Polyphenyl ether/ABS (Acrylonitrile Butadiene Styrene) alloy and preparation method thereof

A polyphenylene ether and alloy technology, which is applied in the field of polyphenylene ether/ABS alloy and its preparation, achieves the effects of low manufacturing cost, broad application prospect and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

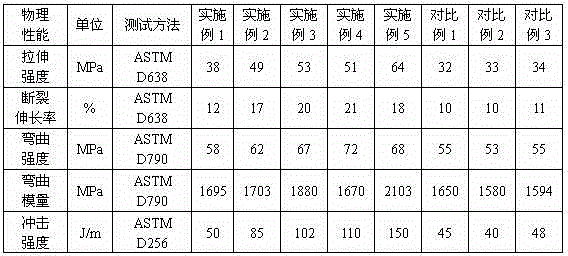

Examples

Embodiment 1

[0058] Example 1 Preparation of polyphenylene ether / ABS alloy of the present invention (1)

[0059] (1) Weigh it according to the following weight percentage: PPE LXR045: 99.5%, maleic anhydride: 0.5%, put it into the high mixer and mix it for 2-5 minutes, and then add it from the first section of the twin-screw extruder. mixed extrusion, granulation;

[0060] (2) Weigh raw materials according to the following weight percentages: step (1) extruded PPE LXR045: 40%, ABS: 40%, Karton G1651: 10%, polystyrene (PS) graft: 9.2%, antioxidant Agent 1098: 0.2%, antioxidant 168: 0.2%, lubricant SR: 0.4%;

[0061] (3) The above-mentioned raw materials were blended in a high-speed mixer for 5 minutes, and then extruded and granulated by a twin-screw extruder. The rotation speed of the screw machine was 500 rpm and the temperature was 245°C.

Embodiment 2

[0062] Example 2 Preparation of polyphenylene ether / ABS alloy of the present invention (2)

[0063] (1) Weigh it according to the following weight percentage: PPE LXR045: 99%, maleic anhydride: 1%, put it into the high mixer and mix it for 2-5 minutes, and then add it from the first section of the twin-screw extruder. mixed extrusion, granulation;

[0064] (2) Weigh raw materials according to the following weight percentages: step (1) extruded PPE LXR045: 45% and ABS: 39.2%, Karton G1650: 5%, hydrogenated triblock copolymer (SEBS) graft: 10 %, antioxidant 1098: 0.2%, antioxidant 168: 0.2%, lubricant paraffin: 0.4%;

[0065] (3) The above-mentioned materials were blended in a high-speed mixer for 5 minutes, and then extruded and granulated by a twin-screw extruder. The rotation speed of the screw machine was 400 rpm and the temperature was 255°C.

Embodiment 3

[0066] Example 3 Preparation of polyphenylene ether / ABS alloy of the present invention (3)

[0067] (1) Weigh it according to the following weight percentage: PPE LXR035: 98%, maleic anhydride: 2%, put it into the high mixer and mix it for 2-5 minutes, and then add it from the first section of the twin-screw extruder. mixed extrusion, granulation;

[0068] (2) Weigh raw materials according to the following weight percentages: step (1) extruded PPE LXR035: 40% and ABS: 53%, Karton G1657: 4.3%, SAN-GMA copolymer: 1.8%, antioxidant 1098: 0.2 %, antioxidant 168: 0.2%, lubricant polyethylene wax: 0.5%;

[0069] (3) The above-mentioned materials were blended in a high-speed mixer for 4 minutes, and then extruded and granulated by a twin-screw extruder. The rotation speed of the screw machine was 450 rpm and the temperature was 240°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com