Platable polyformaldehyde composition and preparation method and electroplating method thereof

A polyoxymethylene composition and the technology of the composition are applied in the field of electroplatable polyoxymethylene composition and its preparation and electroplating to achieve the effects of improved bonding strength and good electroplating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

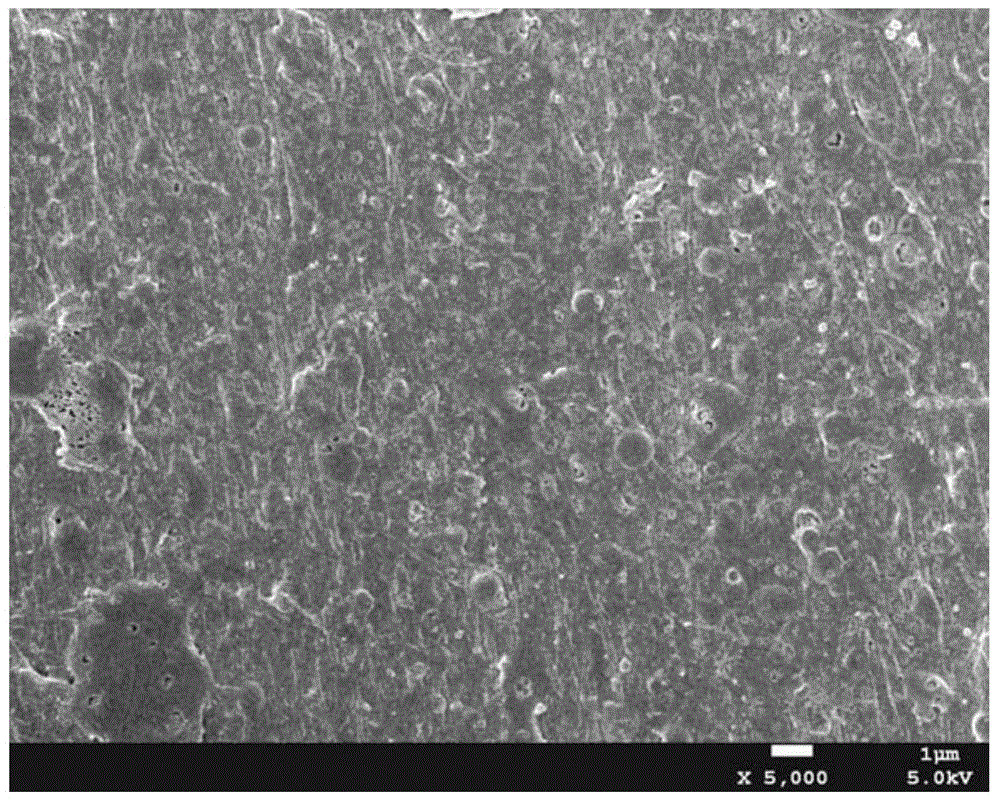

[0040] Embodiment 1 The preparation of electroplatable polyoxymethylene composition and electroplated product thereof of the present invention

[0041] Preparation of polyoxymethylene composition:

[0042] Acetal copolymer: CNOOC Amano Chemical Co., Ltd., with a dioxane content of 4% acetal copolymer;

[0043] Acrylonitrile-butadiene-styrene copolymer (ABS): Taiwan Chimei, butadiene content 30%;

[0044] Inorganic powder: talcum powder, without surface treatment agent treatment, 2000 mesh;

[0045] Silane coupling agent: Nanjing Shuguang Silane Chemical Co., Ltd.

[0046] Put 100 parts of polyoxymethylene, 15 parts of acrylonitrile-butadiene-styrene copolymer, and 15 parts of talcum powder in a high-speed mixer to pre-mix evenly, and then melt, mix, extrude, and granulate in a twin-screw extruder. That is to obtain the polyoxymethylene resin of the present invention, wherein the processing temperature is 170-220° C., and the screw speed is 240 rpm.

[0047] Electroplating ...

Embodiment 2

[0062] Embodiment 2 The preparation of electroplatable polyoxymethylene composition and its electroplating product of the present invention

[0063] The polyoxymethylene composition is prepared according to Example 1, the difference is: the ratio of polyformaldehyde, acrylonitrile-butadiene-styrene copolymer and talcum powder in the composition: 100 parts of polyformaldehyde, acrylonitrile-butadiene- 20 parts of styrene copolymer (30% butadiene content), 15 parts of talcum powder.

[0064] The electroplating process is the same as in Example 1, and the resulting electroplating product is A2.

Embodiment 3

[0065] Embodiment 3 The preparation of electroplatable polyoxymethylene composition and its electroplating product of the present invention

[0066] A polyoxymethylene composition was prepared according to Example 2, except that the content of butadiene in the acrylonitrile-butadiene-styrene copolymer in the composition was 20%.

[0067] Carry out electroplating according to the electroplating process of embodiment 1, the obtained electroplating product is A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com