5mm and diamond polishing fluid during the process;

[0042] Step 2. Perform sandblasting roughening treatment on the dried TC4 titanium alloy thread in step 1; the sand grains of the sandblasting roughening treatment are 300 mesh quartz sand, the sandblasting pressure is 0.80MPa, and the sandblasting time is 20s;

[0043] Step 3. Place the TC4 titanium alloy thread after sandblasting and roughening treatment in step 2 in the coating chamber of the multi-arc ion plating equipment, and then vacuumize the coating chamber to a vacuum degree of 0.004Pa, and put it into the vacuumized reaction ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com