UV-curable PP treating water-free PVD priming paint and preparation method thereof

A light-curing, treatment-free technology, applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of cost and energy waste, VOC consumption, low surface energy, etc., to eliminate oil pits and reduce scratches , enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

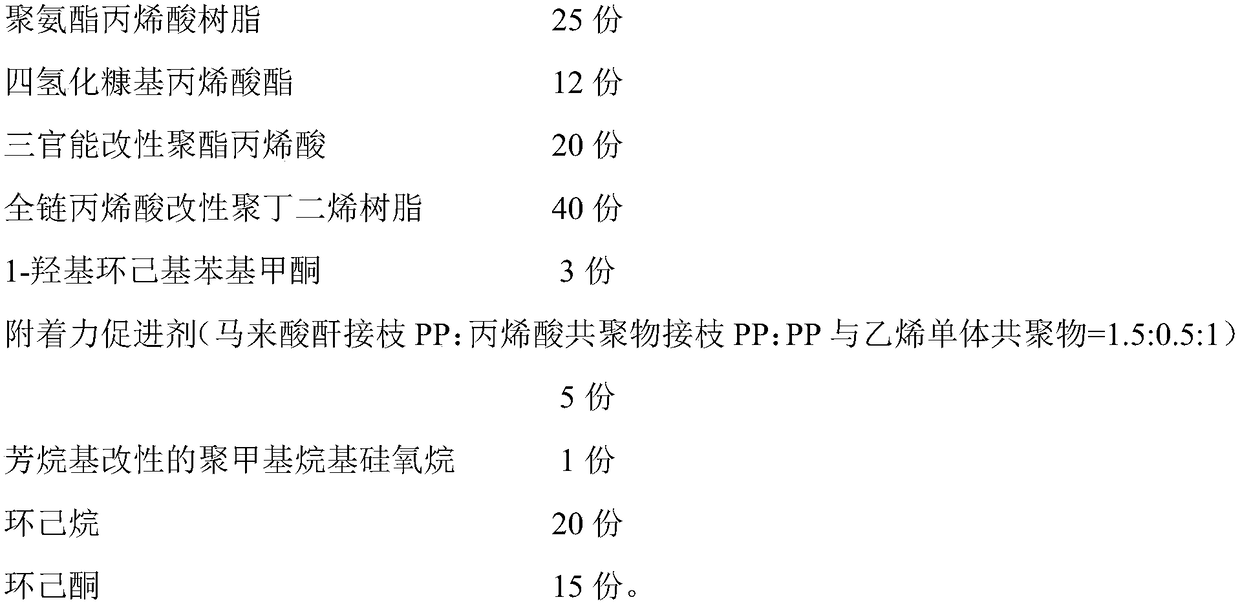

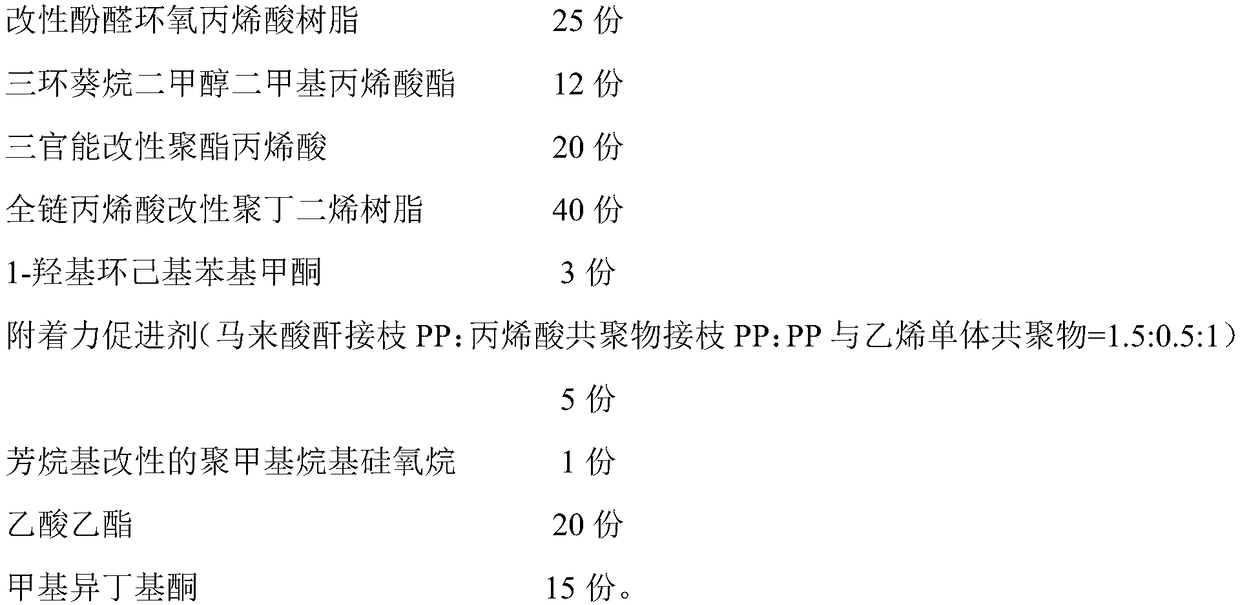

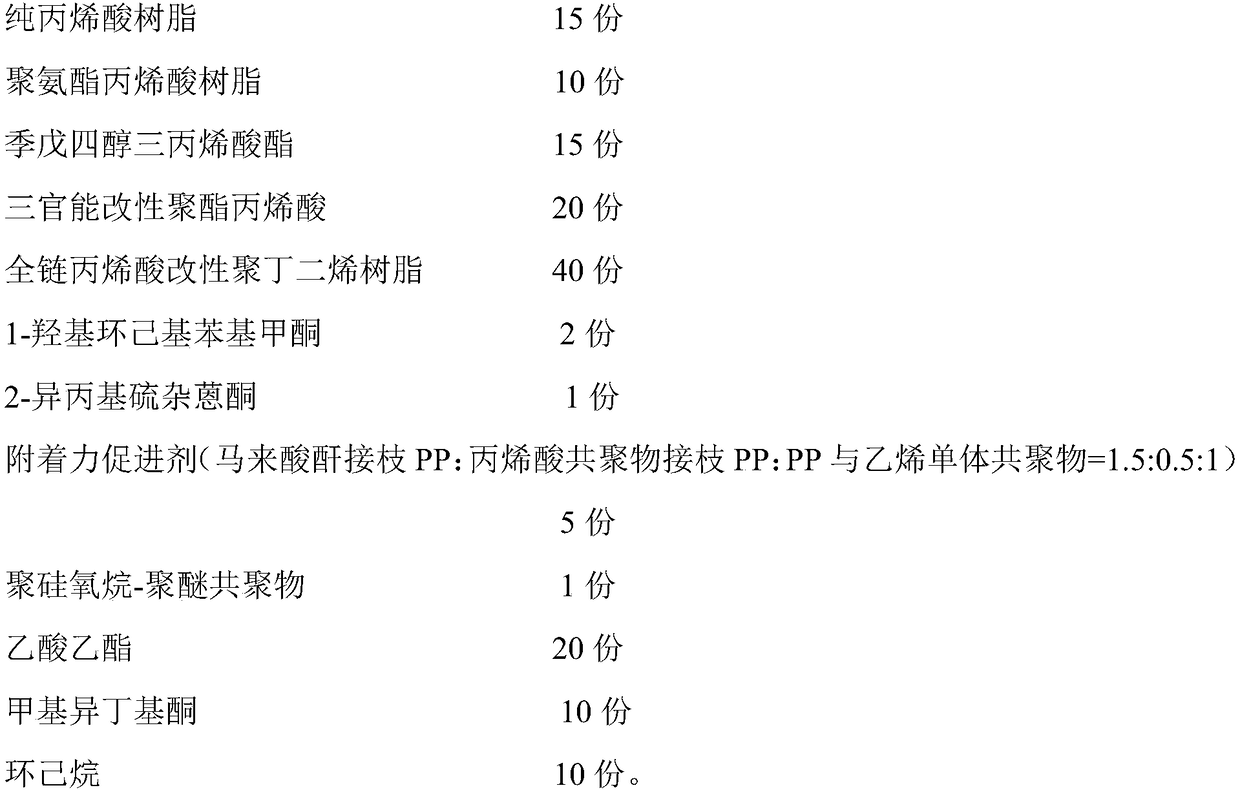

[0037] The following are the preparation methods of PVD primers for various PP materials:

[0038] (1) Add acrylic resin and acrylic acid monomer into the reaction kettle, heat and stir for 6-8 minutes, heat to 55-60°C, add additives and adhesion promoters, keep the temperature and stir, continue heating and stirring for 3-5 minutes;

[0039] (2) Continue to heat until the temperature in the reactor rises to 65-70°C, add photoinitiator and modified polyester alkene resin in the reactor, then adjust the rotating speed of the stirring device to stir for 3-4min; At the same temperature and stirring rate, slowly add full-chain acrylic acid modified polybutadiene resin, and continue heating and stirring for 8-10 minutes;

[0040] (3) When the temperature drops to 28-32°C, add solvent into the reaction kettle, stir evenly, and check the discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com