High-gloss PC/ABS (polycarbonate/acrylonitrile butadiene styrene) electroplating material for vehicles and method for preparing high-gloss PC/ABS electroplating material

A high-gloss, automotive-used technology, applied in the field of plastic blending and modification, can solve the problems of no electroplating, low odor, etc., achieve excellent electroplating performance and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

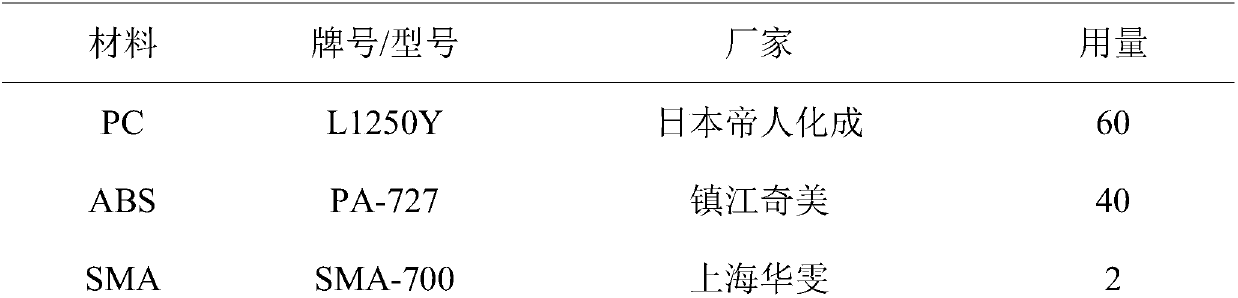

[0035] Table 1 is a list of the amounts of each component in a high-gloss PC / ABS electroplating material for vehicles provided in Example 1 of the present invention.

[0036] Table 1. (Unit: phr)

[0037]

[0038]

Embodiment 2

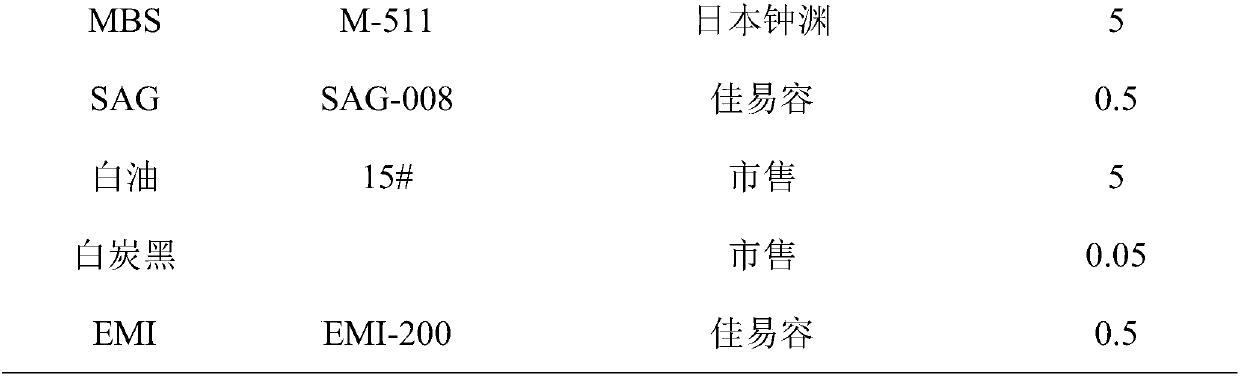

[0040] Table 2 is a list of the amounts of each component in a high-gloss PC / ABS electroplating material for vehicles provided in Example 2 of the present invention.

[0041] Table 2 (unit: phr)

[0042]

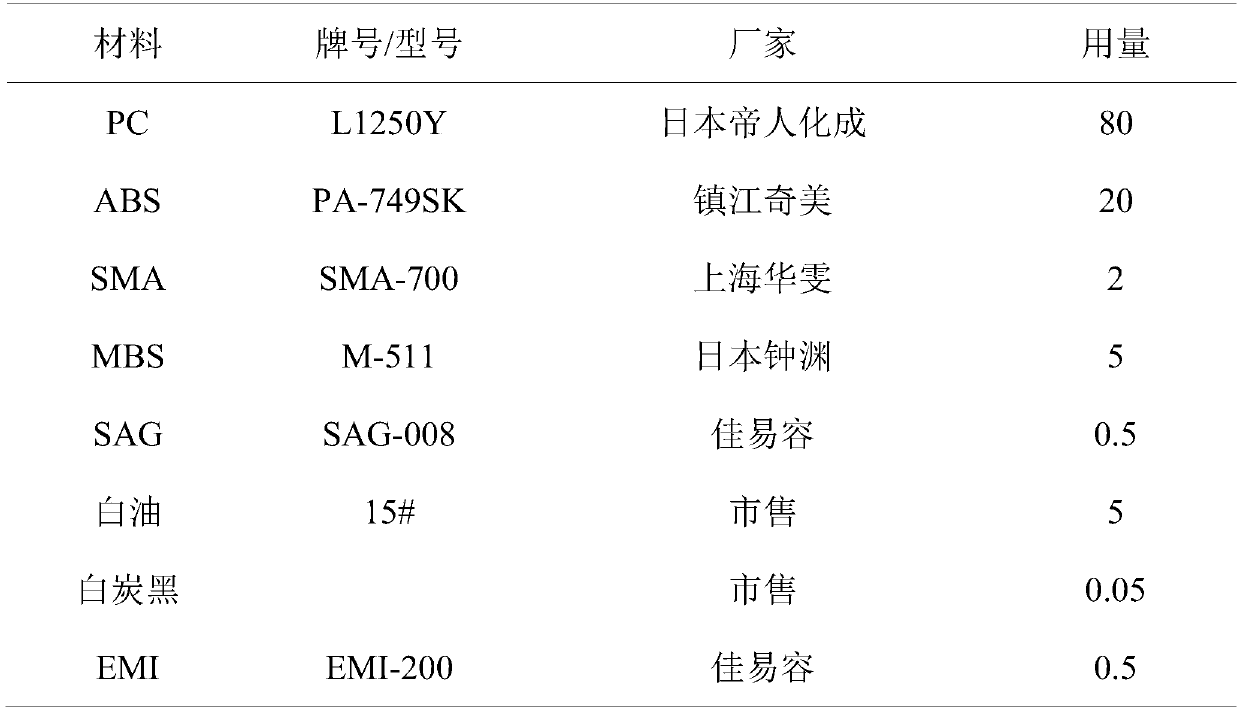

[0043] Table 3 is the list of performance tests of the high-gloss PC / ABS electroplating material for vehicles obtained in Example 1 and Example 2.

[0044] table 3

[0045]

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com